Abstract

Alginates are natural polymers composed of mannuronic and guluronic acid residues. They are currently extracted from brown algae; however, alginate can also be synthesized by some species of Azotobacter and Pseudomonas. Alginates with different proportion of mannuronic and guluronic acids are known to have different characteristics and form gels at different extents in the presence of calcium ions. The aim of this work was to investigate the usefulness of alginate as a non-toxic coagulant used in purification of drinking water. This study utilized alginates from Azotobacter vinelandii having different guluronic acid levels. These were obtained partly by changing the cultivation parameters, partly by epimerizing a purified alginate sample in vitro using the A. vinelandii mannuronan C-5 epimerase AlgE1. The different alginates were then used for coagulation together with calcium. The results showed that turbidity removal capability was dependent on the content of guluronic acid residues. For the best performing samples, the turbidity decreased from 10 NTU to 1 NTU by the use of only 2 mg/L of alginate and 1.5 mM of calcium chloride.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The presence of colloidal particles makes water unacceptable for human consumption due to aesthetical reasons and health concerns. The general approach for the removal of these solids is the agglomeration of particles by coagulation and flocculation processes. Generally, metal salts such as aluminum sulfate are used as coagulants (Berthon 2002). Additionally, natural or synthetic polymeric substances are used as coagulants alone or as coagulant aids together with metal salts. A number of natural materials have coagulating abilities such as chitosan, starch, and alginate (Ahmad et al. 2006; Devrimci et al. 2012; Divakaran and Pillai 2002; Guibal and Roussy 2007; Labille et al. 2005; Madrona et al. 2010; Qudsieh et al. 2008; Sand et al. 2010; Tripathy and Singh 2001). Natural polymers are advantageous because they are less toxic and more biodegradable (Bolto and Gregory 2007). Also, some microbial natural polyelectrolytes can be produced economically in large-scale cultures at high rates and are readily recovered from culture broth (Salehizadeh and Shojaosadati 2001).

Alginates which are linear copolymers of mannuronic (M) and guluronic (G) acid monomers are the structural components of marine brown algae. Even though alginates are currently extracted from marine brown algae, some species of Pseudomonas and Azotobacter also produce alginate. Alginates form gels with calcium ions, and the properties of these gels depend on the content and distribution of the two monomers (Skjåk-Bræk et al. 2015). It is known that if M-blocks formed by consecutive mannuronic acid residues are dominant, soft and more flexible gels are formed, whereas if stretches of consecutive guluronic acid residues (G-blocks) are dominant, strong gels that are mostly resembled by an “egg-box structure” are formed (Grant et al. 1973). Production of alginate from Azotobacter vinelandii has been widely studied by using shake flasks and fermenters (Clementi et al. 1999; Diaz-Barrera et al. 2010; Mejia et al. 2010; Peña et al. 1997; Savalgi and Savalgi 1992), and by differing the growth conditions, it is possible to reproducibly produce alginates with different content of G-blocks (Moral and Sanin 2012; Sabra et al. 2000; Sabra et al. 1999). A. vinelandii encode seven different secreted mannuronan C-5 epimerases (AlgE1-7) which introduce G residues in the polymer, and these may be used to increase the amount of G and G-blocks in vitro (Ertesvåg et al. 2009).

The number of studies concerning the use of alginate for turbidity removal is limited. Some of these studies used alginate in the form of alginate-g-polyacrylamide for the removal of turbidity from iron ore suspensions (Tripathy et al. 2001a), from dyeing wastewater (Xu et al. 2006) and cooking and non-cooking coal suspensions (Tripathy et al. 2001b; Tripathy et al. 1999). Additionally, alginate-g-N-vinyl-2-pyrrolidone was used for the removal of turbidity from coal suspensions (Sand et al. 2010). Most of these studies focused on removing solids from wastewaters. One other study investigated the use of alginate together with calcium as the sole coagulant for turbid water treatment (Devrimci et al. 2012). Devrimci et al. used algal alginate for turbidity removal at three different turbidity levels, 150, 80, and 10 NTU. Alginate was found to be an effective coagulant particularly for turbidity values of 150 and 80 NTU, decreasing the turbidities down to the target value of 1 NTU effectively. However, the effectiveness of algal alginate was comparatively lower at 10 NTU, and the target turbidity reduction could only be achieved by some modifications of mixing regime and experimental procedure with an alginate having higher viscosity. Algal alginates pose some disadvantages since their properties depend on species of algae from which the polymer is harvested and environmental conditions such as climate, seasonal variations, and even water pollution that the algae is exposed to. It is easier to obtain alginates with a more homogenous composition using bacteria. The purpose of this study was to investigate the coagulation potential of alginates having different content of M-blocks, G-blocks, and MG-blocks to find out whether monomer distributions affect turbidity removal efficiency or not. For this purpose, bacterial alginates were produced both in a fermenter under controlled conditions as well as in shake flasks. Under fermenter conditions, it was possible to induce the production of polymer with different MM, MG, and GG proportions. In shake flasks, alginates with limited G-block content were produced, and then the polymer was epimerized externally by using AlgE1 enzyme to obtain a variety of G-blocks containing polymers. After that, all the alginate samples produced were tested for their turbidity removal capability. Finally, turbidity removal efficiency of bacterial alginates was compared to two algal alginates that are commercially available on the market.

Materials and methods

Alginate samples

Properties of the alginate samples are summarized in Table 1. All bacterial alginate samples were produced by A. vinelandii ATCC® 9046 in modified Burk’s medium (Moral and Sanin 2012), deacetylated by alkaline treatment, and purified by acid precipitation followed by ethanol precipitation as described earlier (Ertesvåg and Skjåk-Bræk 1999). Samples coded as AS#1–4 produced in a laboratory fermenter (BIOSTAT® A plus, Sartorius BBI Systems, Germany) at constant dissolved oxygen tension, 5 %, and 30 °C during 72 h of fermentation. In addition, one alginate sample used to produce epimerized alginates obtained from shake flask cultivation at 225 rpm and 30 °C during 72 h. It was named as Non-E alginate which was incubated for different times with the mannuronan C-5 epimerase AlgE1 in enzyme buffer (MOPS (50 mM, pH 6.9), CaCl2 (0.8 mM), and NaCl (20 mM)) at 37 °C to obtain high (48-h incubation) and moderate (8-h incubation) level of epimerization (Holtan et al. 2006).

All alginates were subjected to 1H-NMR analysis in order to determine the monomer distribution. Prior to 1H-NMR analysis, the samples were degraded by partial acid hydrolysis according to ASTM F 2259-03 method (ASTM 2003). Then, 1H-NMR analyses for AS#1–4 and algal alginates (LF240D and LF200S) were carried out on a Bruker DPX 400 spectrometer (Germany) at two different temperatures: 30 °C and/or 70 °C. Furthermore, 1H-NMR analyses for Non-E, Mod-E, and High-E alginates were carried out on a Bruker DPX 300 spectrometer (Germany) at 90 °C. The monomeric distribution was calculated from the integrated spectra as described previously (Grasdalen et al. 1979). 1H-NMR spectra of epimerized alginate samples are presented as supplementary materials in Online Resource 1.

Turbidity removal experiment

Synthetic water having an average turbidity of 10 ± 0.4 NTU was prepared by mixing kaolinite (Fluka (CAT# 03584) in water for 24 h at room temperature. All experiments were performed with VELP Scientifica JLT6 Jar Test apparatus having six mixers with flat blades. The beakers were filled with 500 mL of turbid water samples. The procedure of turbidity removal experiment was chosen according to the previous study (Devrimci et al. 2012) where it was shown that the sequence of addition of these two constituents was found to create difference in favor of adding calcium as the first agent. Accordingly, firstly, CaCl2 (0–3 mM) was added into the turbid water sample and mixed for 5 min at 120 rpm. Then, alginate (0–20 mg/L) was added and mixed for further 5 min at 120 rpm. After this 10-min rapid mixing period, the aggregates were allowed to grow for 12 min by slow mixing at 40 rpm. Finally, the solutions were left to settle for 30 min and residual turbidity was measured by a Hach 2100N turbidimeter. All coagulation experiments were performed in triplicates, and the values are given as averages of these technical replicates.

Scanning electron microscopy

Kaolinite used for turbidity and the ones flocculated with 10 mg/L of AS#1 and AS#4 alginate samples were analyzed by scanning electron microscopy (SEM) (Quanta 400F). The images were taken at an acceleration voltage of 10 kV and a magnification of 10,000-fold.

Results

The effect of alginate composition on turbidity removal

Previous studies indicated that alginates may be used for turbidity removal; however, they did not address how this ability is influenced by alginate structure. In the current studies, alginates with different relative content and distribution of G residues were compared (Table 1). The initial turbidity level to be studied was selected as 10 NTU since this value reflects the turbidity of the typical surface water sources prior to treatment. Besides, such low turbidity samples were found to be more difficult to treat in the previous study (Devrimci et al. 2012). In many developed countries, the quality of water for human consumption requires a maximum level of 1 NTU turbidity; therefore, this value was selected as the target turbidity.

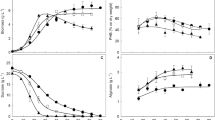

Firstly, the abilities of calcium and alginate to remove turbidity were tested separately. When calcium was the sole agent added, the turbidity removal efficiency was around 30 % (Fig. 1a) and remained nearly constant within the tested range of calcium ion (0.375–3 mM). The alginate with the highest G content (High-E) was used to see the effect of adding only alginate. In this case, the maximum turbidity removal was obtained already at 1 mg/L alginate (Fig. 1b), and an increased alginate concentration resulted in a slight decrease in the turbidity removal efficiency. This might be due to negatively charged functional groups on the surface of alginate that could cause increased repulsive forces within the system. These results showed that neither calcium nor alginate alone could achieve the target turbidity level.

Then, the ability of all alginate samples to decrease the turbidity was evaluated using a fixed amount of calcium ion (1.5 mM). The results are shown in Fig. 2 where the samples are grouped according to the G content. The results of treating the synthetic water with AS#1 and AS#2 showed that there was an important level of turbidity removal with the calcium alginate system (Fig. 2a). AS#1 was found to be greatly effective for turbidity removal since even 1 mg/L of alginate concentration reduced final turbidity value to 2.5 NTU in the presence of 1.5 mM of calcium ion. In fact, 2 mg/L of the alginate concentration was found to be sufficient to bring the turbidity down to 1 NTU which was the target level. AS#2 also seemed to be a good candidate for turbidity removal, but not as efficient as AS#1. In this case, the final turbidity of kaolinite suspension could be reduced to 1 NTU at alginate concentrations higher than 3 mg/L. Beyond 5 mg/L of alginate concentration, the final turbidity value reached a plateau at around 0.3 NTU.

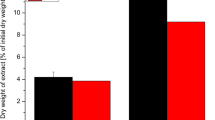

The samples with even higher G content where less efficient for turbidity removal (Fig. 2b). For the high-E alginate, the highest turbidity removal was achieved at 10 mg/L of alginate as 90.8 % (final turbidity 0.92 NTU). Among the doses studied, 7.5 and 10 mg/L concentrations were satisfactory in achieving the target turbidity value. For the Mod-E alginate, the maximum turbidity removal (75 %) was found at 10 mg/L of alginate which yielded a final turbidity of 2.5 NTU (Fig. 2b). As for these bacterial alginates, the turbidity of kaolinite suspension was reduced by LF200S by increasing algal alginate concentrations, and 93 % efficiency was found using 10 mg/L of this alginate. The last high-G sample, AS#4, was less effective than the other samples presented in Fig. 2b and only increasing doses of this alginate, especially higher than 10 mg/L (data not shown), helped to improve the coagulation performance (final turbidity 1.2 NTU at 20 mg/L of AS#4). Since this level of turbidity was not acceptable according to the target value, and this high dose (which is not promoted) was only tested for this polymer, it is not included in the figure. On the other hand, none of the samples with G content below 40 % displayed sufficient turbidity removal efficiencies to meet the target turbidity level at any alginate concentration between 1 and 10 mg/L (Fig. 2c).

In conclusion, two bacterial alginates (AS#1 and AS#2) and one algal alginate (LF200S) were able to decrease the turbidity to below 1 NTU. The results indicated that not only the G content but also the G-block content influenced the coagulation properties, and also that the alginates with the highest G-block content were less efficient than the samples with an intermediary amount of G-blocks.

The effect of calcium on the turbidity removal of different alginates

It is known that the three block types in alginate have different binding constants for calcium (Draget and Taylor 2011). Furthermore, calcium will act as a crosslinking ion between G-blocks, and it might be considered likely that the optimal concentration of this ion would vary between different alginates. In a new set of experiments, the alginate concentration that had provided a final turbidity closest to 2 NTU were chosen for each alginate, while the amount of added calcium was varied from 0 to 3 mM.

For AS#1, 1 mg/L (resulted about 75 % treatment efficiency) was selected with the purpose of investigating whether the achieved turbidity can be reduced to target value with the change in calcium concentration. Results of this experiment showed that still 1.5 mM of calcium ion concentration was optimal for this alginate dose (Fig. 3a). Unfortunately, at 1 mg/L of AS#1, none of the calcium doses studied were sufficient to decrease the turbidity from 10 NTU to 1 NTU. In the case of AS#2, 2 mg/L alginate (which was not able to meet the target turbidity at 1.5 mM calcium dose) was applied. The results show that 2.25 mM of calcium ion dose yielded the highest turbidity reduction as 97 % corresponding to 0.3 NTU of final turbidity. On the other hand, even though the calcium dose was changed to improve the performance of AS#3, only a small improvement was obtained using 2 mg/L of this alginate sample (Fig. 3b). With 15 mg/L of AS#4, the maximum turbidity removal was again found at 1.5 mM of calcium ion concentration.

Furthermore, effect of calcium ion concentration was investigated with 5 mg/L of High-E alginate (Fig. 3c). It was found that turbidity initially decreased sharply by the increase in calcium concentration, and then it rapidly increased. The maximum turbidity removal was observed at 0.75 mM of calcium ion concentration and the final turbidity value was recorded as 1 NTU. Therefore, the required alginate dose for the same turbidity removal efficiency could be reduced from 10 to 5 mg/L by changing the calcium concentration. However, for the Mod-E alginate, turbidity reduction increased with increasing amounts of calcium, and the best result was obtained at 3 mM of calcium ion concentration (92 % reduction, residual turbidity 0.8 NTU). For the non-E sample, turbidity removal was optimal at 0.75 mM of calcium ion concentration, but still the final turbidity was as high as 5 NTU. Finally, the algal alginate samples were subjected to calcium ion optimization. Target turbidity value could only be achieved by LF200S with increasing calcium ion concentration beyond 2.25 mM at a concentration of 7.5 mg/L alginate.

Characterization of flocs using SEM

According to visual observations, the shapes of the flocs were also different for different polymers. Flocs looked considerably more spherical and denser for AS#1 and AS#2, whereas the flocs were somehow looser and of lower density when AS#4 was used and took longer time to settle. It seemed probable that the main mechanism for flocculation of AS#4 might be polymer bridging because of its possibly high ability of gel formation. However, for effective bridging, both charge density of the polymer and coverage ratio of suspended material by the polymer are important (Bolto and Gregory 2007). Figure 4 shows SEM images of original kaolinite suspension together with those after treatment by 10 mg/L AS#1 and AS#4 in the presence of 1.5 mM calcium ion. Most of the kaolinite particles were seen buried when AS#4 was used as a coagulant. On the other hand, coverage of particles was comparably lower in the case of AS#1. It is known that complete coverage of surfaces with polymers adsorbed with flat configuration would lead to steric repulsion resulting in stable suspensions (Besra et al. 2004). Our SEM data indicate that the lower performance of AS#4 compared to AS#1 could result from a higher or even full coverage of suspended particle surfaces by this.

Discussion

The results showed that alginates may be used to reduce the turbidity in drinking water, also from water with the moderate amounts of turbidity previously shown to be difficult. However, only alginates with a sufficiently high content of G-blocks could be used to achieve the goal of less than 1 NTU final turbidity. Since alginate is a natural biopolymer that can be obtained from both algal and bacterial sources, the issue is which source can be used to produce an effective alginate at the lowest cost. This raises the question addressed in this study; what should be the characteristics of alginate for effective turbidity removal.

Our results show that alginates with a low G content (AS#3, non-E alginate and LF240D) displayed very low turbidity removal efficiencies (Figs. 2c and 3). This indicates that the G content is an important determinant of turbidity removal performance. Additionally, it seems that the presence of excessively high G-blocks does not serve the purpose of this work. This statement is based on comparing the efficiencies of the AS#4 and high-E polymers (Fig. 2b) with the AS#1 and AS#2 polymers (Fig. 2a). The former two alginates have very high and similar G-block contents (73 and 76 %, respectively), whereas the latter have intermediate G-block contents (56 and 54 %, respectively). It is obvious that the performances of AS#1 and AS#2 are much better than that of the other two alginates. It is known that selective binding of cations on alginate increases greatly with increasing G residues in the chain and M- and MG-blocks have almost no selectivity (Draget and Taylor 2011). Alginate with higher G-block content may compete with the particles for calcium, making gels, or alginate may just precipitate. Also, the possible reason might be high coverage of particles by alginate shown by the SEM pictures (Fig. 4). This eventually causes almost no space for adsorption of other particles onto the polymer which decreases the chance of bridging as explained below. Therefore, alginates having moderate level of G-blocks seem to be optimal for turbidity removal, and G-block content is not the single factor that determines the effectiveness of the coagulant.

During turbidity removal experiments, calcium was added first and then alginate was applied to the kaolinite sample since combined mixing of alginate and calcium may cause higher amount of calcium alginate precipitation. Additionally, anionic polymers such as alginate can be adsorbed by a negatively charged particle only if there is enough amount of cations available. In this way, calcium ions act as a bridge between negative sites on kaolinite surface and carboxyl groups on the alginate polymer. It is also proposed in this study that calcium has an additional role in turbidity removal since it interacts with G residues. Depending on the block characteristics of alginate, the attraction would be stronger and the polymer together with calcium ion form egg-box structure as it is shown in Fig. 5. This was particularly important when alginate had consecutive G blocks. According to the results, egg-box formation seemed to improve adsorption of alginate onto the kaolinite particles. Then, the adsorbed alginate would be ready to flocculate the suspended particles. Adsorption of long-chain polymers on suspended particles can lead to the formation of loops and tails which extend into solution. These are the polymer segments responsible for the attachment of other particles by polymer bridging (Fig. 5). In fact, linear polymers with high molecular weight such as alginate are generally known as the most effective polymers for bridging (Bolto and Gregory 2007).

Conclusion

The coagulation potential of bacterial alginates was found to be satisfactory, and the target turbidity level could be achieved by quite low doses of alginate having a sufficient, but not too high content of G-blocks. Bacterial alginate together with calcium ions might be used as the sole coagulant for the treatment of low turbidity waters. Given the higher efficiency of the bacterial alginates, they may be more cost-efficient than the tested commercially available alginates for this purpose.

References

Ahmad AL, Sumathi S, Hameed BH (2006) Coagulation of residue oil and suspended solid in palm oil mill effluent by chitosan, alum and PAC. Chem Eng J 118:99–105. doi:10.1016/j.cej.2006.02.001

ASTM (2003) Standard Test Method for Determining the Chemical Composition and Sequence in Alginate by Proton Nuclear Magnetic Resonance (1H NMR) Spectroscopy

Berthon G (2002) Aluminium speciation in relation to aluminium bioavailability, metabolism and toxicity. Coord Chem Rev 228:319–341. doi:10.1016/s0010-8545(02)00021-8

Besra L, Sengupta DK, Roy SK, Ay P (2004) Influence of polymer adsorption and conformation on flocculation and dewatering of kaolin suspension. Sep Purif Technol 37:231–246. doi:10.1016/j.seppur.2003.10.001

Bolto B, Gregory J (2007) Organic polyelectrolytes in water treatment. Water Res 41:2301–2324. doi:10.1016/j.watres.2007.03.012

Clementi F, Crudele MA, Parente E, Mancini M, Moresi M (1999) Production and characterisation of alginate from Azotobacter vinelandii. J Sci Food Agric 79:602–610. doi:10.1002/(sici)1097-0010(19990315)79:4<602::aid-jsfa224>3.0.co;2-n

Devrimci HA, Yuksel AM, Sanin FD (2012) Algal alginate: a potential coagulant for drinking water treatment. Desalination 299:16–21. doi:10.1016/j.desal.2012.05.004

Diaz-Barrera A, Silva P, Berrios J, Acevedo F (2010) Manipulating the molecular weight of alginate produced by Azotobacter vinelandii in continuous cultures. Bioresour Technol 101:9405–9408. doi:10.1016/j.biortech.2010.07.038

Divakaran R, Pillai VNS (2002) Flocculation of river silt using chitosan. Water Res 36:2414–2418. doi:10.1016/s0043-1354(01)00436-5

Draget KI, Taylor C (2011) Chemical, physical and biological properties of alginates and their biomedical implications. Food Hydrocoll 25:251–256. doi:10.1016/j.foodhyd.2009.10.007

Ertesvåg H, Skjåk-Bræk G (1999) Modification of alginate using mannuronan C-5-epimerases. In: Bucke C (ed) Methods in biotechnology 10. Carbohydrate Biotechnology Protocols. Humana Press Inc., Totowa, pp 71–78

Ertesvåg H, Valla S, Skjåk-Bræk G (2009) Enzymatic alginate modification. In: Rehm BHA (ed) Alginates: biology and applications. Springer, Berlin, pp 95–115

Grant GT, Morris ER, Rees DA, Smith PJC, Thom D (1973) Biological interactions between polysaccharides and divalent cations—egg-box Model. FEBS Lett 32:195–198. doi:10.1016/0014-5793(73)80770-7

Grasdalen H, Larsen B, Smidsrød O (1979) PMR study of the composition and sequence of uronate residues in alginates. Carbohydr Res 68:23–31. doi:10.1016/s0008-6215(00)84051-3

Guibal E, Roussy J (2007) Coagulation and flocculation of dye-containing solutions using a biopolymer (Chitosan). React Funct Polym 67:33–42. doi:10.1016/j.reactfunctpolym.2006.08.008

Holtan S, Bruheim P, Skjak-Braek G (2006) Mode of action and subsite studies of the guluronan block-forming mannuronan C-5 epimerases AlgE1 and AlgE6. Biochem J 395:319–329. doi:10.1042/bj20051804

Labille J, Thomas F, Milas M, Vanhaverbeke C (2005) Flocculation of colloidal clay by bacterial polysaccharides: effect of macromolecule charge and structure. J Colloid Interface Sci 284:149–156. doi:10.1016/j.jcis.2004.10.001

Madrona GS, Serpelloni GB, Vieira AMS, Nishi L, Cardoso KC, Bergamasco R (2010) Study of the effect of saline solution on the extraction of the Moringa oleifera seed’s active component for water treatment. Water Air Soil Pollut 211:409–415. doi:10.1007/s11270-009-0309-0

Mejia MA, Segura D, Espin G, Galindo E, Pena C (2010) Two-stage fermentation process for alginate production by Azotobacter vinelandii mutant altered in poly-beta-hydroxybutyrate (PHB) synthesis. J Appl Microbiol 108:55–61. doi:10.1111/j.1365-2672.2009.04403.x

Moral ÇK, Doğan Ö, Sanin FD (2015) Effect of oxygen tension and medium components on monomer distribution of alginate. Appl Biochem Biotechnol 176:875–891. doi:10.1007/s12010-015-1617-z

Moral ÇK, Sanin FD (2012) An investigation of agitation speed as a factor affecting the quantity and monomer distribution of alginate from Azotobacter vinelandii ATCC 9046. J Ind Microbiol Biotechnol 39:513–519. doi:10.1007/s10295-011-1043-3

Peña C, Campos N, Galindo E (1997) Changes in alginate molecular mass distributions, broth viscosity and morphology of Azotobacter vinelandii cultured in shake flasks. Appl Microbiol Biotechnol 48:510–515

Qudsieh IY et al (2008) Preparation and characterization of a new coagulant based on the sago starch biopolymer and its application in water turbidity removal. J Appl Polym Sci 109:3140–3147. doi:10.1002/app.28399

Sabra W, Zeng AP, Lunsdorf H, Deckwer WD (2000) Effect of oxygen on formation and structure of Azotobacter vinelandii alginate and its role in protecting nitrogenase. Appl Environ Microbiol 66:4037–4044. doi:10.1128/aem.66.9.4037-4044.2000

Sabra W, Zeng AP, Sabry S, Omar S, Deckwer WD (1999) Effect of phosphate and oxygen concentrations on alginate production and stoichiometry of metabolism of Azotobacter vinelandii under microaerobic conditions. Appl Microbiol Biotechnol 52:773–780

Salehizadeh H, Shojaosadati SA (2001) Extracellular biopolymeric flocculants—recent trends and biotechnological importance. Biotechnol Adv 19:371–385. doi:10.1016/s0734-9750(01)00071-4

Sand A, Yadav M, Mishra DK, Behari K (2010) Modification of alginate by grafting of N-vinyl-2-pyrrolidone and studies of physicochemical properties in terms of swelling capacity, metal-ion uptake and flocculation. Carbohydr Polym 80:1147–1154. doi:10.1016/j.carbpol.2010.01.036

Savalgi V, Savalgi V (1992) Alginate production by Azotobacter vinelandii in batch culture. J Gen Appl Microbiol 38:641–645. doi:10.2323/jgam.38.641

Skjåk-Bræk G, Donati I, Paoletti S (2015) Alginate hydrogels: properties and applications. In: Matricardi P, Alhaique F, Coviello T (eds) Polysaccharide Hydrogels: Characterization and Biomedical Applications. Pan Stanford Publishing Pte Ltd, p In press

Tripathy T, Bhagat RP, Singh RP (2001a) The flocculation performance of grafted sodium alginate and other polymeric flocculants in relation to iron ore slime suspension. Eur Polym J 37:125–130. doi:10.1016/s0014-3057(00)00089-6

Tripathy T, Karmakar NC, Singh RP (2001b) Development of novel polymeric flocculant based on grafted sodium alginate for the treatment of coal mine wastewater. J Appl Polym Sci 82:375–382

Tripathy T, Pandey SR, Karmakar NC, Bhagat RP, Singh RP (1999) Novel flocculating agent based on sodium alginate and acrylamide. Eur Polym J 35:2057–2072. doi:10.1016/s0014-3057(98)00284-5

Tripathy T, Singh RP (2001) Characterization of polyacrylamide-grafted sodium alginate: a novel polymeric flocculant. J Appl Polym Sci 81:3296–3308. doi:10.1002/app.1786

Xu K, Xu X, Ding Z, Zhou M (2006) Synthesis and flocculability of sodium alginate grafted with acrylamide. China Particuology 4:60–64, doi:10.1016/S1672-2515(07)60235-8

Acknowledgment

This study was funded by the Turkish Prime Ministry-State Planning Organization and METU Research Fund (BAP-DPT 2002 K120510).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Gerald Thouand

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1: Online Resource 1

1H-NMR spectra for epimerized alginates (PDF 121 kb)

Rights and permissions

About this article

Cite this article

Kıvılcımdan Moral, Ç., Ertesvåg, H. & Sanin, F.D. Guluronic acid content as a factor affecting turbidity removal potential of alginate. Environ Sci Pollut Res 23, 22568–22576 (2016). https://doi.org/10.1007/s11356-016-7475-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-7475-6