Abstract

In this paper, a novel compact dual-band textile printed slot antenna with partial ground plane is proposed. The substrate of the designed antenna is prepared from jeans fabric material while the patch and ground plane are made from copper tape. The proposed antenna offers an experimentally measured impedance bandwidth of 46 %, i.e. from 3.01 to 5.30 GHz and 41 %, i.e. from 8.12 to 12.35 GHz. The antenna is further characterized by a peak gain of about 5.7 dB and a comparatively stable radiation pattern in the useful band. The antenna is compact in size and useful for WiMax (3.25–3.85 GHz), WLAN (5.15–5.35 GHz) and X-band (8–12 GHz) applications. Also, a comparison of simulated results is discussed with the measured results of the fabricated prototype.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The key considerations for wearable electronics devices are to be robust, flexible, small size, consume a small amount of power, and comfortable to wear. Ultra Wide Band (UWB) devices do not require transmitting a high-power signal to the receiver and these devices can have a longer battery life. For flexible textile antennas, textile materials form attractive substrates, because fabric antennas can be easily incorporated into clothes. In this paper, by merging the UWB technology with textile technology, an improved UWB antenna using Clothing materials is fabricated and presented. By means of emerge of body-centric wireless communications and the potential and possibilities of wearable healthcare and monitoring systems have made a need for fabric-based antennas which could be seamlessly integrated with clothing [1–4]. With body-worn antennas, it is possible to conceal the technology that often frightens patients, while discreetly providing support. Unobserved monitoring instruments are needed in involuntary treatment and dementia care, where the patients may search for to remove suspicious devices [5, 6].

In welfare industry, there is a sprouting need for on-body sensing with unnoticeable and well-fixed sensor components namely wearable sensors. For instance, the lack of personnel in nursing homes is a significant problem. Instead of replacing human tangency, technology should be helpful and take care of certain monitoring responsibilities, thus saving the time of the staff for more important tasks [7–9]. The recent trend is to assist the elderly live at home instead of caring homes. For giving assistance, technology is needed to improve the feeling of security, for instance, sensing of breathing, regular actions, body temperature, sleep, or body limb movement can help in spontaneous monitoring of well-being. In rehabilitation process, sensors could monitor that the permitted exercises are performed but not too hard training is done. Rapid exploitation of antenna enhances wireless communication technology day by day. The wearable textile antenna is mostly used in health monitoring of vital signs of the wearer such as heart rate, respiration rate, temperature, military application, mobile communication, monitoring pilot or truck driver tiredness [10–17]. Flexible wearable systems need the integration of flexible antennas to provide wireless connectivity operating in specific frequency bands which are extremely demanded by today’s information-oriented society. Smart fabrics or e-textiles have attracted growing interest in the last 10 years, particularly for wearable system applications. The practical use of flexible textile antennas is most suited as soon as they are integrated into clothing. As this can be accomplished easily and unobtrusively, the integration of such an antenna system into a rescue worker’s garment is no clogging for the operations to be performed. Hence the essential requirements of wearable antenna designing are flexible conductive materials in the patch and ground plane, and flexible dielectric materials [18–25].

Micro electromechanical systems (MEMS) are the incorporation of mechanical elements such as sensors and actuators and, diodes with electronics on a common silicon substrate through utilization of micro fabrication technology. Micro electromechanical systems technology can offer improved performance over solid-state devices for instance semiconductor switches, sensors, and varactor diodes [26–28]. There are a number of prominent examples of antennas that employ RF MEMS devices. These can be classified into two distinct categories: generic RF MEMS antennas and RF MEMS antenna circuits.

The first category has radiating elements that physically move under some form of mechanical actuation mechanism. The second category has fixed position radiating elements that employ RF MEMS switches and/or variable capacitors to alter their electrical length [26–28].

2 Antenna Design and Configuration

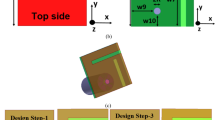

In this article, an octagonal slot loaded circular-shaped textile antenna is fabricated on 40 × 40 mm2 substrate textile. The jeans textile material is used as substrate and conducting (patch and ground) part of the antenna is fabricated by copper tape. The copper tape consist a copper foil is self adhesive and the tape has dual conductivity so current will flow through both sides and the adhesive. Jeans material characteristics such as thickness, relative permittivity, loss tangent are experimentally measured with the help of 1 × 1 m2 jeans textile. The partial antenna ground plane of 40 × 20 mm2 plays a most important task of tuning matching circuit in realizing the antenna to function as UWB application. The patch radius is 8 mm which is calculated by Eq. (1) whereas the length and width of line feed is deliberated using basic equations for the patch antenna. The realistic use of textile antennas is most convenient when they are incorporated into clothing. The SMA connector has been directly soldered to the feed line of the textile antenna. The simulation results are accomplished in the CST simulation software. The shape of the proposed antenna is shown in Fig. 1. The height of substrate and conductive sheet is taken 1.0 and 0.03 mm respectively. The ground plane of proposed textile antenna is made of copper adhesive tape with a thickness of 0.03 mm. All fabrication and measurements are performed at the Indian Institute of Technology (IIT) Kanpur Microwave Lab. All design parameters and dimensions of the slots are shown in Table 1.

3 Results and Discussion

3.1 S11 Parameters of the Desired Antenna

Figure 2 shows the simulated reflection coefficient of circular-shaped UWB textile antenna with octagonal slot. Under tolerable S11 of <−10 dB, the simulated antenna design using copper conducting sheet with octagonal-slot structure has achieved, which meet the design specifications of Ultra Wide Band application at the concern frequency range of 3.1–10.6 GHz. Table 2 shows reflection coefficient (S11) and gain at different resonant frequencies after simulation on CST studio. The efficiency is 94 % at resonant frequency 18.30 GHz and the gain is 5.685 dB at 13.20 GHz.

3.2 Simulated Gain and Efficiency

The variation of frequencies versus gain of the wearable textile Ultra Wide Band antenna are demonstrated in Table 2. The maximum gain achieved was about 5.685 dB at 13.2 GHz while the highest percentage of efficiency reached 94 % at 18.3 GHz. However, the lowest efficiency was about 89 % at 4 GHz. Accordingly, results showed that proposed design has low power consumption due to the high gain results that was more than 4 dB in most span of frequencies between 6 and 20 GHz which is shown in Fig. 3. A photograph of the measured gain environment is depicted in Fig. 8 where the antenna is located in an anechoic chamber. Furthermore, Fig. 9 shows the measured gain vs frequency of proposed textile antenna.

3.3 Radiation Pattern of Desired Antenna

In Fig. 4 it is clear that radiation pattern is different at different frequencies. At frequency 4 GHz the gain is about 3.693 dB which is good for medical purpose. At frequency 8.90 GHz gain is about 4.53 dB having the efficiency 92 % which can be used for wearable wireless body area network (WBAN) sensor applications in the military. The omnidirectional pattern is essential for the reason that when we are wearing an antenna it can be in any orientation during sleep or if a patient is wearing it, it might not be directional towards base station as it is impossible for a human to be in single orientation during the day and night, as a result, omnidirectional pattern is chosen. Furthermore, at frequency 13.2 GHz, the gain is about 5.685 dB and efficiency is about 92 % which is quite remarkable and at frequency 18.3 GHz the gain is 5.461 dB with maximum efficiency of 94 %. The total efficiency, radiation efficiency, and gain are shown in Table 3.

4 Antenna Testing

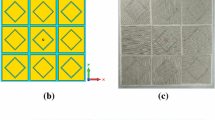

In Fig. 5, Photograph of hardware of proposed textile antenna with SMA connector soldered carefully on the conductive patch. Jeans substrate is taken as substrate as it is formed of 99 % cotton and easily available and the cheapest clothing material. Conductive fabric is copper fabric purchased from the market. It is a fabric of conductive threads which makes it vigorous for use it wherever necessary.

4.1 Antenna Measurement and Measured Results

The proposed Textile Antenna is kept straight with transmission line of vector network analyser due to continuous fluctuations in results on screen due to change in its orientation with slight movement as shown in Fig. 5. To measure the reflection coefficient (S11) results of the fabricated UWB prototype antenna, a network analyser is used. Figure 6 demonstrates a snapshot of the fabricated prototype using jeans fabric. In addition, reflection coefficient (S11) & gain measurement environment of UWB antenna prototype using jeans fabric is illustrated in Figs. 7, 8.

4.2 Analysis of Circular Patch Textile UWB Antenna

Figure 9 shows a comparison of simulated and measured results in terms of reflection coefficient and bandwidth of proposed textile antenna. The slight change between simulated and measured result is due to the flexibility of the textile material, fabrication tolerance, humidity and temperature effect on cotton. However, simulated and measured results show a good correlation. Significant characteristics of designed antenna are given as below Figs. 10, 11 & described in Tables 4, 5.

-

Dual Measured bandwidth = 46 % (3.01–5.30 GHz) and 41 % (8.12–12.35 GHz).

-

Frequency range of the first band is 3.01–5.30 GHz is used for WiMax application.

-

Frequency range of the second band is 8.12–12.35 GHz is used for earth exploration satellite service.

-

At frequency 13.2 GHz the maximum gain is about 5.685 dB.

5 Conclusion

The proposed design consists of jeans substrate while the radiating element and ground plane were made from copper self-adhesive tape. The proposed UWB antenna with partial ground plane is successfully designed, fabricated and measured. The operating frequency of measured results of the existing manuscript designs span from 3.01 to 5.30 GHz is for WiMax application and the second band is 8.12–12.35 GHz for X-band application. The reflection coefficient (|S11|) results indicated that jeans fabric acted as a good candidate for textile wearable applications. The simulated and measured results have a good agreement and showed that the proposed antenna has high gain, high efficiency and constant radiation pattern over its whole range of frequencies. However, the very compact size of the antenna further confirms its appropriateness for portable UWB devices.

References

Balanis, C. A. (2004). Antenna theory: Analysis and design. New York: Wiley.

Hall, P. S., & Hao, Y. (2006). Antennas and propagation for body-centric wireless communications. London: Artech House.

Osman, M. A. R., Rahim, M. K. A., Samsuri, N. A., Salim, H. A. M., & Ali, M. F. (2011). Embroidered fully textile wearable antenna for medical monitoring applications. Progress in Electromagnetics Research, 117, 321–337.

Singh, N., Singh, A. K., & Singh, V. K. (2015). Design and performance of wearable ultra wide band textile antenna for medical application. Microwave and optical technology Letters, 57(7), 1553–1557.

Zhu, S., & Langley, R. (2009). Dual-band wearable textile antenna on an EBG substrate. IEEE Transactions on Antennas and Propagation, 57(4), 926–935.

Jalil, M. E., Rahim, M. K. A., Samsuri, N. A., Murad, N. A., Majid, H. A., Kamardin, K., et al. (2013). Fractal koch multiband textile antenna performance with bending, wet conditions and on the human body. Progress in Electromagnetics Research, 140, 633–652.

Zhang, H. S., Chai, S. L., Xiao, K., & Ye, L. F. (2013). Numerical and experimental analysis of wideband e-shaped patch textile antenna. Progress in Electromagnetics Research C, 45, 163–178.

Ouyang, Y., & Chappell, W. J. (2008). High frequency properties of electro-textiles for wearable antenna applications. IEEE Transactions on Antennas and Propagation, 56(2), 381–389.

Osman, M. A. R., Rahim, M. K. A., Azfar, M., Samsuri, N. A., Zubir, F., & Kamardin, K. (2011). Design, implementation and performance of ultra-wideband textile antenna. Progress in Electromagnetics Research B, 27, 307–325.

Axisa, F., Schmitt, P. M., Gehin, C., Delhomme, G., McAdams, E., & Dittmar, A. (2005). Flexible technologies and smart clothing for citizen medicine, home healthcare, and disease prevention. IEEE Transactions on Information Technology in Biomedicine, 9(3), 325–336.

Osman, M. A. R., Rahim, M. K. A., Samsuri N. A., et al. (2012). Textile UWB antenna bending and wet performances. International Journal of Antennas Propagation 2012, Hindawi Publishing Corporation, Article ID 251682. doi: 10.1155/2012/251682.

Rawat, S., & Sharma, K. K. (2014). A compact broadband microstrip patch antenna with defected ground structure for C-band applications. Central European Journal of Engineering, 4, 287–292.

Mourad, M., & Essaaidi, M. (2014). A dual ultra wide band slotted antenna for C and X-band application. Progress in Electromagnetics Research Letters, 47, 91–96.

Samsuzzaman, M., & Islam, M. T. (2014). Inverted S-shaped compact antenna X-band applications. The Scientific World Journal, 14, 1–11.

Ansari, J. A., Verma, S., Verma, M. K., & Agrawal, N. (2015). A novel wide band microstrip-line-fed antenna with defected ground for CP operation. Progress in Electromagnetics Research C, 58, 169–181.

Osman, M. A. R., Rahim, M. K. A., Samsuri, N. A., Salim, H. A. M., & Ali, M. F. (2013). Embroidered fully textile wearable antenna for medical monitoring applications. In 2013 7th European conference on antennas and propagation (EuCAP), pp. 777–781.

Osman, M. A. R., Rahim, M. K. A., Samsuri, N. A., Elbasheer, M. K., & Ali, M. E. (2012). UWB wearable textile antenna. Jurnal Teknologi (Sciences and Engineering), 58(Suppl 1), 39–44.

Chandran, A. R. & Scanlon, W. G. (2010). Dual-band low probe antennas for body-centric communications. In 2010 International workshop on antenna technology (IWAT), 1–4, Mar, pp. 1–3.

Sankaralingam, S., & Gupta, B. (2012). Experimental results on HiperLAN/2 antennas for wearable applications. Progress in Electromagnetics Research C, 25, 27–40.

Sankaralingam, S., & Gupta, B. (2010). Development of textile antennas for body wearable applications and investigations on their performance under bent conditions. Progress in Electromagnetics Research B, 22, 53–71.

Osman, M. A. R., Rahim, M. K. A., Samsuri, N. A., Salim, H. A. M., & Ali, M. F. (2013) Embroidered fully textile wearable antenna for medical monitoring applications. In: 2013 7th European conference on antennas and propagation (EuCAP), pp. 777–781.

Sankaralingam, S., & Gupta, B. (2010). Determination of dielectric constant of fabric materials and their use as substrates for design and development of antennas for wearable applications. IEEE Transactions on Instrumentation and Measurement, 59(12), 3122–3130.

Loni, J., Singh, V. K., Ayub, S. (2014). Performance analysis of Microstrip Patch Antenna by varying slot size for UMTS application. In Communication systems and network technologies (CSNT-2014) (pp. 01–05). Print ISBN: 978-1-4799-3070-8/14, April-2014, NITTR, Bhopal.

Liu, N., Lu, Y., Qiu, S., & Li, P. (2011). Electromagnetic properties of electro-textile for wearable antennas applications. Frontiers of Electrical and Electronic Engineering in China, 6, 563–566.

Sankaralingam, S., & Gupta, B. (2010). Use of electro-textiles for development of wibro antennas. Progress in Electromagnetics Research C, 16, 183–193.

Lucyszyn, S. (2004). Review of radio frequency micro-electromechanical systems (RF MEMS) technology. IEE Proceedings Science, Measurement and Technology, 151(2), 93–103.

Lucyszyn, S. (Ed.). (2010). Advanced RF MEMS. Cambridge: Cambridge University Press.

Pranonsatit, S., Holmes, A. S., & Lucyszyn, S. (2011). Microwave modelling of radio frequency micro-electromechanical rotary switches. IET Microwaves, Antennas and Propagation, 5(3), 255–261.

Acknowledgments

The authors would like to thank Dr. Kumar Vaibhav Srivastava, Assistant Professor, I.I.T. Kanpur, India for the assistance in the antenna measurements at I.I.T. Kanpur Microwave Lab.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, V.K., Dhupkariya, S. & Bangari, N. Wearable Ultra Wide Dual Band Flexible Textile Antenna for WiMax/WLAN Application. Wireless Pers Commun 95, 1075–1086 (2017). https://doi.org/10.1007/s11277-016-3814-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11277-016-3814-7