Abstract

An electrochemically activated persulfate (EC/PS) system was proposed for the degradation of herbicide diuron in this study. In the EC/PS system, the ferrous ions (Fe2+) produced from iron electrode can activate persulfate to generate sulfate radical (SO4 ·-) as well as hydroxyl radical (OH•). The results showed that the degradation of diuron was significantly enhanced in the EC/PS system, compared to electrocoagulation, persulfate, and Fe2+/PS process. Both of SO4 ·- and OH· contributed to the degradation of diuron in the EC/PS system according to the radical scavenging studies. The pseudo first-order rate constants of diuron increased with increasing the applied currents and dosages of persulfate. pH affected the degradation of diuron indirectly through the speciation of iron and resulted in higher removal efficiency in acidic condition than in alkaline condition. Chloride, carbonate, and bicarbonate in real water inhibited the degradation of diuron dramatically through consuming SO4 ·- and OH· and abided by the order of CO3 2−>HCO3 −>Cl−. This study demonstrates that the EC/PS system is a novel, efficient, promising, and environmental-friendly method to treat diuron contamination.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Diuron [N-(3,4-dichlorophenyl)-N, N-dimethylurea], a kind of broad-spectrum herbicide, is widely used in agricultural areas to control annual and perennial broadleaf, as well as grassy weeds. And it has been used for more than 40 years worldwide (Carrier et al. 2009; Gao et al. 2009; Tan et al. 2012a, b). Diuron could contaminate the surface water by agricultural runoffs and wastewater generated from diuron manufacturing plants (Chiron et al. 2000; Romero et al. 2010). Moreover, diuron is chemically stable, and its half-life in water is about 2 weeks (Guardiola et al. 2012; Huovinen et al. 2015). The US EPA has classified diuron as a “known/likely” human carcinogen. Diuron also ranges from moderately toxic to highly toxic to aquatic organisms and may cause long-term adverse effects to the aquatic environment. Due to the toxic and harmful impacts to the human beings and aquatic organisms, the wastewater effluent containing diuron should be cautiously disposed prior to release into the environment (Chen and Huang 2015; Messeguer 2011).

With the development of water treatment technologies, advanced oxidation processes (AOPs) are becoming popular and have been widely used to treat diuron in wastewater owing to its recalcitrance for biodegradation (Chen and Huang 2015). AOP are a promising alternative for degrading diuron mainly based on the high oxidation ability of hydroxyl radicals (OH·) or sulfate radical (SO4 ·-) generated by the chemical reaction in the aqueous solutions (Bu et al. 2016; Chu et al. 2015; Tan et al. 2013). Among all the AOPs, electrochemically activated persulfate (EC/PS) process has been considered as a potential technology in water treatment due to its high efficiency (Govindan et al. 2014; Lin et al. 2013; Wu et al. 2012).

Although the EC/PS system is still not widely known, more attention have been paid as it is relatively inexpensive, nontoxic, and effective compared to other typical activators, such as heat-, photo-, metal-, chelated metal-, quinone-, phenols-, hydrogen peroxide-activated persulfate. In the EC/PS system, Fe2+ is released from a sacrificial iron electrode at a specified rate under direct current. And electro-generation of hydrogen peroxide (H2O2) may occur in the EC systems. Therefore, both SO4 ·- and OH· are generated in the system based on the Reaction Nos. 1 to Nos. 4 (Luo et al. 2015; Yu et al. 2004; Yuan et al. 2013). SO4 ·- are very strong aqueous oxidizing species with a redox potential estimated to be 2.6 V, similar to that of the OH·, 2.7 V (Vicente et al. 2011; Wacławek et al. 2016). Moreover, SO4 ·- have a longer half-life than OH· because of their preference for electron transfer reaction, while OH· can participate in a diversity of reaction with equal preference (Anipsitakis and Dionysiou 2004; Furman et al. 2010; Govindan et al. 2014). Therefore, SO4 ·- are more selective than OH· for the oxidation of many organic contaminants (Bu et al. 2016; Neta et al. 1988).

So far, the degradation kinetics and mechanism of diuron in the EC/PS system have not been investigated. Therefore, the objectives of this study are (1) to study the degradation kinetics of diuron in the EC/PS system, (2) to identify the main activated radical species responsible for diuron degradation, (3) and to evaluate the influential factors on diuron degradation performance.

2 Materials and Methods

2.1 Materials and Reagents

All the chemicals used in the experiments were analytical reagent grade. The solutions were prepared by ultrapure water (18.2 MΩ · cm) deionized by an ELGA purelab water system. Diuron (≥99.0 %) was obtained from Aladdin Co., Ltd. (Shanghai, China). Methyl alcohol (MeOH) and acetonitrile (HPLC grade, ≥99.9 %) were purchased from Sigma-Aldrich Chemical Co., Ltd. (USA). Sodium persulfate (Na2S2O8, ≥99.5 %), sodium sulfate (Na2SO4, ≥99.5 %), ferrous sulfate (FeSO4 · 7H2O, ≥99.0 %), tertiary butanol (TBA, ≥98.0 %), sodium chloride (NaCl, ≥99.0 %), sodium carbonate (Na2CO3, ≥98.0 %), and sodium bicarbonate (NaHCO3, ≥99.0 %) were supplied by Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China).

2.2 Experimental Procedures

A series of experiments were conducted in a glass beaker containing 200-mL solution and were performed at constant current controlled by a direct current (DC) power supply. The sacrificial iron plates with dimensions of 5 cm × 2 cm were employed as electrode material and set in parallel at a distance of 2 cm. The total submerged area of electrodes was 6 cm2 (3 cm × 2 cm) in the electrolytic cell.

The stock solution of diuron was prepared before the experiments. The required experimental concentrations of solutions were diluted with ultrapure water when necessary. Na2S2O8 stock solution was freshly prepared promptly prior to use. The concentration of diuron in the experiments was fixed at 10 μM. 0.5 mM Na2SO4 was added into the beaker as a background electrolyte to raise the solution conductivity. Before the reactions, pH of the diuron solutions was adjusted to 7.0 by adding 0.1 M NaOH or H2SO4, except for the effect of initial pH. At predetermined time intervals, samples were collected and mixed immediately with appropriate amounts of methanol to quench the residual oxidants. Then, the samples were filtered with 0.45-μm filter membranes before analysis. All the experiments were performed at least in duplicate. Data in figures presented as the mean value of the tested data, and error bars indicated one standard deviation.

2.3 Chemical Analysis

The concentrations of diuron were measured by high-performance liquid chromatography (HPLC, Agilent 1260, USA) equipped with a Symmetry C18 column (150 mm × 4.6 mm × 5 μm, Agilent, USA) and a VWD detector (Agilent, USA) set at 254 nm. An ultrapure water/acetonitrile (v:v = 35:65) mixture was used as the mobile phase with a constant flow of 0.8 mL/min, and the injection volume was 10 μL.

3 Results and Discussion

3.1 Degradation of Diuron in the EC/PS System

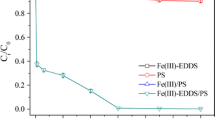

To investigate the degradation efficiency of diuron, a set of comparative experiments were carried out by uEC alone, PS alone, and EC/PS system. As shown in Fig. 1, the concentrations of diuron remain unchanged when treated by PS alone, and the removal rate of diuron was almost negligible owing to the low oxidation ability of PS. Similarly, only 15 % of diuron was degraded in 15 min in the EC process as seen in Fig. 1. And the removed part was probably attributed to the surface chelation or electrostatic attraction of Fe(OH)n precipitates produced in the system. However, the EC/PS system significantly promoted the removal efficiency of diuron, and more than 77 % of diuron was degraded within 15 min in the samples with 0.5 mM initial PS concentration. The high removal efficiency was achieved in the EC/PS system because Fe2+ produced on the iron electrode can activate persulfate to generate SO4 ·- and OH·. The results demonstrated that combination of EC and PS can significantly enhance the degradation efficiency of diuron.

To further investigate the mechanism of the EC/PS system, a comparison between the EC/PS system and the Fe2+-activated persulfate (Fe2+/PS) system was conducted. The added Fe2+ concentrations in the Fe2+/PS system were calculated via the following Faraday’s law with a reaction time of 15 min.

where, C is the generated molecular concentration of Fe2+ (mol/L), Z is the number of electrons (2 equivalents/mol), F is Faraday’s constant (96485.3 Coulombs/mol), I is the given current (A), t is the reaction time (s), and V is the volume of electrolyte (L).

As shown in Fig. 2, different from the EC/PS system, the diuron degradation did not increase as the added Fe2+ concentration in the Fe2+/PS system. And the optimum mole ratio of Fe2+ to PS was about 1:1, which was similar to other studies focusing on Fe2+/PS system or Fe2+/PMS system (Rastogi et al. 2009; Tan et al. 2012a, b). Figure 2 also reveals that the removal rates of diuron by the Fe2+/PS system were always lower than that by the EC/PS system at all the applied currents. This phenomenon could be ascribed to the different utilization of Fe2+ between the two systems. In the Fe2+/PS system, excess Fe2+ would compete with diuron for OH· and SO4 ·- and, thus, hindered the diuron degradation (Cao et al. 2008; Usman et al. 2014; Xu and Li 2010). However, in the EC/PS system, Fe2+ was generated gradually from the iron electrode, which assured the optimal utilization of both Fe2+ and PS.

Comparison of diuron degradation by the EC/PS and Fe2+/PS process under similar reaction conditions. a I0 = 10 mA, [Fe2+]0 = 232 μM; b I0 = 20 mA, [Fe2+]0 = 464 μM; c I0 = 30 mA, [Fe2+]0 = 696 μM; d I0 = 40 mA, [Fe2+]0 = 928 μM; e overall removal rate. Experimental conditions: [Diuron]0 = 10 μM, [PS]0 = 0.5 mM, initial pH = 7.0, reaction time =15 min

3.2 Role of Sulfate Radical and Hydroxyl Radical in the EC/PS System

To identify the role of SO4 ·- and OH· on the degradation of diuron in the EC/PS system, two scavengers, MeOH and TBA, were used in further experiments. TBA is an effective quencher for OH· (k = 6.0 × 108 M−1s−1), but not for SO4 ·- (k = 4.0 × 105 M−1s−1), while MeOH is considered as an effective scavenger for both SO4 ·- (k = 1.1 × 107 M−1s−1) and OH· (k = 9.7 × 108 M−1s−1) (Buxton et al. 1988; Neta et al. 1988; Xie et al. 2015). Therefore, the difference of degradation rate of diuron in the presence of scavengers could be used to distinguish the role of SO4 ·- and OH·.

Figure 3 shows the coexistence of MeOH or TBA inhibited the degradation of diuron in the EC/PS system. Initially, the pseudo-first-order rate constants of diuron degradation decreased rapidly. With further increasing the dosages of MeOH or TBA, the decreasing speed of the pseudo-first-order rate constants reduced dramatically. As shown, the pseudo-first-order rate constants decreased from 0.099 to 0.029 min−1 with increasing the concentration of TBA from 0 to 50 mM. While the pseudo-first-order rate constants decreased more rapidly from 0.099 to 0.020 min−1 with increasing the concentration of MeOH from 0 to 50 mM. These results suggested that both SO4 ·- and OH· are existing in the EC/PS system and responsible for the diuron degradation.

3.3 Effect of Applied Current

Figure 4 illustrated the degradation efficiency of diuron by the EC/PS system at different applied currents ranging from 10 to 40 mA. The results showed that the diuron degradation in the EC/PS system was current-dependent. As the applied current increased from 10 to 40 mA, the removal rate of diuron significantly increased from 69 to 84 % within 15 min, and the pseudo-first-order rate constant increased from 0.078 to 0.102 min−1, accordingly. As shown in the insert image of Fig. 4, a linear correlation between diuron degradation rate constants and applied currents on the iron electrode is determined as:

where k obs and I 0 are the pseudo-first order degradation constant (min−1) and the applied current (mA), respectively. A rational explanation for this phenomenon is that increasing the applied current would accelerate the generation of ferrous ions from iron electrode, and then improve the decomposition of the persulfate to generate more sulfate radicals, which account for the increase of diuron removal rate. Similar phenomenon was observed by Antonin et al. who studied on the incineration of ciprofloxacin using an electrochemical method (Antonin et al. 2015).

3.4 Effect of PS Dosage

The effect of initial PS dosage on the degradation of diuron was evaluated by conducting experiments at PS dosages ranging from 0.10 to 1.00 mM. In the absence of PS, the removal efficiency of diuron was minimal within 15 min (seen in Fig. 1). However, the removal efficiency increased significantly with the addition of PS as shown in Fig. 5. The degradation rates under various PS dosages all followed pseudo-first-order kinetics. When the PS dosage increased from 0.10 to 1.00 mM, the degradation rate constants increased accordingly from 0.014 to 0.247 min−1. Persulfate is a source of sulfate radicals in the EC/PS system, and more reactive radicals would be generated to degrade diuron at higher PS dosage. Similar results were reported by Zhao et al. (2012) who researched on the transformation of refractory pollutants by electro-Fenton process. Furthermore, as the insert image of Fig. 5 presented, the degradation rate constant also exhibited a linear trend as a function of PS dosage in this study (k obs = 0.254 [PS]0–0.015, [PS]0 = 0.1–1.0 mM, R 2 = 0.991).

3.5 Effect of Initial pH

The speciation of iron differs in different solution pH and, thereby, the initial pH is a key factor that influences the degradation efficiency in the EC/PS system (Lakshmanan et al. 2009). Figure 6 shows the degradation of diuron in the EC/PS system among different initial pH (3.0∼11.0). Obvious degradation of diuron was observed in acidic condition, and the optimum pH was at 3.0 in this study, which is consistent with Fenton-like oxidation (Sheng et al. 1999). As the initial pH increased from 3.0 to 11.0, the diuron degradation rate constants decreased from 0.154 to 0.008 min−1. This is because that when the initial pH was at and above 2.5, FeOH2+ and Fe(OH)3 occupy a dominant part instead of Fe2+, and the formation of FeOH2+ and Fe(OH)3 decreased the concentration of free Fe2+, thus decreasing the activation of sulfate radicals through reaction 1. Besides, the regeneration of Fe2+ from ferric ions at the cathode was also inhibited, further slowing down the degradation rate of diuron. Therefore, a conclusion could be drawn that the EC/PS system could be better applied in acidic condition than in alkaline condition.

3.6 Effect of Coexisting Anions

Chloride (Cl−), carbonate (CO3 2−), and bicarbonate (HCO3 −) are common anions present in real surface water and may affect the degradation efficiency of diuron in the EC/PS system. In this study, the concentrations of different anions were fixed at 0.5 mM. As shown in Fig. 7, the presence of Cl−, CO3 2−, and HCO3 − inhibited the diuron degradation to different degrees, which could be ascribed to their scavenging effect on SO4 ·- and OH· as the following reactions (Buxton et al. 1988; Luo et al. 2015).

Besides, the pseudo-first-order rate constants were calculated to be 0.086, 0.072, and 0.046 min−1 in the presence of Cl−, HCO3 −, and CO3 2−, respectively. This can be reasonably explained by the redox potential of different radicals, and it may abide by the following order: SO4 ·- > OH· > Cl· > CO3 ·-. Therefore, the inhibiting effect of diuron degradation was in the order of CO3 2− > HCO3 − > Cl−.

3.7 Mineralization of Diuron in the EC/PS System

The changes of TOC and diuron removal efficiency were investigated with initial diuron concentration 10 μM, persulfate concentration 1.0 mM, applied current 40 mA, initial pH 3.0. As shown in Fig. 8, the removal efficiency of diuron increased quickly and approximately 2 % of diuron was detected in 10 min, and there was nearly no diuron existed as the reaction proceeded. However, the TOC removal efficiency was only 10.8 % after 10 min reaction. The TOC removal efficiency achieved about 22.5 % when the reaction time extended to 30 min, implying that mineralization of diuron was poor and only 22.5 % of diuron was mineralized to CO2 and H2O in the EC/PS system, which is consistent with other studies (Tan et al. 2012a, b). The results indicated that most of diuron transformed to its intermediate by-products instead of CO2 and H2O in the EC/PS system and, thus, optimized persulfate dosage, applied current, or reaction time is needed to completely mineralize diuron into inorganics.

4 Conclusions

This study showed that diuron in water can be removed effectively by the electrochemically activated persulfate (EC/PS) system, and the removal efficiency is better than in EC alone, PS alone, and Fe2+/PS process. The radical scavenging studies using MeOH and TBA further indicated that both SO4 ·- and OH· contributed to the degradation of diuron in the EC/PS system. Increasing the applied current and PS dosage increased the degradation of diuron. pH affected the degradation of diuron and faster degradation occurred in acidic condition. Chloride, carbonate, and bicarbonate are likely to be radical scavengers in real water, and the inhibiting effect was in the order of CO3 2−>HCO3 −>Cl−. Of course, further studies will be followed when using the EC/PS system to control diuron pollution.

References

Anipsitakis, G. P., & Dionysiou, D. D. (2004). Radical generation by the interaction of transition metals with common oxidants. Environmental Science & Technology, 38, 3705–3712.

Antonin, V. S., Santos, M. C., Garcia-Segura, S., & Brillas, E. (2015). Electrochemical incineration of the antibiotic ciprofloxacin in sulfate medium and synthetic urine matrix. Water Research, 83, 31–41.

Bu, L., Zhou, S., Shi, Z., Deng, L., Li, G., Yi, Q., & Gao, N. (2016). Degradation of oxcarbazepine by UV-activated persulfate oxidation: kinetics, mechanisms, and pathways. Environmental Science and Pollution Research, 23(3), 2848–2855.

Buxton, G. V., Greenstock, C. L., Helman, W. P., & Ross, A. B. (1988). Critical-review of rate constants for reactions of hydrated electrons, hydrogen-atoms and hydroxyl radicals (•OH/•O−) in aqueous solution. Journal of Physical and Chemical Reference Data, 17, 513–886.

Cao, J., Zhang, W.-X., Brown, D. G., & Sethi, D. (2008). Oxidation of lindane with Fe (II)-activated sodium persulfate. Environmental Engineering Science, 25, 221–228.

Carrier, M., Besson, M., Guillard, C., & Gonze, E. (2009). Removal of herbicide diuron and thermal degradation products under Catalytic Wet Air Oxidation conditions. Applied Catalysis B: Environmental, 91, 275–283.

Chen, W.-S., & Huang, C.-P. (2015). Mineralization of aniline in aqueous solution by electrochemical activation of persulfate. Chemosphere, 125, 175–181.

Chiron, S., Fernandez-Alba, A., Rodriguez, A., & Garcia-Calvo, E. (2000). Pesticide chemical oxidation: state-of-the-art. Water Research, 34, 366–377.

Chu, W., Li, D., Gao, N., Templeton, M. R., Tan, C., & Gao, Y. (2015). The control of emerging haloacetamide DBP precursors with UV/persulfate treatment. Water Research, 72, 340–348.

Furman, O. S., Teel, A. L., & Watts, R. J. (2010). Mechanism of base activation of persulfate. Environmental Science & Technology, 44, 6423–6428.

Gao, N., Chu, W., Zhao, D., & Dong, B. (2009). Removal of the herbicide diuron from drinking water by nanofiltration membrane. Fresenius Environmental Bulletin, 18, 1723–1729.

Govindan, K., Raja, M., Noel, M., & James, E. (2014). Degradation of pentachlorophenol by hydroxyl radicals and sulfate radicals using electrochemical activation of peroxomonosulfate, peroxodisulfate and hydrogen peroxide. Journal of Hazardous Materials, 272, 42–51.

Guardiola, F. A., Cuesta, A., Meseguer, J., & Esteban, M. A. (2012). Risks of using antifouling biocides in aquaculture. International Journal of Molecular Sciences, 13, 1541–1560.

Huovinen, M., Loikkanen, J., Naarala, J., & Vähäkangas, K. (2015). Toxicity of diuron in human cancer cells. Toxicology in Vitro, 29, 1577–1586.

Lakshmanan, D., Clifford, D. A., & Samanta, G. (2009). Ferrous and ferric Ion generation during iron electrocoagulation. Environmental Science & Technology, 43, 3853–3859.

Lin, H., Wu, J., & Zhang, H. (2013). Degradation of bisphenol A in aqueous solution by a novel electro/Fe3+/peroxydisulfate process. Separation and Purification Technology, 117, 18–23.

Luo, C., Ma, J., Jiang, J., Liu, Y., Song, Y., Yang, Y., Guan, Y., & Wu, D. (2015). Simulation and comparative study on the oxidation kinetics of atrazine by UV/H2O2. Water Research, 80, 99–108.

Messeguer, A. (2011). Potential implication of aniline derivatives in the Toxic Oil Syndrome (TOS). Chemico-Biological Interactions, 192, 136–141.

Neta, P., Huie, R. E., & Ross, A. B. (1988). Rate constants for reactions of inorganic radicals in aqueous solution. Journal of Physical and Chemical Reference Data, 17, 1027–1284.

Rastogi, A., Al-Abed, S. R., & Dionysiou, D. D. (2009). Sulfate radical-based ferrous–peroxymonosulfate oxidative system for PCBs degradation in aqueous and sediment systems. Applied Catalysis B: Environmental, 85, 171–179.

Romero, A., Santos, A., Vicente, F., & González, C. (2010). Diuron abatement using activated persulphate: effect of pH, Fe (II) and oxidant dosage. Chemical Engineering Journal, 162, 257–265.

Sheng, H. L., Lin, C. M., & Leu, H. G. (1999). Operating characteristics and kinetic studies of surfactant wastewater treatment by fenton oxidation. Water Research, 33, 1735–1741.

Tan, C., Gao, N., Chu, W., Li, C., & Templeton, M. R. (2012a). Degradation of diuron by persulfate activated with ferrous ion. Separation and Purification Technology, 95, 44–48.

Tan, C., Gao, N., Deng, Y., An, N., & Deng, J. (2012b). Heat-activated persulfate oxidation of diuron in water. Chemical Engineering Journal, 203, 294–300.

Tan, C., Gao, N., Deng, Y., Zhang, Y., Sui, M., Deng, J., & Zhou, S. (2013). Degradation of antipyrine by UV, UV/H2O2 and UV/PS. Journal of Hazardous Materials, 260, 1008–1016.

Usman, M., Tascone, O., Faure, P., & Hanna, K. (2014). Chemical oxidation of hexachlorocyclohexanes (HCHs) in contaminated soils. Science of the Total Environment, 476, 434–439.

Vicente, F., Santos, A., Romero, A., & Rodriguez, S. (2011). Kinetic study of diuron oxidation and mineralization by persulphate: effects of temperature, oxidant concentration and iron dosage method. Chemical Engineering Journal, 170, 127–135.

Wacławek, S., Antoš, V., Hrabák, P., Černík, M., & Elliott, D. (2016). Remediation of hexachlorocyclohexanes by electrochemically activated persulfates. Environmental Science and Pollution Research, 23(1), 1–9.

Wu, J., Zhang, H., & Qiu, J. (2012). Degradation of Acid Orange 7 in aqueous solution by a novel electro/Fe2+/peroxydisulfate process. Journal of Hazardous Materials, 215, 138–145.

Xie, P., Ma, J., Liu, W., Zou, J., Yue, S., Li, X., Wiesner, M. R., & Fang, J. (2015). Removal of 2-MIB and geosmin using UV/persulfate: contributions of hydroxyl and sulfate radicals. Water Research, 69, 223–233.

Xu, X.-R., & Li, X.-Z. (2010). Degradation of azo dye Orange G in aqueous solutions by persulfate with ferrous ion. Separation and Purification Technology, 72, 105–111.

Yu, X.-Y., Bao, Z.-C., & Barker, J. R. (2004). Free radical reactions involving Cl, Cl2-, and SO4-in the 248 nm photolysis of aqueous solutions containing S2O82-and Cl. The Journal of Physical Chemistry. A, 108, 295–308.

Yuan, S., Liao, P., & Alshawabkeh, A. N. (2013). Electrolytic manipulation of persulfate reactivity by iron electrodes for trichloroethylene degradation in groundwater. Environmental Science & Technology, 48, 656–663.

Zhao, X., Zhang, B., Liu, H., Chen, F., Li, A., & Qu, J. (2012). Transformation characteristics of refractory pollutants in plugboard wastewater by an optimal electrocoagulation and electro-Fenton process. Chemosphere, 87, 631–636.

Acknowledgments

This work was financially supported by the National Natural Science Foundation (51508174) and the Central University Basic Scientific Research Business Special Fund Projects (531107040812).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Y., Zhou, S., Bu, L. et al. Degradation of Diuron by Electrochemically Activated Persulfate. Water Air Soil Pollut 227, 279 (2016). https://doi.org/10.1007/s11270-016-2978-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-016-2978-9