Abstract

The advanced oxidation process based on sulfate radicals (SO4.−) is one of the most promising wastewater treatment technologies. In this study, we utilized potassium hydrogen phthalate (KHP) as an organic pollutant to configure simulated wastewater that was then treated by activation of sodium persulfate (PS) by zero-valent iron (ZVI) to produce SO4.−. Our results showed that the ZVI-PS system had a greater degradation rate in acidic, neutral, and weakly alkaline solutions compared with the Fenton method. After 180 min of reaction time under the experimental conditions (pH = 3.0, temperature = 20 °C, ZVI = 3.57 mM, and PS = 2.52 mM), chemical oxygen demand (COD) was 53.72%, indicating that these reaction conditions were optimal for COD degradation. This reaction was described by the kinetic rate Eqs. Y = K1X + b (0–10 min) and Y = C + B X + K2X2 (30–180 min) within the above experimental conditions. The results of this study showed that the ZVI-PS system may be an interesting alternative for the treatment of organic pollutants.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Rapid industrial development produces a large amount of complex wastewater, which is difficult to handle; industrial wastewater often contains biologically toxic components which are not suitable for direct biodegradation technology (Ren 2010). According to statistics on water pollution prevention and the Chinese ecological environment bulletin, industrial pollutants are still the main contributors to environmental pollutants (MEP 2019). Because most organic pollutants contain chemical components that are carcinogenic, teratogenic, and mutagenic, they have a strong negative effect on the ecological environment and are a threat to human health (MEP 2019).

Advanced oxidation processes (AOPs) are an effective alternative for removing many toxic and biodegradable organic pollutants from wastewater (Yang and Wang 2011; Su 2013; Wu 2014). In traditional AOPs such as UV/H2O2, UV/TiO2, and the Fenton method, the strong oxidizing hydroxyl radical (·OH) is used as the main reactive group to degrade organic pollutants (Yao 2012). The advanced oxidation technique utilizing sulfate radicals (SR-AOPs) has a higher standard reduction potential (E- = 2.5–3.1 V) under neutral conditions than that of hydroxyl radicals (·OH) (Yang and Wang 2011), and has stronger selectivity to target contaminants under acidic conditions (Guan et al. 2011; Long et al. 2014; He et al. 2015; Ma 2014). In addition, SO4.− has a longer half-life (40 μs vs. 1 μs for ·OH), which prolongs its continuous contact time with target contaminants and thus allows greater elimination of organic pollutants in water (Seok-Young 2010; Yan 2012; Tang et al. 2015; Zhao 2015). SRs are generated upon PS activation. There are several means of activation, including thermal activation (Antoine and Tuqan (2012); Antoine et al. (2012a, 2012b, 2015)), chemical activation (Sahar and Ghauch 2016; Suha et al. 2019), and photolysis (Antoine et al. 2017; Maya et al. 2018a, 2018b; Suha et al. 2020). In summary, activated persulfate technology has several advantages, including strong oxidizability, small pH influence, and mild reaction conditions. It has been widely used for the removal of organic pollutants in soil and groundwater.

The experiment uses KHP as the target pollutant to establish a kinetic model for the degradation of KHP by SR-AOPs. KHP is often used as a benchmark agent in chemical research. Its strong corrosiveness and other characteristics pose a threat to the human body and water quality. The presence of benzene rings also increases the difficulty of degradation and it is a common component in industrial wastewater. Therefore, KHP was chosen as the target pollutant in the ZVI-PS system; this allowed for a more comprehensive and objective analysis of the system’s performance in degradation of recalcitrant pollutants, but also provided a reference for environmental pollution control. By adjusting the effects of pH, temperature, ZVI addition amount, PS addition amount, and other changes on the degradation of KHP, we aimed to provide a theoretical basis and technical support for industrial wastewater treatment.

2 Materials and Methods

2.1 Experimental Materials

C8H5KO4, FeSO4.7H2O, [(NH4)2Fe(SO4)2.6H2O] (FAS), NaOH, Na2S2O8, H2SO4, Ag2SO4, HgSO4, and K2Cr2O7 were used as experimental reagents. All reagents used were of analytical grade and were purchased from Sinopharm Chemical Reagent Co., Ltd. (Beijing, China). The following equipment were used throughout the experiment: an electronic balance (Model AUY220, Shimadzu, Japan), standard chemical oxygen demand (COD) digestion device (Model HCA-102, Huachen Medical Instruments Co., Ltd., Taizhou, China), pH meter (Model Mine magnetic PHS-3C, Yidian Science Instrument Co., Ltd., Shanghai, China), magnetic heating stirrer (Model CJJ-931 (HJ-6), Putian Instrument Manufacturing Co., Ltd., Changzhou, China), digital thermostat water bath (Model HH-8, Runhua Electric Appliance Co., Ltd., Changzhou, China), centrifuge (Model TDZ5-WS, Huxi Instrument Equipment Co., Ltd., Hunan, China), electric blast drying oven (Model GZX-9070MBE, Boxun Industrial Co., Ltd., Shanghai, China), and ultra-pure water machine (Model Clear-D24UV pure water system, Merck Chemicals [Shanghai] Co., Ltd., Shanghai, China).

2.2 Experimental and Analytical Methods

We added an appropriate amount of KHP to a 1-L volumetric flask to make 1 L of simulated wastewater with a COD of 500 mg L−1, then diluted with 10% H2SO4 to adjust to a pH of 3.0. We then added an appropriate amount of ZVI, and while stirring with a magnetic stirrer, we quickly added an appropriate amount of PS, adjusted the stirring speed to the maximum setting, and started timing. We stopped stirring after the set time, then added NaOH solution to adjust the pH to between 9.0 and 10.0 to terminate the reaction. Following this, we centrifuged the solution for 30 min at a centrifugal speed of 1369.55 × g, after which we removed 20 mL of the resulting supernatant to measure COD. We used this COD value as a reference for optimal conditions in additional analyses.

COD is defined as the amount of a specified oxidant that reacts with the sample under controlled conditions. The quantity of oxidant consumed is expressed in terms of its oxygen equivalence. The COD index is determined by the dichromate method (approved by Standard Methods Committee 1998). The unreduced K2Cr2O7 in the water sample was titrated with FAS, and the mass concentration of O2 consumed was calculated according to the amount of K2Cr2O7 consumed. The calculation formula is as follows:

where V0 = mL FAS used for blank, V1 = mL FAS used for sample, C = molarity of FAS, and 8000 = mg L−1 M mass of 1/4 O2.

We used Excel 2010 for data analysis and Origin 8.5 Pro to fit the kinetic equations.

3 Results and Discussion

3.1 Effect of pH on the Degradation Rate of COD

3.1.1 Effect of pH of the ZVI-PS System on COD Degradation Rate

When the pH value was gradually increased, the degradation rate of COD in the ZVI-PS system showed a downward trend. The COD degradation rate gradually decreased from 56.71 to 50% throughout the experiment, and the degradation rate of KHP in the ZVI-PS system gradually reduced (Fig. 1a). However, the analysis of the comparative reduction in the COD degradation rate was not significant, and it was maintained above 50%.

Prior studies have shown that ZVI can effectively activate PS to produce SO4.− for the removal of organic pollutants in an acidic or neutral environment. Based on the change in the COD degradation rate, it can be inferred that the ZVI-PS system incorporating SR-AOPs has obvious advantages for decontamination of acidic to neutral wastewater, and the pH range of SO4.− is relatively broad (Fig. 1a). These results were similar to the effect of pH on the formation of sulfate and ·OH in the UV/peroxide sulfate system in a prior study by Guan et al. (2011) and a previous study on arsenic in wastewater treated by ZVI-activated persulfate by Zhou et al. (2017). These studies found that SO4.− produced by persulfate activation under acidic and neutral conditions has a positive degradation effect on the poorly soluble organic pollutant benzoic acid (BA), which is found under alkaline conditions with a pH of 8.0–11.0. Sulfate can also have a certain degradation effect on BA. Based on the results of the reaction experiment, we can conclude that PS may produce ·OH under alkaline conditions. Because the generated ·OH and SO4.− are quenched by OH- in solution, the degradation rate of COD decreases with increasing pH; therefore, this system cannot oxidize and degrade organic pollutants under alkaline conditions.

3.1.2 Effect of pH of the Fenton System on COD Degradation Rate

The degradation rate of COD in the Fenton system decreased significantly with the increase in pH, and the highest observed COD was 83.79% at pH 3.0 (Fig. 1b). We observed that the degradation rate of COD in the Fenton system was higher than that in the ZVI-PS system for pH levels between 3.0 and 6.0 (Fig. 1).

He et al. (2015) used a ZVI/H2O2 Fenton system to pretreat pharmaceutical chemical wastewater and found that acidic conditions were more favorable in the Fenton system. Ma (2014) also attempted to prepare new catalysts to expand the pH range of the Fenton system. Excessive addition of H2O2 affects the degradation of organic matter in the normal Fenton system, which could explain why the overall degradation rate was higher than in the ZVI-PS system. However, it would be difficult to achieve an excessive removal of pharmaceuticals with this system in practical industrial applications. The COD degradation rate of the Fenton system was slow (pH = 7.0, Fig. 1b), indicating that COD degradation rate of the Fenton system is inhibited under neutral to alkaline conditions, and therefore, this system is more suitable for acidic conditions (Fig. 1b). The Fenton system is only effective over a small pH range, which limits its industrial applications. Although the Fenton system showed an advantage in the COD degradation rate in simulated wastewater, it was more affected by pH level, and the acid adjustment step in the actual wastewater treatment process often causes difficulties in engineering applications. Therefore, the wider application of the effective pH range of the ZVI-PS system is more advantageous for engineering applications (Shi et al. 2013).

Consequently, regarding pH range, the ZVI-PS system based on SR-AOPs has certain advantages. It can effectively produce SO4.− under weak acid and weak alkaline conditions to degrade organic pollutants, which is very helpful for the treatment of industrial wastewater.

3.2 Effect of Different Dosages of ZVI on COD Degradation Rate

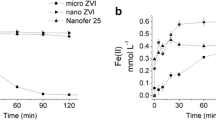

As shown in Fig. 2a, at a PS concentration of 2.02 mM with ZVI ranging between 0.89 and 3.57 mM, the degradation rate of COD by the ZVI-PS system increased from 43.86 to 49.62%, which was mainly because an increase of ZVI can greatly improve the catalytic active site and enhance the performance of activated PS. Previous studies found that in degradation studies using SO4.− produced by the ZVI-PS system, adding an appropriate amount of ZVI will promote the degradation of organic matter in the PS system (Sahar and Ghauch 2016; Zhao et al. 2010). However, when ZVI ranged from 3.57 to 17.86 mM, the COD degradation rate of the ZVI-PS system decreased from 49.62 to 36.49%; this was mainly due to the excessive addition of ZVI, which lead to an increase of dissolved Fe3+, subsequently causing the quenching of a large number of free radicals and resulting in the inhibition of the pollutant degradation rate (Eqs. 1 and 2) (Yongjie Wan et al. 2020). Our results indicate that the optimum concentration of ZVI for COD degradation is 3.57 mM.

Excessive addition of ZVI has an inhibitory effect. Excessive levels of Fe2+ compete with organic pollutants, consume a portion of SO4.−, and reduce the degradation rate of organic pollutants; however, significantly reduced ZVI concentrations are not conducive to the activation of PS to produce SO4.−, which consequently also reduces the degradation rate of organic pollutants. Zhao (2010) speculated on the mechanism of ZVI-activated PS; he believed that ZVI may activate PS by various means, but that the main method of activation was the production of Fe2+.

3.3 Effect of Different PS Dosages on COD Degradation Rate

As shown in Fig. 2b, as the PS dosage increased, the COD degradation rate first increased and then decreased in the ZVI-PS system; the highest COD degradation rate was 53.72% at a PS concentration of 2.52 mM. After adding too much PS, the COD degradation rate decreased.

This decrease in the COD degradation rate may be due to a lack of complete reaction after the excessive addition of PS, causing PS to become an interference factor in COD determination by potassium dichromate titration, and resulting in an increase in COD. Moreover, the addition of excessive PS could also affect the treated wastewater, causing the remaining SO4.− to pollute the environment. Introducing a large amount of PS into the system could theoretically be helpful to improve the COD degradation rate, but the gain effect is limited, as reported in a previous study by Guo (2013). Therefore, PS additions should vary according to the actual situation, so that the tail water after the degradation of the PS system can also directly enter the next stage of treatment. In addition, Yongjie Wan et al. (2020) found that the addition of excessive PS led to enhanced self-quenching of free radicals. In short, the quantity of PS added to the treatment solution is only useful for COD degradation up to a certain concentration, after which it has negative effects. Residual PS could cause an improvement in COD determination. Previous studies have shown that the contribution of 1 mg K2S2O8 to the COD change value is 0.02979 mg. In the ZVI-PS system, Fe2+ undergoes a similar sequential batch reaction process, which continuously activates PS. Finally, the contribution of residual PS to the COD value is almost negligible (Wang et al. 2014). In this experiment, the ideal PS concentration for high COD degradation was 2.52 mM with a PS:COD ratio of 12:1.

3.4 Effect of Temperature on COD Degradation Rate

Temperature has a great influence on chemical reactions, and appropriate temperature helps to break and regenerate the chemical bonds of the reactants and promote effective reactions. In the contrast group, increasing the temperature did not degrade KHP; at pH 3.0, as temperature increased from 20 to 90 °C, COD increased from 492 to 612 mg L−1 (Fig. 3). High temperatures will also break down large molecules into small molecules, resulting in increased COD. In PS systems, the degradation rate increased with increasing temperature; at pH 3.0, as temperature increased from 20 to 90 °C, COD decreased from 648 to 112 mg L−1 (Fig. 3), indicating that heating promotes the formation of SO4.−. Zhao et al. (2010) reported that high temperatures helped the O–O bond in persulfate to break, thereby promoting PS to produce more SO4.− and improving the degradation rate of organic matter.

The ZVI-PS system had an effective COD degradation rate, which was further improved when the temperature increased; at pH 3.0, as temperature increased from 20 to 90 °C, COD decreased from 290 to 183 mg L−1 (Fig.3). As the temperature of the reaction system increases, the internal thermal motion of the reactants accelerates, resulting in an increased likelihood of effective collisions between the particles, and therefore increasing the reaction rate. Zhao et al. (2010) studied the degradation of p-chlorophenol (4-CP) by heating PS and found that the degradation efficiency reached 100% at 60 °C. Pu et al. (2018) observed that temperature had a greater influence on the activation reaction; as the temperature increased, the degradation rate of pollutants increased by nearly 100%. Previous studies by Antoine and Tuqan (2012); Antoine et al. (2012a, 2012b, 2015)) and Suha et al. (2019) proved that high temperature is beneficial to PS activation. However, when the temperature was increased to 90 °C, COD degradation rate of the ZVI-PS system was lower than that of the PS system. This may be because PS is fully activated at 90 °C and produces a large amount of SO4.−, causing a reduction in the COD degradation rate. Zhang et al. 2011proved that ZVI activation is more effective than thermal activation; therefore, ZVI activation is mainly used in practical applications.

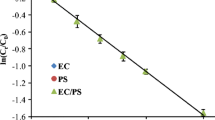

3.5 Change Law and Kinetics of the COD Degradation Process in the ZVI-PS System

During the first (0–10 min) and second (30–180 min) stages of the reaction, COD was 42.54% and 55.04%, respectively; the COD degradation rate slowed over time (Fig. 4). The kinetic rate Eqs. Y = K1X + b (0–10 min) and Y = C + B X + K2X2 (30–180 min). This may be due to free radicals preferentially adding to the pollutants and electrophiles, thereby quickly degrading the target pollutants into small molecules; however, because of their relatively stable performance, some intermediate products may be difficult to further mineralize into CO2 and H2O. A large quantity of free radicals are lost in this process, which slows down the COD degradation rate. In addition, during the PS activation process of ZVI, a large amount of SO4.− is generated in the first stage, which quickly degrades KHP, resulting in less SO4.− in the second stage; however, ZVI will continue to produce Fe2+ and will also consume part of the SO4.−, reducing the second stage reaction rate.

Comparing the kinetic constants K1 and K2, we found that the value of K1 was about 96 times that of K2 (Table 1). According to the data, the Fe2+ concentration is the factor that had the greatest impact on the reaction rate, and the rate in which SO4.− was produced by Fe2+-activated PS was lower than the rate of degradation of organic pollutants by SO4.−, indicating that the SO4.− concentration was also a constraint (Zuo Chuanmei 2012). The study of reaction kinetics can provide a reference for the application of industrial wastewater treatment. TOC removal rate was 23%, indicating that the ZVI-PS system has an effective pollutant mineralization rate (Wang et al. 2014).

4 Conclusions

The experimental results were in line with our expectations: ZVI-activated PS, which produced more sulfate radicals, and the ZVI-PS system effectively degraded organic pollutants in our simulated wastewater. In practical applications, the concentration of industrial wastewater is large, composition of the contents is complicated, and reaction time can be appropriately extended. Therefore, the ZVI-PS activation system has considerable economic value.

References

Antoine, G., Baalbaki, A., Amasha, M., Asmar, R. E., & Tantawi, O. (2017). Contribution of persulfate in UV-254 nm activated systems for complete degradation of chloramphenicol antibiotic in water. Chemical Engineering Journal, 317, 1012–1025.

Antoine, G., Tuqan, A. M., & Kibbi, N. (2012a). Ibuprofen removal by heated persulfate in aqueous solution: a kinetics. Chemical Engineering Journal, 197, 483–492.

Antoine, G., Tuqan, A. M., Kibbi, N., & Geryes, S. (2012b). Methylene blue discoloration by heated persulfate in aqueous solution. Chemical engineering journal, 213, 259–271.

Antoine, G., & Tuqan, A. M. (2012). Oxidation of bisoprolol in heated persulfate/H2O systems: kinetics and products. Chemical Engineering Journal, 183, 162–171.

Antoine, G., Tuqan, A. M., & Kibbi, N. (2015). Naproxen abatement by thermally activated persulfate in aqueous systems. Chemical Engineering Journal, 279, 861–873.

Guan, Y. h., Ma, J., Li, X. C., et al. (2011). Influence of pH on the formation of sulfate and hydroxyl radicals in the UV/peroxymonosulfate system. Environmental Science & Technology, 45(21), 9308–9314.

Guo, X. (2013). Study on advanced treatment of papermaking wastewater based on advanced oxidation of sulfate radicals. China: South China University of Technology.

He, L., Xinjun, J., & JinShiwei, Y. D. (2015). Pretreatment of pharmaceutical chemical wastewater by zero-valent iron-Fenton oxidation. Journal of Hubu University(Natural science edition), 37(5), 407–410.

Long, A., Yang, L., et al. (2014). In-situ chemical oxidation of activated persulfate to repair organic contaminated soil and groundwater. Progress in Chemistry, 26(5), 898–908.

Ma, J. (2014). Fe-g-C3N4/graphitized mesoporous carbon composite as an effective Fenton-like catalyst in a wide pH range. Applied Catalysis B:Environmental, 201(2017), 232–240.

Maya, A., Baalbaki, A., Al Hakim, S., El Asmar, R., & Ghauch, A. (2018a). Degradation of a toxic molecule o-toluidine in industrial effluents using UV254/PS system. Journal of Advanced Oxidation Technologies, 21(1), 20,170,099.

Maya, A., Baalbaki, A., & Ghauch, A. (2018b). A comparative study of the common persulfate activation techniques for the complete degradation of an NSAID: the case of ketoprofen. Chemical Engineering Journal, 350, 395–410.

Ministry of Ecology and Environment of the People’s Republic of China (MEP). (2019). 2018 China Environmental Bulletin. China.

Pu, J., Wan, J., Wang, Y., et al. (2018). Preparation of copper oxide activated potassium peroxymonosulfate with HKUST-1 as template to degrade rhodamine B. Environmental Science, 39(1), 152–159.

Ren, N. (2010). Key to biological treatment technology of high concentration refractory organic industrial wastewater. Water Supply and Drainage, 36(09), 1–3.

Sahar, N., & Ghauch, A. (2016). Ranitidine abatement in chemically activated persulfate systems: assessment of industrial iron waste for sustainable applications. Chemical Engineering Journal, 288, 276–288.

Seok-Young, O. (2010). Degradation of 2,4-dinitrotoluene by persulfate activated with zero-valent iron. Science of the Total Environment, 408, 3464–3468.

Shi, X., Zhu, L., Jinkai, L., et al. (2013). Fenton/engineering application analysis of deep treatment of pulp and paper wastewater by flocculation process. Chinese Journal of Environmental Engineering, 7(9), 3415–3420.

Standard Methods for the Examination of Water and Wastewater. (1998). American Public Health Association. American Water Works Association and Water Environment Federation: Washington.

Su, S. (2013). Study on the degradation of organic pollutants in water based on sulfate radical. China: Jinan University.

Suha, A. H., Baalbaki, A., Tantawi, O., & Ghauch, A. (2019). Chemically and thermally activated persulfate for theophylline degradation and application to pharmaceutical factory effluent. RSC Advances, 9(57), 33,472–33,485.

Suha, A. H., Jaber, S., Eddine, N. Z., Baalbaki, A., & Ghauch, A. (2020). Degradation of theophylline in a UV254/PS system: matrix effect and application to a factory effluent. Chemical Engineering Journal, 380, 122,478.

Tang, H., Junpeng, S., et al. (2015). Study on deep treatment of coking tail water based on sulfate radical oxidation. Industrial Water Treatment, 35(6), 58–60.

Wan, Y., Wan, J., Ma, Y., et al. (2020). Sustaunable synthesis of modulated Fe-MOFs with enhanced catalyst performance for persulfate to degrade organic pollutants. Science of the Total Environment, 701, 134–806.

Wang, Z., Lu, Y., Wu, Z., & Zaiwu, Z. (2014). Study on interference and elimination of persulfate to COD determination. Indusrial Water Treatment, 34(8), 78–81.

Wu Yanlin. (2014). Study on advanced oxidation technology based on hydroxyl radical HO.- and sulfate radical SO4.-. Fudan University. China.

Yan, X. (2012). Study on the treatment of dimethyl phthalate wastewater by sulfate radical. China: Dalian University of Technology.

Yang, D., & Wang, B. (2011). New application of advanced oxidation technology in papermaking wastewater treatment. Zhonghua Paper, 32(03), 40–43.

Yao, M. (2012). Experimental study on advanced treatment of pharmaceutical wastewater and pulp and papermaking wastewater by different Fenton-like methods. China: Zhengzhou University.

Zhang, C., Wan, J., et al. (2011). Study on the oxidation of azo dye AO7 by S2O82−oxidation and zero-valent iron activation. Environmental science, 32(10), 2949–2955.

Zhao, J. (2010). Study on oxidative degradation of chlorophenol by sulfate radical by zero-valent iron/sodium persulfate system. China: Dalian University of Technology.

Zhao, J., Yaobin, Z., et al. (2010). Study on oxidative degradation of 4-CP by sodium persulfate activated by heating and ferrous ions. Chinese Journal of Environmental Science, 31(5), 1233–1238.

Zhao, L. (2015). Experimental study on degradation of quinolones based on advanced oxidation of sulfate radicals. China: Xi’an University of Technology.

Zhou, Z., Deng, W., Yang, Y., et al. (2017). Zero-valent iron activated sodium persulfate to remove arsenic from wastewater (V). Environmental Science 38(11), 4623–4631.

Zue, C. (2012). Study on the treatment of dye wastewater by Fe(II) activated persulfate advanced oxidation technology. China: Chongqing University.

Acknowledgments

Thanks to Yongjie Wan of South China University of Technology; Dr. Zhenyu Wang of Jiangxi Normal University; and Dr. Pei Hu of Wuhan Business School for their help in our work. Also, thanks to Dr. Mo Chen for the support.

Funding

This work has been supported by the National Natural Science Foundation of China (41807452) and Special Fund for Water Pollution Control of Honghu Lake.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interest

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xue, J., Chen, M. & Wang, M. Potassium Hydrogen Phthalate Abatement by Activated Persulfate in ZVI-PS Systems. Water Air Soil Pollut 231, 235 (2020). https://doi.org/10.1007/s11270-020-04621-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-020-04621-y