Abstract

The accumulation of ash, heavy metals, and polycyclic aromatic hydrocarbons (collectively called potential accumulating substances, PAS) was evaluated to ascertain the stability of lysis–cryptic growth sludge reduction process (LSRP) for municipal sludge treatment. One sequencing batch reactor (SBR) incorporated with homogenization was run to test the LSRP and another SBR as a control. The continuous monitoring results for 2 months showed that the ash and heavy metals slightly increased, and the polycyclic aromatic hydrocarbons decreased by 18.0%, indicating that there may be negligible accumulations during the LSRP. Their accumulations met pattern I, as demonstrated by statistical analysis, proving no PAS accumulation for LSRP. This was further confirmed by sludge activity and system performance. Moreover, the mechanism for no PAS accumulation was discussed. It was concluded that the LSRP was stable with no worries about PAS accumulation under the operational conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Municipal sludge is a worldwide environmental problem for its enormous production and huge disposal cost (Amudha et al. 2016; Yan et al. 2016). Lysis–cryptic growth sludge reduction process (LSRP) is a biotechnique to reduce sludge production on-site in municipal wastewater treatment plant (MWWTP) (Foladori et al. 2015; Lv et al. 2016). Much attention has been paid to LSRP because of its easy implementation, high sludge reduction efficiency, and remarkable minimization of odor production in sludge transportation and disposal. Moreover, LSRP has been proved economically sustainable (Lan et al. 2013; Wang et al. 2015) and is available for practical application and commercialization (Laurent et al. 2011). The process includes two steps. First, excess sludge is disrupted by chemical, physical, or biological methods for cell lysis to release intracellular matter. Second, the disrupted sludge is back flowed to the bioreactor and then metabolized by activated sludge, thus resulting in mineralization of organic matter by cryptic growth. Here, the biomass growth on its own lysis and leakage products is termed as cryptic growth to distinguish it from the growth on original organic substances (Anthony Mason and Hamer 1987). During the process, excess sludge can be reduced by more than 40% (Wang et al. 2015; Lv et al. 2016), even with no excess sludge discharge (Lee et al. 2005; Sakai et al. 1997).

Ash, heavy metals, and polycyclic aromatic hydrocarbons (PAHs) that standing for inert inorganic materials and refractory organic matters are collectively called potential accumulating substances (PAS) in the current study, because of their properties of accumulation in MWWTP (Delgadillo-Mirquez et al. 2011; Liu et al. 2011; Sakai et al. 1997). Although a MWWTP is designed for the removal of pollutants such as chemical oxygen demand (COD), total nitrogen (TN), and total phosphorus (TP) in wastewater, it also deals with PAS. A significant portion of PAS is transformed into the excess sludge and is discharged out of MWWTP by sludge wasting (Laurent et al. 2011; Low and Chase 1999; Stringfellow and Alvarez-Cohen 1999). In general, the removal efficiency for PAS is satisfactory, and the MWWTP undergoes normal running. However, a backflow of the disrupted sludge containing PAS undoubtedly imposes a burden on the bioreactor in a MWWTP during LSRP, and the minimization of sludge discharge multiplies the burden (Hirooka et al. 2009; Sakai et al. 1997). This leads to a risk of PAS accumulation. Numerous studies have shown that high ash content in activated sludge decreases sludge activity, and high heavy metals and PAH contents in activated sludge inhibit sludge activity (Ke et al. 2012; Sakai et al. 1997; Sponza and Gok 2012). Thus, PAS accumulation could trigger the breakdown of the bioreactor in a MWWTP.

Previous studies mainly focused on sludge reduction and effluent quality for LSRP, and few works on PAS accumulation have been reported. For ash accumulation, Sakai et al. (1997) found a few inorganic substances accumulation (increased from 13 to 19%) in a full-scale MWWTP with no excess sludge production and observed a decrease of endogenous respiration rate by 32% in the process. In a dairy wastewater treatment plant, the membrane bioreactor (MBR) was incorporated with nozzle cavitation for excess sludge reduction, leading to a sludge minimization by 80%; although the organic materials in the nozzle-treated sludge were well biodegraded, the inorganic materials accumulated in the activated sludge, with ash percentage increasing from 15 to 24% (Hirooka et al. 2009). For heavy metal accumulation, Sakai et al. (1997) also found small accumulation of Hg, As, Zn, Cr, Cu, Cd, Pb, and Ni in activated sludge during LSRP (from 0.19, 63, 240, 10, 130, 1.6, 15, 4.0 mg/kg SS to 0.32, 78, 410, 17, 230, 2.0, 37, 8.0 mg/kg SS, respectively). Zhang et al. (2009) evaluated heavy metals accumulation in a sequencing batch reactor (SBR) achieving a sludge reduction of 54% and reported that the sludge concentration of Ni increased by 141% while As decreased by 53%. Further study on artificial wastewater with heavy metals showed that various heavy metals behaved very differently (Ni, Cu, Cd increased by 14, 44, 19% and As, Pb decreased by 11, 33%), while the total sludge heavy metal content increased only by 3.5%, but the accumulation of heavy metals decreased the oxygen utilization rate by 57% (Ke et al. 2012). Laurent et al. (2011) investigated heavy metals accumulation at a laboratory scale activated sludge process coupling thermal (90 °C) sludge disruption and observed that Cu slightly increased and Cd doubled. For PAH accumulation, no literature has been available, though Sakai et al. (1997) and Hirooka et al. (2009) mentioned a possibility of inert organic materials accumulation. In summary, it is clear that the PAS may tend to accumulate in activated sludge during LSRP and would affect the process stability. However, these studies lack information about accumulation time trend and accumulation pattern during LSRP, which is critical for an improved understanding of the accumulation problem to ascertain the process stability.

In our previous works, chlorine dioxide, chlorine dioxide-ultrasound, and homogenizer incorporated into the pilot SBRs were all effective in sludge reduction, with 58, 55, and 42% reduction in excess sludge production, respectively; the effluent quality and sludge activity were not affected (Lan et al. 2013; Lin et al. 2012; Wang et al. 2011). But we have been worried about the PAS accumulation in activated sludge, which will affect the running of LSRP. Therefore, the present study provides a comprehensive characterization of the PAS during LSRP, aiming to observe the accumulation (especially accumulation time trend and accumulation pattern) and assess the process stability. Meanwhile, sludge activity and system performance are used to indirectly reflect the accumulation, and the accumulation mechanism is also discussed.

Materials and methods

Lysis–cryptic growth sludge reduction process and sample collection

Two identical pilot SBRs with working volume of 1260 L were employed to test LSRP. One SBR incorporated with a homogenizer (called test SBR) was implemented for LSRP (Fig. 1). The other SBR served as the control (called control SBR). Both SBRs were filled with municipal wastewater (with a fraction of industrial wastewater) obtained from the primary settling tank of a MWWTP in Foshan city, China. The main characteristics of the wastewater during the operational period of the current study are shown in Table 1. Both SBRs were operated at six equally separated cycles per day. The distributions of each 4 h cycle followed Table 1. Airflow rate in aeration period was fixed at 700 L/h to maintain the DO at approximately 2–3 mg/L. Sludge discharge was carried out once a day in the idle period. After manual stirring, the completely mixed liquor was partly discharged through a mud hole at the bottom of SBR to maintain a mixed liquor suspended solids (MLSS) concentration of approximately 3000 mg/L and a sludge retention time (SRT) of 10 days. The discharged excess sludge was recorded in dry weight.

For LSRP, 66.7% of the excess sludge obtained from the mud hole of test SBR was pretreated once a day using a high-pressure homogenizer (JN-02HC, China). The percentage of excess sludge for treatment was determined empirically, which was appropriate for a stable system (Lin et al. 2012; Wang et al. 2015). The optimized operational conditions for the homogenizer were working pressure 70 MPa and excess sludge concentration 35,000 mg/L (by gravity settling for 12 h to gain this concentration), which was determined by the homogenizer performance as detailed in our previous study (Lan et al. 2013). The sludge disruption by homogenizer resulted in an increase of organic and inorganic substances in the supernatant, with soluble COD from 30 to 1727 mg/L, soluble TN from 13 to 180 mg/L, soluble TP from 2.0 to 39.6 mg/L, soluble protein from 3.2 to 693.3 mg/L, and soluble polysaccharide from 6.9 to 68.0 mg/L. The BOD/COD (biochemical oxygen demand/chemical oxygen demand) ratio of the final supernatant was 0.5. This disrupted sludge with high biodegradability was subsequently returned to the test SBR in the filling period for lysis–cryptic growth.

Every week, 20 L of the completely mixed liquor was obtained from the mud hole of SBR during the idle period, settled for 4 h. The supernatant was discharged, and the solid was air-dried in darkness at room temperature. The dry sample was crushed and sieved through 2 mm mesh and stored at − 20 °C until the subsequent analysis of heavy metal and PAH contents (Belkessam et al. 2005; Kao et al. 2006). All samples were periodically collected in the same manner.

Analysis of PAS in the sludge samples

Ash content analysis was conducted under 600 °C for 60 min in a muffle furnace.

For heavy metals analysis, Cu, Cd, and Pb were selected as targets because of their frequent occurrence in the MWWTP and their limit control in municipal sludge for land application according to China’s framework directive (GB 18918-2002). Acidic digestion in a sand bath (HNO3 + HClO4 + HF) was performed on a sludge sample of approximately 0.5 g (Scancar et al. 2000). The digested solution was made a constant volume 25 mL with 10% HNO3 solution and then was filtered through a 0.45-μm membrane prior to analysis by inductively coupled plasma-atomic emission spectrometry (iCAP6500Duo, USA). The detection limits of Cu, Cd, and Pb were 0.001, 0.001, and 0.003 mg/L, respectively. The analysis of each sample was conducted in triplicate, the differences between replications were maintained at <3%, and their mean value was considered as the final result. The value was expressed as milligrams of metal per kilogram of dry sludge.

For PAH analysis, the 16 PAHs in the list of priority pollutants published by the Environmental Protection Agency (EPA, USA) were considered (Liu et al. 2011). The analysis was conducted using a sludge sample of approximately 15 g. Sample extraction and cleanup were performed using modified USEPA 3540C and 3630C methods, respectively; PAHs were analyzed via gas chromatography–mass spectrometry GC–MS (Agilent 5975B/6890N) according to method of USEPA 8270C as detailed in the study of Cai et al. (2007), where QA/QC measures and performances were also executed. The separation column was a 30.00- to 0.25-mm I.D. DB-5 column (J&W Scientific, Folsom, CA, USA). The experiment results were expressed as micrograms of PAHs per kilogram of dry sludge.

Definition of accumulation and accumulation pattern

In the present study, when the PAS in activated sludge of the test SBR (C test SBR) is higher than that of the control SBR (C control SBR), an accumulation happens. Thus, accumulation value (△a) in Eq. (1) is a positive value. Otherwise, the accumulation does not happen.

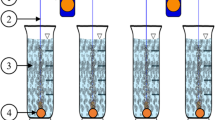

The accumulation may follow three possible accumulation patterns during LSRP. Pattern I: the time trend of the PAS concentrations for the test SBR is parallel to that of the control SBR, with little disparity. In this case, the system is adaptive under the operational conditions, even with the recycle of pretreated sludge. The accumulation is negligible (no accumulation) and would not put an impact on the system. Pattern II: the time trend of the PAS concentrations for the test SBR is that it increases initially, then stabilizes in a new balance and becomes parallel to the control SBR at last. In this case, the system is not adaptive under the operational conditions but becomes adaptive after a period of acclimatization. Although the accumulation has put an acceptable impact on the system, it is still controllable. Pattern III: the time trend of the PAS concentrations for the test SBR shows an increase all the time. In this case, the system is out of control, and the accumulation is too serious to achieve a new balance, which would finally result in a breakdown of the bioreactor in MWWTP for a long-term run. These accumulation patterns are depicted in Fig. 2.

Scheme of accumulation pattern for potential accumulating substances (ash, heavy metals, and polycyclic aromatic hydrocarbons) in the bioreactor during the lysis–cryptic growth sludge reduction process. a Pattern I. b Pattern II. c Pattern III. The full line is the test SBR, and the dashed line is the control SBR

Statistical analysis

Statistical analysis was used to demonstrate the difference between the test SBR and control SBR. First, the assumption of normality for the two data sets of both groups was tested with the Shapiro–Wilk test for normality prior to any additional analysis. If the two data sets met the assumption of normality, then t test was administered on the data. Second, since the difference values between the two groups also met the assumption of normality, paired-samples t test was employed to identify any significant difference between the two groups. And a probability of p < 0.05 was set as a level of significance for all comparisons. All the statistical analyses were carried out using the Statistical Package for the Social Sciences software of SPSS 17.0, Inc., Chicago, IL, USA (Norman and Streiner 2008).

Results

Sludge reduction efficiency during lysis–cryptic growth sludge reduction process

In the operational period of the current study (a continuous monitoring of PAS for 2 months), 9448 g sludge (in dry weight) was discharged from the test SBR, whereas 16,404 g sludge from the control SBR, indicating a sludge minimization of 6956 g. This suggested a sludge reduction efficiency of 42.4%, which agreed well with the literature data (Lin et al. 2012; Lv et al. 2016; Wang et al. 2015).

In the meantime, 30,641.5 g COD was removed in the test SBR, whereas 29,891.1 g COD in the control SBR. Based on the calculation method adopted by Velho et al. (2016), the observed biomass yield (Y obs) of the test SBR was 0.308 kg TSS/kg CODremoved, and the Y obs of the control SBR was 0.549 kg TSS/kg CODremoved. Hence, the observed sludge yield was decreased by 43.9% in the LSRP.

PAS accumulation during lysis–cryptic growth sludge reduction process

Ash accumulation

Ash percentage indicates a composition of activated sludge and is related to sludge activity and system operation. The average ash percentage in the control SBR and the test SBR were 58.67 and 59.97%, respectively, indicating that ash may slightly accumulate. Also, it could be seen from the △a with small positive values in almost all cases (Fig. 3).

Nevertheless, the time trend of ash percentage in the test SBR was parallel to that of the control SBR with little disparity (Fig. 3), indicating an accumulation pattern I. The statistical analysis results did suggest that it cannot be considered as significant differences between the two groups for ash percentages (t = − 1.585, p = 0.174). This indicated that the time trend of ash in the test SBR was similar to that in the control SBR (pattern I). Therefore, the ash accumulation was negligible.

Heavy metal accumulation

Heavy metals in the MWWTP have attracted much attention because of their noticeable toxicity to activated sludge. The heavy metal accumulation in activated sludge at certain concentrations can negatively affect sludge activity and system operation. In the control SBR, the average sludge heavy metals content was 911.9 mg/kg, whereas that in the test SBR was 919.6 mg/kg. The increase was not evident, indicating that heavy metals may only slightly accumulate. Also, it could be seen from the △a with positive values in some cases (Fig. 4a).

The average Cd, Cu, and Pb contents of activated sludge in the control SBR were 2.6, 789.5, and 119.8 mg/kg, respectively, whereas those in the test SBR were 2.6, 794.9, and 122.1 mg/kg, respectively. The results revealed increases of 0.7 and 1.9% in Cu and Pb, respectively. The differences of those heavy metals were attributed to their different physical and chemical properties. It can be seen that in some cases, negative accumulation happens for the heavy metal species (Fig. 4b–d), which illustrated the slight accumulation of the total heavy metals (Fig. 4a).

Nevertheless, the time trend of heavy metals in the test SBR was parallel to that of the control SBR, with little disparity (Fig. 4), which also met pattern I. The statistical analysis results did show that it cannot be considered as significant differences between the two groups for heavy metal contents (t = − 0.237, p = 0.822). This indicated that the time trend of heavy metals in the test SBR was similar to that in the control SBR (pattern I). Therefore, the heavy metal accumulation was negligible.

PAH accumulation

PAHs are ubiquitous in the MWWTP, and their removal is a hot research topic because they may give rise to environmental problems for their transfer ability and mutagenic and carcinogenic properties. PAHs are refractory to biodegradation and may tend to accumulate in activated sludge during LSRP, but there have been no reports about this. In the present study, the ∑16PAHs varied from 164 to 439 μg/kg during the operational period in the control SBR (Fig. 5a), with an average value of 242.3 μg/kg. The ∑16PAHs ranged from 44 to 355 μg/kg in the test SBR, with an average value of 198.7 μg/kg. A decrease of 18.0% was observed, indicating a removal of PAHs. Also, it could be seen from the △a with negative values in most cases (Fig. 5). This result did not support our hypothesis: PAHs would remain in the test SBR and may accumulate in activated sludge due to their slow biodegradation. Here, the fact was that the application of LSRP resulted in a clear decrease by 18.0% for PAHs.

PAHs with different rings were also removed similar to the ∑16PAHs (Fig. 5b–f). Their average sludge contents in both SBRs and their removal rates are shown in Table 2. The four-ring and five-ring PAHs were removed more efficiently than the two-ring and three-ring PAHs. The removal rates of four-ring PAHs (benzanthracene, benzofluoranthrene, and benzofluoranthrene) were higher than 20% (data not shown). It was worthy to mention that in some cases, positive accumulation may happen for PAHs during the operational period (Fig. 5b, e), but there were no positive accumulation for the total PAHs during LSRP (Fig. 5a).

Despite a negative accumulation for PAHs, it was still clear that the time trend of PAHs in the test SBR was parallel to that in the control SBR, with little disparity (Fig. 5), which was the same as that of ash and heavy metals. Hence, the negative accumulation of PAHs also met pattern I. The statistical analysis results did prove that it cannot be considered as significant differences between the two groups for PAHs contents (t = 2.110, p = 0.089). This indicated that the time trend of PAHs in the test SBR was similar to that in the control SBR (pattern I). Therefore, the removal of PAHs (negative accumulation) was negligible.

Linking sludge activity and system performance with PAS accumulation

The change of sludge heavy metals content will affect the sludge activity as well as system performance. Thus, sludge activity and system performance can be used to reflect the accumulation. So far, studies connecting sludge activity data and accumulation data are limited but are of great importance in improving the understanding of accumulation. As reported in our previous study, there was no noticeable difference in SOUR between the control SBR and the test SBR (3.64 and 3.47 mg O2/g MLSS h) in the operational period of the current study (Lan et al. 2013). This reflected no accumulation of inert inorganic materials and refractory organic matters in the bioreactor during LSRP.

In order to further reflect the accumulation, the system performance was also investigated. As detailed in our previous study (Lan et al. 2013), the removals of COD, TN, NH3–N, TP, and SS in the test SBR (90.5, 50.0, 93.7, 91.6, and 93.8%) were similar to that in the control SBR (88.3, 50.5, 94.6, 93.1, and 95.0%). This also reflected no accumulation of inert inorganic materials and refractory organic matters in the bioreactor during LSRP.

Mechanism of accumulation and transport of PAS

The PAS in the bioreactor has a mass balance taking into account the quantity of influent (Q influent), the accumulation within the bioreactor (Q accumulation), and the losses in treated effluent (Q effluent) and sludge discharge (Q discharge) as described in Eq. (2). On the one hand, the Q accumulation is related to the Q influent and Q effluent. Actually, the Q influent and Q effluent are usually fluctuating as a result of PAS concentrations change in influent for the MWWTP treating real wastewater. And the Q accumulation also changes mainly caused by the dynamic absorption and desorption, which takes place between the activated sludge and PAS. Therefore, the Q accumulation is often within a dynamic equilibrium, which is clearly observed in this paper. On the other hand, the Q accumulation is linked to the Q discharge. In case the Q influent and the Q effluent are not fluctuating, a low Q discharge would certainly lead to a high Q accumulation. Nevertheless, how is it when the Q influent and the Q effluent are fluctuating just like the situation in the current study? Here, we try to answer the question.

In the present study, 42.4% of sludge reduction was achieved. It meant the Q discharge decreased by 42.4% in the test SBR. Since the Q influent in the test SBR was equal to that of the control SBR, the sum of the Q accumulation and the Q effluent should rise by 42.4% in the test SBR if it desired a mass balance as that in the control SBR. In fact, 23% increase of effluent SS in the test SBR was observed in our study, which was enough to make a big rise of the Q effluent. Because heavy metals and PAHs distributed more in the particulate phase (SS) when compared to the dissolved phase in wastewater, such as Cu with a distribution of 70 and 30%, respectively (Karvelas et al. 2003), it will undoubtedly raise the Q effluent. It was also indicated by Laurent et al. (2011). Thus, no change of the Q accumulation could exist, which illustrated the negligible PAS accumulation during LSRP.

Discussion

Negligible PAS accumulation during lysis–cryptic growth sludge reduction process

For ash accumulation, Sakai et al. (1997) found inorganic substances (sand and silt) in activated sludge increased from 13 to 19% in an activated sludge process with no excess sludge production. Hirooka et al. (2009) also detected an ash accumulation (ash percentage increased from 15 to 24%) after an adoption of 80% sludge reduction in the MBR treating dairy wastewater. The ash accumulations in both literatures were higher than this paper (from 58.67 to 59.97%), which may be caused by their higher sludge reduction percentages. Therefore, the ash accumulation can be negligible under the operational conditions in the present study.

For heavy metal accumulation, Ke et al. (2012) reported that the total heavy metal sludge concentration in the bioreactor implementing sludge reduction process is similar to that in the control bioreactor, with only a negligible increase of 3.5% even at a high heavy metals load. This result is in accordance with this paper. The accumulation order (with Pb > Cu > Cd) was also determined by Sakai et al. (1997), but Laurent et al. (2011) and Zhang et al. (2009) found a different accumulation situation with Cd > Cu, which was probably due to the usage of different pretreatment methods (ozone, thermal, and ultrasonic) in those studies. However, this standpoint deserves closer inspection in the future study. Despite in some cases negative accumulation happening for the heavy metal species, there is invariably accumulation for the total heavy metals during LSRP (Ke et al. 2012). Ke et al. (2012) also studied the time trend of sludge heavy metals content during the sonication–cryptic growth sludge reduction process at a laboratory scale and observed the same accumulation pattern. Therefore, the heavy metal accumulation is negligible.

For PAHs, the removal rates of four-ring and five-ring PAHs were a little higher than others, because the four-ring and five-ring compounds have the highest bioavailability (Oleszczuk 2008), and bioavailability is a crucial parameter in the biodegradation of PAHs (Barret et al. 2010). Nevertheless, the PAH removal (negative accumulation) is still negligible as indicated by the statistical analysis result.

Usage of sludge activity and system performance to reflect PAS accumulation

Sludge activity was used to reflect an accumulation of inorganic substances including ash and heavy metals (Ke et al. 2012; Sakai et al. 1997). In the current study, the sludge activity and system performance data were linked to the accumulation data, demonstrating that there was no PAS accumulation.

PAS transport during lysis–cryptic growth sludge reduction process

There was only a slight increase in ash and heavy metals in the sludge. It has been reported that part of the inorganic matter solubilized in the effluent to compensate for the decrease in excess sludge output (Hirooka et al. 2009). The same to ash, the solution of heavy metals in the effluent may also exist in the present study to compensate for the decrease in excess sludge output. This has been demonstrated by Laurent et al. (2011). Therefore, the accumulation can be negligible through an effluent leakage.

A decrease in sludge PAHs was observed. Studies showed that PAHs in the MWWTP were removed by the effluent SS adsorption and the activated sludge biodegradation (Liu et al. 2011). In the present work, PAHs may be adsorbed by SS and would leak through the effluent. Meanwhile, highly biodegradable organic matter released from excess sludge by homogenization pretreatment can serve as a nutrient to promote the degradation process through cometabolism (Delgadillo-Mirquez et al. 2011).

All these mechanisms served the dynamic equilibrium of the system. However, a potential leak of PAS into aquatic ecosystems exists, and special attention should be paid to the outflow of heavy metals and PAHs (Laurent et al. 2011). In most situations, their concentrations in municipal wastewater are adequately low; thus, any leakage would not significantly affect aquatic ecosystems and can be ignored. Otherwise, leakage should be controlled by subsequent treatments, such as activated carbon adsorption and constructed wetland treatment.

To sum up, LSRP is stable with no worries about PAS accumulation under the operational conditions. Together with high sludge reduction efficiency, simple implementation, and favorable economic sustainability, LSRP is applicable for on-site excess sludge reduction in the MWWTP.

References

Amudha V, Kavitha S, Fernandez C, Adishkumar S, Rajesh Banu J (2016) Effect of deflocculation on the efficiency of sludge reduction by Fenton process. Environ Sci Pollut Res 23:19281–19291

Anthony Mason C, Hamer G (1987) Cryptic growth in Klebsiella pneumonia. Appl Microbiol Biotechnol 25:577–584

Barret M, Cea Barcia G, Guillon A, Carrère H, Patureau D (2010) Influence of feed characteristics on the removal of micropollutants during the anaerobic digestion of contaminated sludge. J Hazard Mater 181:241–247

Belkessam L, Lecomte P, Milon V, Laboudigue A (2005) Influence of pre-treatment step on PAHs analyses in contaminated soils. Chemosphere 58:321–328

Cai QY, Mo CH, Wu QT, Zeng QY, Katsoyiannis A, Ferard JF (2007) Bioremediation of polycyclic aromatic hydrocarbons (PAHs)-contaminated sewage sludge by different composting processes. J Hazard Mater 142:535–542

Delgadillo-Mirquez L, Lardon L, Steyer JP, Patureau D (2011) A new dynamic model for bioavailability and cometabolism of micropollutants during anaerobic digestion. Water Res 45:4511–4521

Foladori P, Velho VF, Costa RHR, Bruni L, Quaranta A, Andreottola G (2015) Concerning the role of cell lysis-cryptic growth in anaerobic side-stream reactors: the single-cell analysis of viable, dead and lysed bacteria. Water Res 74:132–142

Hirooka K, Asano R, Yokoyama A, Okazaki M, Sakamoto A, Nakai Y (2009) Reduction in excess sludge production in a dairy wastewater treatment plant via nozzle-cavitation treatment: case study of an on-farm wastewater treatment plant. Bioresour Technol 100:3161–3166

Kao PH, Huang CC, Hseu ZY (2006) Response of microbial activities to heavy metals in a neutral loamy soil treated with biosolid. Chemosphere 64:63–70

Karvelas M, Katsoyiannis A, Samara C (2003) Occurrence and fate of heavy metals in the wastewater treatment process. Chemosphere 53:1201–1210

Ke XY, Zhang GM, Wan T, Gao F (2012) Heavy-metal accumulation in low-sludge wastewater treatment technique: sonication-cryptic growth. J Environ Eng 138:248–251

Lan WC, Li YY, Bi Q, Hu YY (2013) Reduction of excess sludge production in sequencing batch reactor (SBR) by lysis–cryptic growth using homogenization disruption. Bioresour Technol 134:43–50

Laurent J, Jaziri K, Guignard R, Casellas M, Dagot C (2011) Comprehensive insight of the performances of excess sludge reduction by 90°C thermal treatment coupled with activated sludge at pilot scale: COD and N removal, bacterial populations, fate of heavy metals. Process Biochem 46:1808–1816

Lee JW, Cha HY, Park KY, Song KG, Ahn KH (2005) Operational strategies for an activated sludge process in conjunction with ozone oxidation for zero excess sludge production during winter season. Water Res 39:1199–1204

Lin JT, Hu YY, Wang GH, Lan WC (2012) Sludge reduction in an activated sludge sewage treatment process by lysis-cryptic growth using ClO2-ultrasonication disruption. Biochem Eng J 68:54–60

Liu JJ, Wang XC, Fan B (2011) Characteristics of PAHs adsorption on inorganic particles and activated sludge in domestic wastewater treatment. Bioresour Technol 102:5305–5311

Low EW, Chase HA (1999) Reducing production of excess biomass during wastewater treatment. Water Res 33:1119–1132

Lv XM, Song JS, Li J, Zhai K (2016) Reduction of excess sludge in sequencing batch reactor (SBR) by lysis-cryptic growth using quick lime for disintegration under low temperature. Environ Technol 1:1–27

Norman GR, Streiner DL (2008) The bare essentials, third edn. BC Decker Inc, Hamilton

Oleszczuk P (2008) Forms of polycyclic aromatic hydrocarbon in the formation of sewage sludge toxicity to Heterocypris incongruens. Sci Total Environ 404:94–102

Sakai Y, Fukase T, Yasui H, Shibata M (1997) An activated sludge process without excess sludge production. Water Sci Technol 36:163–170

Scancar J, Milacic R, Strazar M, Burica O (2000) Total metal concentrations and partitioning of Cd, Cr, Cu, Fe, Ni and Zn in sewage sludge. Sci Total Environ 250:9–19

Sponza DT, Gok O (2012) Aerobic biodegradation and inhibition kinetics of poly-aromatic hydrocarbons (PAHs) in a petrochemical industry wastewater in the presence of biosurfactants. J Chem Technol Biotechnol 87:658–672

Stringfellow WT, Alvarez-Cohen L (1999) Evaluating the relationship between the sorption of PAHs to bacterial biomass and biodegradation. Water Res 33:2535–2544

Velho VF, Foladori P, Andreottola G, Costa RHR (2016) Anaerobic side-stream reactor for excess sludge reduction: 5-year management of a full-scale plant. J Environ Manag 177:223–230

Wang GH, Sui J, Shen HS, Liang SK, He XM, Zhang MJ, Xie YZ, Li LY, Hu YY (2011) Reduction of excess sludge production in sequencing batch reactor through incorporation of chlorine dioxide oxidation. J Hazard Mater 192:93–98

Wang YW, Xiao QC, Liu JB, Yan H, Wei YS (2015) Pilot-scale study of sludge pretreatment by microwave and sludge reduction based on lysis–cryptic growth. Bioresour Technol 190:140–147

Yan X, Li BQ, Lei F, Feng X, Pang B (2016) Enhanced deodorization and sludge reduction in situ by a humus soil cooperated anaerobic/anoxic/oxic (A2O) wastewater treatment system. Environ Sci Pollut Res 23:15963–15969

Zhang GM, He JG, Zhang PY, Zhang J (2009) Ultrasonic reduction of excess sludge from activated sludge system II: urban sewage treatment. J Hazard Mater 164:1105–1109

Acknowledgements

The authors thank Instrumental Analysis & Research Center, Sun Yat-sen University for heavy metals analysis; more thanks to China National Analytical Center, Guangzhou for PAH analysis.

Funding

This research was supported by Major Science and Technology Project of Guangdong Province of China (2016B020240005) and Natural Science Foundation of Guangdong Province of China (2016A030310317).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Angeles Blanco

Rights and permissions

About this article

Cite this article

Li, Y., Hu, Y., Lan, W. et al. Investigation of the accumulation of ash, heavy metals, and polycyclic aromatic hydrocarbons to assess the stability of lysis–cryptic growth sludge reduction in sequencing batch reactor. Environ Sci Pollut Res 24, 24147–24155 (2017). https://doi.org/10.1007/s11356-017-0042-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-0042-y