Abstract

Heavy metals in higher concentrations are often encountered in domestic sewage of developing and under-developed countries. High metallic concentrations can stress reactor sludge biomass morphology impeding its performance in organics reduction. However, the extent of damage and ability of sludge biomass to recover from the metallic stress is not fully understood. Also, there is no protocol to identify and prevent the sludge biomass from metallic stress in fully functional sewage treatment plants (STPs). This study investigates performance, metabolic activity, morphology, and settling characteristics of the sludge biomass under different Co(II) stress conditions. The extent of recovery in biomass, when the supply of Co(II) metal ion was discontinued in the inlet stream, was explored. The study also proposed a protocol based on simple settling characteristics of sludge biomass to get an early indication of metal infiltration to prevent potential damage to the biomass morphology. Four sequencing batch reactors (SBRs) with Co(II) ion concentrations of 0 (designated as RCo0), 5 (RCo5), 25 (RCo25), and 75 mg/L (RCo75) in the feed were operated with a cycle time of 12 h. Reactors were operated for 35 days with Co(II) in the feed (termed as stressed phase operation) followed by 24 days of operation without Co(II) in the feed (termed as recovery phase operation). Results show that COD removal in reactor RCo75 reduced to 48% on the 10th day of stressed phase operation, showing a lag in COD removal due to metallic stress. The activity of biomass in reactors RCo5, RCo25, and RCo75 was reduced by 39%, 45%, and 49%, respectively, in the stressed phase compared to the biomass in control reactor. Recovery in COD removal efficiency and specific biomass activity were observed in all the reactors after the removal of metallic stress. The settleability of sludge biomass in reactors RCo25 and RCo75 was significantly affected. Transformation in the shape of flocs in reactor RCo25 and RCo75 biomasses revealed the prolonged effect of metallic stress, which was observed to be irreversible even during the recovery phase operation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Aerobic sludge biomass converts biodegradable organics into stable end-products in a biological wastewater treatment system. It also derives energy and materials to form new cells through catabolic and anabolic reactions (Peavy et al. 1985). The sludge biomass can adapt itself if exposed to a changed aqueous environment containing organic toxicants such as phenols through the production of special enzymes (Peavy et al. 1985). However, the level of damage to biomass caused by inorganic toxicants, such as heavy metals, needs further investigation. It remains to be seen whether the biomass will recover its performance and morphology once the inorganic toxicant has been withdrawn.

Domestic wastewater treatment plants are designed to receive sewage (free from inorganic toxicants) collected from an urban area. However, the plants may receive heavy metal–laden toxic waste streams generated from industrial activities near domestic dwellings. Typically, heavy metal sources in domestic area include electroplating works, battery repairing, jewelry cleaning, electronic waste processing, construction works, runoff from solid waste dumpsites, and mining operations, among others (Negi et al. 2020). The biological treatment systems are likely to get exposed to relatively high metal concentrations from these sources continuously until they are identified and segregated. In Delhi (India), for example, about 3000 authorized and unauthorized electroplating units are in operation, with copper and nickel concentrations exceeding 80 mg/L in their effluent (Singh 2014). Similarly, in Chandigarh and Haryana (India), the effluents from drains of nearby electroplating industries have reported high metal concentrations, specifically nickel and zinc, of around 243 and 731 mg/L, respectively (Singh et al. 2016). These small-scale industries do not have sufficient land area and funds to construct treatment plants and hire skilled manpower (Tyagi 2013). Hence, heavy metals containing effluents are intentionally or unintentionally disposed of to the nearby open drains or sewers at night (having low flow condition). This may lead to a high heavy metal concentration in the wastewater treatment systems.

The transitional heavy metal — cobalt [Co(II)] — is used in various fields such as in metallurgy industries, food products, cosmetics, jewelry, paints, batteries, electronic devices, and diamond polishing (Leyssens et al. 2017). Due to its extensive use in populated urban centers, wastes containing Co(II) are likely to find its way to sewers leading to biological wastewater treatment plants. Trace level concentrations of Co(II) are essential for the metabolism of many organisms and it is also a vital cofactor for metabolic activities of sludge biomass (Gikas 2008). The available studies focus on the adsorption of Co(II) ions from wastewater samples (Al-Jlil 2017; Taka et al. 2018). However, the effects of Co(II) on activated sludge biomass have been investigated to a lesser extent as compared to other metals such as Ni(II), Cu(II), and Zn(II). Negi et al. (2021) analyzed the effect of 1:1 (w/w) mixture of Ni(II) and Co(II) metal ions on the performance and morphology of aerobic sludge biomass. This study presented the combined effect of Ni(II) and Co(II) metal ions, which could be different from the individual impact of the metal ions. Hence, it entails an interest in investigating the impact of Co(II) on aerobic sludge biomass at lower (< 10 mg/L) as well as higher (over 30 mg/L) concentrations.

Heavy metal exposure can adversely affect the treatment process depending upon metallic species, solubility, and concentration (Madoni et al. 1996). Lower concentrations (< 5 mg/L) of heavy metals enhance the organic removal process (Zhang et al. 2017). However, there is a threshold concentration above which heavy metals exert toxicity to the microorganisms in sludge biomass (Gikas and Romanos 2006; Gikas 2008). The impacts of metals on biological reactors include biomass activity inhibition, poor settling characteristics with slow biodegradation, and morphological changes in sludge biomass. The effect of Ni(II) on aerobic sludge biomass was studied by Ong et al. (2004). The authors reported small reduction in organic removal at 5 mg/L Ni(II), but when the sludge biomass was exposed to a 10 mg/L Ni(II) concentration, the removal was reduced to 87%. Similarly, the addition of 20 mg/L of Ni(II) in activated sludge was shown to cause 43% inhibition in the biomass activity — a measure of specific substrate consumption rate (Wang et al. 2013). The impact level of heavy metals also depends on the exposure time. Long-term exposure of Ni(II) at 1 and 10 mg/L substantially reduced sludge flocculability while gradually improving settleability and dewaterability (Wang et al. 2016). The decrease in biomass flocculation was attributed to a decrease in hydrophobicity and surface charge in sludge biomass flocs (Yang et al. 2017). The effects of increased inorganic toxicants on the performance of aerobic sludge biomass were also ascribed to decrease in EPS generation and a shift in microbial community (Kedves et al. 2020; 2021).

Studies are available on the evaluation of reactor performance, microbial activity, and characteristics of sludge biomass subjected to undesirable heavy metal exposure either on a continuous mode (lower concentrations) or a slug form of sudden load (higher concentrations). However, limited literature is available studying the reversal of sludge biomass characteristics when the undesirable supply of heavy metal in the feed stream is discontinued (Ong et al. 2004; Negi et al. 2020, 2021). Whether the stressed biomass will be able to regain its original performance, activity and morphology remains a gap in the literature. The available studies have contributed well to understand the effect and mechanism of hazard posed by the inorganic toxicants on the aerobic sludge biomass. However, the extension of conclusions from laboratory scale setup to large scale wastewater treatment systems has been missing for preventive operation and maintenance. The objectives of the study are: (1) to investigate the adverse impact of Co(II) on the performance and morphology of aerobic sludge biomass, as well as explore the recovery potential of the biomass when Co(II) in the feed is discontinued; and (2) to develop a protocol using the parameters of routine maintenance that semi-skilled operators can apply for early indication of heavy metal infiltration. This study attempts to simulate the operational condition of a fully functional wastewater treatment plant in a developing region. In these regions, a third party is involved in the operation and maintenance of a wastewater treatment plant (CPHEEO 2013), but without employing skilled technicians to save on the operational costs. A relatively well-equipped treatment plant laboratory in developing countries mainly rely on analyzing basic wastewater parameters such as COD, BOD, pH, MLSS and SVI to evaluate their efficiency or performance. This study aims to assess the impact of Co(II) using the analysis that can be performed in a typical wastewater treatment facility and suggest preventive operation strategy. The biomass recovery potential has been examined for organic removal performance, settling characteristics and morphology before and after the exposure of Co(II) stress at different levels. The impact of Co(II) on nutrient removal, EPS, enzyme activity, and microbial community shift is not in the scope of this study.

Material and methods

Setup and operations

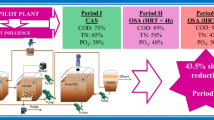

The experimental setup used in the present study is shown in Fig. 1. It comprised of four similar sequencing batch reactors (SBRs) with a working volume of 1 L (diameter 6 cm and height 36.5 cm). The four SBRs were designated as RCo0, RCo5, RCo25, and RCo75. These SBRs were planned to be operated with a cycle of 12 h, giving a total of 2 cycles per day. Each cycle had five time periods: 5 min for filling of wastewater (or feed); 685 min for the biochemical reaction between biomass and the wastewater; 5 min for settling of heavier biomass; 15 min for decanting supernatant (inclusive of dispersed biomass) and 10 min for idling before starting the next cycle; summing all the periods to 720 min or 12 h. The biomass in SBRs was kept in suspension by bubbling air through aeration stones at a flow rate of 2.5 L/min using aquarium air pumps. A short settling time of 5 min was adopted to ensure retention of quickly settleable heavier biomass. The dispersed and non-easily settleable biomass fractions were discarded out of the reactors along with the decanted supernatant. It is also essential to indicate that no planned wastage of biomass from the reactors (except the dispersed and non-easily settleable fractions) was practiced during experimentation. However, a small fraction of biomass was withdrawn from the reactors for biomass related analysis.

The biomass for the study was grown in a separate reactor termed as Mother Reactor (MR) by seeding with domestic wastewater from the sewage treatment plant located in the IIT Guwahati campus. The SBRs for investigating Co(II) stress were started by adding biomass from MR with initial MLSS concentration in the range of 2500–3500 mg/L. Each SBR was fed with carbon source prepared by mixing 0.48 g of lactogen uniformly in 150 mL lukewarm tap water for 8–10 min using a magnetic stirrer. The composition of lactogen per 100 g was: 59.3 g carbohydrates, 4.3 g sugar, 440 mg calcium, 310 mg phosphorous, 280 mg chlorides, 0.28 mg copper, 3 mg zinc, 165 mg sodium, 500 mg potassium, 40 mg magnesium, 360 µg vitamin A, 47 mg vitamin C, 5.25 µg vitamin D, 3 mg vitamin E, 21 µg vitamin K, 0.35 mg vitamin B6, and 0.7 µg vitamin B12. The lactogen fed to the reactors was equivalent to a COD of ~ 550 mg/L. In addition to the carbon source, reactors RCo5, RCo25, and RCo75 were also fed with 5, 25 and 75 mg/L of Co(II), respectively. A cobalt metallic stock solution was prepared by dissolving 4.77 g of CoSO4.7H2O in 1 L of deionized water, yielding a strength of 1 mg of Co(II) per mL of solution. The control reactor RCo0 was only fed with lactogen solution (150 mL in volume), whereas reactors RCo5, RCo25, and RCo75 were fed with the lactogen solution along with 5 mL, 25 mL, and 75 mL of cobalt metallic stock solution, respectively to yield the desired metal ion and COD concentration in 1 L of reactor volume. The reactors operation in the stressed phase was carried out for 35 days with Co(II) ions fed to the reactors in addition to the carbon source. Thereafter, the reactors were operated for another 24 days in the recovery phase in which Co(II) was discontinued from the feed and lactogen solution was only provided as organic carbon substrate.

The stressed phase operation was intended to investigate the impact of Co(II) ions on the reactor performance in the biodegradation of organics and the morphological changes caused to the sludge biomass, whereas the recovery phase was aimed to study the potential of the reactors in regaining their performance and biomass morphology when Co(II) ions were discontinued in the feed.

Sample collection and analysis

The influent samples from the reactors were collected just after feed addition and complete mixing of reactor contents. The effluent samples were collected while decanting the supernatant towards the end of the cycle. The samples were collected every alternate day and analyzed for COD, pH, alkalinity and Co(II) concentrations. During the stressed phase operation of the reactors, it was not possible to drain out the liquid fraction completely after decanting the supernatant. The retained liquid fraction contained residual Co(II) ions. Its concentration was likely to build up further due to accumulation of residual metal ions with every addition of metal ion in the reactor feed in subsequent operation cycles. Hence, to avoid possible built-up of Co(II) beyond the planned exposure concentration levels, the biomass in each reactor was washed using tap water. The washing was carried out after decanting the supernatant and then making up the reactor volume using tap water. The aqueous solution in the reactor was mixed gently for 1 or 2 min, allowing settling for 5 min and then decanting the supernatant. The reactor volumes were filled with tap water until the 1 L mark. Further, the reactor content was gently mixed, and a portion of clear liquid was withdrawn before adding new feed of lactogen and metal ions. The drawn liquid portion was used for determining the residual or background concentration of Co(II) ion present in the reactor — which was designated as “Co(II)BG.” The sludge biomass (unwashed) samples withdrawn from the reactors were analyzed through energy-dispersive X-ray (EDX) to examine the weight (%) of heavy metal adsorbed on its surface. The field emission scanning electron microscopic (FESEM) analysis was used to inspect changes in the morphology of sludge biomasses (Make – Zeiss, Sigma, Germany). No special biomass sample preparation was required for FESEM and EDX analysis.

To visually record changes in the structures of the flocs, the images of sludge biomass under a light source were taken at appropriate intervals during reactor operations in both the phases. The sludge volume index (SVI30) and settling velocity of biomass (SVB) were estimated at regular intervals to examine the changes in settling characteristics of the sludge biomass.

The analytical methods for estimation of COD, pH, alkalinity, mixed liquor suspended solids (MLSS), mixed liquor volatile suspended solids (MLVSS), or volatile suspended solids (VSS) were adopted from Standard Methods (APHA 2012). Co(II) ion concentration was measured using atomic absorption spectroscopy (Varian, iCE 3000 series). Duplicate samples were used in the analysis of all the parameters. Settling velocity of biomass (SVB) was determined using the method specified by Peavy et al. (1985). Sludge volume index (SVI30) was determined using the procedures specified in Metcalf and Eddy (2003).

Biomass activity

The biomass activity was estimated by modifying the method specified by Jawed and Tare (1996; 1999) for the determination of the specific methanogenic activity (SMA). The modified method estimated aerobic sludge biomass activity by utilizing cumulative substrate (COD) degradation (Tomar and Chakraborty 2018). An amount of ~500 mg/L of MLVSS was withdrawn from the reactor and taken into a reaction vessel (plastic beaker of 1 L capacity). Lactogen feed amounting to ~500 mg/L as COD was added to the reaction vessel and total mixed liquor volume was made up to 1 L using tap water. The activity test was initiated by providing aeration in the vessel, and soluble COD was estimated by withdrawing samples at suitable time intervals. Sampling was continued for 6 h after the start of test and thereafter the test was terminated. The concentration of biomass present in the vessel at the end of the test was estimated as VSS. The highest slope from the plot of cumulative COD removal (Y-axis) versus time (X-axis) was obtained for estimating the biomass activity using Eq. (1).

Results and discussion

Reactor performance

The variations in influent COD, effluent COD, and COD removal (%) during reactor operation in the stressed and recovery phases are shown in Fig. 2. During the stressed phase operation, the average COD removals in reactors RCo0, RCo5, RCo25, and RCo75 during the first 11 days of reactor operation were around 90%, 84%, 82%, and 61%, respectively. Average steady-state COD removals during 16–35 days of operation in the stressed phase for reactors RCo0, RCo5, RCo25, and RCo75 were around 85%, 86%, 83%, and 74%, respectively. The decreasing trend in COD removals for reactor RCo0 could be attributed to lower feed concentration compared to MR (as shown in Fig. S1). The COD removal in reactors RCo5 and RCo25 was comparable to the control reactor. However, due to higher metallic concentrations in reactor RCo75, the COD removal decreased to a minimum of 48% on the 10th day of operation after the startup of stressed phase operation. The biochemical oxidation was retarded significantly due to the increase in Co(II) ion concentration (> 25 mg/L) which was observed in RCo75 (Gikas 2008). A gradual increase of Co(II) ion concentration up to 20 mg/L in a SBR reactor had no effect on COD removal, while increasing the Co(II) ion concentration to 40 mg/L reduced the COD removal to 50% (El-Bestawy et al. 2013). In the present study, the COD removal increased after the 10th day in reactor RCo75 indicating acclimatization of the reactor biomass to the metallic stress and steady-state operation of the reactor. Microorganisms use alternative metabolic pathways that are marginally affected until they adapt to the high heavy metal concentration (Gikas and Romanos 2006).

During the recovery phase operations, the average COD removals in reactors RCo0, RCo5, RCo25, and RCo75 were close to 83%, 83%, 81%, and 74%, respectively. Particularly, during 50–59 days of operation in the recovery phase, the steady-state COD removals were ~80%, 80%, 86%, and 89% for reactors RCo0, RCo5, RCo25, and RCo75 respectively. Reactors RCo25 and RCo75 showed an increasing trend in COD removals during the recovery phase operation compared to the stressed phase operation. Ong et al. (2004) also observed an increase in COD removal from 87 to 96% on suspending the Ni(II) dosing after exposing the biomass to 10 mg/L of Ni(II) ions. Similarly, Li et al. (2011) reported an increase in COD removal from 5 to 95% after stoppage of exposure to the biomass with 240 mg/L of Ni(II) ions concentration. In the present study, the reason for increased COD removal in recovery phase operation might be the availability of trace amount of Co(II) ions in reactors RCo25 and RCo75. Trace levels of Co(II) ions left after stressed phase might have stimulated the organic removal process in the reactors (refer to Fig. 3).

The average values of initial and effluent pH for the stressed and recovery phases in all the reactors were in the range of 6.80–7.35, while alkalinity values varied from 37 to 44 mg/L as CaCO3. A summary of all the performance-related parameters (average values with standard deviations) for the reactors in both phases of operations is presented in Table S1.

The variations in Co(II) ion and MLSS concentration in the reactors are shown in Fig. 3. The average influent Co(II) ion concentration in reactors RCo5, RCo25, and RCo75 were 5.05 ± 0.95, 23.42 ± 3.73, 76.79 ± 7.97 mg/L, respectively. The Co(II) ion concentrations amounted to 2.15, 11.54 and 37.83 mg Co(II)/g MLSS loading for the reactor biomass in RCo5, RCo25, and RCo75 reactors, respectively. It was observed that ~ 44%, 83%, and 90% of Co(II) eluted with the effluent from reactors RCo5, RCo25, and RCo75, respectively. This indicated the retention of approximately 1.20, 1.97, and 3.78 mg Co(II)/g MLSS on the reactor biomasses. The retained fraction of Co(II) might have affected reactor performance in COD removals, as explained earlier. Gikas (2008), in a review, reported the concentration of Co(II) in the activated sludge process to be 0.14 mg Co(II)/g MLSS. The progressive built up of Ni(II) ion concentration in SBR after long-term exposure, however, valued to 8.71 mg/g MLSS and 96.64 mg/g MLSS for 1 mg/L and 10 mg/L Ni(II), respectively (Yang et al. 2017). In the present study, around 50–20% of aqueous solution remained in the reactor, which could have led to the accumulation of Co(II) ions with every subsequent cycle. Washing of the sludge prevented this progressive built up, and the metal exposure concentration was close to the desired levels.

The pH of the reactors was much below to the value of 9.5, up to which Co(II) is considered to exist in ionic form (Rai and Serne 1978). The average ratio of MLVSS to MLSS for reactors RCo5, RCo25, and RCo75 were 0.94, 0.89 and 0.92 during stressed phase operation, indicating a lack of built-up of inorganic fraction in the biomasses. Hence, it is safe to assume that Co(II) was present in ionic form and not as a precipitated solid fraction in the reactors during stressed phase operation. Co(II) background [Co(II)BG] concentrations left in the reactors after washing of the biomass ranged from 8–13% of the influent Co(II) concentration. A typical energy dispersive X-ray (EDX) analysis for reactor RCo25 biomass withdrawn on 25th day of stressed phase operation is shown in Fig. 4. The analysis suggests that there was deposition of Co(II) on the biomass surface. The wt.% of Co(II) on the surface of reactor RCo0, RCo5, RCo25, and RCo75 biomasses were 0, 1.0, 1.6 and 9.3, respectively (as could be seen from Figs. 4 and Fig. S2 to S4 given in supplementary information). The Co(II) ion concentration reduced in the effluent and was therefore not detected in the reactors during the recovery phase operation.

Average MLSS levels for reactor RCo0, RCo5, RCo25, and RCo75 biomasses during the stressed phase operation were 2.2, 2.4, 2.0, and 2.0 g/L, respectively, and during the recovery phase operation were 1.9, 1.5, 1.5, and 2.8 g/L, respectively. The MLSS levels followed decreasing trends for reactors RCo5, RCo25, and RCo75 biomasses during stressed phase operation. The decrease in MLSS might be attributed to the transformation of sludge from large dense flocs to pinpoint sludge biomass, particularly in reactors RCo25 and RCo75 (refer to Fig. 7). The slow settling rate of dispersed flocs that were earlier part of large dense flocs resulted in their washout, thus decreasing MLSS levels in the reactor. Co(II) was reported to be a growth inhibitor that decreased the MLSS upon increasing its concentration (Gikas 2008). The decreasing trend in the MLSS is in corroboration with Ong et al. (2004), and Ma et al. (2019) for the sludge biomass stressed with 10 mg/L and 30 mg/L of Ni(II), respectively. During the recovery phase operation, the MLSS levels in reactor RCo0 were relatively stable while, decreased MLSS levels were observed in reactor RCo5 and RCo25. The possible reason behind this reduction was the washout of slow settling flocs. Settling time given to biomass in the reactors was only 5 min. The heavier biomass usually settled within this settling time, whereas lighter biomass got decanted with the supernatant, causing a reduction in MLSS levels. Due to improved settleability, the MLSS levels in reactor RCo75 increased during the recovery phase as most of the biomass was retained in the reactor, and no washout of flocs was observed.

Sludge biomass settleability

The results of sludge volume index (SVI30) and settling velocity of biomass (SVB) are presented in Table 1. The average values of SVI30 in reactor RCo0, RCo5, RCo25, and RCo75 biomasses during stressed phase were 145.9, 141.3, 97.5 and 68.7 mL/g respectively. Reactor biomasses exposed to higher Co(II) concentrations of 25 and 75 mg/L showed a reduction in the values of SVI30 during stressed phase operation. The SVI30 values during the recovery phase were 147.9, 179.3, 152.8 and 57.3 mL/g for reactor RCo0, RCo5, RCo25, and RCo75 biomasses respectively. The SVI30 of reactor biomass in RCo75 was not observed to increase despite Co(II) discontinuation in the feed during the recovery phase operation showing irreversible changes in the sludge biomass. It is a well-established fact that the aerobic sludge biomass having SVI30 values lower than 100 mL/g is considered good settling sludge due to the absence of filamentous growth. The SVI30 values above 150 mL/g are typically associated with predominant filamentous growth (Metcalf and Eddy 2003) which result in bulking of sludge with poor settling characteristics (Neufeld 1976). During the stressed phase operation, the SVI30 was below 100 for reactor RCo25 and RCo75 biomasses, which can be categorized as non-bulking sludge. Similar observations for Ni(II) dosing in an SBR was made by Ma et al. (2019). Li et al. (2011) also reported a sharp decrease in SVI values from 700 mL/g to 104 mL/g on dosing the SBR with 60 mg/L of Ni(II).

The average values of SVB in reactor RCo0, RCo5, RCo25, and RCo75 biomasses were 7.6 m/h, 8.6 m/h, 12.7 m/h and 13.8 m/h, respectively during stressed phase operation and 10.4 m/h, 4.5 m/h, 11.6 m/h and 11.5 m/h, respectively during the recovery phase operation. The SVB values were quite high during the stressed phase operation for reactor RCo25 and RCo75 biomasses. The lower SVI30 values (less than 100 mL/g) and correspondingly higher SVB values indicate improved settling properties of reactor biomass when exposed to higher metal concentrations — apparently a pseudo positive impact of Co(II) in the feed! The lower SVI30 values and declining MLSS levels in reactor RCo25 and RCo75 biomasses indicate conversion of filamentous biomass into highly stable pinpoint floc (Neufeld 1976). Filamentous microorganisms play a vital role in forming strong flocs. Toxic chemicals affect the abundance of filamentous organisms, thereby yielding lower SVI30 values. Toxicant overdosing leads to its penetration into the flocs, killing interior filaments and causing floc break-up with the formation of pinpoint floc/biomass, which finally gets washed out of the reactor (Sezgin et al. 1978). The washing of pin-point flocs may leave insufficient biomass in the reactor for operation, ultimately leading to shutting down of the treatment facility (Negi et al. 2021).

The observed improvement in the settleability of the aerobic sludge biomass was ascribed to the absence of filamentous microorganisms (Ong et al. 2004). In a similar study with Ni(II) dosing of 240 mg/L, the ionic double layer compression mechanism was associated with increased settleability (Li et al. 2011). However, the double-layer compression was possible in the presence of high ionic concentration (Peavy et al. 1985), which, fortunately, was not the case in the present study.

Biomass activity

The results of the biomass activity test and the estimated activity values are given in Fig. 5 and Table 2, respectively. The activity of reactor RCo5, RCo25, and RCo75 biomasses in the stressed phase decreased by 39%, 45%, and 49%, respectively, as compared to control reactor biomass. El–Bestawy et al. (2013) reported a 70% reduction in the activity of biomass upon increasing the concentration of Co(II) ions from 0 to 40 mg/L. The level of inhibition was reported to depend upon the metallic type, concentration of metal and biomass (Hernandez-Martinez et al. 2018). Wang et al. (2013) also observed reduction of up to 50% in the biomass activity values after the addition of 40 mg/L of Ni(II).

In the recovery phase, the overall activity values significantly increased for reactor RCo25 and RCo75 biomasses compared to the stressed phase. Ong et al. (2004) reported that the specific oxygen uptake rate was completely recovered 12 days after the termination of 10 mg/L Ni(II) ions in the feed. Negi et al. (2020) showed improved consumption rate of substrate after the termination of 75 mg/L of Ni(II) from the feed. However estimated biomass activity for RCo75 was not equivalent to the control reactor suggesting incomplete recovery in the biomass activity after termination of the metallic stress.

The highest activity value was recorded for reactor RCo5 biomass, which correlated well with the COD removal in the reactor with an efficiency of above 90%. For all reactors, the COD removal on the day of biomass activity test and the activity values showed a positive correlation with the correlation coefficient (r) of 0.83.

Biomass morphology in stressed and recovery phase operations

Figure 6 shows the SEM images of sludge biomasses in the stressed phase and recovery phase operations. The filamentous microorganisms remained unaffected in reactor RCo5 biomass in both the phases of operation. However, the abundance of the microorganisms was affected in reactor RCo25 and RCo75 biomass during stressed phase.

In the recovery phase operation, the regrowth of filaments was not observed in reactor RCo25 and RCo75 biomasses. The changes in the physical appearance of reactors biomasses are shown in Fig. 7. The shape and structure of sludge biomasses changed drastically in reactors RCo25 and RCo75 compared to reactors RCo0 and RCo5 in the stressed phase operation. The sludge biomasses in reactors RCo25 and RCo75 appeared to lack filaments, with decreased floc size and enhanced dispersed growth. In contrast, the biomasses in reactors RCo0 and RCo5 appeared to have filaments attached with flocs, and relatively large-sized and almost negligible dispersed growth. The biomass in reactors RCo25 and RCo75 indicated conversion of biomass to pinpoint flocs due to a high concentration of Co(II) in the feed. Despite recovery phase operation, the biomasses in reactors RCo25 and RCo75 continued to have pinpoint flocs without showing any filamentous growth, indicating that biomass had suffered persistent, irreparable damage. The impacts of heavy metal toxicity on the filamentous growth as observed in this study are in corroboration with published literature (Ong et al. 2004). In this study, there was no addition of new microbial seeds that might not be the case in a wastewater treatment plant. Therefore, this aspect is still open for investigation.

Practical implications

Wastewater collection, conveyance, and treatment infrastructure in developing and underdeveloped countries are growing. However, there are no special provisions to segregate and treat heavy metal-laden waste streams separately which may reach the wastewater treatment plants. Hence, it has become necessary to develop a technique/protocol for detecting early signs of metallic infiltration. The technique/protocol might be based on simple tests that could be conducted onsite by semi-skilled operators. The results of this study indicate that metallic infiltration causes an initial lag in organic removal. The sludge biomass might get acclimatized to the feed containing heavy metal and restore its organic removal efficiency if the metal concentration is in the lower range. Hence, performing COD removal tests routinely might not catch the attention of the operators or technicians towards any incoming metallic hazard to the plant. Similarly, biomass activity provides quantitative information about substrate degradation rate and shows a long-term change in biomass due to metallic infiltration. Therefore, COD removal and biomass activity are not feasible as early indicators for metallic infiltration.

From the study, it is clear that the metal infiltration has caused drastic changes in SVI30 and SVB. The average SVI30 decreased by 3%, 33%, and 53% for reactor RCo5, RCo25, and RCo75 biomasses, respectively, compared to the control reactor biomass during stressed phase operation. At the same time, SVB increased by 20%, 69%, and 85% for reactor RCo5, RCo25, and RCo75 biomasses, respectively in comparison to control reactor biomass. A decrease in SVI30 value by 30% or more and an increase in SVB values by 50% or more could be considered skeptical for the desired operation of a treatment plant. Hence, SVI30 and SVB tests appear to be the best alternatives as onsite tools considering the simplicity and ease in performance. Therefore, semi-skilled plant operators could use them as an early alert for metallic infiltration.

SVB has an advantage over SVI30 to be utilized as the early indicator because of its sensitivity and simplicity. Performing SVI30 analysis requires a temperature-controlled furnace, graduated cylinder, filter papers, and analytical balance. These equipment may not be typically available in the small-scale centralized and decentralized treatment plants. On the other hand, a graduated cylindrical vessel and stopwatch (available in mobile phone) are required for the estimation of SVB. Further, a simple training to plant operators for determining the highest slope on a graph paper for the calculation of SVB can help in detecting metallic infiltration. Timely knowledge about the infiltration might give an edge to the operators in segregating the metallic stream and isolating it from incoming sewage, thus preventing the sludge biomass from permanent damage.

Conclusion

The study investigated the change in performance and morphology of the aerobic sludge biomass under Co(II) stress. The effect of Co(II) on COD removal of reactor RCo0 and RCo5 was negligible throughout reactor operation. The removal in reactor RCo75 was significantly affected during stressed phase, while in the recovery phase, the reactor performance was reestablished. The settling and dewatering characteristics of sludge biomass for reactors RCo0 and RCo5 were comparable and remained unaffected to the addition of Co(II) ion in the feed. On the other hand, the sludge volume index (SVI30) decreased, and the settling velocity of biomass (SVB) increased significantly in reactor RCo25 and RCo75 biomasses compared to control reactor biomass during the stressed phase operation. A significant recovery in terms of biomass activity was also observed for reactor RCo75 biomass. However, the irreversible changes noticed for reactor RCo75 were: (1) SVB of sludge biomass remained high even during the recovery phase, (2) regrowth of filamentous microorganisms was not observed, and 3), the sludge biomasses in reactors RCo25 and RCo75 remained as pinpoint flocs, unable to recover back, suggesting permanent, irreversible damage caused to the floc’s morphology due to the presence of the metal ion in the feed. The intrinsic linkage between SVI30, SVB, and metallic infiltration is not new and has been identified in the other studies as well. However, the perspective of these parameters as indicators is visualized for the first time in this study. A decrease in SVI30 value by 30% or more and an increase in SVB values by 50% or more could be considered skeptical for the desired operation of a treatment plant. Quantifying SVI30 and SVB can be suggested as simple tools for unskilled laborers, to indicate metallic infiltration which can help in preventing deterioration of sludge biomass for the safe operation of a wastewater treatment plant.

Data Availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Al-Jlil SA (2017) Adsorption of cobalt ions from waste water on activated Saudi clays. Appl Water Sci 7(1):383–391. https://doi.org/10.1007/s13201-014-0253-z

APHA (2012) Standard methods for the examination of water and wastewater, 22nd edn. American Public Health Association, American Water Works Association and Water Environment Federation, Washington, DC

CPHEEO (2013) Manual on sewerage and sewage treatment systems Ministry of Housing and Urban Affairs, Government of India

El Bestawy E, Helmy S, Hussein H, Fahmy M (2013) Optimization and/or acclimatization of activated sludge process under heavy metals stress. World J Microbiol Biotechnol 29(4):693–705. https://doi.org/10.1007/s11274-012-1225-9

Gikas P, Romanos P (2006) Effects of tri-valent (Cr(III)) and hexa-valent (Cr(VI)) chromium on the growth of activated sludge. J Hazard Mater 133:212–217. https://doi.org/10.1016/j.jhazmat.2005.10.023

Gikas P (2008) Single and combined effects of nickel (Ni(II)) and cobalt (Co(II)) ions on activated sludge and on other aerobic microorganisms: a review. J Hazard Mater 159:187–203. https://doi.org/10.1016/j.jhazmat.2008.02.048

Hernandez-Martinez GR, Ortiz-Alvarez D, Perez-Roa M, Urbina-Suarez NA, Thalasso F (2018) Multiparameter analysis of activated sludge inhibition by nickel, cadmium, and cobalt. J Hazard Mater 351:63–70. https://doi.org/10.1016/j.jhazmat.2018.02.032

Jawed M, Tare V (1996) Methanogenic activity and performance of UASB, DSFF and USFF reactors. Water Sci Technol 34:483–487. https://doi.org/10.1016/0273-1223(96)00682-8

Jawed M, Tare V (1999) Microbial composition assessment of anaerobic biomass through methanogenic activity tests. Water SA 25:345–350

Kedves A, Sánta L, Balázs M, Kesserű P, Kiss I, Rónavári A, Kónya Z (2020) Chronic responses of aerobic granules to the presence of graphene oxide in sequencing batch reactors. J Hazard Mater 389:121905. https://doi.org/10.1016/j.jhazmat.2019.121905

Kedves A, Rónavári A, Kónya Z (2021) Long-term effect of graphene oxide on the aerobic granular sludge wastewater treatment process. J Environ Chem Eng 9(1):104853. https://doi.org/10.1016/j.jece.2020.104853

Leyssens L, Vinck B, Van Der Straeten C, Wuyts F, Maes L (2017) Cobalt toxicity in humans—a review of the potential sources and systemic health effects. Toxicology 387:43–56. https://doi.org/10.1016/j.tox.2017.05.015

Li J, Liu Y, Zhang T, Wang L, Liu X, Dai R (2011) The effect of Ni (II) on properties of bulking activated sludge and microbial analysis of sludge using 16S rDNA gene. Bioresour Technol 102(4):3783–3789. https://doi.org/10.1016/j.biortech.2010.12.022

Ma B, Li Z, Wang S, Liu Z, Li S, She Z, Yu N, Zhao C, Jin C, Zhao Y, Guo L (2019) Insights into the effect of nickel (Ni (II)) on the performance, microbial enzymatic activity and extracellular polymeric substances of activated sludge. Environ Pollut 251:81–89

Madoni P, Davoli D, Gorbi G, Vescovi L (1996) Toxic effect of heavy metals on the activated sludge protozoan community. Water Res 30:135–141. https://doi.org/10.1016/0043-1354(95)00124-4

Metcalf and Eddy (2003) Wastewater engineering: treatment and reuse. Tata McGraw Hill, New Delhi, India

Negi R, Kumar R, Jawed M (2020) Reactor performance and morphology of aerobic sludge biomass in the presence and absence of Ni (II) ion in feed. J Inst of Eng (India): Series A 101(1): 153–162. https://doi.org/10.1007/s40030-019-00407-6

Negi R, Kumar R, Jawed M (2021) Effect of nickel (II) and cobalt (II) mixture on aerobic sludge biomass. J Environ Eng Sci. https://doi.org/10.1680/jenes.20.00035

Neufeld RD (1976) Heavy metals-induced deflocculation of activated sludge. J Water Pollut Control Fed 48(8):1940–1947

Ong SA, Toorisaka E, Hirata M, Hano T (2004) Effects of nickel(II) addition on the activity of activated sludge microorganisms and activated sludge process. J Hazard Mater 113:111–121. https://doi.org/10.1016/j.jhazmat.2004.05.031

Peavy H S, Rowe DR, Tchobanoglous G (1985) Environmental engineering. McGraw Hill Education (India) ed., New Delhi, India

Rai D, Serne RJ (1978) Solid phases and solution species of different elements in geologic environments. United States. https://doi.org/10.2172/7044838

Sezgin M, Jenkins D, Parker DS (1978) A unified theory of filamentous activated sludge bulking. J Water Pollut Control Fed 50(2):362–381

Singh RK (2014) Pollution threat to surface and ground water quality due to electroplating units. Int J Res Appl Sci and Eng Technol 2(2):50–53

Singh V, Ram C, Kumar A (2016) Physico-chemical characterization of electroplating industrial effluents of Chandigarh and Haryana region. J Civil Environ Eng 6(237):2. https://doi.org/10.4172/2165-784X.1000237

Taka AL, Fosso-Kankeu E, Pillay K, Mbianda XY (2018) Removal of cobalt and lead ions from wastewater samples using an insoluble nanosponge biopolymer composite: adsorption isotherm, kinetic, thermodynamic, and regeneration studies. Environ Sci Pollut Res 25(22):21752–21767. https://doi.org/10.1007/s11356-018-2055-6

Tomar SK, Chakraborty S (2018) Effect of air flow rate on development of aerobic granules, biomass activity and nitrification efficiency for treating phenol, thiocyanate and ammonium. J Environ Manag 219:178–188. https://doi.org/10.1016/j.jenvman.2018.04.111

Tyagi A (2013) Guide to cleaner production in electroplating sector. CPCB, New Delhi, India

Wang W, Li X, Wang P, Song X, Jiang D, Wang K (2013) Long-term effects of Ni (II) on the performance and activity of activated sludge processes. Ecotoxicol Environ Saf 92:144–149. https://doi.org/10.1016/j.ecoenv.2013.03.022

Wang Y, Li X, Xie T, An H, Yang Q, Wang S, Yao F, Chen F, Sun J, Wang D, Zeng G, Zhong Y (2016) Effect of nickel on the flocculability, settleability, and dewaterability of activated sludge. Bioresour Technol 224:188–196. https://doi.org/10.1016/j.biortech.2016.11.018

Yang Q, Sun J, Wang D, Wang S, Chen F, Yao F, Zeng G (2017) Effect of nickel on the flocculability, settleability, and dewaterability of activated sludge. Bioresour Technol 224:188–196. https://doi.org/10.1016/j.biortech.2016.11.018

Zhang X, Zhou Y, Zhang N, Zheng K, Wang L, Han G, Zhang H (2017) Short-term and long-term effects of Zn (II) on the microbial activity and sludge property of partial nitrification process. Bioresour Technol 228:315–321. https://doi.org/10.1016/j.biortech.2016.12.099

Acknowledgements

The authors would like to thank the Department of Civil Engineering for facilitating all the necessary resources required for the study and Central Instruments Facility at IIT Guwahati for FESEM and EDX analysis. The authors also thank the editor and anonymous reviewers for their valuable suggestions. Thanks are due to Ms. Krishna R. Nair for her suggestions and comments, which improved the language of the manuscript.

Author information

Authors and Affiliations

Contributions

RN carried out the experiments, performed the data analysis, and wrote the original draft of the manuscript. RK helped in reactors fabrication, project administration, and in review and editing of the manuscript. MJ supervised the project, reviewed, and edited the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Negi, R., Kumar, R. & Jawed, M. Recovery potential of aerobic sludge biomass from Co (II) stress in sequencing batch reactors. Environ Sci Pollut Res 29, 61954–61966 (2022). https://doi.org/10.1007/s11356-022-19965-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-19965-7