Abstract

In this work, the capacity of Trametes polyzona in degrading three textile dyes (amaranth, denim blue, and orange G) to three different concentrations (100, 150, and 200 mg/L) was evaluated. Two growth conditions were tested; in the first condition, the fungus was grown in a defined minimal medium with an initial glucose concentration of 10 g/L and adding the different concentrations of each of the dyes, and in the second condition, the same minimum medium was used but with a concentration of 3 g/L of glucose, after 7 days of fungus growth, at which time the glucose in the medium was completely consumed; each of the dyes was added at the three different concentrations. T. polyzona was able to decolorize the three dyes at the concentrations tested and a 200% increase in the decolorization rate was observed when the medium lacks glucose. Enzymatic activities of laccase, lignin peroxidase, and manganese peroxidase were detected; the enzyme laccase was the one that presented the greatest enzymatic activities in all the media tested. A simultaneous process of adsorption by the mycelium and degradation of extracellular enzymes was observed. A decrease of more than 90% COD was observed and the effluent generated showed no algal growth toxicity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Azo-type dyes are the most commonly used in the textile industry due to their high water solubility; effluents with these types of dyes cause serious environmental problems when they are discarded into water bodies without prior treatment (Garcia-Segura and Brillas 2016). The presence of these molecules in water bodies can affect the photosynthetic processes of aquatic plants and reduction of dissolved oxygen in water and many of them are highly toxic to aquatic flora and to humans (Murcia et al. 2020); another serious problem is that its decomposition under inappropriate conditions usually generates much more toxic compounds than the original dye. The treatment of this type of effluent through conventional treatment plants involves the generation of a large amount of sediments that make their disposal even more difficult (Vikrant et al. 2018); it is common to use anoxic systems for the treatment of solids which entails the generation of dangerous aromatic compounds (Ito et al. 2016). Textile dyes are very stable; a lifetime is estimated that goes from 2 to 13 years (Copaciu et al. 2013; Morajkar et al. 2019) and this persistence in the environment can favor their integration into the food chain generating serious health problems for both humans and animals (Khan and Malik 2018).

It has been described that textile dyes can be potentially carcinogenic (Tsuda et al. 2001; Feng et al. 2017) and cause kidney damage (Clode et al. 1987) in addition to presenting genotoxic and mutagenic effects (Das and Mukherjee 2004; Khan et al. 2020) among others. The great diversity of textile dyes and the presence of additives, ligands, and metals associated with textile effluents make their treatment very complex; it has been described that the molecules present in this type of effluent can be the cause of toxicity, and Valdivia-Rivera et al. (2018) reported that kidney damage may be related to the presence of molecules of aromatic and phenolic origin because in a Mexican population they found that the presence of aromatic compounds in bodies of water was probably responsible for this type of damage. On the other hand, the natural processes of degradation of textile dyes involve anaerobic processes that generated aromatic compounds that are highly toxic (Ito et al. 2016). A great diversity of treatment processes for effluents with dyes have been developed; however, they are not very efficient in terms of degradability and are only based on a decrease in effluent color (Lin and Wu 2018) without determining the presence of toxic compounds derived from the treatments. The decolorization is a process in which the structure of the dye molecule (chromophore group) must be specifically degraded (Paszczynski et al. 1992). In the case of azo-type dyes, it is necessary to break this bond or other types of chemical groups attached to the chromophore groups such as the aromatic groups associated with the azo bonds (Spadaro et al. 1992). Ligninolytic enzymes are specialized in the degradation of lignin, a structurally complex molecule; in addition, its catalytic action is facilitated through highly reactive mediating molecules so they are excellent candidates for the development of biological effluent treatment systems of textile origin also. The reaction conditions of this type of enzymes favor oxidative conditions that are favorable to avoid the formation of toxic compounds. The oxidizing conditions can favor the generation of compounds with low toxicity unlike the anaerobic processes carried out by the bacteria that usually generate highly toxic degradation products such as aromatic amines (Tauber et al. 2005).

An option to avoid the formation of toxic compounds is biological treatments (Belouhova et al. 2014) with bacteria or fungi (Rani et al. 2012; Haddaji et al. 2015) that have been proven to be more efficient in the removal of dyes although they have the concentration limitation because, at high concentrations, the dyes are very toxic for microbial growth.

Basidiomycete white-rot fungi have demonstrated to be very efficient in removing recalcitrant compounds (Revankar and Lele 2007; Asgher et al. 2006, Asgher et al. 2008) mainly due to their extracellular enzymatic battery composed of laccase (Lcc), lignin peroxidase (LiP), and manganese peroxidase (MnP); all of them are oxidative enzymes capable of depolymerizing lignin until its complete mineralization (Tien and Kirk 1983; Kaal et al. 1995). The use of basidiomycete fungi has advantages over bacterial degradation since, unlike the latter, where consortia are required for degradation (Saratale et al. 2011), with the use of fungi, it is possible to use pure cultures, in addition to high redox potential that they generate during their growth that facilitates the oxidation of the molecules generating degradation products with minimal toxicity. Trametes polyzona being a white-rot fungus has the enzymatic battery capable of carrying out decolorization processes of textile effluents; on the other hand, it is known that basidiomycete can produce this type of enzyme constitutively or be induced by some substance in the growth medium. Azo-type dyes can function as inducers of ligninolytic activity and improve decolorization processes, which is why the ability of T. polyzona to degrade two azo-type dyes: amaranth, and orange G and commercial dye denim blue, was studied. On the other hand, the presence of the ligninolytic enzymes that are key molecules to carry out this process was determined.

2 Materials and Methods

2.1 Maintenance and Strain Propagation

The strain used was Trametes polyzona isolated from Huasteca hidalguense, México (Cruz-Ramírez et al. 2012). The strain was propagated each month using sterile Papa Dextrose-PDA Agar plates (DIBICO™) and incubated at 37 °C for 7 days. The strain was kept at 4 °C until use.

2.2 Pre-inoculum Preparation

For decolorization tests in reactor, T. polyzona was grown on PDA plates at 37 °C for 7 days; after this time, the agar was cut into squares of approximately 1 cm2 under aseptic conditions and with the help of a sterile scalpel. The squares were added to 100 mL of sterile water contained in an Erlenmeyer flask; subsequently, the flasks were placed in an orbital shaker at 200 rpm overnight to facilitate the release of the mycelium. The pre-inoculum was standardized to a plate with the fungus grown for 7 days per 100 mL of sterile water. The resulting supernatant was used as inoculum for the decolorization tests.

2.3 Decolorization Tests

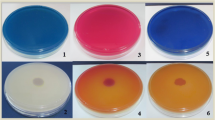

A 3-L reactor (height = 30 cm, diameter = 10 cm) (Applikon™) with pH, dissolved oxygen, and temperature sensors coupled to the system was used with stirring at 150 rpm and without aeration. The minimum defined medium Kirk (Kirk and Farrell 1987) was used as a base; we test two growth conditions where only the initial glucose concentration was varied with 10 g/L and 3 g/L. Each growth condition was supplemented with three different dyes: amaranth (azo dye, CI 16185) (SIGMA™), orange G (azo dye, CI 16230) (SIGMA™), and denim blue (commercial dye) (Caballito™) at three different concentrations (100, 150, and 200 mg/L). For inoculation, the pre-inoculum described in the previous point was used, inoculating with 10% of the total volume of each reactor. The reactors were incubated at 28 °C and at 150 rpm. All tests were performed in triplicate.

2.4 Decolorization Measurement

A total of 2 mL aliquot was taken from the reactor every 24 h; the samples were centrifuged at room temperature at 5000 rpm for 10 min to remove the biomass present and other solids, and a total of 1 mL aliquot was taken and read on a spectrophotometer (Thermo Scientific) at 521 nm for amaranth, 596 nm for denim blue, and 477 nm for orange G. The remaining supernatant was used for the determination of the enzymatic activities of laccase, manganese peroxidase, and lignin peroxidase.

2.5 Adsorption Tests of Dye

To determine the adsorption capacity of each of the dyes by the biomass of T. polyzona, adsorption tests were carried out which consisted of growing T. polyzona in Kirk medium (Kirk and Farrell 1987) for 7 days at 37 °C and 150 rpm; subsequently, the biomass was filtered with the help of Whatman paper (No. 1) and washed with 250 mL of sterile water. The biomass was inactivated through sterilization at 15 lb. pressure and 121 °C for 15 min according to the protocol described by Wang and Yu (1998). The inactive biomass was placed in Erlenmeyer flasks containing 200 mL of a sterile water solution with 200 mg/L of each of the dyes; 1 mL of sample was taken every 12 h and the absorbance was read at the corresponding wavelength of each dye until absorbance remained unchanged. At the end of the process, the amount of adsorbed dye was calculated using the calibration curves of each of the dyes.

2.6 Analytical Determinations

2.6.1 Calibration Curves

Calibration curves were constructed for the quantification of the concentration of the dyes necessary for monitoring the discoloration and adsorption tests. Stock solutions of each dye were prepared at a concentration of 500 mg/L; decimal dilutions were made and each dilution was read at 521, 596, and 477 nm for the amaranth, denim blue, and orange G dyes, respectively. The data were plotted and the corresponding equation was obtained that was used to quantify the concentration of each dye based on its absorbance.

2.6.2 Laccase (Lcc) Enzymatic Activity Quantification

To quantify the enzymatic Lcc activity, the method described by Bourbonnais et al. (1997) was used. A 5 mM ABTS solution in acetate buffer (10 mM, pH 6) was used. The reaction volume was 1 mL (500 μL of ABTS + 500 μL of crude extract). Enzymatic activity was determined from 2-min kinetics at an absorbance of 420 nm.

2.6.3 Lignin Peroxidase (LiP) Enzymatic Activity Quantification

For the quantification of the enzymatic LiP activity, the method described by Maganhotto de Souza Silva et al. (2005) was used. The formation of veratraldehyde produced by the oxidation of veratrilic alcohol read at 310 nm was quantified. The reaction mixture was 373 μL of sodium tartrate buffer (0.33 M, pH 3), 125 μL of veratryl alcohol (4 mM), 50 μL of H2O2 (10 mM), 450 μL of H2O, and 250 μL of crude extract.

2.6.4 Manganese Peroxidase (MnP) Enzymatic Activity Quantification

The method described by Kuwahara et al. (1984) quantifying the oxidation of phenol red at 610 nm was used. The reaction mixture was 500 μL of crude extract, 100 μL of phenol red solution (0.01%), 100 μL of sodium lactate (250 mM), 200 μL of bovine serum albumin (0.5%), 50 μL of sulfate of magnesium, and 50 μL of H2O2.

2.6.5 Chemical Oxygen Demand Determination

For the quantification of chemical oxygen demand (COD), a chemical kit (HACH™) was used reading on a spectrophotometer (HANNA™) for a high COD value.

2.6.6 Glucose Quantification

The glucose concentration was determined using a GOD-POD enzyme kit (SPINREACT™) that is based on the quantification of a chromophore from the hydrogen peroxide generated from the oxidation of glucose by the glucose-oxidase enzyme.

2.6.7 Evaluation of the Cytotoxicity of Effluents

The method described by Sáenz et al. (2003) uses Nannochloropsis salina as a model algae, lighting of 3000 lx/cm2, 200 rpm, and complementing the effluent with 4 g/L of NaCl and 0.3 g/L of Byfolan™ to cover the nutritional requirements of the algae. Algae growth was measured every 24 h for 5 days at 560 nm.

2.7 Experimental Design

To estimate the effect of the level of aeration on the discoloration of the azo dyes used, a factorial design 33 was applied, with three factors (amaranth, denim blue, and orange G) and three levels per factor (100, 150, and 200 mg/L) keeping the inoculum size and reactor temperature (28 °C) constant.

2.8 Statistical Analysis

For the data analysis, SPSS software (version 20.0) was used using a comparison between means (Tukey and Duncan), analysis of variance of a factor (ANOVA), and a significance level of 0.05.

3 Results

3.1 Dye Decolorization

The results of the decolorization tests of the three dyes at three different concentrations are presented in Fig. 1. The highest decolorization was observed with the amaranth dye since, on day 3 of the kinetics, 60, 63.3, and 67.5% discoloration was detected for concentrations of 100, 150, and 200 mg/L, respectively; however, to reach 100% decolorization, 21 and 24 days for the concentrations of 100 and 150 mg/L and 27 days for the concentration of 200 mg/L (Fig. 1a) were necessary. For the commercial denim blue dye (Fig. 1b), the decolorization process is more gradual; it was observed that after day 23 the observed discoloration was 97% for the three concentrations tested to reach 100% on day 27. With the orange G dye, decolorization was faster: 98% decolorization was observed on day 16 for concentration of 150 and 100 mg/L, while on day 20, a similar result was observed for the concentration of 200 mg/L (Fig. 1c).

The efficiency of the decolorization process was higher in the amaranth dye, with 100% decolorization observed on days 21, 24, and 27 for the concentrations of 100, 150, and 200 mg/L, respectively (Table 1). It was observed that, in the case of the orange G dye, the decolorization time was 17 days on average regardless of the dye concentration tested. The lowest decolorization rate was for the commercial denim blue dye reaching 93.5% decolorization at a concentration of 200 mg/L and 27 days of incubation, probably due to the additives present in the dye.

Ligninolytic enzymes involved in the decolorization process were Lcc, LiP, and MnP, which are key enzymes to which the decolorization capacity of basidiomycete fungi is attributed. The results are presented in Table 2. The predominant enzyme was laccase since it was the highest enzymatic activity detected except for the medium with denim blue at 200 mg/L and orange G where the highest activity was LiP.

3.2 Dye Decolorization Under Glucose Limitation Conditions

As a next step, the behavior of T. polyzona was studied using each of the dyes tested as the only carbon source; for this, the fungus was grown using the saline medium as a base described by Tien and Kirk (1988) but with 3 g/L of glucose, and once the glucose was consumed (7 days), each of the dyes was added to the different concentrations and the Lcc activity was measured, which was the predominant enzyme in the previous stage. The results obtained (Table 3) indicate a decrease in the decolorization time. A 200% decrease in decolorization time was observed for all dyes. It is likely that the previous growth of the fungus generates an accumulation of ligninolytic enzymes and that, thanks to the action of these enzymes, it is expected that the degradation products of the dyes are used by Lcc as mediators to make the process even more efficient of degradation. A continuous decrease in the coloration of the medium associated with the growth of the fungus was observed, which may suggest mineralization of the dyes so that they can be used as the only carbon source by T. polyzona (Fig. 2).

The Lcc activity detected was different in each condition, observing a tendency to increase depending on the concentration of dye (with the exception of the denim blue dye); it is possible that the complexity of the dye molecule and its concentration has an impact at the metabolic level since it has been described that, the more complex the carbon source, the greater the production of the Lcc enzyme (Mikiashvili et al. 2006) (Table 3).

3.3 Dye Adsorption by T. polyzona Mycelium

In order to estimate whether the decolorization of the dyes tested was due to the action of extracellular enzymes or mycelium-associated enzymes, dye adsorption studies were carried out. During decolorization process of T. polyzona, two simultaneous phenomena were observed: the degradation of the dye in the extracellular medium and the adsorption of the same by the biomass of the fungus. This phenomenon was most evident with the denim blue commercial dye that coincided with a faster rate of decolorization. It has been described that adsorption is one of the main mechanisms that basidiomycete fungi use to carry out the degradation of dyes or pigments and the adsorbed dye is subsequently degraded by enzymes associated at mycelium (Selvam et al. 2003). Adsorption isotherms can be used to determine the maximum amount of dye adsorbed by the fungus and estimate the percentage of dye that is decolorized by the action of extracellular enzymes. It was observed that the biomass of T. polyzona adsorbs 11.9, 15.96, and 55.23% of the amaranth, orange G, and denim blue dyes, respectively; with this result, it can be deduced that the T. polyzona extracellular enzymes decolorize the amaranth dye more efficiently (88.1%) and are less efficient in decolorizing denim blue commercial dye (44.77%). The presence of the mycelium during the degradation of the dyes in addition to accelerating the degradation of the molecule can also favor the elimination of toxic compounds because these enzymes participate in the complete mineralization of this type of molecules.

3.4 Evaluation of COD and Toxicity of Generated Effluent

COD was monitored throughout the dye degradation process, and a significant decrease was observed in all cases. Table 4 shows the results obtained for the highest concentration of dye tested (200 mg/L). The greatest decrease was observed for the amaranth dye with a decrease of 96.46% followed by orange G with a 92.71% and denim blue with a 91.89% decrease.

All the toxicity tests carried out with the alga were negative. In all treatments with the dyes and at different concentrations, the algae were able to grow without showing inhibition problems; no significant differences were observed in the growth of the algae. This suggests that the action of extracellular enzymes plus the presence of mycelium prevent the generation of toxic compounds for both the fungus and, in this case, the alga that was used as a monitor for toxicity.

4 Discussion

4.1 Decolorization Process

The results obtained indicated that T. polyzona has the ability to decolorize the three dyes tested. The efficiency in the decolorization depends on different factors being one of the main ones the complexity of the chemical structure of the dye (Knapp et al. 1995) which defines the rates of decolorization of the fungus; the results obtained indicate that T. polyzona has a high efficiency in the decolorization of textile dyes since in all cases the fungus was able to achieve decolorization greater than 90%.

Decolorization processes with different genera of Trametes have been described. Legerská et al. (2018a, 2018b) found that Trametes versicolor was able to decolorize up to 72.8% of orange 2 dye and 45.3% of orange 6 acid dye in concentrations of 0.04 to 5 g/L. On the other hand, Rodríguez-Couto et al. (2006) observed that the fungus Trametes hirsuta was able to decolorized various dyes, among them is methyl orange in solid growth conditions with a percentage of 81%. On the other hand, Ortiz-Monsalve et al. (2019) observed that Trametes villosa was able to decolorize the acidic orange 142 dye reaching a decolorization of 93.8% at 246 h of incubation and under reduced nitrogen conditions. Hai et al. (2013) reported the degradation of orange 7 with Coriolus versicolor pellets reaching a decolorization of up to 95% in a membrane reactor in 1 day. Marcharchand and Ting (2017) reported that Trametes asperellum was able to decolorize dye solutions, one of them being violet blue. Mechichi et al. (2006) observed the decolorization of bright remazol blue by Trametes trogii up to 97% at a concentration of 100 mg/L. Rodríguez-Couto (2014) reported the discolorization of the industrial dyes Bemaplex navy and Bezaktiv blue by Trametes pubescens under conditions of immobilization and in conditions of growth in successive batch, while Osma et al. (2007) found that T. pubescens was able to decolorize bright blue remazol and methyl green. Rodríguez-Couto et al. (2006) reported that T. pubescens was able to decolorize bright remazol blue solutions reaching decolorization percentages of up to 80% in 96 h. Enayatzamir et al. (2009) observed the discoloration of bright remazol blue reaching a 95% decolorization.

In the case of amaranth, 100% decolorization was observed in the three concentrations tested, improving what was observed by Revankar and Lele (2007) and Ramsay et al. (2006). They observed 96 and 95% decolorization with Ganoderma and T. versicolor, respectively. In the case of orange G, we observed a decolorization of 99% for the concentrations of 100 and 200 mg/L, while for the concentration of 150 mg/L, it was 98.6%; very similar results described by Selvam et al. (2003), Eichlerová et al. (2006), and Casas et al. (2007) report decolorization of 98.8, 91, and 97% with Thelephora sp. and Dichomitus squalens, respectively. Novotný et al. (2001) described a possible inhibitory effect of dyes in solution on fungi such as Irpex lacteus and Pleurotus ostreatus situation that was not observed in T. polyzona since the fungus grew similarly in all the tests performed. When comparing the decolorization with those reported by other authors, the efficiency of T. polyzona in this type of processes is evident (Table 1).

4.2 Ligninolytic Enzymes Participating in the Decolorization Process

It has been described that in the decolorization of textile dye the enzymes responsible for the degradation of lignin are involved; in T. versicolor, the decolorization has been attributed to the enzymes Lcc, LiP, and MnP (Gavril et al. 2007). The action of the laccase of different Trametes genera has been reported during the discoloration of dyes similar to those studied in this work, such as orange 2 and acid orange 6 by T. versicolor (Legerska et al. 2018b), methyl orange by T. hirsuta (Rodríguez-Couto et al. 2006), and acid orange 142 by T. villosa (Ortiz-Monsalve et al. 2019). Regarding blue dyes, Mechichi et al. (2006) studied the decolorization of bright remazol blue and determined that the enzyme responsible was the laccase of T. trogii. Similar results were found by Rodríguez-Couto (2014) by attributing the discoloration of Bezaktiv blue to the laccase of T. pubescens. Similarly, the T. pubescens laccase was also primarily responsible for the decolorization of bright blue of remazol (Rodríguez-Couto et al. 2006; Osma et al. 2007; Enayatzamir et al. 2009).

The expression of ligninolytic enzymes such as LiP and MnP in T. polyzona can be regulated by the carbon source or under conditions of nitrogen limitation since it has been observed that Phanerochaete chrysosporium begins to produce this type of enzymes when the nitrogen begins to be limited and in addition, it has been proven that the presence of this type of enzymes is fundamental for the processes of decolorization in addition to the occurrence of adsorption phenomena whose purpose is to improve the process (Spadaro et al. 1992). Eichlerová et al. (2005) carried out the decolorization of orange G using three basidiomycete fungal strains using as a base the Kirk medium supplemented with 500 mg/L dye; the authors observed a 95% decolorization with the Ischnoderma resinosum fungus in nitrogen-rich Kirk medium at 14 days of incubation, Lcc being the predominant enzyme. In the case of D. squalens, a 95% decolorization was observed at 14 days but MnP was the predominant enzyme in nitrogen-limited Kirk medium. It has been described that this enzyme has a very important role in decolorization processes of anthraquinone and azo-type dyes (Dias et al. 2003) and specifically in D. squalens, the expression of this enzyme is favored in limited nitrogen media. It has also been observed that the presence of oxygen can favor highly oxidative conditions such as aeration, which improves the processes of decolorization probably due to a higher production of LiP and MnP (Johansson and Nyman 1987). On the other hand, it has been found that LiP is responsible for a large number of decolorization processes but the difficulty in detecting it represents a problem (Eichlerová et al. 2005). It is a fact that the expression of ligninolytic enzymes such as LiP and MnP in T. polyzona can be regulated by the carbon source or under conditions of nitrogen limitation since it has been observed that, in other basidiomycete fungi such as Phanerochaete chrysosporium, this type of enzymes is produced when the N begins to be limited and in addition, it has been proven that the presence of this type of enzymes is fundamental for the decolorization processes. It has also been observed that highly oxidative conditions such as aeration favor a high redox potential by improving the catalytic capacities of ligninolytic enzymes (Johansson and Nyman 1987) facilitating the oxidation of compounds of phenolic origin and azo bonds (Bibi et al. 2011); also, the catalytic mechanism of these enzymes is based on the generation of highly reactive molecules which can directly attack the azo bond and thus favor the process of decolorization.

The use of ligninolytic enzymes to carry out discoloration processes of dyes of textile origin is viable. The scale-up of the process can present several problems. One of them is the biomass that is generated during the process; this biomass is capable of adhering to the propellants or air sprinklers, impacting on the power necessary to agitate and mix the medium, which would present oxygen transfer problems. It is important to note that the presence of mycelium accelerates the discoloration and degradation of the dye, so scale-up would be a factor to consider. High levels of agitation in a bioreactor cause the pellets to develop associated mycelium around them (Brand and Gow 2009), which can favor the adsorption of the dyes as there is more surface area, but an excess in the mixture can cause the breakage of the mycelium and stress on the microorganism. Regarding pH, basidiomycete fungi have been described as being able to control the pH of their growth medium (Vieira et al. 2008). There are several factors to take into account so further studies are needed to find the best conditions for scale-up.

4.3 Effect of Carbon Source Concentration on Decolorization

It has been observed that the presence or absence of glucose and nitrogen in the growth medium of basidiomycete fungi can favor the degradation of compounds of phenolic origin or other toxic compounds. Rodríguez-Couto (2014) observed an increase in the decolorization of the Bezaktiv blue and Bemaplex navy dyes by T. pubescens when the glucose in the medium reached residual concentrations. However, Shin et al. (2002) reported that, for the decolorization of textile dyes using T. versicolor, it was better to use glucose-supplemented media as a carbon source. It has been described that low glucose concentrations in the production medium can stimulate the overall production of lignocellulolytic enzymes (Schneider et al. 2018) and that the combination of simple sugars such as glucose with complex nitrogen sources can intervene in the regulation of lignocellulolytic metabolism (Kandasamy et al. 2016). With regard to the nitrogen source as well as for the carbon source, the reports can be contradictory; it has been described that nitrogen-deficient media can significantly improve the decolorization process (Swamy and Ramsay 1999). On the other hand, it has been reported that the presence of biomass can accelerate the degradation of textile dyes due to a bioadsorption process because of the presence of mycelium-associated enzymes that improve degradation (Osma et al. 2007; Hai et al. 2013; Rodríguez-Couto 2014; Marcharchand and Ting 2017). However, it has also been observed that the decolorization may be due more to the action of extracellular enzymes, such as Lcc, than to adsorption processes (Osma et al. 2010). The rate of decolorization was estimated as well as the decolorization efficiency in each of the tests performed. In the case of amaranth dye, 100% decolorization was observed with a maximum decolorization speed of 19,335 mg/L day for a concentration of 200 mg/L. In the case of the commercial denim blue dye, the maximum decolorization rate was 20,888 mg/L day for the concentration of 200 mg/L. Finally, for the orange G dye, the maximum decolorization rate was 11,498 mg/L day for the concentration of 200 mg/L (Table 5). The results obtained suggest that decolorization is favored when there is no glucose in the medium which stimulates the fungus to use the dye as a possible source of carbon and nitrogen.

4.4 Dye Bioadsorption and COD

Adsorption is a mechanism that helps the fungus in the degradation of the dye; the presence of biomass is of the crucial importance to improve the decolorization due to the possible presence of degrading enzymes associated with mycelium or other factors (Spadaro et al. 1992; Swamy and Ramsay 1999). It is known that during the degradation of azo dyes toxic compounds (mainly amines) can be generated that depend on the type of enzymes involved in their degradation (Polak et al. 2016); ligninolytic enzymes such as laccase have the ability to break azo bonds symmetrically or non-symmetrically, which provides a great advantage over bacterial enzymes because degradation compounds with low toxicity are generated (Telke et al. 2009); in addition, the same degradation products enhance the enzymatic activity of these enzymes accelerating the degradation and metabolization of the dyes present in an effluent. The presence of mycelium in dye degradation processes can have an impact on biosorption of the dye that provides greater tolerance to the compound and the action of other enzymes such as cytochrome P450 that improves degradation (Nguyen et al. 2014). Therefore, the presence of mycelium, in addition to considerably improving the degradation rate, also prevents the formation of toxic compounds by improving effluent treatment systems of textile origin.

An advantage of using degradation systems with basidiomycete fungi is the efficient reduction of COD. Ortiz-Monsalve et al. (2019) reported an 80% decrease in COD using a strain of T. villosa and solutions of Acid Red 357 and Acid Orange 142 in nitrogen-rich media. Navada et al. (2018) observed up to 80% in the COD reduction of effluents containing bright blue remazol with Phomopsis sp. On the other hand, Sathian et al. (2014) reported COD drops of up to 80% using different fungi and textile effluents. The results obtained show a clear efficiency of T. polyzona exceeding that reported by other authors, making it an excellent candidate for the generation of textile effluent treatment systems. Finally, the toxicity of the effluent resulting from the treatment of the fungus was evaluated; the growth of the Nannochloropsis algae was determined during 5 days, and no decrease in growth was observed with respect to the target. In the effluent with denim blue, a slight increase in algae growth was observed probably due to other metabolic products generated by the fungus during its growth. The decrease in the toxicity of effluents of textile origin using basidiomycete fungi of the Trametes genus has been described as in the case of T. villosa with a 50–70% toxicity decrease percentage (Ortiz-Monsalve et al. 2019), T. pubescens (Gaitan et al. 2011; Si et al. 2013), T. trogii (Yan et al. 2014), and T. versicolor (Romero et al. 2006). Reports indicate that the Trametes genus efficiently degrades textile dyes, thanks to its complex enzymatic battery which makes them very attractive for use either using biomass or enzymatic extracts, in effluent degradation systems.

5 Conclusions

The fungus Trametes polyzona was able to decolorized the dyes amaranth, denim blue, and orange G at the three concentrations tested; although the presence of the Lcc, LiP, and MnP was detected, the enzyme that was detected in greater quantity was the Lcc which is the key enzyme responsible for the highest percentage of decolorization. The decolorization rate increased by almost two-thirds of the time when the dye was added after 7 days of fungus growth, making this process more efficient. A bioadsorption process of the dye by the free biomass of the fungus could be appreciated, indicating that T. polyzona is capable of simultaneously carrying out a bioadsorption and extracellular degradation process. The presence of mycelium improves the degradation of the dyes in addition to generating effluents with minimal toxicity, so T. polyzona is an excellent candidate for the treatment of textile effluents.

References

Asgher, M., Shah, S. A. H., Ali, M., & Legge, R. L. (2006). Decolorization of some reactive textile dyes by white rot fungi isolated in Pakistan. World Journal of Microbiology and Biotechnology, 22(1), 89–93. https://doi.org/10.1007/s11274-005-5743-6

Asgher, M., Bhatti, H. N., Ashraf, M., & Legge, R. L. (2008). Recent developments in bioremediation of industrial pollutants by white rot fungi and their enzyme system. Biodegradation, 19(6), 771. https://doi.org/10.1007/s10532-008-9185-3.

Belouhova, M., Schneider, I., Chakarov, S., Ivanova, I., & Topalova, Y. (2014). Microbial community development of biofilm in amaranth decolourization technology analysed by FISH. Biotechnology and Biotechnological Equipment, 28, 635–642. https://doi.org/10.1080/13102818.2014.947725.

Bibi, I., Bhatti, H. N., & Asgher, M. (2011). Comparative study of natural and synthetic phenolic compounds as efficient laccase mediators for the transformation of cationic dye. Biochemical Engineering Journal, 56(3), 225–231. https://doi.org/10.1016/j.bej.2011.07.002.

Bourbonnais, R., Paice, M. G., Freiermuth, B., Bodie, E., & Borneman, S. (1997). Reactivities of various mediators and laccases with Kraft pulp and lignin model compounds. Applied and Environmental Microbiology, 63(12), 4627–4632.

Brand, A., & Gow, N. A. (2009). Mechanisms of hypha orientation of fungi. Current Opinion in Microbiology, 12(4), 350–357. https://doi.org/10.1016/j.mib.2009.05.007.

Casas, N., Blánquez, P., Gabarrell, X., Vicent, T., Caminal, G., & Sarrá, M. (2007). Degradation of orange G by laccase: Fungal versus enzymatic process. Environmental Technology, 28(10), 1103–1110. https://doi.org/10.1080/09593332808618874.

Clode, S. A., Hooson, J., Grant, D., & Butler, W. H. (1987). Long-term toxicity study of amaranth in rats using animals exposed in utero. Food and Chemical Toxicology, 25(12), 937–946. https://doi.org/10.1016/0278-6915(87)90287-0.

Copaciu, F., Opriş, O., Coman, V., Ristoiu, D., Niinemets, U., & Copolovici, L. (2013). Diffuse water pollution by anthraquinone and azo dyes in environment importantly alters foliage volatiles, carotenoids and physiology in wheat (Triticum aestivum). Water, Air, and Soil Pollution, 224(3), 1478. https://doi.org/10.1016/j.jenvman.2018.11.094.

Cruz-Ramírez, M. G., Rivera-Ríos, J. M., Téllez-Jurado, A., Maqueda-Gálvez, A. P., Mercado-Flores, Y., & Arana-Cuenca, A. (2012). Screening of thermotolerant ligninolytic fungi with laccase, lipase, and protease activity isolated in Mexico. Journal of Environmental Management, 95, S256–S259. https://doi.org/10.1016/j.jenvman.2010.10.045.

Das, A., & Mukherjee, A. (2004). Genotoxicity testing of the food colours amaranth and tartrazine. International Journal of Human Genetics, 4(4), 277e80. https://doi.org/10.1080/09723757.2004.11885906.

Dias, A. A., Bezerra, R. M., Lemos, P. M., & Pereira, A. N. (2003). In vivo and laccase-catalysed decolourization of xenobiotic azo dyes by a basidiomycetous fungus: Characterization of its ligninolytic system. World Journal of Microbiology and Biotechnology, 19(9), 969–975. https://doi.org/10.1023/B:WIBI.0000007331.94390.5c.

Eichlerová, I., Homolka, L., Lisá, L., & Nerud, F. (2005). Orange G and remazol brilliant blue R decolorization by white rot fungi Dichomitus squalens, Ischnoderma resinosum and Pleurotus calyptratus. Chemosphere, 60(3), 398–404. https://doi.org/10.1016/j.chemosphere.2004.12.036.

Eichlerová, I., Homolka, L., & Nerud, F. (2006). Synthetic dye decolorization capacity of white rot fungus Dichomitus squalens. Bioresource Technology, 97(16), 2153–2159. https://doi.org/10.1016/j.biortech.2005.09.014.

Enayatzamir, K., Tabandeh, F., Yakhchali, B., Alikhani, H. A., & Couto, S. R. (2009). Assessment of the joint effect of laccase and cellobiose dehydrogenase on the decolouration of different synthetic dyes. Journal of Hazardous Materials, 169(1–3), 176–181. https://doi.org/10.1016/j.jhazmat.2009.03.088.

Feng, Y. P., Gaztelumendi, N., Fornell, J., Zhang, H. Y., Solsona, P., Baró, M. D., & Nogués, C. (2017). Mechanical properties, corrosion performance and cell viability studies on newly developed porous Fe-Mn-Si-Pd alloys. Journal of Alloys and Compounds, 724, 1046–1056. https://doi.org/10.1016/j.jallcom.2017.07.112.

Gaitan, I. J., Medina, S. C., González, J. C., Rodríguez, A., Espejo, A. J., Osma, J. F., & Sánchez, O. F. (2011). Evaluation of toxicity and degradation of a chlorophenol mixture by the laccase produced by Trametes pubescens. Bioresource Technology, 102(3), 3632–3635. https://doi.org/10.1016/j.biortech.2010.11.040.

Garcia-Segura, S., & Brillas, E. (2016). Combustion of textile monoazo, diazo and triazo dyes by solar photoelectro-Fenton: Decolorization, kinetics and degradation routes. Applied Catalysis B: Environmental, 181, 681–691. https://doi.org/10.1016/j.apcatb.2015.08.042.

Gavril, M., Hodson, P. V., & Mclellan, J. (2007). Decoloration of amaranth by the white-rot fungus Trametes versicolor. Part I statistical analysis. Canadian Journal of Microbiology, 53, 313–326. https://doi.org/10.1139/w06-123.

Haddaji, D., Bousselmi, L., Saadani, O., Nouairi, I., & Ghrabi-Gammar, Z. (2015). Enzymatic degradation of azo dyes using three macrophyte species: Arundo donax, Typha angustifolia and Phragmites australis. Desalination and Water Treatment, 53, 1129–1138. https://doi.org/10.1080/19443994.2014.884475.

Hai, F. I., Yamamoto, K., Nakajima, F., Fukushi, K., Nghiem, L. D., Price, W. E., & Jin, B. (2013). Degradation of azo dye acid orange 7 in a membrane bioreactor by pellets and attached growth of Coriolus versicolour. Bioresource Technology, 141, 29–34. https://doi.org/10.1016/j.biortech.2013.02.020.

Ito, T., Adachi, Y., Yamanashi, Y., & Shimada, Y. (2016). Long–term natural remediation process in textile dye–polluted river sediment driven by bacterial community changes. Water Research, 100, 458–465. https://doi.org/10.1016/j.watres.2016.05.050.

Johansson, T., & Nyman, P. O. (1987). A llananese ll-depende extracellular peroxidase from the white-rot fungus Trametes versicolor. Acta Chemica Scandinavica, 41, 762–765.

Kaal, E. E. J., Field, J. E., & Joyce, T. W. (1995). Increasing ligninolytic enzyme activation in several white rot basidiomycetes by nitrogen sufficient media. Bioresource Technology, 53, 133–139. https://doi.org/10.1016/0960-8524(95)00066-N.

Kandasamy, S., Muniraj, I. K., Purushothaman, N., Sekar, A., Sharmila, D. J. S., Kumarasamy, R., & Uthandi, S. (2016). High level secretion of laccase (LccH) from a newly isolated white-rot basidiomycete, Hexagonia hirta MSF2. Frontiers in Microbiology, 7, 707. https://doi.org/10.3389/fmicb.2016.00707.

Khan, S., & Malik, A. (2018). Toxicity evaluation of textile effluents and role of native soil bacterium in biodegradation of a textile dye. Environmental Science and Pollution Research, 25(5), 4446–4458. https://doi.org/10.1007/s11356-017-0783-7.

Khan, I. S., Ali, M. N., Hamid, R., & Ganie, S. A. (2020). Genotoxic effect of two commonly used food dyes metanil yellow and carmoisine using Allium cepa L. as indicator. Toxicology Reports, 7, 370–375. https://doi.org/10.1016/j.toxrep.2020.02.009.

Kirk, T. K., & Farrell, R. L. (1987). Enzymatic combustion: The microbial degradation of lignin. Annual Review of Microbiology, 41(1), 465–501.

Knapp, J. S., Newby, P. S., & Reece, L. P. (1995). Decolourization of dyes by wood rotting basidiomycetes fungi. Enzyme and Microbial Technology, 17, 664–668. https://doi.org/10.1016/0141-0229(94)00112-5.

Kuwahara, M., Glenn, J. K., Morgan, M. A., & Gold, M. H. (1984). Separation and characterization of two extracellular H2O2-dependent oxidases from ligninolytic cultures of Phanerochaete chrysosporium. FEBS Letters, 169, 247–250. https://doi.org/10.1023/A:1008371209913.

Legerská, B., Chmelová, D., & Ondrejovič, M. (2018a). Azonaphthalene dyes decolorization and detoxification by laccase from Trametes versicolor. Nova Biotechnologica et Chimica, 17(2), 172–180. https://doi.org/10.2478/nbec-2018-0018.

Legerská, B., Chmelová, D., & Ondrejovič, M. (2018b). Decolourization and detoxification of monoazo dyes by laccase from the white-rot fungus Trametes versicolor. Journal of Biotechnology, 285, 84–90. https://doi.org/10.1016/j.jbiotec.2018.08.011.

Lin, K. Y. A., & Wu, C. H. (2018). Efficient adsorptive removal of toxic amaranth dye from water using a zeolitic imidazolate framework. Water Environment Research, 90(11), 1947–1955. https://doi.org/10.2175/106143017X14902968254692.

Maganhotto de Souza Silva, C. M., Soares de Melo, I., & de Oliveira, P. R. (2005). Ligninolytic enzyme production by Ganoderma spp. Enzyme and Microbial Technology, 37(3), 324–329.

Marcharchand, S., & Ting, A. S. Y. (2017). Trichoderma asperellum cultured in reduced concentrations of synthetic medium retained dye decolourization efficacy. Journal of Environmental Management, 203, 542–549. https://doi.org/10.1016/j.jenvman.2017.06.068.

Mechichi, T., Mhiri, N., & Sayadi, S. (2006). Remazol brilliant blue R decolourization by the laccase from Trametes trogii. Chemosphere, 64(6), 998–1005. https://doi.org/10.1016/j.chemosphere.2005.12.061.

Mikiashvili, N., Wasser, S. P., Nevo, E., & Elisashvili, V. (2006). Effects of carbon and nitrogen sources on Pleurotus ostreatus ligninolytic enzyme activity. World Journal of Microbiology and Biotechnology, 22(9), 999–1002. https://doi.org/10.1007/s11274-006-9132-6.

Morajkar, P. P., Naik, A. P., Bugde, S. T., & Naik, B. R. (2019). Photocatalytic and microbial degradation of amaranth dye. Advances in Biological Science Research, 327–345. https://doi.org/10.1016/B978-0-12-817497-5.00020-3.

Murcia, M. D., Gómez, M., Gómez, E., Gómez, J. L., Hidalgo, A. M., Murcia, S., & Campos, D. (2020). Comparison of two excilamps and two reactor configurations in the UV-H2O2 removal process of amaranth. Journal of Water Process Engineering, 33, 101051. https://doi.org/10.1016/j.jwpe.2019.101051.

Navada, K. K., Sanjeev, G., & Kulal, A. (2018). Enhanced biodegradation and kinetics of anthraquinone dye by laccase from an electron beam irradiated endophytic fungus. International Biodeterioration and Biodegradation, 132, 241–250. https://doi.org/10.1016/j.ibiod.2018.04.012.

Nguyen, L. N., Hai, F. I., Yang, S., Kang, J., Leusch, F. D., Roddick, F., & Nghiem, L. D. (2014). Removal of pharmaceuticals, steroid hormones, phytoestrogens, UV-filters, industrial chemicals and pesticides by Trametes versicolor: Role of biosorption and biodegradation. International Biodeterioration and Biodegradation, 88, 169–175. https://doi.org/10.1016/j.ibiod.2013.12.017.

Novotný, C., Rawal, B., Bhatt, M., Patel, M., Šašek, V., & Molitoris, H. P. (2001). Capacity of Irpex lacteus and Pleurotus ostreatus for decolorization of chemically different dyes. Journal of Biotechnology, 89(2–3), 113–122. https://doi.org/10.1016/S0168-1656(01)00321-2.

Ortiz-Monsalve, Valente, S. P., Poll, E., Jaramillo-García, V., Henriques, J. E. P., & Gutterres, M. (2019). Biodecolourization and biodetoxification of dye-containing wastewaters from leather dyeing by the native fungal strain Trametes villosa SCS-10. Biochemical Engineering Journal, 141, 19–28. https://doi.org/10.1016/j.bej.2018.10.002.

Osma, J. F., Herrera, J. L. T., & Couto, S. R. (2007). Banana skin: A novel waste for laccase production by Trametes pubescens under solid-state conditions. Application to synthetic dye decolouration. Dyes and Pigments, 75(1), 32–37. https://doi.org/10.1016/j.dyepig.2006.05.021.

Osma, J. F., Toca-Herrera, J. L., & Rodríguez-Couto, S. (2010). Biodegradation of a simulated textile effluent by immobilised-coated laccase in laboratory-scale reactors. Applied Catalysis A: General, 373(1–2), 147–153. https://doi.org/10.1016/j.bej.2018.10.002.

Paszczynski, A., Pasti-Grigsby, M. B., Goszczynski, S., Crawford, R. L., & Crawford, D. L. (1992). Mineralization of sulfonated azo dyes and sulfanilic acid by Phanerochaete chrysosporium and Streptomyces chromofuscus. Applied and Environmental Microbiology, 58(11), 3598–3604.

Polak, J., Wilkolazka, A. J., Szuster-Ciesielska, A., Wlizlo, K., Kopycinska, M., Sojka-Ledakowicz, J., & Lichawska-Olczyk, J. (2016). Toxicity and dyeing properties of dyes obtained through laccase-mediated synthesis. Journal of Cleaner Production, 112, 4265–4272. https://doi.org/10.1016/j.jclepro.2015.07.044.

Ramsay, J., Shin, M., Wong, S., & Goode, C. (2006). Amaranth decoloration by Trametes versicolor in a rotating biological contacting reactor. Journal of Industrial Microbiology and Biotechnology, 33(9), 791. https://doi.org/10.1007/s10295-006-0117-.

Rani, C., Jana, A. K., & Bansal, A. (2012). Potential of different white rot fungi to decolourize textile azo dyes in the absence of external carbon source. Environmental Technology, 33, 887–896. https://doi.org/10.1080/09593330.2011.602431.

Revankar, M. S., & Lele, S. S. (2007). Synthetic dye decolorization by white rot fungus, Ganoderma sp. WR-1. Bioresource Technology, 98, 775–780. https://doi.org/10.1016/j.biortech.2006.03.020.

Rodríguez-Couto, S. (2014). Decolouration of industrial metal-complex dyes in successive batches by active cultures of Trametes pubescens. Biotechnology Reports, 4, 156–160. https://doi.org/10.1016/j.btre.2014.10.006.

Rodríguez-Couto, S., Rosales, E., & Sanromán, M. A. (2006). Decolourization of synthetic dyes by Trametes hirsuta in expanded-bed reactors. Chemosphere, 62(9), 1558–1563. https://doi.org/10.1016/j.chemosphere.2005.06.042.

Romero, S., Blánquez, P., Caminal, G., Font, X., Sarrà, M., Gabarrell, X., & Vicent, T. (2006). Different approaches to improving the textile dye degradation capacity of Trametes versicolor. Biochemical Engineering Journal, 31(1), 42–47. https://doi.org/10.1016/j.bej.2006.05.018.

Sáenz, M. E., Tortorelli, M. C., & Freyre, L. R. (2003). Evaluación de la fitotoxicidad de efluentes industriales. Limnetica, 22(3–4), 137–146.

Saratale, R. G., Saratale, G. D., Chang, J. S., & Govindvar, S. P. (2011). Bacterial decolorization and degradation of azo dyes: A review. Journal of the Taiwan Institute of Chemical Engineers, E42, 138–157. https://doi.org/10.1016/j.jtice.2010.06.006.

Sathian, S., Rajasimman, M., Rathnasabapathy, C. S., & Karthikeyan, C. (2014). Performance evaluation of SBR for the treatment of dyeing wastewater by simultaneous biological and adsorption processes. Journal of Water Process Engineering, 4, 82–90. https://doi.org/10.1016/j.jwpe.2014.09.004.

Schneider, W. D. H., Fontana, R. C., Mendonça, S., de Siqueira, F. G., Dillon, A. J. P., & Camassola, M. (2018). High level production of laccases and peroxidases from the newly isolated white-rot basidiomycete Marasmiellus palmivorus VE111 in a stirred-tank bioreactor in response to different carbon and nitrogen sources. Process Biochemistry, 69, 1–11. https://doi.org/10.1016/j.procbio.2018.03.005.

Selvam, K., Swaminathan, K., & Chae, K. S. (2003). Decolourization of azo dyes and a dye industry effluent by a 27white rot fungus Thelephora sp. Bioresource Technology, 88(2), 115–119. https://doi.org/10.1016/S0960-8524(02)00280-8.

Shin, M., Nguyen, T., & Ramsay, J. (2002). Evaluation of support materials for the surface immobilization and decoloration of amaranth by Trametes versicolor. Applied Microbiology and Biotechnology, 60(1–2), 218–223. https://doi.org/10.1007/s00253-002-1088-3.

Si, J., Peng, F., & Cui, B. (2013). Purification, biochemical characterization and dye decolorization capacity of an alkali-resistant and metal-tolerant laccase from Trametes pubescens. Bioresource Technology, 128, 49–57. https://doi.org/10.1016/j.biortech.2012.10.085.

Spadaro, J. T., Gold, M. H., & Renganathan, V. (1992). Degradation of azo dyes by the lignin-degrading fungus Phanerochaete chrysosporium. Applied and Environmental Microbiology, 58(8), 2397–2401.

Swamy, J., & Ramsay, J. A. (1999). Effects of glucose and NH4+ concentrations on sequential dye decoloration by Trametes versicolor. Enzyme and Microbial Technology, 25(3–5), 278–284. https://doi.org/10.1016/S0141-0229(99)00058-7.

Tauber, M. M., Guebitz, G. M., & Rehorek, A. (2005). Degradation of azo dyes by laccase and ultrasound treatment. Applied and Environmental Microbiology, 71, 2600–2607. https://doi.org/10.1128/AEM.71.5.2600-2607.2005.

Telke, A. A., Kalyani, D. C., Dawkar, V. V., & Govindwar, S. P. (2009). Influence of organic and inorganic compounds on oxidoreductive decolorization of sulfonated azo dye C.I. reactive Orange 16. Journal of Hazardous Materials, 172, 298–309. https://doi.org/10.1016/j.jhazmat.2009.07.008.

Tien, M., & Kirk, T. K. (1983). Lignin degrading from Phanerochaete chrysosporium purification, characterization and catalytic properties of unique H2O2-requiringoxygenase. Proceedings of the National Academy of Sciences, 81, 2280–2284.

Tien, M., & Kirk, T. K. (1988). Lignin peroxidase of Phanerochaete chrysosporium. In Methods in enzymology (Vol. 161, pp. 238–249). Academic Press. https://doi.org/10.1016/0076-6879(88)61025-1

Tsuda, S., Murakami, M., Matsusaka, N., Kano, K., Taniguchi, K., & Sasaki, Y. F. (2001). DNA damage induced by red food dyes orally administered to pregnant and male mice. Toxicological Sciences, 61(1), 92e9. https://doi.org/10.1093/toxsci/61.1.92.

Valdivia-Rivera, S., Martínez-Cano, A. K., Aguirre-García, G., & Lizardi-Jiménez, M. A. (2018). Hydrocarbon water-pollution related to chronic kidney disease in Tierra Blanca, a perfect storm. Environment International, 121, 1204–1209. https://doi.org/10.1016/j.envint.2018.10.036.

Vieira, G. R. T., Liebl, M., Tavares, L. B. B., Paulert, R., & Smânia Júnior, A. (2008). Submerged culture conditions for the production of mycelial biomass and antimicrobial metabolites by Polyporus tricholoma Mont. Brazilian Journal of Microbiology, 39(3), 561–568. https://doi.org/10.1590/S1517-83822008000300029.

Vikrant, K., Giri, B. S., Raza, N., Roy, K., Kim, K. H., Rai, B. N., & Singh, R. S. (2018). Recent advancements in bioremediation of dye: Current status and challenges. Bioresource Technology, 253, 355–367. https://doi.org/10.1016/j.biortech.2018.01.029.

Wang, Y., & Yu, J. (1998). Adsorption and degradation of synthetic dyes on the mycelium of Trametes versicolor. Water Science and Technology, 38(4–5), 233.

Yan, J., Niu, J., Chen, D., Chen, Y., & Irbis, C. (2014). Screening of Trametes strains for efficient decolorization of malachite green at high temperatures and ionic concentrations. International Biodeterioration and Biodegradation, 87, 109–115. https://doi.org/10.1016/j.ibiod.2013.11.009.

Acknowledgments

This work was carried out, thanks to the support of the National Council of Science and Technology (CONACyT) Mexico.

Author information

Authors and Affiliations

Contributions

Uribe-Arizmendi, I: formal analysis, methodology, investigation, writing - original draft; Anducho-Reyes M.A.: data curation, software, validation; Ramírez-Vargas, M.R.: investigation, supervision; Cadena-Ramírez, A.: conceptualization, validation; Muro-Urista, C.R.: conceptualization, supervision, visualization; Téllez-Jurado, A.: conceptualization, project administration, resources, writing-review and editing

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Uribe-Arizmendi, I., Anducho-Reyes, M.A., Ramírez-Vargas, M.R. et al. Biological Decolorization of Amaranth, Denim Blue, and Orange G with Trametes polyzona. Water Air Soil Pollut 231, 307 (2020). https://doi.org/10.1007/s11270-020-04705-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-020-04705-9