Abstract

Using high resolution and ambient pressure X-ray photoelectron spectroscopy we show that the catalytically active FeO\(_{2}\) trilayer films grown on Pt(111) are very active for water dissociation, in contrast to inert FeO(111) bilayer films. The FeO\(_{2}\) trilayer is so active for water dissociation that it becomes hydroxylated upon formation, regardless of the applied preparation method. FeO\(_{2}\) trilayers were grown by oxidation of FeO(111) bilayer films either with molecular oxygen in the mbar regime, or by NO\(_2\) and atomic oxygen exposures, respectively, in the ultrahigh vacuum regime. Because it was impossible to prepare clean FeO\(_{2}\) without any hydroxyls we propose that catalytically highly active FeO\(_{2}\) trilayer films are generally hydroxylated. In addition, we provide spectroscopic fingerprints both for Pt(111)-supported FeO(111) and FeO\(_2\) films that can serve as reference for future in situ studies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

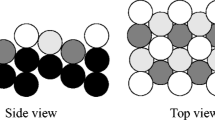

The ultrathin FeO(111) bilayer film grown on Pt(111) is one of best studied hetero-oxide hybrid system that couples a subnanometer sized oxide phase to a metal surface [1]. It was first grown and characterized in 1988 by Vurens et al. [2] Since then the FeO(111) bilayer film on Pt(111) has been characterized in great detail using the combination of scanning tunneling microcopy (STM) and low energy electron diffraction (LEED) [3–7], X-ray photoelectron diffraction [8], and density functional theory (DFT) [7, 9, 10]. From these studies it is known that the FeO(111) bilayer consist of hexagonal closed packed O- and Fe-layers with the O-layer at the surface and the Fe-layer sandwiched between the surface O-layer and the Pt(111) support. Due to a small misfit angle (0.6\(^{\circ }\)) between the FeO(111) film and the Pt(111) support and the lattice mismatch between the FeO lattice (\(\sim\) 3.1 Å) and the Pt(111) substrate (2.77 Å) a characteristic moiré pattern with a \(\sim\) 25 Å periodicity is formed.

Numerous interesting properties of the FeO(111) films have been discovered in various studies that focused on: (i) the reduction of the film by atomic hydrogen [11–13]; (ii) reduction of the film by CO [14]; (iii) nanopattering using the films moiré structure [15–18]; (iv) adsorption of molecules on the film [5, 19–22]; and (v) catalytic activity of the film [23, 24].

One of the reactivity studies published by Sun et al. in 2009 [23] revealed that an oxygen-rich FeO\(_x\) (1\(~<~\)x\(~<~\)2) trilayer phase is formed when FeO(111) bilayer films are exposed to O2 pressures in the mbar regime at elevated temperatures. The formation of this oxygen-rich FeO\(_x\) phase at reaction conditions was linked to the enhanced CO oxidation activity observed for ultrathin FeO(111) as compared to clean Pt(111) and nm-thick Fe\(_3\)O\(_4\)(111). In the following, the O-enriched FeO\(_x\) phase will be referred to as FeO\(_2\) trilayer. Since its discovery, the FeO\(_{2}\) trilayer phase has been studied extensively by a variety of techniques, including STM [25–28], Auger electron spectroscopy (AES) [25], and DFT [26, 29, 30]. In a study by Giordano et al. [10] it was shown that the transition from FeO(111) to FeO\(_2\) strongly depends on the specific region, leading to oxygen enrichment in specific areas of the FeO(111) moiré unit cell. In addition, it was shown that the FeO\(_2\) trilayer islands have a O–Fe–O–Pt\(_{substrate}\) stacking. Compared with the FeO(111) bilayer film, the FeO\(_2\) islands thus contain O atoms at the interface between the oxide film and the Pt(111) substrate. Finally, high resolution STM studies revealed a \((\sqrt{3}\times \sqrt{3})R30^{\circ }\) superstructure on the FeO\(_2\) trilayer islands. On the basis of DFT calculations it was suggested that this superstructure originates from a energetically preferred location of O-interphase atoms atop the Pt atoms of the substrate [10]. In two more recent studies by Giordano et al. [29, 30] theoretical core level shifts (CLS’s), work function changes between FeO(111) and FeO\(_2\), and OH stretching frequencies were reported and the mapping of the local activity at different sites showed that oxygen easily can be adsorbed and released at the FeO(111)/FeO\(_2\) boundaries, which might explain the high CO oxidation activity. Studies by Lewandowski et al. [27] showed (i) that the FeO\(_2\)(111) phase is also formed on Pt particles supported on Fe\(_3\)O\(_4\)(111) upon annealing in O\(_2\) in the mbar pressure range, and (ii) that CO\(_2\) formation occurs via a Mars-van Krevelen mechanism, where CO reacts with the FeO\(_2\) trilayer film, thereby reducing it, while O\(_2\) oxidizes FeO back to FeO\(_2\) [28]. This proposed mechanism by Lewandowski et al. fits well with the reaction mechanism proposed in the DFT study by Giordano et al. [30] All the studies addressing the FeO\(_2\) trilayer mentioned above considered the formation of FeO\(_2\) by O\(_2\) and its reduction by CO. However, a recent study by Ringleb et al. demonstrates that hydroxylated FeO\(_2\) can be formed from FeO(111) if H\(_2\)O and O\(_2\) are dosed simultaneously at near ambient pressure, leading to a H-O-Fe-O-Pt\(_{substrate}\) structural motive [31].

Indeed, a lot of efforts have been devoted in determining the topology, local electronic structure, and reactive sites of FeO\(_2\) trilayer films using STM and DFT. However, spectroscopic information on the electronic structure of FeO\(_2\) films is still lacking. Solely the study by Ringleb et al. [31] reports on X-ray photoelectron spectroscopy (XPS) data, but in this study the FeO\(_2\) surface was intentionally hydroxylated, as it was produced by co-dosing of O\(_2\) and H\(_2\)O onto a FeO(111) bilayer film.

Here we present a spectroscopic investigation of the FeO\(_2\) trilayer film grown on Pt(111). We report XPS and X-ray absorption spectroscopy (XAS) fingerprints for bilayer FeO(111) and trilayer FeO\(_2\). The FeO\(_2\) trilayer films were formed by oxidizing FeO(111) either with molecular oxygen in the mbar regime or with NO\(_2\) and atomic oxygen, respectively, dosed in the ultrahigh vacuum (UHV) regime. Independent of the preparation method we observe spectroscopic evidence for a significant degree of hydroxylation on the FeO\(_2\) trilayer films, and our STM data are fully consistent with this conclusion. Ambient pressure X-ray photolectron spectroscopy (APXPS) measurements conducted while oxidizing FeO(111) to FeO\(_2\) further reveals that the onset and degree of hydroxylation correlate with the coverage of FeO\(_2\) trilayer islands. Altogether, our observations are strong evidence for an astonishing high activity of the FeO\(_2\) trilayer towards water dissociation. Furthermore, our experimental data suggest that Pt(111)-supported FeO\(_2\) trilayer films are generally hydroxylated, regardless of the applied preparation recipe.

2 Experimental

High resolution X-ray photoelectron spectroscopy (HRXPS) and XAS in UHV were performed at beamline I311 of the MAX IV Laboratory in Lund, Sweden. The beamline as well as the endstation are described in detail elsewhere [32]. High-pressure experiments in the mbar range were performed at the APXPS endstation of beamline I511. The APXPS instrument is capable of performing in situ experiments in pressures up to \(\sim\)5 mbar in a dedicated reaction cell inside the main analysis chamber. A description of the instrument and the beamline can be found in refs. [33] and [34], respectively.

In the HRXPS and the APXPS experiments, the Pt(111) crystal was cleaned by repeated cycles of Ar\(^+\) sputtering followed by annealing to 870 K in 1 \(\times\) \(10^{-7}\) mbar O\(_2\). After annealing the crystal was subsequently flashed to 970 K. The cleanness of the crystal was probed by LEED and XPS. To grow the FeO(111) bilayer film, Fe was deposited onto Pt(111) with an e-beam evaporator. The deposited Fe was oxidized by heating the crystal to 870 K in \(1\cdot 10^{-6}\) mbar O\(_2\). This procedure is known to result in a FeO(111) bilayer film, which grows layer-by-layer up to a coverage of about 2.5 ML [4]. The coverage of the FeO film in the XPS experiments was calibrated by saturating the surface with CO at room temperature. As CO only binds to the exposed Pt surface at room temperature the intensity of the C 1s and O 1s signal can be used directly to follow the growth of the film. By cycles of Fe deposition (submonolayer amounts) at room temperature and subsequent oxidation, we tuned the coverage of FeO to the point where the C 1s signal disappeared. We define a monolayer (ML) as a complete coverage of a bilayer FeO(111) film, noting that the FeO(111) lattice is expanded by about 12 % [13] resulting in 0.8 layer coverage with respect to the Pt(111) surface density. All sample temperatures given in our work are measured with a type K thermocouple spot-welded to the edge of the Pt(111) single crystal surface. In the APXPS experiments we used O\(_2\) (99.9999 % purity) without further purification. The base pressure of the APXPS chamber was \(\sim\)5 \(\times\) 10\(^{-10}\) mbar. In the HRXPS measurements performed at beamline I311 we used NO\(_2\) (99.5 % purity) for the oxidation. The NO\(_2\) was dosed at a maximum pressure of 1 \(\times\) \(10^{-7}\) mbar at room temperature. No filaments were on during NO\(_2\) exposure and a cold cathode gauge was used to measure the pressure when NO\(_2\) was dosed. The base pressure of the HRXPS setup was \(\sim\)1 \(\times\) 10\(^{-10}\) mbar. The XPS spectra shown in this paper are calibrated to the Fermi level. All O 1s spectra were acquired using a photon energy of 650 eV. In our experiments, this yields a resolution of 580, 950 and 250 meV for UHV, mbar and NO\(_2\) experiments, respectively. The Pt 4f and Fe 3p/Pt 5p regions were recorded with a photon energy of 190 eV, yielding corresponding resolutions of 110 meV for the Pt 4f and 330 meV for the Fe 3p/Pt 5p levels. Polynomial backgrounds were subtracted from all spectra before or during the curve fitting. For Pt 4f spectra Doniach-Šunjić (DS) functions convoluted with Gaussians line shapes were used for the curve fitting. O 1s spectra were deconvoluted using asymmetric Voigt functions. Due to the open-shell nature of Fe, fitting of Fe 3p features is non-trivial. For simplicity we used three DS components convoluted with Gaussians for curve fitting of the Fe 3p features.

The Fe L-edge XAS spectra were recorded in normal incidence in Auger yield mode by collecting electrons with a kinetic energies between 540 and 550 eV using a SES-200 analyzer. The photon energy of the XAS spectra was calibrated by measuring the Pt 4f peak using first and second order light from the monochromator.

STM measurements were conducted in a separate UHV system in Aarhus with a base pressure of \(\sim\)2 \(\times\) 10\(^{-10}\) mbar, using a home-built Aarhus STM operated at room temperature with a mechanically cut Pt–Ir tip. Preparation of the Pt(111) crystal and growth of the FeO film were conducted in the same way as for the spectroscopy measurements. To form the FeO\(_2\) trilayer, the bilayer FeO(111) film was exposed to atomic oxygen at 385 K using a thermal atom source (Oxford Applied Research TC-50) operated at a power of 54 W with a chamber background O\(_2\) pressure of 2 \(\times\) 10\(^{-8}\) mbar. Exposure for 8 min under these conditions followed by flash annealing to 500 K was found to produce a film that was nearly saturated with FeO\(_2\) trilayer islands, similar to a previous study of the oxidation of FeO/Pd(111) [35] conducted using the same experimental system.

3 Results and Discussion

The spectroscopic and structural properties of Pt(111)-supported FeO(111) bilayer films are well documented in the literature [5, 13]. Nevertheless, to facilitate a direct comparison of the XPS data acquired on FeO\(_2\) we first show the spectra of clean Pt(111) surface (top Fig. 1) and the bilayer FeO(111) film (middle Fig. 1). Subsequently, the spectroscopic and structural properties of FeO\(_2\) will be discussed. Ball models and LEED images for the different preparation steps are also shown in Fig. 1.

3.1 Spectroscopic Fingerprints of FeO

Before growing of the FeO(111) film the spectral features corresponding to a clean Pt(111) surface is discussed. No signal is observed in the O 1s region. In the Pt 4f\(_{7/2}\) line bulk (Pt\(_B\)) and surface (Pt\(_S\)) components are observed at 70.94 and 70.52 eV [36], respectively. The small component observed at 51.40 eV originates from the Pt 5p core level of the clean Pt(111) surface. Following the growth of 1 ML FeO(111) a single O 1s peak is observed at 529.4 eV (denoted I). In the Pt 4f\(_{7/2}\) region the previously observed surface component disappears and one single component is observed at 70.94 eV, i.e. the position of the bulk component of the Pt(111). The CLS of the topmost layer of Pt atoms that binds to Pt atoms beneath and Fe atoms above is thus indistinguishable from that of the Pt bulk atoms. In the Fe 3p region a component with first moment—i.e. ’center of mass’—at 54.99 eV and peak maximum at 54.11 eV is observed. The spectra acquired here on FeO(111) are in good agreement with those published previously [5, 13]. The cleanliness of our FeO(111) films was further confirmed by acquiring survey scans, which showed no sign of the presence of other elements than Fe, O, and Pt. The ordering of the film was checked with LEED, which revealed the expected floret patterns due to the film’s moiré structure (see the insets in Fig. 1). Careful inspection of the individual diffraction spots reveal an arc shape that could indicate the formation of slightly rotated FeO(111) domains on the sample. Most likely a higher oxidation temperature after iron deposition would have given sharp spots without any arc shape.

3.2 Spectroscopic Fingerprints of FeO\(_2\)

For the formation of the FeO\(_2\) trilayer film the FeO(111) film was oxidized by dosing 0.6 mbar O\(_2\) while annealing the sample at 500 K. Subsequently the sample was cooled to room temperature in an oxygen atmosphere. Following the oxidation, the main O 1s peak shifts to lower binding energy and a shoulder component develops at the high binding energy side. The full width at half maximum (FWHM) of the main O 1s peak of the FeO\(_2\) trilayer film is significantly larger (1.1 eV) than the FWHM of the O 1s component (I) observed on the bilayer FeO(111) (0.9 eV) suggesting that more than one component should be used for its deconvolution. On the basis of this observation we fitted the main O 1s peak by two components with similar widths as component I positioned at 529.0 eV (III) and 528.5 eV (IV), respectively. Our experimental CLS of \(-\)0.4 eV (III) and \(-\)0.9 eV (IV) with respect to component I of FeO(111) agree very well with DFT-calculated final state CLS of \(-\)0.4 eV (interface O) and \(-\)0.7 eV (surface O) reported by Giordano et al. [29] Accordingly, we assign component III to interface O atoms sandwiched between Pt and Fe atoms and component IV to surface O atoms in FeO\(_2\).

The shoulder component (II) located at 531.0 eV is shifted by +2.5 eV with respect to component IV originating from surface O atoms in FeO\(_2\). Core-level shifts of \(\sim\)2 eV have previously been observed for hydroxylation of oxide films such as FeO(111) (2.2 eV) [13], Fe\(_3\)O\(_4\)(111) (2.1 eV) [37], \(\alpha\)-Al\(_2\)O\(_3\)(0001) (1.9–2.0) [38], and \(\alpha\)-Fe\(_2\)O\(_3\)(0001) (1.9–2.2 eV) [38]. On this basis we assign the shoulder component (II) to OH groups. Comparing the relative area of the OH component II (49%) and the FeO\(_2\) surface component IV (51%) we conclude that approximately half of the surface O atoms in the FeO\(_2\) film are hydroxylated. However, it should be noted that the area of component IV is very sensitive to the peak widths of component IV and III. Thus, the real coverage of OH-groups could easily be higher or lower than 0.5 ML.

In contrast to the FeO(111) film, the FeO\(_2\) trilayer film contains interface O atoms in direct contact with the topmost layer of Pt atoms. Therefore, we expect the Pt 4f\(_{7/2}\) spectra of FeO(111) and FeO\(_2\)(111) to be clearly distinguishable. Figure 1b confirms this expectation as we find a new component (Pt\(_O\)) at 71.15 eV binding energy in addition to the bulk component (Pt\(_B\)) at 70.94 eV for the FeO\(_2\)(111) film. For comparison, ref. [36] reported a Pt 4f\(_{7/2}\) binding energy of 71.12 eV for a p(2 \(\times\) 2)-O chemisorption phase on Pt(111) with O atoms located in the threefold hollow sites.

In the Fe 3p spectrum the oxidation of FeO(111) to FeO\(_2\) causes a CLS of +0.53 eV of the Fe 3p component peak maximum, suggesting a higher oxidation state of Fe in the FeO\(_2\) film. However, the CLS causes only the first moment to shift by +0.18 eV. Hence, the overall peak has shifted possibly due to multiple changes on the surface. We did not attempt to explicitly curve fit the Fe 3p peak since both the Fe 2p and 3p curve fitting are non trivial [39–41] and beyond the scope of the present study. Instead we used three Doniach-Šunjić (DS) functions to fit the Fe 3p peak in order to determine the integrated area. In Fig. 1c the sum of these three DS functions is plotted as one component shown in orange. By normalizing the spectra to the integrated area of the Pt 5p component we observe a 13 % increase of the Fe 3p component upon oxidation from FeO(111) to FeO\(_2\), fitting well with the fact that more attenuation of the photoelectrons from underlying Pt is expected for FeO\(_2\) than for FeO(111).

Finally, we note that also the LEED pattern acquired on FeO\(_2\) shows a floret pattern, similar to the one observed on the FeO(111) film, but without any arc shape of the individual diffraction spots. First of all this indicates that the in-plane structures of the FeO(111) and FeO\(_2\) surfaces are comparable even though the spectroscopic fingerprints of these two surfaces are very different. Secondly, the disappearance of the arc shape upon FeO\(_2\) formation might be an indication that rotational micro domains disappeared upon oxidation when the interphase O layer became present. Note that the two LEED images shown in Fig. 1 are acquired on the the same sample before and after FeO\(_2\) formation. More experimental work and a careful analysis of many LEED images before and after oxidation are, however, needed to verify our second conclusion.

XP spectra acquired on the clean Pt(111) crystal (top), with a bilayer FeO(111) overlayer (middle), and with a trilayer FeO\(_2\) overlayer (bottom). Panel a shows the O 1s core levels, while panels b, c show Pt 4f\(_{7/2}\) and Fe 3p/Pt 5p regions, respectively. LEED images of FeO(111) and FeO\(_2\) overlayers acquired in the XPS setup with energies of 62 and 65 eV, respectively, are also included in the figure.

As mentioned above, our O 1s deconvolution indicates that approximately 50 % of the surface oxygen atoms are hydroxylated. To validate this conclusion we tried to selectively remove the H atoms from the surface, by flashing the FeO\(_2\) trilayer to 580 K. In Fig. 2 we compare the O 1s spectrum of FeO\(_2\) before (bottom) and after (middle) flashing to 580 K. Clearly, component II assigned to the OH groups decrease in intensity upon flashing, while component I assigned to FeO(111) and component IV assigned to surface FeO\(_2\) without OH groups increase in intensity. Further, we note that the FeO\(_2\) interface component decreases in intensity. This is as expected because part of the surface is converted to FeO(111) without an interface component. Hence, flashing in vacuum leads to removal of the hydrogen, as expected, and a partial removal of oxygen leads to the observed trilayer/bilayer mixture. This observation suggests that OH groups help to stabilize the FeO\(_2\) trilayer. Recently, it has been reported by Liu et al. [42] that hydroxyl groups also stabilize ultrathin Zinc oxide films.

The topmost O 1s spectrum in Fig. 2 was acquired after a subsequent room temperature exposure of H\(_2\)O (1 \(\times\) \(10^{-6}\) mbar for \(\sim\)15 minutes) onto this trilayer/bilayer mixture. Clearly, the water exposure leads to re-appearance of the OH-component (II) and a reduced FeO\(_2\) surface component (IV). In contrast, the FeO(111) component (I) and the FeO\(_2\) interface component (III) are unaffected by the water exposure. Hence, the conclusion from these observations is that a surface with FeO\(_2\)(111) patches effectively dissociates H\(_2\)O, whereas a continuous FeO(111) film is inert with respect to water exposure at room temperature.

For the oxidation of FeO(111) to FeO\(_2\) discussed above a pressure of 0.6 mbar was used. At such high pressures—high as in orders of magnitudes higher than standard UHV techniques—it is difficult to avoid water impurities. In order to reduce the water contamination we also studied the oxidation of FeO(111) by NO\(_2\). Previous surface oxidation studies have shown that NO\(_2\) functions as a very efficient oxidation agent and quite similar to atomic oxygen [43], meaning that the partial pressure of water can be reduced significantly. Figure 3 show a series of O 1s spectra of FeO(111) exposed to an increasing amount of NO\(_2\) dosed at room temperature. As the gas dosing was done in the preparation chamber the sample was transferred between dosing and measurement. After 250 L NO\(_2\) (dosed at 1 \(\times\) \(10^{-6}\) mbar) the OH component (II), the FeO\(_2\) surface component (IV), and the FeO\(_2\) interface component (III) start to become visible. At lower NO\(_2\) doses (not shown) the spectrum looked very similar to that of pristine FeO(111) and only very small changes were observed. With increasing NO\(_2\) dose the components assigned to FeO\(_2\) (II, III, IV) increase in intensity while the FeO(111) component (I) decreases. Between a dose of 400 and 550 L the surface oxidation seems to saturate and the FeO(111) component (I) almost disappears. No N 1s signal was observed upon NO\(_2\) oxidation in any of our experiments suggesting formation of NO or N\(_2\) that immediately desorbs. Comparing the O 1s spectra after O\(_2\) oxidation (Fig. 1a) and the NO\(_2\) oxidation (Fig. 3) of FeO(111) it is evident that the two different oxidation methods are very similar and both result in extensive surface hydroxylation. In none of our NO\(_2\) oxidation experiments we observed FeO\(_2\) interface (II) and surface (IV) components without also observing a OH component (IV). Altogether, these observations suggest that a surface with FeO\(_2\)(111) trilayer patches undergoes quickly hydroxylation, whereas the bilayer FeO(111) film does not hydroxylate.

3.3 STM Comparison of FeO and FeO\(_2\)

Evidence for spontaneous hydroxylation of the FeO\(_2\) trilayer is also provided by STM measurements. Figure 4 shows STM images of the pristine bilayer FeO film (Fig. 4a) and the oxidized film (Fig. 4b), produced by exposure to atomic oxygen from a thermal cracker. Immediately after exposure at room temperature, it was found to be impossible to establish stable STM imaging, presumably due to the presence of weakly-bound oxygen-containing species on the surface which interact strongly with the STM tip. After flashing the surface to 500 K, however, stable images could be obtained, one of which is shown in Fig. 4b. Similar to previous reports [23, 26, 35], the STM images show bright patches of FeO\(_2\) organized following the moiré superstructure. Atop these patches we observe bright protrusions showing poor short-range order, but typical separations corresponding to \(\sqrt{3}\) \(\times\) a, or next-nearest-neighbor spacing or larger. This is very similar to what has previously been observed for H adatoms adsorbed on the FeO bilayer [22], and we therefore propose that these protrusions correspond to OH groups which are either residual features following the flash (note that the OH component of the O 1s spectra shown above was not completely removed by heating) or which formed by adsorption while the sample cooled. To distinguish between these two possibilities, it would be interesting to scan on FeO\(_2\) trilayer samples at elevated temperatures. The unintentional adsorption of water upon sample cooling was previously observed in STM studies addressing rutile TiO\(_2\)(110) [44]. In an earlier report by Giordano et al. [26] protrusions were observed in STM images similar to those here, but forming a more well-ordered \(\sqrt{3}\times \sqrt{3}R30^{\circ }\) arrangement atop the trilayer patches. In that work the superstructure was attributed to outward relaxation of 1/3 of the Fe ions based on the finding by DFT+U calculations that such a structure was stable. Though we cannot rule out this explanation completely, we find it unlikely that displacement of single ions is responsible for the protrusions observed in the present case, where variability in the number of protrusions observed at each FeO\(_2\)(111) patch and their relatively random ordering is suggestive of the presence of foreign species. We furthermore suggest that the superstructure observed in this previous work was also caused by OH groups, the better ordering being attributable to a higher concentration of these species.

a STM image (65 mV, 3.0 nA) of bilayer FeO/Pt(111), with the moiré coincidence cell marked. b STM image (2.0 V, 0.2 nA) of the FeO bilayer following exposure to atomic oxygen and flashing to 500 K. Bright protrusions assigned to OH groups incorporated into patches of the FeO\(_2\) trilayer are indicated with arrows. Ovals mark pairs of protrusions separated by a lattice distance of \(\sqrt{3}\)

3.4 XAS Comparison of FeO and FeO\(_2\)

We now take a closer look at the oxidation state of Fe in FeO(111) and FeO\(_2\). In Fig. 5 Fe L\(_3\) spectra of a FeO(111) film and FeO\(_2\) prepared by dosing NO\(_2\) are shown together with their difference spectra. The spectrum of the FeO(111) bilayer film is, as expected, in accordance with that of Fe\(^{2+}\) [5, 45, 46]. For FeO\(_2\) the main component is shifted to higher photon energies and a shoulder is seen at a lower photon energy. Clearly, the iron atoms in FeO\(_2\) are at least partly in a different oxidation state. Indeed, the observed line-shape of the difference spectrum [FeO\(_2\)–FeO(111)] is characteristic of an Fe\(^{3+}\) oxidation state [45, 46]. Hence, the trilayer is composed of Fe\(^{2+}\) and Fe\(^{3+}\) contributions. From the relative intensities of the contributions we find that roughly 60 % of the ions are in an Fe\(^{2+}\) oxidation state. As previously discussed, no bilayer FeO(111) contributions could be found with XPS. Therefore, the different Fe ion oxidation state must originate from the trilayer FeO\(_2\) patches.

3.5 In Situ Oxidation of FeO to FeO\(_2\) Followed with APXPS

a Image plot of O 1s spectra acquired in 0.6 mbar O\(_2\) while heating the sample from 300 to 500 K followed by subsequent cooling. The temperature profile is plotted in panel c. b Selected O 1s spectra from a. c Top development of the 3 surface components [FeO(111)(I), FeO\(_2\)-OH(II), and FeO\(_2\)-Surface (IV)] as function of temperature and exposure time obtained from curve fitting the O 1s spectra shown in panel a. Bottom measured work function shift as function of temperature and exposure time obtained from the energy shift of the O\(_2\) gas phase peak plotted together with the calculated workfunction shift obtained by combining theoretical values from ref. [29] and the coverage of FeO\(_2\)-OH(II) and FeO\(_2\)-Surface(IV)

In all our experiments where FeO(111) was oxidized to FeO\(_2\) with O\(_2\), NO\(_2\), and atomic oxygen we observed that the surface is to a large extent hydroxylated. To follow the kinetics of the FeO(111) to FeO\(_2\) transformation and to probe whether the surface first is oxidized to FeO\(_2\) and subsequently becomes hydroxylated we followed the oxidation process in situ with APXPS. In the APXPS experiment the FeO(111) surface was exposed to 0.6 mbar O\(_2\) while the sample temperature was ramped from room temperature to 500 K (Fig. 6). At the same time O 1s XP spectra were measured. Figure 6a shows an image plot of the O 1s spectra acquired in situ while selected O 1s spectra are shown in panel (b). The doublet observed near 538 eV originates from the O\(_2\) gas phase molecules and the peaks near 530 eV originate from surface O species. In the top part of panel (c) in Fig. 6 we plot the relative surface area of all O 1s surface components obtained from simultaneous curve fitting of all O 1s spectra acquired in situ. At 300 K the surface is completely covered by bilayer FeO(111) (I). At a temperature of 315 K after \(\sim\)20 min of O\(_2\) exposure we observe the onset of the reduction of FeO(111) component (I) and the simultaneous increase of the FeO\(_2\)-OH component (II) and the FeO\(_2\) (IV) component. Thus, the FeO\(_2\) surface atoms with and without adsorbed H occurs simultaneously and both components grow with the same rate until a temperature of 360 K is reached. Above this temperature the FeO\(_2\)-surface component start to increase faster than the FeO\(_2\)-OH component, and above 400 K the OH coverage reaches maximum (33 %) and start to decrease at higher temperatures. Both observations suggest that hydroxylation is suppressed at higher temperature. Even though the OH formation is suppressed at higher temperature we always observe a significant degree of hydroxylation also at the maximum temperature of 500 K (20 %). Upon cooling the OH coverage increase again and the FeO\(_2\)-surface component decrease.

Finally, we take a look at the peak position of the O\(_2\) gas phase doublet. In contrast to the O 1s surface atoms that are pinned to the Fermi level the gas phase molecules are pinned to the vacuum level. As a result, the binding energy of gas phase molecules follows surface work function shift during the reaction, in this case, the film growth [47]. It should, however, be kept in mind that the gas phase molecules probed by APXPS are located in a small volume between the sample surface and the grounded electron analyzer aperture. Therefore, the measured binding energy shift of the gas phase molecules is reduced as compared to the work function shift of the sample surface. Nevertheless, at the bottom of Fig. 6c we plot the work function change obtained from the peak position of the O\(_2\) doublet as function of time and temperature. In ref. [29] Giordano et al. calculated the work function change relative to Pt(111) of FeO(111) (+0.31 eV), FeO\(_2\) (+1.72 eV), and FeOOH (-3.89 eV). Using these values and the relative surface coverage of the same components from the top part of Fig. 6c we estimated the expected work function shifts as the FeO(111) film is oxidized and hydroxylated as \(\Delta \phi = \Theta (FeO_2-surface)\cdot 1.41\) eV\(-\Theta (FeO_2-OH)\cdot 4.20\) eV. As Fig. 6c demonstrates the estimated work function qualitatively reproduce the measured work function rather well keeping in mind the simplicity of our model and the error bars of the curve fitting. In addition, we note that the calculated work function shift for FeOOH (\(-\)3.89 eV) probably overestimates the work function shift in our case, because it was calculated for a full OH coverage, leading to vertical configuration of all OH groups. In our case with partial hydroxylation of the FeO\(_2\), the OH groups are dynamically distorted leading to a reduced effective dipole moment. Altogether we conclude from the data presented in Fig. 6c that: (i) the onset of hydroxylation coincides with the onset of the FeO\(_2\) formation and initially the OH coverage and the FeO\(_2\) formation grows simultaneously, meaning that OH formation is closely connected to the trilayer structure and/or growth; (ii) the degree of hydroxylation is strongly temperature dependent; (iii) the O atoms in the FeO\(_2\) patches are always only partly covered with H atoms, in agreement with our STM observations; (iv) the FeO\(_2\) formation and hydroxylation lead to a measurable work function shift that fits well with our assignment of the the O 1s components and the calculated work function differences between FeO\(_2\), hydroxylated FeO\(_2\), and FeO(111).

As discussed above, the onset of hydroxylation coincides with the onset of FeO\(_2\) formation, suggesting that hydroxylation occurs during the formation of the FeO\(_2\) trilayer rather than after its formation is completed. On this basis and the fact that hydroxylation also occurred after the formation of FeO2 patches was completed (see Fig. 2c) we suggest that water dissociates at the FeO\(_2\)-FeO(111) interface and at defects that are present mainly during the oxidation process. In contrast, we do not expect that water dissociates on perfect continuous FeO(111) films and on the FeO\(_2\) patches.

Previous studies have shown that FeO bilayer films can be grown also on other Pt facets [48], and many other single-crystalline metal substrates such as Pd(111) [35], Ag(100) [41], Ag(111) [49], Mo(100) [50], Ru(0001) [51] and Au(111) [52, 53]. In other studies it has been found that FeO(111) films encapsulate Fe\(_3\)O\(_4\) supported Pt particles [54]. In addition, it has been demonstrated recently that Co–O bilayer films on Au(111) can be transformed to O–Co–O trilayer films , both of which are structurally very similar to the iron oxide phases discussed here [55]. Our finding that the Pt(111) supported FeO\(_{2}\) trilayer films are generally hydroxylated could thus be relevant both for surface iron oxides on other supports and for other trilayer surface oxides on (111) noble metal surfaces.

4 Conclusions

To conclude, we monitored the FeO(111)/Pt(111) to FeO\(_2\)/Pt(111) conversion upon oxidation with different oxidizing agents with HRXPS and APXPS and provided spectroscopic fingerprints of these surface iron oxide phases. Most importantly, we showed that FeO\(_2\) supported by Pt(111) is very active for water dissociation. Once FeO\(_2\) trilayer patches are formed upon oxidation of bilayer FeO(111) films with O\(_2\), NO\(_2\), or atomic oxygen, they immediately become partly hydroxylated. Since we always observe a significant degree of hydroxylation also when FeO(111) is oxidized to FeO\(_2\) at excellent UHV conditions and since our STM data of the hydroxylad FeO\(_2\) patches looks almost identical to previously published STM images of FeO\(_2\) [23, 26] we propose that catalytically highly active FeO\(_{2}\) trilayer films are generally hydroxylated even at normal UHV conditions. We believe this result is also of relevance for iron oxide films on other supports and for other trilayer oxides grown on (111) noble metal surfaces.

References

Surnev S, Fortunelli A, Netzer FP (2013) Chem Rev 113:4314

Vurens GH, Salmeron M, Somorjai GA (1988) Surf Sci 201:129

Ritter M, Ranke W, Weiss W (1998) Phys Rev B 57:7240

Ranke W, Ritter M, Weiss W (1999) Phys Rev B 60:1527

Weiss W, Ranke W (2002) Prog Surf Sci 70:1

Rienks EDL, Nilius N, Rust HP, Freund HJ (2005) Phys Rev B 71:241404

Merte LR, Grabow LC, Peng G, Knudsen J, Zeuthen H, Kudernatsch W, Porsgaard S, Laegsgaard E, Mavrikakis M, Besenbacher F (2011) Jour Phys Chem C 115:2089

Kim YJ, Westphal C, Ynzunza RX, Galloway HC, Salmeron M, Van Hove MA, Fadley CS (1997) Phys Rev B 55:R13448

Zhang W, Li Z, Luo Y, Yang J (2009) Jour Phys Chem C 113:8302

Giordano L, Pacchioni G, Goniakowski J, Nilius N, Rienks EDL, Freund HJ (2007) Phys Rev B 76:075416

Huang W, Ranke W (2006) Surf Sci 600:793

Merte LR, Knudsen J, Grabow LC, Vang RT, Laegsgaard E, Mavrikakis M, Besenbacher F (2009) Surf Sci 603:L15

Knudsen J, Merte LR, Grabow LC, Eichhorn FM, Porsgaard S, Zeuthen H, Vang RT, Laegsgaard E, Mavrikakis M, Besenbacher F (2010) Surf Sci 604:11

Merte LR, Knudsen J, Eichhorn FM, Porsgaard S, Zeuthen H, Grabow LC, Laegsgaard E, Bluhm H, Salmeron M, Mavrikakis M, Besenbacher F (2011) J Am Chem Soc 133:10692

Nilius N, Rienks EDL, Rust HP, Freund HJ (2005) Phys Rev Lett 95:066101

Giordano L, Pacchioni G, Goniakowski J, Nilius N, Rienks EDL, Freund HJ (2008) Phys Rev Lett 101:026102

Berdunov M, Mariotto G, Balakrishnan K, Murphy S, Shvets IV (2006) Surf Sci 600:L287

Lin X, Nilius N (2008) J Phys Chem C 112:15325

Joseph Y, Ranke W, Weiss W (2000) J Phys Chem B 104:3224

Leist U, Ranke W, Al-Shamery K (2003) Phys Chem Chem Phys 5:2435

Merte LR, Peng C, Bechstein R, Rieboldt F, Farberow CA, Grabow LC, Kudernatsch W, Wendt S, Laegsgaard E, Mavrikakis M, Besenbacher F (2012) Science 336:889

Merte LR, Bechstein R, Peng G, Rieboldt F, Farberow CA, Zeuthen H, Knudsen J, Laegsgaard E, Wendt S, Mavrikakis M, Besenbacher F (2014) Nat Commun 5:4193

Sun YN, Qin ZH, Lewandowski M, Carrasco E, Sterrer M, Shaikhutdinov S, Freund H (2009) J Catal 266:359

Fu Q, Li WX, Yao Y, Liu H, Su HY, Ma D, Gu XQ, Chen L, Wang Z, Zhang H, Wang B, Bao X (2010) Science 328:1141

Sun YN, Giordano L, Goniakowski J, Lewandowski M, Qin ZH, Noguera C, Shaikhutdinov S, Pacchioni G, Freund HJ (2010) Angew Chem Int Ed 49:4418

Giordano L, Lewandowski M, Groot IMN, Sun YN, Goniakowski J, Noguera C, Shaikhutdinov S, Pacchioni G, Freund HJ (2010) J Phys Chem C 114:21504

Lewandowski M, Sun YN, Qin ZH, Shaikhutdinov S, Freund HJ (2011) Appl Catal A 391:407

Lewandowski M, Groot IMN, Shaikhutdinov S, Freund HJ (2012) Catal Today 181:52

Giordano L, Pacchioni G, Noguera C, Goniakowski J (2013) Top Catal 56:1074

Giordano L, Pacchioni G, Noguera C, Goniakowski J (2014) ChemCatChem 6:185

Ringleb F, Fujimori Y, Wang HF, Ariga H, Carrasco E, Sterrer M, Freund HJ, Giordano L, Pacchioni G, Goniakowski J (2011) J Phys Chem C 115:19328

Nyholm R, Andersen JN, Johansson U, Jensen BN, Lindau I (2001) Nucl Instrum Methods A 467:520

Schnadt J, Knudsen J, Andersen JN, Siegbahn H, Pietzsch A, Hennies F, Johansson N, Mårtensson N, Öhrwall G, Bahr S, Mähl S, Schaff O (2012) J Synchotron Radiat 19:701

Denecke R, Väterlein P, Bässler M, Wassdahl N, Butorin S, Nilsson A, Rubensson JE, Nordgren J, Mårtensson N, Nyholm R (1999) J Electron Spectro Relat Phenom 101:971

Zeuthen H, Kudernatsch W, Peng G, Merte LR, Ono LK, Lammich L, Bai Y, Grabow LC, Mavrikakis M, Wendt S, Besenbacher F (2013) J Phys Chem C 117:15155

Björneholm O, Nilsson A, Tillborg H, Bennich P, Sandell A, Hernnäs B, Puglia C, Mårtensson N (1994) Surf Sci 315:L983

Joseph Y, Kuhrs C, Ranke W, Ritter M, Weiss W (1999) Chem Phys Lett 314:195

Liu P, Kendelewicz T, Brown GE, Nelson EJ, Chambers SA (1998) Surf Sci 417:53

Sirotti F, Rossi G (1994) Phys Rev B 49:15682

McIntyre NS, Zetaruk DG (1977) Anal Chem 49:1521

Merte LR, Shipilin M, Ataran S, Blomberg S, Zhang C, Mikkelsen A, Gustafson J, Lundgren E (2015) J Phys Chem C 119:2572

Liu BH, Boscoboinik JA, Cui Y, Shaikhutdinov S, Freund HJ (2015) J Phys Chem C 119:7842

Schnadt J, Knudsen J, Hu XL, Michaelides A, Vang RT, Reuter K, Li Z, Lægsgaard E, Scheffler M, Besenbacher F (2009) Phys Rev B 80:075424

Wendt S, Schaub R, Matthiesen J, Vestergaard EK, Wahlström E, Rasmussen MD, Thostrup P, Molina LM, Laegsgaard E, Stensgaard I, Hammer B, Besenbacher F (2005) Surf Sci 598:226

Laan GVD, Kirkman IW (1992) J Phys Condens Matter 4:4189

Cressey G, Henderson CMB, Laan GVD (1993) Phys Chem Miner 20:111

Bluhm H (2010) J Electron Spectrosc Relat Phenom 177:71

Shaikhutdinov S, Ritter M, Weiss W (2000) Phys Rev B 62:7535

Waddill GD, Ozturk O (2005) Surf Sci 575:35

Corneille JS, He JW, Goodman DW (1995) Surf Sci 338:211

Ketteler G, Ranke W (2003) J Phys Chem B 107:4320

Khan NA, Matranga C (2008) Surf Sci 602:93

Deng X, Lee J, Wang C, Matranga C, Aksoy F, Liu Z (2011) Langmuir 27:2146

Qin ZH, Lewandowski M, Sun YN, Shaikhutdinov S, Freund HJ (2008) J Phys Chem C 112:10209

Walton AS, Fester J, Bajdich M, Arman MA, Osiecki J, Knudsen J, Vojvodic A, Lauritsen JV (2015) ACS Nano 9:2445

Acknowledgments

Financial support from Vetenskapsrådet (Grants Nos. 2010-5080 and 2012-3850) and assistance by the staff at the MAX IV Laboratory are gratefully acknowledged. The work in Aarhus was supported by the Villum Kahn Rasmussen Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Johansson, N., Merte, L.R., Grånäs, E. et al. Oxidation of Ultrathin FeO(111) Grown on Pt(111): Spectroscopic Evidence for Hydroxylation. Top Catal 59, 506–515 (2016). https://doi.org/10.1007/s11244-015-0521-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-015-0521-7