Abstract

To efficiently produce bioactive compounds of Echinacea via adventitious root (AR) culture, we established an AR co-culture system of Echinacea species. ARs of different combination of Echinacea species [E. pallida (Epa), E. purpurea (Epu), and E. angustifolia (Ean)] were inoculated into 5 L balloon-type airlift bioreactors to select a suitable combination group. The biomass of ARs increased in the Epa+Epu group but decreased in co-culture groups of Epa+Ean and Epa+Epu+Ean. In the Epa+Epu group, the content and productivity of total phenolics, flavonoids, and caffeic acid derivatives increased, a monomer of caffeic acid derivatives (caffeic acid) that is absent in single-species cultures (Epa or Epu) were synthesized; moreover, Epa+Epu also showed the highest antioxidant activity. The inoculum proportions in Epa+Epu significantly influenced the co-culture effect; among the proportion groups (Epa:Epu = 1:6, 2:5, 3:4, 1:1, 4:4, 5:2, and 6:1), the Epa:Epu proportion of 4:3 was the most favorable for AR biomass and bioactive compound accumulation, and the antioxidant activity also peaked at 4:3 proportion. In addition, the co-culture system is suitable for large bioreactors (10 and 20 L), wherein the AR biomass increased without a decrease in the amount of bioactive compounds. A co-culture system was thus successfully established in this study, and AR cultures are expected to be used as an alternative raw material for the production of Echinacea-derived products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Echinacea Moench, a perennial plant of the Asteraceae family, is generally cultivated in various parts of the world for commercial purposes. Among the Echinacea genus, Echinacea pallida (Epa), E. purpurea (Epu), and E. angustifolia (Ean) have been mainly used in drug production (Zhang et al. 2001). Echinacea-derived drugs are the most widely used herbal medicines to treat colds, flu, and chronic respiratory infections in Europe, North America, and Australia (Barrett 2003). The entire plant body of Echinaea species contains various bioactive compounds, such as caffeic acid derivatives, phenolics, flavonoids, and polysaccharides (Pellati et al. 2004). However, the type and amount of metabolites in different species vary; for instance, the caffeic acid derivatives, echinacoside (0.3‒1.7%) is detected in the roots of Epa and Ean but not in the roots of Epu (Kindscher 1989); cichoric acid is rich in flowers and roots of Epu but insufficient in the root of Ean. The raw material from Echinacea has been derived mainly through artificial cultivation; however, the cultivation yield is limited by several factors, including difficulty in seed collection, low seed germination rate, and inefficient breeding technology (Wu et al. 2007). As a result, extraction and product production have been limited, and meeting the growing needs of the market has become difficult. For this reason, an alternative route was developed to mass produce the raw plant material.

Adventitious root (AR) cultures of plants are the good biological material for stable commercial production of higher metabolites (Cui et al. 2013). Various bioactive compounds, including ginsenosides of Panax ginseng (Hahn et al. 2003), hypericin of Hypericum perforatum (Cui et al. 2010a), phenolics of Oplopanax elatus (Jiang et al. 2015), and eleutherosides of Eleutherococcus koreanum (Lee et al. 2015), have been produced through AR culture in bioreactors. For Echinacea, AR bioreactor culture has been repeatedly conducted in different species (Cui et al. 2013; Jeong et al. 2009; Wu et al. 2013). Cui et al. (2013) cultured ARs of Ean in a 500 L balloon type bioreactor and provided a protocol for mass production of caftaric acid, cynarin, chlorogenic acid, echinacoside, cichoric acid, phenolics, and flavonoids. Jeong et al. (2009) have established a bioreactor technology for mass cultivation of ARs of Epu to produce phenolics, flavonoids, and caffeic acid derivatives; Wu et al. (2013) have developed a bioreactor AR culture of Epa to produce caffeic acid derivatives. Consequently, the AR bioreactor culture technology of Echinacea matured basically. However, our preliminary study found that phenolic and flavonoid compound accumulation can be enhanced when ARs of Epu and Epa were co-cultured in a bioreactor. Therefore, we systemically studied the several factors affecting the co-culture in the present study to establish an optimized co-culture system.

Co-culture, two or more than two cell types are cultured in a single environment, has been developed in the late 1980s of last century, and widely used on cytology studies because of the good communication and mutual support for growth and development of cells. However, several researchers have introduced the co-culture technique to the plant tissue culture for efficient production of secondary metabolites. To date, co-culture systems, such as co-culture of different plant species (Wu et al. 2008) and different explants (Łuczkiewicz and Kokotkiewicz 2005), have been successfully established. In these co-culture systems, metabolite biosynthesis is obviously increased, and new metabolites are produced. Thus, although the co-culture technique is still in its exploration stage in plant cell, tissue, and organ culture, it displays a significant potential for mass production of target metabolites.

In the present study, to establish an AR co-culture system involving different Echinacea species (Epa, Epu, and Ean) in bioreactors, we firstly compared the different co-culture groups (Epa+Epu, Epa+Ean, Epa+Ean, and Epa+Epa+Ean) with the single-species cultures (Epa, Epu, and Ean) to select the optimal co-culture group that can mass produce ARs containing high amounts of phenolics, flavonoids, and caffeic acid derivatives and demonstrating high antioxidant activity; the effect of the different inoculum proportions of Epa and Epu was then investigated. Finally, the ARs were co-cultured in bioreactors with different sizes to investigate the stability of the culture.

Materials and methods

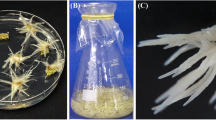

AR maintenance

ARs of Echinacea spp. (Epa, Epu, and Ean) were induced according to the procedures described by Wu et al. (2007). The induced ARs were inoculated in three-quarter strength Murashige and Skoog (MS) medium (Murashige and Skoog 1962) supplemented with 1 mg L−1 of indole-3-butyric acid (IBA) (Beijing Solarbio Science and Technology Co., Ltd., Beijing, China), 50 g L−1 sucrose (Tianjin Kemiou Chemical Reagent Co., Ltd., Tianjin, China), and 2.2 g L−1 gelrite (Duchefa Biochemie B.V, Haarlem, Netherlands). The pH of the medium was adjusted to 5.8 before sterilization at 121 °C and 1.2 kg cm−2 for 15 min and then sub-cultured in fresh medium every 4 weeks at 25 ± 2 °C in the dark.

AR co-culture in bioreactors

Five-liter balloon-type airlift bioreactors containing 4 L of half-strength MS medium supplemented with 1 mg L−1 IBA and 50 g L−1 sucrose were used in all experiments. The pH of the medium was adjusted to 5.7. Each bioreactor was inoculated with 4-week-old ARs, aerated at 100 mL min−1, and maintained at 25 ± 2 °C in the dark. In the first experiment, seven experimental groups (Epa+Epu, Epa+Ean, Epa+Ean, Epa+Epa+Ean, Epa, Epu, and Ean) were designed for selecting a suitable co-culture group. The total inoculation density was 7 g L−1 in all groups, and the inoculum proportion for each Echinacea species was identical in the co-culture groups. AR biomass, contents of phenolics, flavonoids, and the six monomers (caffeic acid, caftaric acid, cynarin, chlorogenic acid, echinacoside, and cichoric acid) of caffeic acid derivatives, and antioxidant activities were determined after 30 days of culture. In the second experiment, the Epa+Epu co-culture group was selected to study the effect of different inoculum proportions (Epa:Epu = 1:6, 2:5, 3:4, 1:1, 4:3, 5:2, 6:1). The total inoculation density was 7 g L−1. AR biomass, bioactive compound content, and antioxidant activity were determined after 30 days of culture. In the third experiment, the adaptability of AR co-culture in bioreactors of different sizes was investigated. The co-culture system consisting of Epa and Epu (Epa:Epu = 4:3) was selected, and the ARs were cultured in 5 L (4 L medium), 10 L (8 L medium), and 20 L (16 L medium) balloon-type airlift bioreactors. The total inoculation density was 7 g L−1 AR inoculum for each bioreactor. AR biomass and bioactive compound content were determined after 30 days of culture.

Determination of biomass

The harvested ARs were separated from the medium by draining them in a 1 mm stainless steel sieve, rinsed twice with sterile water, and dried at 50 °C for 48 h. The root dry weight (DW) was subsequently recorded.

Determination of phenolic, flavonoid, and caffeic acid derivative content

To determine the phenolic and flavonoid content, we extracted the dry ARs by using the method described by Wu et al. (2007). The phenolic content was determined spectrophotometrically by using the Folin–Ciocalteu colorimetric method (Folin and Ciocalteu 1927). The absorbance was recorded at 760 nm on a spectrophotometer (UV-2600, Shimadzu Corporation, Kyoto, Japan) and expressed as milligram gallic acid equivalent per gram DW ARs. The flavonoid content was estimated using a colorimetric method (Cui et al. 2010b). The absorbance at 510 nm was recorded, and the results were expressed as milligram of (+)-catechin equivalents per gram DW ARs. The caffeic acid derivatives were extracted and analyzed according to the method described by Wu et al. (2007). The caffeic acid fractions were analyzed using a high-performance liquid chromatography system equipped with XTerra RP 18 column (150 × 3 mm, 3.0 µM; Waters Corporation, Milford, MA, USA). The mobile phases were water (A) and acetonitrile (B). The gradient elution was modified as follows: initial 10% B for 40 min; 25% B for 11 min; 50% B for 1 min; with recycling to initial condition for 8 min at a flow rate of 0.3 mL min−1. Caffeic acid derivatives were detected at 330 nm. Standard caftatic acid, chlorogenic acid, cynarin, echinacoside, and cichoric acid were purchased from ChromaDex (Laguna Hills, CA, USA). The total content of caffeic acid derivatives was the sum content of the six monomers. The productivity of bioactive compounds was calculated as follows (Jiang et al. 2015):

Determination of antioxidant activity

The antioxidant activity of ARs was evaluated based on the activities of of 1,1-diphenyl-2-picrylhydrazyl (DPPH) and hydroxyl radical (OH) scavenging, Fe2+ chelating and reducing power. DPPH radical scavenging activity was measured according to the method described by Cui et al. (2010a) with slight modifications. In brief, 2 mL of ethanol extract (0.16 mg mL−1) of AR samples were mixed with 1 mL of DPPH ethanol solution (0.2 mM); the reaction mixture was shaken gently and allowed to stand at room temperature (~25 °C) in the dark for 30 min. The absorbance was measured by a spectrophotometer (UV-2600, Shimadzu Corporation, Kyoto, Japan) at 517 nm. The DPPH radical scavenging activity (I 1) was calculated as follows (Cui et al. 2010a): I 1 (%) = (A 0− A s)/A 0 × 100, where A s is the absorbance of the extract mixed with DPPH solution and A 0 is the absorbance of the DPPH solution alone.

The ·OH scavenging assay was performed according to the method described by de Kong et al. (2008) with some modifications. Two milliliters of 1,10-phenanthroline (0.75 mM), 2 mL of FeSO4 (0.75 mM), 2 mL of phosphate buffer (pH 7.4), 2 mL of H2O2 (0.1% v/v), and 1 mL of AR ethanol extract (8 mg mL−1) were mixed thoroughly. The mixture was incubated at 37 °C for 60 min and then the absorbance was measured at 536 nm. The ·OH scavenging activity (I 2) was calculated as follows (Kong et al. 2008): I 2 (%) = [(A S− A 1)/ (A 0− A 1)] × 100. A S is the absorbance of the AR sample, A 1 is the absorbance of the control solution containing 1,10-phenanthroline, FeSO4, and H2O2, and A 0 is the absorbance of the blank solution containing 1,10-phenanthroline and FeSO4.

The Fe2+-chelating activity was measured using the method described by Hsu et al. (2006) with some modifications. In brief, the reaction mixture contained 2 mL of ethanol extract of the AR sample (0.8 mg mL−1), 0.1 mL of FeCl2 (2 mM), and 2 mL of deionized water. The mixture was shaken gently and allowed to stand at room temperature (~25 °C) for 10 min; 0.2 mL of ferrozine (5 mM in ethanol) was subsequently added, mixed and left for another 5 min to allow complexation with the residual Fe2+. The absorbance of the Fe2+-ferrozine complex was measured at 562 nm against the blank of ethanol. Fe2+ chelating activity (I 3) was calculated as follows (Hsu et al. 2006):

A S is the absorbance of the sample extract and A 0 is the absorbance of the blank.

The reducing power was measured according to the method described by Zhu et al. (2008). In brief, 1 mL of diluted sample extract (0.8 mg mL−1) was mixed with 1 mL of 0.2 M phosphate buffer (pH 6.6) and 0.1 mL of 1% (v/w) potassium ferricyanide. The mixture was incubated at 50 °C for 20 min, and 1 mL of 10% trichloroacetic acid was subsequently added. The mixture was centrifuged for 10 min at 3000 g, and 2 mL of the supernatant was mixed with 1.4 mL of deionized water and 0.3 mL of 0.1% (v/w) FeCl3. After the reaction proceeded for 10 min, the absorbance of the solution was read at 700 nm.

Statistical analysis

All data in the experiments were collected from three replicates. The results are presented as mean ± standard error (SE). The mean values were subjected to Duncan’s multiple range test by using the SPSS17.0 program (IBM Institute, USA). A probability of P < 0.05 indicated statistical significance.

Results and discussion

Selection of a suitable combination of Echinacea species during AR co-culture in bioreactors

To investigate the effect of co-culture, the single-species cultures were used as controls. Table 1 shows that the Epa+Epu co-culture can better enhance AR DW than the single-species cultures (Epa or Epu); however, AR DW was lower in Epa+Ean than in Epa but higher than that in Ean; AR biomass accumulation was inhibited in Epa+Ean or Epa+Epa+Ean co-culture. The co-culture differently affected culture’s biomass in the previous studies. A report indicated that co-culture of different species (Ruta graveolens and Ammi majus) with different explants (shoots and hairy roots) increased the biomass of R. graveolens shoots but reduced the hairy roots in A. majus (Sidwa-Gorycka et al. 2003), suggesting that growth of one explant can be positively or negatively affected by another explant in a co-culture system. In another study, the ARs of different species (P. ginseng and Echinacea spp.) were co-cultured in a bioreactor, and the biomass in the co-culture declined relative to that in single-species cultures (Wu et al. 2008). The different effect of co-culture on biomass accumulation also exerted in our study, where AR biomass increased in Epa+Epu but decreased in Epa+Ean, Epa+Ean, and Epa+Epa+Ean.

Moreover, phenolic and flavonoid content increased in the Epa+Epu co-culture group. The productivity of phenolics and flavonoids in Epa+Epu was 1.4- and 1.3-fold higher than those in Epa and Epu, respectively (Table 1). However, the content of caffeic acid derivative monomers (caffeic acid, caftaric acid, cynarin, chlorogenic acid, echinacoside, and cichoric acid) was differently affected by various co-culture (Fig. 1). Caffeic acid was detected in all co-culture groups but not contained in single-cultures, its maximum content was observed in co-culture groups of Epa+Epa+Ean and the productivity in the Epa + Ean group (Fig. 1a). Caftaric acid was synthesized in all groups containing Epu, and the maximum content and productivity were found both in Epa+Epu and Epu (Fig. 1b). Cynarin, chlorogenic acid, echinacoside, and cichoric acid were detected in all groups, the highest content of cynarin was found in Epa+Ean or Epa but the highest productivity was observed in Epa (Fig. 1c); the highest content and productivity of chlorogenic acid (Fig. 1d) and cichoric acid (Fig. 1f) were observed in Epa+Epu, whereas those for echinacoside were observed in Epa (Fig. 1e). The content and productivity of total caffeic acid derivatives (Fig. 1g) reached the maximum in the Epa+Epu group.

Effect of co-culture of different Echinacea species on caffeic acid derivative accumulation of adventitious roots after 30 days culture in 5 L bioreactors. Data are presented as the mean ± SE of three replicates. The different letters within the same color column indicate significant difference by Duncan’s multiple range test at P < 0.05. (Color figure online)

Studies have indicated that co-culture is characterized by enhanced metabolite accumulation and biosynthesis of specific metabolites. Subroto et al. (1996) found that a co-culture involving shooty teratomas and hairy roots of Atropa belladonna produced the highest levels of scopomamine. Sidwa-Gorycka et al. (2003) indicated that the xanthotoxin and bergapten in A. majus hairy roots were detected in a co-culture system consisting of A. majus hairy roots and R. graveolens shoots but were absent in the single-culture of A. majus hairy roots. Łuczkiewicz and Kokotkiewicz (2005) found that the co-culture of shoots and hairy roots of Genista tinctoria produced large amounts of a single isoflavone-isoliquiritigenin. Similar to these findings, our result showed that accumulation of phenolics, flavonoids, and caffeic acid derivatives was promoted in Epa+Epu. In the present study, we firstly provided evidences that differences occur between co-cultures and single cultures and that the co-culture of different Echinacea species in one bioreactor can be used for efficient production of metabolites. Studies have indicated that co-culture affects metabolite accumulation of cultures possibly because the metabolites produced by one culture are excreted into the medium and the other culture takes up certain metabolites for further biosynthesis and conversion (Wu et al. 2008). However, the detailed mechanism of this phenomenon remains unclear (Yue et al. 2010). Therefore, further studies should identify the chemical compounds of the culture’s excretion occurred in the co-culture and investigate the relationship between the excretion and metabolite synthesis for verifying the basic mechanisms.

Moreover, the present study investigated the antioxidant activity of ARs by evaluating the activities of DPPH and ·OH radical scavenging, Fe2+ chelating, and reducing power. Antioxidant activities exerted a similar trend in the four evaluation indexes (Fig. 2). In the co-culture groups, the maximum activities of DPPH and ·OH radical scavenging, Fe2+ chelating, and reducing power were observed in Epa+Epu followed by those in Epa + Ean and then in Epa+Epa+Ean. Among the single-species culture groups, Epu showed the highest antioxidant activity followed by Epa and then by Ean. In all experimental groups, the maximum antioxidant activity was found in Epa+Epu. Studies have indicated that Echinacea plants display an antioxidant property, but different Echinacea species show varied antioxidant activities (Mao et al. 2007). The antioxidant activity of plants is related to phenolics and flavonoids (Zou et al. 2012); we found that the antioxidant property of Epa+Epu was higher than that of the other co-culture or single-species culture groups, consistent with the accumulated amounts of phenolics, flavonoids, and caffeic acid derivatives in ARs. Therefore, the present study suggested that mass production of bioactive compounds by AR co-culture of Echinacea species is an efficient approach, and the Epa+Epu is the optimal combination group, although a suitable inoculum proportion of Epa and Epu should be selected to optimize the co-culture system.

Effect of co-culture of different Echinacea species on antioxidant activities of adventitious roots after 30 days culture in 5 L bioreactors. Data are presented as the mean ± SE of three replicates. The different letters within the same color column indicate significant difference by Duncan’s multiple range test at P < 0.05

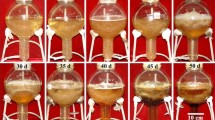

Effect of inoculum proportion of Epa and Epu in co-culture systems

The inoculum proportions of Epa and Epu in the co-culture system significantly affected AR biomass, bioactive compound accumulation, and antioxidant activities. Figure 3 shows that AR biomass increased when the proportion of Epa to Epu was increased from 1:6 to 4:3 but decreased when the proportions were higher than 4:3. The maximum DW was found at 4:3, which was significantly higher than other proportion groups (Table 2). A similar pattern was found in phenolic and flavonoid accumulation. Table 2 shows that the groups with higher proportions of Epa to Epu (1:1, 4:3, 5:2, and 6:1) produced higher amounts of phenolics and flavonoids than the groups with lower proportions of Epa to Epu (1:6, 2:5, and 3:4). The phenolic and flavonoid contents were highest at 4:3 followed by those at 5:2. The maximum productivity of phenolics and flavonoids was also found at 4:3 inoculum proportion. For caffeic acid derivative monomers, the effect of inoculum proportion differed. Figure 4 shows that the content of caffeic acid reached the maximum at three proportions of 3:4, 1:1, and 4:3, but the highest productivity at 4:3 proportion (Fig. 4a); for caftaric acid, the maximum content and productivity were observed at 5:2 proportion (Fig. 4b); the highest content of cynarinwas found at 3:4 proportion but the productivity at both proportions of 3:4 and 1:1 (Fig. 4c); for chlorogenic acid (Fig. 4d), echinacoside (Fig. 4e), and cichoric acid (Fig. 4f), their contents and productivities reached the highest level at 4:3 proportion. Total highest amount and productivity of caffeic acid derivatives were observed at 4:3 inoculum proportion (Fig. 4g). Moreover, the effect of inoculum proportion of Epa to Epu reflected AR antioxidant property. Figure 5 shows that the activities of DPPH,·OH radical scavenging, Fe2 + chelating, and reducing power increased with increasing proportions of Epa to Epu, peaked at 4:3, and then decreased. This trend was identical to the effect of increasing proportions of Epa to Epu on accumulation of phenolics, flavonoids, and caffeic acid derivatives.

Effect of inoculum proportions of Epa and Epu on caffeic acid derivative accumulation of adventitious roots after 30 days co-culture in 5 L bioreactors. Data are presented as the mean ± SE of three replicates. The different letters within the same color column indicate significant difference by Duncan’s multiple range test at P < 0.05. (Color figure online)

Effect of inoculum proportions of Epa and Epu on antioxidant activities of adventitious roots after 30 days co-culture in 5 L bioreactors. Data are presented as the mean ± SE of three replicates. The different letters within the same color column indicate significant difference by Duncan’s multiple range test at P < 0.05

Inoculum proportion is critical in biomass and metabolite production in a co-culture system. Sidwa-Gorycka et al. (2003) co-cultured the hairy roots of A. majus and R. graveolens cells at varying inoculum proportions. Their result showed that growth of hairy roots was inhibited in the co-culture containing high proportions of R. graveolens cell to A. majus hairy roots (6:1), wherein the growth index was approximately 40 times lower than that in a low proportion of Epa to Epu (1:6). Wu et al. (2008) indicated that AR co-culture with high inoculum proportion of ginseng to Echinacea spp. (4:1 and 3:2) can produce increased amounts of ginsenosides and caffeic acid derivatives. We found that growth of AR and synthesis of phenolics, flavonoids, and caffeic acid derivatives were higher under an inoculum proportion of Epa to Epu of 4:3 than those under other proportions. The selection of the appropriate inoculum proportion in a co-culture system was thus a key factor in accumulation of AR biomass and bioactive active compounds (Łuczkiewicz and Kokotkiewicz 2005).

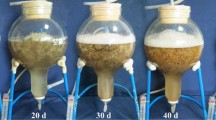

Co-culture in bioreactors of different sizes

To confirm the adaptability of the co-culture in bioreactors of different sizes, we co-cultured ARs (Epa:Epu = 4:3) in 5, 10, and 20 L bioreactors. AR DW per liter of medium increased with increasing bioreactor size and working volume; AR DW was highest in the 20 L bioreactor, in which the AR DW was 1.2- and 1.1-fold higher than that in the 5 and 10 L bioreactors, respectively (Table 3). In addition, phenolic and flavonoid content in the bioreactors with different sizes did not significantly differ, and the maximum productivity of phenolics (416.7 mg L −1) and flavonoids (323.6 mg L −1) was found in the 20 L bioreactor (Table 3). Synthesis of caffeic acid derivative monomers was similar to that of phenolics and flavonoids, and the contents of caftaric acid (Fig. 6b), chlorogenic acid (Fig. 6d), echinacoside (Fig. 6e), and cichoric acid (Fig. 6f) did not obviously differ among the bioreactors with different sizes, but the caffeic acid (Fig. 6a) and cynarin contents (Fig. 6c) in the 10 and 20 L bioreactors were higher than those in the 5 L bioreactor. Moreover, Fig. 6g shows that total the amount of caffeic acid derivatives did not differ in the bioreactors of different sizes. The productivity of all caffeic acid derivatives increased with increasing the sizes of the bioreactor, 244.1 mg L −1 of total caffeic acid derivatives was produced in the 20 L bioreactor. This finding indicated that the established co-culture system (Epa:Epu = 4:3) in a 5 L bioreactor is also suitable in larger bioreactors (10 and 20 L) at a laboratory scale; moreover, positive effect was observed when a large bioreactor was used.

Effect of bioreactor sizes on caffeic acid derivative accumulation of adventitious roots after 30 days co-culture (Epa:Epu = 4:3) in bioreactors. Data are presented as the mean ± SE of three replicates. The different letters within the same color column indicate significant difference by Duncan’s multiple range test at P < 0.05. (Color figure online)

For mass production of metabolites, an optimized bioreactor system can be established by performing numerous laboratory-scale experiments (Murthy et al. 2014), and the experimental data will serve as important reference in designing a pilot-scale bioreactor and to broaden its use. Therefore, researchers have conducted laboratory-scale experiments on bioreactor size. Yin et al. (2014) found that the fresh weight and DW of Glycyrrhiza uralensis AR were significantly higher in a 5 L bioreactor than in a 3 L bioreactor, but the amounts of glycyrrhizic, glycyrrhetinic, and flavonoids did not change in both bioreactors. Cui et al. (2013) showed that the growth of E. angustifolia AR was higher in a 20 L bioreactor than in a 5 L bioreactor but the amount of phenolics, flavonoids, and cafferic acid derivatives did not significantly differ. Furthermore, the present study found that AR biomass enhanced with increasing bioreactor size, but bioactive compound content in Echinacea AR co-culture system did not change in the three bioreactors. In addition, Choi et al. (2000) demonstrated that the saponin content of P. ginseng ARs in the pilot-scale culture was similar to that obtained in a small-scale bioreactor. We expect that the established co-culture system of Echinacea ARs can be successfully applied in the pilot-scale bioreactor as an alternative material source for stable production of bioactive compounds.

Conclusion

Co-culture of AR of Echinacea species effectively improved bioactive compound synthesis and can produce the compound (caffeic acid) that is not detected in single-species cultures; however, the effect of the different combinations of Echinacea species varied. The co-culture group Epa+Epu exerted positive effect on AR biomass, accumulation of phenolics, flavonoids, and caffeic acid derivatives, and antioxidant activity. The inoculation proportion of Epa to Epu is critically important, and the maximum AR DW and biosynthesis of phenolics, flavonoids, and caffeic acid derivatives were found at an Epa to Epu proportion of 4:3, under which the antioxidant activity of ARs peaked. When the established co-culture system was used in bioreactors of different sizes (5, 10, and 20 L), AR biomass increased in the large bioreactor (20 L), and the amount of the bioactive compounds did not decrease. The present study provides a novel co-culture technique for mass production of Echinacea bioactive compounds and the cultured ARs are expected to be used as an alternative raw material for the production of Echinacea-derived products.

References

Barrett B (2003) Medicinal properties of Echinacea: a critical review. Phytomedicine 10:66–86

Choi SM, Son SH, Yun SR, Kwon OW, Seon JH, Paek KY (2000) Pilot-scale culture of adventitious roots of ginseng in a bioreactor system. Plant Cell Tiss Organ Cult 62:187–193

Cui XH, Chakrabarty D, Lee EJ, Paek KY (2010a) Production of adventitious roots and secondary metabolites by Hypericum perforatum L. in a bioreactor. Bioresour Technol 101:4708–4716

Cui XH, Chakrabarty D, Lee EJ, Paek KY (2010b) Production of adventitious roots and secondary metabolites by Hypericum perforatum L. in a bioreactor. Bioresour Technol 101:4708–4716

Cui HY, Baque MA, Lee EJ, Paek KY (2013) Scale-up of adventitious root cultures of Echinacea angustifolia in a pilot-scale bioreactor for the production of biomass and caffeic acid derivatives. Plant Biotechnol Rep 7:297–308

Folin O, Ciocalteu V (1927) On tyrosine and tryptophane determination in proteins. J Biol Chem 27:627–650

Hahn EJ, Kim YS, Yu KW, Jeong CS, Paek KY (2003) Adventitious root cultures of Panax ginseng CV. Meyer and ginsenoside production through large-scale bioreactor system. J Plant Biotechnol 5:1–6

Hsu B, Coupar IM, Ng K (2006) Antioxidant activity of hot water extract from the fruit of the Doum palm, Hyphaene thebaica. Food Chem 98:317–328

Jeong JA, Wu CH, Murthy HN, Hahn EJ, Paek KY (2009) Application of an airlift bioreactor system for the production of adventitious root biomass and caffeic acid derivatives of Echinacea purpurea. Biotechnol Bioprocess E 14:91–98

Jiang YJ, Piao XC, Liu JS, Jiang J, Lian ZX, Kim MJ, Lian ML (2015) Bioactive compound production by adventitious root culture of Oplopanax elatus in balloon-type airlift bioreactor systems and bioactivity property. Plant Cell Tiss Organ Cult 123:413–425

Kindscher K (1989) Ethnobotany of purple coneflower (Echinacea angustifolia, Asteraceae) and other Echinacea species. Econ Bot 43:498–507

Kong XZ, Zhou HM, Hua YF (2008) Preparation and antioxidant activity of wheat gluten hydrolysates (WGHs) using ultrafiltration membranes. J Sci Food Agric 88:920–926

Lee EJ, Park SY, Paek KY (2015) Enhancement strategies of bioactive compound production in adventitious root cultures of Eleutherococcus koreanum Nakai subjected to methyl jasmonate and salicylic acid elicitation through airlift bioreactors. Plant Cell Tiss Organ Cult 120:1–10

Łuczkiewicz M, Kokotkiewicz A (2005) Co-cultures of shoots and hairy roots of Genista tinctoria L. for synthesis and biotransformation of large amounts of phytoestrogens. Plant Sci 169:862–871

Mao SH, Li ZY, Li C (2007) Antioxidant activity of three plants from Echinacea moench. Nat Prod Res Dev 19:474–476

Murashige T, Skoog F (1962) A revised medium for rapid growth and bioassays with tobacco tissue cultures. Physiol Plant 15:473–497

Murthy HN, Georgiev MI, Kim YS, Jeong CS, Kim SJ, Park SY, Paek KY (2014) Ginsenosides: perspective for sustainable biotechnological production. Appl Microbiol Biotechnol 98:7319–7329

Pellati F, Benvenuti S, Magro L, Melegari M, Soragni F (2004) Analysis of phenolic compounds and radical scavenging activity of Echinacea spp. J Pharmaceut Biomed 35:289–301

Sidwa-Gorycka M, Królicka A, Kozyra M, Głowniak K, Bourgaud F, Łojkowskaa L (2003) Establishment of a co-culture of Ammi majus L. and Ruta graveolens L. for the synthesis of furanocoumarins. Plant Sci 165:1315–1319

Subroto MA, Kian HK, John DH, Pauline MD (1996) Co-culture of genetically transformed roots and shoots for synthesis, translocation, and biotransformation of secondary metabolites. Biotechnol Bioeng 49:481–494

Wu CH, Murthy HN, Hahn EJ, Paek KY (2007) Large-scale cultivation of adventitious roots of Echinacea purpuria in airlift bioreactors for the production of cichoric acid, chlorogenic acid and cafteric acid. Biotechnol Lett 29:1179–1182

Wu CH, Murthy HN, Hahn EJ, Paek KY (2008) Establisment of adventitious root co-culture of Ginseng and Echinacea for the production of secondary metabolites. Acta Physiol Plant 30:891–896

Wu CH, Wang M, Song H, Cui XH (2013) Medium salt strength and sucrose concentration affectroot growth and secondary metabolite contents in adventitious root cultures of Echinacea pallida. Nat Prod Res Dev 25:1167–1171

Yin SS, Zhang Y, Gao WY, Wang J, Man SL, Liu H (2014) Effects of nitrogen source and phosphate concentration on biomass and metabolites accumulation in adventitious root culture of Glycyrrhiza uralensis Fisch. Acta Physiol Plant 36:915–921

Yue CJ, Zang ZJ, He YP, Xiao LJ (2010) Progress of co-culture impact on production of plant secondary metabolites. Anhui Agri Sci Bull 16:26–28

Zhang Y, Liu K, Wu LJ (2001) Advances in studies on Echinacea Moench. Chin Tradit Herb. Drugs 32:852–855

Zhu L, Chen J, Tang X, Xiong YL (2008) Reducing, radical scavenging, and chelation properties of in vitro digests of alcalase-treated zein hydrolysate. J Agric Food Chem 56:2714–2721

Zou Y, Liao S, Shen W, Liu F, Tang C, Chen C (2012) Phenolics and antioxidantactivity of mulberry leaves depend on cultivar and harvest month in Southern China. Int J Mol Sci 13:16544–16553

Acknowledgements

This work was supported by National Natural Science Foundation of China (31370388) and Dalian Municipal Science and Technology Plan Project (2009E11SF126).

Author contributions

CHW conceived and designed the research. DA, LNS, MW, GNC, and CYZ conducted experiments. MLL wrote the manuscript. All authors read and approved the manuscript.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Communicated by Ali R Alan.

Rights and permissions

About this article

Cite this article

Wu, C.H., An, D., Sun, L.N. et al. A novel co-culture system of adventitious roots of Echinacea species in bioreactors for high production of bioactive compounds. Plant Cell Tiss Organ Cult 130, 301–311 (2017). https://doi.org/10.1007/s11240-017-1224-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11240-017-1224-5