Abstract

The reduction of disordered and ordered tin oxide monolayers and multilayers on Pt(111) by H2 was studied in situ by ambient pressure X-ray photoelectron spectroscopy. The disordered tin oxide monolayer was highly reactive and reduced by 5.5 × 10−7 Torr H2 at 295 K. However, the ordered monolayer was much less reactive, and nearly inert even in 2.2 Torr H2 at 295 K. Reduction of the tin oxide monolayer occurred only when the sample temperature increased to above 600 K in 5.5 × 10−7 Torr H2 or when the sample temperature was 450 K in 2.2 Torr H2. Disordered and ordered multilayers were found to be much less reactive by comparison to the disordered monolayer film. The reduction activity of these ordered and disordered Sn oxide films varied dramatically (by a factor of 107), demonstrating the structural flexibility of Sn oxides and the key interplay of structure and reactivity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A fundamental understanding of materials by measuring and correlating electronic structure, geometric structure, and chemisorption properties is essential to interpreting and predicting catalytic reactions [1–4]. It is often found that bimetallic catalysts have improved activity, selectivity, and lifetime compared to their pure counterparts due to the ability of the second metal to produce large perturbations in the electronic structure of the surface allowing the fine tuning of the catalyst’s properties for the target reaction [5]. Platinum-tin bimetallic catalysts have a number of important applications in catalysis, including naptha reforming [6, 7], reforming of paraffins [8], hydrogenation/dehydrogenation [9], and also CO oxidation [10–12] and methanol electrooxidation [13–15]. Pt–Sn bimetallic catalysts usually show great improvement in selectivity and lifetime over that of Pt catalysts for these reactions, however the origin of this increase in performance has not been settled. Specifically the role of pure metal and alloy phases, oxidized Sn, and the Pt–SnOx interface in supported Pt–Sn bimetallic catalysts is not clear [16, 17].

In part due to this issue, oxidation and reduction of bulk Pt–Sn alloys has been studied for a long time [18], along with related studies on Pd-Sn [19], in which oxidation at low temperatures (T < 500 K) formed a “quasimetallic” state of Sn with a Sn 3d binding energy less than SnO (Sn2+), and oxidation at higher temperatures leads to an “oxidic” state of SnO2 (Sn4+). In addition, model catalyst studies of the structure and properties of wetting layers and SnO2 crystallites in tin-oxide films on Pt(111) single crystal surfaces have been reported [20–25]. At room temperature Sn oxidation leads to amorphous tin-oxide films, and elevated temperatures (above 800 K) lead to a variety of ordered structures in the oxide monolayer. X-ray photoelectron spectroscopy (XPS) of these tin-oxide films confirmed the existence of three Sn states that have been labeled previously as metallic, ‘‘quasimetallic,’’ and oxidic Sn, and furthermore it was concluded that the ‘‘quasimetallic’’ state results from oxidized Sn that is still alloyed within the Pt surface layer [25].

The reactivity of these SnOx/Pt(111) surfaces for CO oxidation has been investigated [7]. In UHV studies, S. Axnanda et al. found that the CO oxidation rate was strongly dependent on the presence of reduced tin oxide sites at the Pt–SnOx interface. Similar SnOx nanostructures supported on Pt(111) were probed in situ using ambient pressure XPS (APXPS) and high-pressure scanning tunneling microscopy (STM) to follow the oxidation state and morphology of SnOx nanoparticles on the SnOx/Pt(111) surface in the presence of CO gas [26]. It was found that SnOx nanoparticles are highly reduced, with Sn2+ being the dominant oxide species. Under CO gas at 450 K, the Sn2+ peak shows a steady decrease and the Sn0 peak shows a steady increase, with a negligible amount of Sn4+ for lower SnOx coverages. For higher coverages, both Sn4+ and Sno relative peak ratios sharply increase. No change was observed in the SnOx nanoparticle shape or density under 0.1 Torr of CO gas. In related studies, in situ APXPS measurements of colloidal PtSn nanoparticle catalysts found that CO oxidation occurred at the interface of Pt and tin oxide domains formed under reaction conditions [27].

The primary objective for the studies reported herein is to provide a clear correlation between structure and reactivity for specific, well-defined tin-oxide surfaces by synthesis of several oxide nanostructures on the Pt(111) surface and utilizing HPXPS (also known as high-pressure photoelectron spectroscopy, HPPES) to obtain XPS data while the sample is exposed to ambient gas pressures up to 2.5 Torr. The reaction investigated is the reduction of the tin oxide surface by hydrogen, and the range of structures studied range from disordered to ordered surfaces in films from monolayer to multilayer thickness. These results will aid in establishing the role that surface structure plays in catalytic reactivity and will help elucidate the role played by Pt in affecting Sn reduction.

2 Experimental Methods

All of the experiments described in this paper were performed in the high pressure photoemission spectroscopy (HPPES) system operated at Beamline 11.0.2 of the advanced light source (ALS) at Lawrence Berkeley National Laboratory (LBL) [28], which is equipped with a differentially pumped electrostatic energy analyzer, low-energy electron diffraction (LEED) optics, an ion sputtering gun for sample cleaning, leak valves and gas dosing lines, and a Sn evaporation doser. The Pt(111) single crystal sample was heated using a ceramic heater that was situated directly beneath the sample. The base pressure in the system was 2 × 10−10 Torr. XPS data were obtained at an X-ray photon energy of 735 eV, with a spot size less than 1 mm and resolution of 0.2–0.4 eV, and no beam damage was observed in control experiments conducted during these investigations.

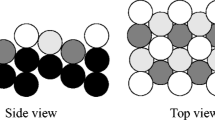

The Pt(111) single crystal was prepared by a standard procedure consisting of cycles of 500-eV Ar+ sputtering, annealing at 1000 K in 2 × 10−7 Torr O2, and finally annealing at 1100 K in UHV. The cleanliness of the sample surface was monitored by XPS. The sample temperature was monitored by a chromel/alumel thermocouple spot welded directly to the side of the Pt(111) crystal. Tin oxide monolayers were prepared using procedures described previously [25]. A (√3 × √3)R30°-Sn/Pt(111) surface alloy was created by depositing 1-monolayer (ML) Sn on the Pt(111) crystal at 300 K and subsequently annealing to 1000 K for 10 s [29]. This surface was then oxidized by exposure to 4 × 10−8 Torr NO2 for 40 s at a sample temperature of 400 K. This temperature was chosen to avoid NO adsorption on the surface. No nitrogen contamination of the surface was subsequently detected in XPS. This structure is denoted as the “disordered tin-oxide monolayer”, which showed a diffuse LEED pattern with no diffraction spots [25]. Annealing this surface in vacuum to 860 K for 1 min resulted in a (4 × 4) LEED pattern, corresponding to what we denote here as the “ordered tin-oxide monolayer” structure [25]. Oxidation and annealing of the (√3 × √3)R30°-Sn/Pt(111) surface alloy 3–5 times resulted in a (5 × 5) LEED pattern, which results from ordered “nanodots” of SnOx at the Pt surface. [22] The 2–3 layer disordered oxide film denoted as the “disordered tin-oxide multilayer” was produced by depositing 3-ML Sn in an ambient background gas of NO2 on the (√3 × √3)R30°-Sn/Pt(111) surface alloy at 600 K. Annealing this oxide film in vacuum at 900 K for 30 s caused the formation of SnO2 nanocrystals and an interface layer with a (4 × 4) LEED pattern, which we will denote herein as the “ordered tin-oxide multilayer” [25].

3 Results and Discussion

3.1 Disordered Tin Oxide Monolayer

The XPS spectrum of a disordered tin-oxide monolayer, as prepared by oxidation of the (√3 × √3)R30°-Sn/Pt(111) surface alloy at 400 K using NO2, is shown in Fig. 1. Three components were observed in Sn 3d5/2 spectra: fully oxidized Sn4+ at 486.3 eV, quasimetallic Sn at 485.1 eV, and metallic, alloyed Sno at 484.6 eV. The assignment of Sn oxidation states corresponding to these peaks has been discussed in previous work [25, 26]. These data show that the disordered tin oxide monolayer is formed by an oxide comprised of nearly all quasimetallic Sn, a state in which Sn is in an oxidation state somewhat below Sn2+ and proposed to be Sn that is alloyed with Pt at the surface, but has a Sn–O bond [25]. Consistent with the Sn core levels, Fig. 1 also shows two components for the O 1s spectra: fully oxidized SnO2 at 530.8 eV and quasimetallic SnO at 529.5 eV.

Sn 3d5/2 (left) and O 1s (right) core-level spectra from a disordered tin-oxide monolayer on Pt(111) at 295 K. Decomposition of the curves into principal components indicates the presence of primarily a strongly reduced type of tin oxide phase, previously referred to as “quasimetallic” Sn, [25], with small amounts of a more oxidized phase similar to SnO2, along with a trace of reduced, alloyed Sn

H2 reduction of the disordered tin oxide monolayer at 295 K was investigated by collecting both Sn 3d5/2 and O 1s spectra alternately and continuously during H2 gas exposure, as shown in Fig. 2. Upon exposure of 5.5 × 10−7 Torr H2 to the film, the Sn 3d5/2 peak at 485.1 eV was immediately reduced in height and broadened to lower binding energy. The Sn peak eventually evolved to a narrower peak at 484.6 eV over the course of less than 10 min. This shift in the Sn 3d spectra from 485.1 to 484.6 eV represents a quasimetallic to metallic transition of Sn on the Pt(111) surface. During this reduction process, the O 1s peak decreased in size steadily, but with the quasimetallic component at 529.5 eV more reactive, reducing more quickly, than the SnO2 component at 530.8 eV. No O 1s signals due to OH or H2O were detected. An isosbestic point was observed in the XPS spectra, indicating a simple equilibrium between these two species in each case. We note that the disordered oxide monolayer film made from an initial (2 × 2)-Sn/Pt(111) alloy showed a similar reactivity, i.e., was readily reducible at 295 K (data not shown).

Sequence of Sn 3d5/2 (left) and O 1s (right) XPS spectra obtained during reduction of a disordered oxide monolayer using 5.5 × 10−7 Torr H2 at 295 K. Top bolded curves were obtained prior to H2 exposure. Bottom bolded curves were obtained after H2 exposure of 571s. Other curves were collected after H2 exposure of 10, 57, 113, 170, 227, 284, and 340 s, respectively

Reduction using the same H2 pressure (5.5 × 10−7 Torr) was also measured at sample temperatures of 350, 400, and 454 K (not shown). Higher temperatures led to a faster reduction rate. The activation energy of reduction was found to be 8.6 kJ/mol, which was derived from an Arrhenius plot of this data (not shown). This small activation energy indicates a very reactive and easily reducible SnOx surface at room temperature.

3.2 Ordered Oxide Monolayers

As reported previously [25], LEED and STM show a disordered oxide film below 800 K. Annealing in vacuum orders the tin oxide adlayer such that LEED spots appear at 840 K and eventually forms a “diamond necklace” pattern and subsequently a (4x4) pattern with increasing temperature. This transition from a disordered monolayer to an ordered monolayer causes the Sn 3d5/2 peak to shift (not shown) from 485.0 to 484.8 eV, which indicates that Sn was reduced to some degree during the transition. Concomitantly, the O 1s peak shifted from 529.5 to 529.3 eV and decreased in size. Some oxygen desorbs during the annealing, but this causes only small changes in XPS. Larger changes in XPS, and huge changes in the reactivity of the film, are observed for the formation of the specific ordered monolayer structures discussed below, and thus are associated with the loss of highly reactive species or sites during annealing.

Specific reduction experiments were carried out on the (4 × 4) ordered oxide monolayer, which was prepared by annealing the disordered monolayer film at 860 K for 1 min. No reduction occurred upon exposure to 5.5 × 10−7 Torr H2 at 295 K, and the ordered monolayer was inert even in 2.2 Torr H2 at 295 K. Reduction of the SnOx film happened only when the sample temperature increased to 450 K in 2.2 Torr H2, as shown in Fig. 3 (or when the sample temperature reached to 630 K in 5.5 × 10−7 Torr H2 as shown later in Fig. 4). In Fig. 3, the top curves for Sn 3d5/2 and O 1s spectra were collected at 530 K in 5.5 × 10−7 Torr H2, and these showed no change compared to those prior to H2 exposure. Curve fitting shows that this ordered monolayer has an increased contribution from metallic tin, as described above. The bottom panels show that reduction in 2.2 Torr H2 carried out over a 15 min period at a sample temperature of 450 K caused a shift in the Sn 3d5/2 peak from 484.8 to 484.6 eV and eliminated the O 1s peak at 529.5 eV. Reduction leads to formation of fully reduced metallic Sn species, however, the appearance of a shoulder around 484.0 eV may indicate that there are small binding energy differences between different forms of this Sn, for example surface and subsurface alloyed Sn as well as non-alloyed Sn.

Top panels Sn 3d5/2 (left) and O 1s (right) core-level spectra from an ordered tin-oxide monolayer on Pt(111) obtained by annealing the disordered film at 860 K for 1 min. Spectra were obtained at 530 K. Decomposition of the curves into principal components indicates a large increase in the contribution of metallic Sn as well as the presence of a strongly reduced type of tin oxide phase, previously referred to as “quasimetallic” Sn, [25], with little SnO2 phase, compared to that in Fig. 1. Bottom panels Sequences of Sn 3d5/2 and O 1s core-level spectra obtained during reduction of this ordered tin oxide monolayer on Pt(111) at 450 K in the presence of 2.2 Torr H2. The top bolded curves were obtained at a temperature of 530 K. Other curves shown were obtained after H2 exposures of 57, 113, 170, and 227 s

In Fig. 4, the curves for Sn 3d5/2 and O 1s spectra were collected at 295 K in 5.5 × 10−7 Torr H2, and these showed no change compared to those prior to H2 exposure. Reduction did occur when the sample temperature was increased to ~630 K. During reduction over a 5 min period, the Sn 3d5/2 peak shifted from 484.8 eV to 484.6 eV, and the O 1s peak at 529.3 eV decreased in intensity, i.e. the amount of metallic tin increased and the amount of quasimetallic tin decreased. Following reduction under these conditions, some small amount of SnO2 and OH groups remain at the surface.

A different ordered oxide monolayer can be formed. Upon oxidation and annealing of the (√3 × √3)R30°-Sn/Pt(111) alloy 3–5 times, a (5 × 5) LEED pattern results. Previous STM studies reveal that oxidation of the surface forms dense, regular, oxide-island arrays, i.e. ordered “nanodots” of SnOx at the Pt surface [22]. There are large interfacial areas available for the oxide nanodots, and the large crevices and packing defects may give reactants access to the underlying Pt and/or Pt–Sn alloy surface. The top panels in Fig. 5 shows the core level spectra obtained from the (5 × 5) ordered tin-oxide monolayer surface prior to H2 exposure. The Sn 3d5/2 spectrum has peaks at 484.5 and 486.2 eV and the O 1s spectrum has a peak at 529.9 eV. These spectra can be decomposed into peaks that indicate the surface contains a substantial amount of SnO2, less of the quasimetallic tin oxide state, and a larger component of reduced Sn compared to the (4 × 4) structure investigated above. The bottom panels show the spectra obtained during reduction at 520 K using 2.1 Torr H2 over a 10 min period. These conditions were sufficient to fully reduce the surface, eliminating any oxidized Sn species and removing any OH species. The (5 × 5) “nanodot” surface structure is thus less reactive than that of the (4 × 4) monolayer (requiring 2.1 Torr H2 at 520 K for 10 min vs. 2.2 Torr H2 at 450 K for 5 min) and this difference can be ascribed at least in part to the increased amount of SnO2 present for the (5 × 5) monolayer film. Importantly, both of the ordered tin-oxide monolayers were found to be dramatically less reactive than the disordered monolayer.

Top panels: Sn 3d5/2 (left) and O 1s (right) core-level spectra from a (5 × 5) ordered oxide monolayer on Pt(111) at 295 K. Decomposition of the curves into principal components indicates the presence of primarily a strongly reduced type of tin oxide phase, previously referred to as “metallic” Sn, along with a large amount of reduced, alloyed Sn. Bottom panels Sequence of Sn 3d5/2 and O 1s core-level spectra obtained during reduction of a (5 × 5) ordered oxide monolayer using 2.1 Torr H2. The top bold curves were obtained at 295 K, and the curves below were obtained sequentially during reduction at 520 K at 57, 113, 170, and 227 s, respectively

3.3 Disordered 2–3 Layer Oxide Film

A disordered oxide multilayer film was prepared by depositing 3-ML Sn on the Pt(111) crystal at 600 K in a background of NO2. Initially, prior to reduction, Fig. 6 (top left) and (top right) shows that two components are present at 486.1 and 485.3 eV for the Sn 3d5/2 peaks and 529.6 and 530.7 eV for the O 1s peaks. This represents a nearly fully oxidized amorphous SnO2 film, where the oxide layer is thick enough to block photoemission from the metallic substrate. This multilayer was much less reactive than the disordered oxide monolayer film. Reduction of this film occurred readily in 2.5 Torr H2 only when the sample temperature was increased to 625 K. Figure 6(bottom left) and (bottom right) provides core-level spectra obtained during reduction of this disordered oxide multilayer film during exposure to 2.5 Torr H2 at 625 K obtained over a 10 min period. As shown in Fig. 6(bottom left), the Sn 3d5/2 peak decreased in intensity and shifted to lower binding energy during the reduction process. The O 1s peak, as shown in Fig. 6(bottom right), decreased in intensity at a constant peak position during reduction under these conditions.

Top panels Sn 3d5/2 (left) and O 1s (right) core-level spectra from a disordered oxide multilayer film on Pt(111) at 295 K. Bottom panels Sequence of Sn 3d5/2 and O 1s core-level spectra obtained during reduction of a disordered oxide multilayer film using 2.5 Torr H2. The top bold curves were obtained at 295 K, and the subsequent curves were obtained sequentially during the reduction at 625 K

3.4 Ordered 2–3 Layer Oxide Film

Upon annealing a disordered oxide multilayer (as prepared above) to 900 K for 30 s, a 2–3 layer oxide film giving a (4 × 4) LEED pattern was produced. Core-level spectra for this film prior to reduction are shown in Fig. 7(top left) and (top right), along with an STM image obtained under similar conditions by Batzill et al. [21, 22] to give a qualitative picture of the film. The image displayed protrusions separated by twice the Pt(111) surface lattice constant, where every second protrusion in every second row was missing. These protrusions were attributed to SnO ‘pseudomolecules’. The Sn 3d5/2 core level spectr has a peak at 486.3 eV due to the SnO2 crystallites, a peak at 484.6 eV due to reduced Sn species in the (4 × 4) adlayer lattice and alloyed Sn, and a very small peak at 485.1 eV. The O 1s peak can be decomposed into two components at 530.8 eV also indicates a large signal from the SnO2 crystallites and the peak at 529.9 eV indicates a smaller contribution from the reduced oxide species in the (4 × 4) adlayer lattice. Both the Sn 3d5/2 peak at 486.3 eV and the O 1s peak at 530.8 eV have slightly higher binding energies than that for the disordered multilayer perhaps because this annealing treatment forms fully oxidized SnO2 crystals.

Top panels Sn 3d5/2 (left) and O 1s (right) core-level spectra from a (4 × 4) ordered oxide multilayer film on Pt(111) at 295 K. Bottom panels Sequence of Sn 3d5/2 and O 1s core-level spectra obtained during reduction of a (4 × 4) ordered oxide multilayer film using 1.9 Torr H2. The top bold curves were obtained at 295 K, and the curves below were obtained sequentially during reduction at 600 K

This ordered multilayer film was more reactive than the disordered multilayer film by about a factor of two. Figure 7(bottom left) and (bottom right) provides APXPS spectra obtained during reduction of this (4 × 4) ordered multilayer oxide film at 600 K during exposure to 1.9 Torr H2 obtained over a 6 min period. During reduction of this film, the Sn 3d5/2 peak at 486.3 disappears, leaving a single peak at 484.6, as shown in Fig. 7(bottom left). The O 1s peak at 530.8 eV was eliminated without any shift.

3.5 Comparison of Tin Oxide Films on Pt(111) Surfaces

APXPS spectra of hydrogen reduction of tin oxides on Pt(111) show that the disordered monolayer is 107 times more reactive than the ordered (4 × 4) monolayer produced by annealing in vacuum prior to reduction. As we discussed, annealing in vacuum from 328 to 872 K to enable the transition from a disordered to ordered tin oxide monolayer causes some oxygen to be desorbed during the annealing, but this reduction causes only small changes in the Sn 3d5/2 and O 1s XPS spectra. Thus, determination of the origin of this high reactivity awaits further study, but we can conjecture that it is due to the presence of defects and vacancies in the disordered tin oxide film that are very reactive species or special sites, and these are removed during the formation of ordered monolayer produced at high temperatures. Consistent with such an explanation is the lack of evidence for a long induction time observed for well-ordered oxide films in many cases (except for the film in Fig. 7, which contains well-ordered SnO2 nanocrystalllites). Further oxidation and annealing treatments that convert the ordered (4 × 4) oxide monolayer can produce an ordered (5 × 5) nanodot monolayer structure, but this was found to be less reactive than the (4 × 4) monolayer. This also might be expected due to the higher concentration of fully oxidized SnO2 component.

The disordered monolayer tin oxide film is also dramatically more reactive for hydrogen reduction than the disordered multilayer tin oxide films. Thus, it is not only the disordered nature of the tin oxide film that controls reactivity. This higher reactivity of the disordered monolayer tin oxide film compared to disordered multilayer films can be attributed to the reduced Sn species that characterize the “quasimetallic” nature of both the ordered and disordered monolayers. Electronic effects due to bonding at the interface are expected since the Pt–Sn bond involves charge transfer from Sn to Pt atoms and rehybridization in Pt atoms that localize electrons in the region between the metal centers [30]. The large decrease in reactivity that occurs after growth of a disordered tin oxide multilayer film on top of the disordered monolayer can be attributed to formation of a tin oxide film that is composed much more extensively of SnO2 and a reduced influence of the reactive quasimetallic Sn.

The mechanism for reducing these oxide films by hydrogen involves several elementary steps, including importantly hydrogen dissociation, water formation, and water desorption, but the detailed reaction mechanism and the rate determining step is not known and could easily depend on the oxide film structure. A better understanding of this chemistry and the rates for the elementary steps involved would be helpful to explain the origin of the large changes in reactivity we observed. For example, it would be important to understand the ability of each of these film structures to dissociate hydrogen. This information is not known and will need to come from future additional studies.

4 Conclusions

We have shown that even for this model study using ultrathin films of tin oxide on a Pt(111) single crystal substrate, the Pt–SnOx interface is characterized by a variety of structures that illustrate the complexity of metal/oxide interfaces and difficulties in modeling and predicting the structure and reactivity of such interfaces. These Sn-oxide nanostructures have different chemical and electronic properties that may be important to existing devices/catalysts and future developments of heterogeneous catalysts, electrocatalysts, and sensors. We find enormous sensitivity of the reduction of these tin oxide films on the detailed chemical nature and structure of the films. Such sensitivity can alter the thermal reduction temperature by 300 K and the reducibility in H2 by many orders of magnitude. For example, a disordered tin oxide monolayer is reduced at 300 K by 6 × 10−7 Torr H2 in 10 min, while the ordered (4 × 4) monolayer is only reduced at 450 K in 2.2 Torr H2 in 5 min, more than a factor of 107 difference in reactivity.

References

Somorjai GA, Li Y (2010) Introduction to surface chemistry and catalysis. Wiley, Hoboken

Yu W, Porosoff M, Chen J (2012) Review of Pt-based bimetallic catalysts: from model surfaces to supported catalysts. Chem Rev 112:5780–5817

Kraya LY, Kraya R (2013) Polarization dependence of molecular adsorption on ferroelectrics. Acta Crystallogr Sect B B69:105–109

Zhou W, An W, Su D, Palermo R, Liu P, White M, Adzic R (2012) Electrooxidation of methanol at SnOx-Pt interface: a tunable activity of tin oxide nanoparticles. J Phys Chem Lett 3:3286–3290

Rodriguez J, Goodman D (1992) The nature of the metal-metal bond in bimetallic surfaces. Science 257(5072):897–903

Rahimpour M, Jafari M, Iranshahi D (2013) Progress in catalytic naptha reforming process: a review. Appl Energy 109:79–93

Axnanda S, Zhou WP, White MC (2012) CO oxidation on nanostructured SnOx/Pt(111) surfaces: unique properties of reduced SnOx. Phys Chem Chem Phys 14:10207–10214

Bentahar FZ, Candy JP, Basset JM, Le Peltier F, Didillon B (2001) Surface organometallic chemistry on metal in water: chemical modification of platinum catalyst surface reaction with hydrosoluble organotin complexes: application to the selective dehydrogenation of isobutane to isobutane. Catal Today 66(2–4):303–308

Cortright RD, Dumesic JA (1995) Effects of potassium on silica-supported Pt and Pt/Sn catalysts for isobutane dehydrogenation. J Catal 157:576

Schubert MM, Kahlich MJ, Feldmeyer G, Huttner M, Hackenberg S, Gasteiger HA, Behm RJ (2001) Bimetallic Pt-Sn catalyst for selective CO oxidation in H2-rich gases at low temperature. Phys Chem Chem Phys 3:1123–1131

Morimoto Y, Yeager E (1998) CO oxidation on smooth and high area Pt, Pt-Ru, and Pt-Sn electrodes. J Electroanal Chem 441(1–2):77–81

Hayden B, Rendall M, South O (2003) Electro-oxidation of carbon monoxide on well-ordered Pt(111)/Sn surface alloys. J Am Chem Soc 125(25):7738–7742

Gokagac G, Kennedy B, Cashion J, Brown LJ (1993) Characterization of carbon supported Pt-Sn bimetallic catalysts for the electrochemical oxidation of methanol. J Chem Soc Faraday Trans 89:151–157

Arico AS, Antonucci V, Giordano N (1994) Methanol oxidation on carbon-supported platinum-tim electrodes in sulfuric acid. J Power Sources 50(3):295–309

Knani S, Chirchi L, Baranton S, Napporn T, Leger J-M, Ghorbel A (2014) A methanol—tolerant carbon supported Pt-Sn cathode catalysts. Int J Hydrogen Energy 39(17):9070–9079

Antos GJ, Aitani A (2004) Catalytic naptha reforming, revised and expanded. CRC Press, Boca Raton

Vigne F, Haubrich J, Loffreda D, Sautet P, Delbecq F (2010) Highly selective hydrogenatio of butadiene on Pt/Sn alloy elucidated by first-principles calculations. J Catal 275(1):129–139

Asbury DA, Hoflund GB (1988) The influence of annealing and low-pressure oxygen exposure on a sputtered Pt3Sn alloy surface. Surf Sci 199:552–566

Rotermund HH, Penka V, De Louise LA, Brundle CR (1987) Oxygen interaction with Pd3Sn: X-ray photoelectron spectroscopy and secondary ion mass spectrometry. J Vac Sci Technol A 5:1198

Saliba N, Tsai Y, Koel B (1999) Oxidation of ordered Sn/Pt(111) surface alloys and thermal stability of the oxides formed. J Phys Chem B 103:1532–1541

Batzill M, Beck D, Koel B (2001) Structure of monolayer tin oxide films on Pt(111) formed using NO2 as an efficient oxidant. Phys Rev B 64:245402

Batzill M, Beck DE, Koel BE (2001) Self-organized molecular-sized hexagonally ordered SnOx nanodot superlattices on Pt(111). Appl Phys Lett 78:2766–2768

Batzill M, Beck D, Jerdev D, Koel B (2001) Tin-oxide overlayer formation by oxidation of Pt-Sn(111) surface alloys. J Vac Sci Technol A 4:1953

Batzill M, Beck D, Koel B (2004) Metastable surface structures of the bimetallic Sn/Pt(100) system. Surf Sci 558:35–48

Batzill M, Kim J, Beck D, Koel B (2004) Epitaxial growth of tin oxide on Pt(111): structure and properties of wetting layers and SnO2 crystallites. Phys Rev B 69:165403

Axnanda S, Zhu Z, Zhou W, Mao B, Chang R, Rani S, Crumlin E, Somorjai G, Liu Z (2014) In situ characterizations of nanostructured SnOx/Pt(111) surfaces using ambient-pressure XPS (APXPS) and high-pressure scanning tunneling microscopy (HPSTM). J Phys Chem C 118:1935–1943

Michalak W, Krier J, Alayoglu S, Shin J, An K, Komvopoulos K, Liu Z, Somorjai G (2013) CO oxidation on PtSn nanoparticle catalysts occurs at the interface of Pt and Sn oxide domains formed under reaction conditions. J Catal 312:17–25

Bluhm H, Andersson K, Araki T, Benzerara K, Brown GE, Dynes JJ, Ghosal S, Gilles MK, Hansen HC, Hemminger JC (2006) Soft X-ray microscopy and spectroscopy at the molecular environmental science beamline at the advanced light source. J Electron Spectrosc Relat Phenom 150:86–104

Paffett MT, Windham RG (1989) Surface modification of Pt(111) by Sn adatoms: evidence for the formation of ordered overlayers and the surface alloys. Surf Sci 208:34–54

Rodriguez JA, Jirsak T, Chaturvedi S, Hrbek J (1998) Surface chemistry of SnO2 on Sn and Sn/Pt(111) alloys: effects of metal-metal bonding on reactivity towards sulfur. J Am Chem Soc 120:11149–11157

Acknowledgments

BEK acknowledges that this material is based upon work supported by the National Science Foundation under Grant No. CBET-1264737. The authors would like to acknowledge H. Bluhm at LBL National Lab for his contribution to the experimental section of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kraya, L.Y., Liu, G.F., He, X. et al. Structures and Reactivities of Tin Oxide on Pt(111) Studied by Ambient Pressure X-ray Photoelectron Spectroscopy (APXPS). Top Catal 59, 497–505 (2016). https://doi.org/10.1007/s11244-015-0522-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-015-0522-6