Abstract

(S)-N-Boc-3′-hydroxyadamantylglycine (I) is an important intermediate of saxagliptin for type 2 diabetes mellitus (T2DM). It was prepared from 1-adamantanecarboxylic acid(1) via mild reaction with sulfuric acid/nitric acid, VHA reagent (SOCl2/DMF) and sodium diethyl malonate, then was treated with hydrolysis, decarboxylation, alkalization and oxidation to give 2-(3-hydroxy-1-adamantyl)-2-oxoacetic acid (4), then through oximation, reduction and (Boc)2O protection to give the N-Boc-3′-hydroxyadamantylglycine(6), then was treated with quinidine to get (S)- N-Boc-3′-hydroxyadamantylglycine(I) and quinine to get (R)–N-Boc-3′-hydroxyadamantylglycine(II). Finally, Compound II was racemized by dicyclohexylcarbodiimide (DCC) and sodium hydride (NaH) to afford compound 6. In this route, the overall yield of preparing compound I was about 35 % and the enantiomeric excess (ee) reach to 99 %. This route provided a novel idea for the preparation of (S)-N-Boc-3′-hydroxyadamantylglycine.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Diabetes is a complicated and progressive disease that seriously influence patients’ health and severely threaten their lives. According to the data showed in the seventh edition of the DIABETES ATLAS, published by the International Diabetes Federation, until 2015, there were about 415 million adults subjected to the threats of diabetes all over the world, and this number will probably rise to 642 million in 2040 [1]. Saxagliptin [2], co-designed by AstraZeneca and Bristol-Myers Squibb, is an original antidiabetic drug with the merit of high selectivity, less side effect and good treatment compliance, which rapidly attracted widespread attention when it was authorized by FDA in 2009 [3]. By means of retrosynthetic analysis, we find (S)-N-Boc-3′-hydroxyadamantylglycine (I), a tailor-made α-amino acid [4], is an essential synthetic intermediate of saxagliptin (Scheme 1). The synthesis of tailor-made α-amino acids gradually becomes to be a subject of current research interest and continually plays an important role in the new generation drug design. Although a significant progress in this area has been already achieved, a general and cost-effective access to tailor-made chiral amino acid, on relatively large scale, has not been reached thus far [5]. In accordance with some relevant synthetic strategies, the asymmetric hydrogenation of α,β-dehydro-α-amino acid derivatives [6] and the Strecker reaction [7] has produced outstanding results in the last decade. However, both methods cannot be successfully applied to the synthesis of all types of α-amino acids. Another landmark in the asymmetric synthesis of α-amino acids is the application of chiral derivatives of glycine [8]. However, the main disadvantage is the low C–H acidity of the glycine methylene moiety, which requires the use of strong bases, such as n-BuLi, low temperatures (−78 °C), and anhydrous conditions to form the corresponding enolates. Furthermore, preparation of these derivatives requires multi-step sequences, rendering them relatively expensive, in particular for application on a large scale. Despite a large number of papers reported the synthetic applications of Ni(II) complexes of glycine and other α-amino acids to get the tailor-made amino acid [9–11], however, the use of heavy metal Ni and the requirement of harsh conditions blocked its actual application on industrial production. Therefore, the general methodologies available for preparation of various amino acids are not applicable for preparation of 3′-hydroxyadamantylglycine. A latest approach that employed chemical dynamic kinetic resolution of unprotected racemic tailor-made α-amino acids can be available for Ref. [12]. However, this method required already made racemic amino acids and therefore more comprehensive procedure starting from inexpensive materials is highly desirable.

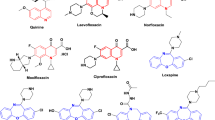

As for the specific synthesis of the (S)-N-Boc-3′-hydroxyadamantylglycine, a lot of methods were reported (Scheme 2). Vu et al. [13] and Hanson et al. [14] originally described a method of inverting acid 4 to compound I by enzyme catalytic ammoniation and then protected by (Boc)2O. In this route, it used the inaccessible enzyme as the catalyst, which made the process was hard to control and consequently raised the difficulty of its implementation. Vu et al. [13] treated the 1-adamantaneacetic acid as initial material, which reacted with SOCl2 and N,N-dibromohydantoin to get 2-bromo-2-(3-hydroxyadamantan-1-yl)acetic acid that was then substituted by amino and protected by (Boc)2O to obtain compound I after resolution. This route required greatly multiple reaction steps as well as relatively complicated procedures. Moreover, the enantiomeric excess (ee) only reach to 70–80 %, therefore, it cannot meet the demand of the criterion for pharmaceutical intermediates, which needs no less than 99 % ee. Besides, Augeri et al. [15] regarded methyl adamantane-1-carboxylate as crude material, through reduction, oxidation and asymmetric Strecker reaction, which was ulteriorly hydrolyzed under acidic condition, reduced by hydrogen and protected by (Boc)2O to produce (S)-N-Boc-1-adamantylglycine. Subsequently, it was oxidized by potassium permanganate to acquire compound I. This route applied the asymmetric synthesis to provide compound I, exacting severe reaction conditions and badly hypertoxic reactants, which limited the application to industrial production. Benito-Garragori et al. [16] treated 1-acetyladamantane with potassium permanganate yielded 2-(adamantan-1-yl)-2-oxoacetic acid, through catalytic amination, which was accordingly hydroxylated by mixed acid to generate 3-hydroxyadamantylglycine. However, the route mentioned above capitalized on expensive metal catalyst and didn’t involve the protection of amino as well as the chiral separation. Chen et al. [17] and Wang et al. [18] formerly brought forward a relatively simple route, but the yield of the oxidation of adamantane ring was too low to reproduce and the chiral separator was early reported in a world patent [19]. A latest approach was reported to net compound I, published by Reddy et al. [20] and Dong et al. [21], treatment of 1-adamantanecarboxylic acid with esterification, reduction and oxidation attained adamantane-1-carbaldehyde, which afterwards tracked five steps to achieve compound I. Nevertheless, the reaction reagents were too extremely sophisticated to utilize, especially the use of highly venomous sodium cyanide, which was not conductive to laborers’ health as well as environmental protection. Additionally, putting the oxidation of adamantane ring in last step dissipated some intermediates that were produced before, which increased its cost and blocked the adhibition on large production. Furthermore, all of these reported methods did not concern the separation of remaining (R)-N-Boc-3′-hydroxyadamantylglycine and its racemization, which could be recycled to synthesize compound I. To sum up, owing to such defects that were described above, our group came up with a facile and economic approach to synthesize compound I and racemize compound II with rare moderate operation circumstance and inexpensively acceptable materials (Scheme 3).

Results and discussion

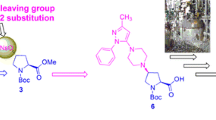

As obviously figured in Scheme 3, this synthetic method thought of 1-adamantanecarboxylic acid (1) as premier material which was hydroxylated afterwards by sulfuric acid/nitric acid to afford 3-hydroxy-1-adamantanecarboxylic (2). After reacting with VHA reagent (SOCl2/DMF) and sodium diethyl malonate, compound 2 went through hydrolysis, decarboxylation and alkalization without separating and extracting the intermediates, which immediately obtained 1-acetyl-3-hydroxyadamantane (3), then oxidized to yield 2-(3-hydroxy-1-adamantyl)-2-oxoacetic acid (4). Subsequently, treating compound 4 with hydroxylamine hydrochloride acquired 2-(3-hydrox-1-adamantyl)-2- hydroxyimino acetic acid (5). Sequentially, compound 5 was reduced by Ni–Al and protected by (Boc)2O to make N-Boc-3′-hydroxyadamantylglycine (6), which accordingly afforded compound I or compound II by the way of chiral separation. Furthermore, compound II was racemized by DCC/NaH to afford compound 6, which can be recycled to synthesize compound I. This route neither utilized expensive and dangerous reagents nor demanded severe and inaccessible conditions to achieve the synthesis of compound I. And most importantly, compared to other methods mentioned in Scheme 2, this route not only particularly possessed creative academic value but also contained comprehensive application prospect, which was not ever reported before and largely allayed the expense of preparing compound I.

In this work, we put the emphasis on the synthesis of compound 4 and the chiral separation of compound 6 as well as the racemization of compound II.

There were three main methods were covered to preparing compound 4. Method one [22] used extremely deleterious oxalyl chloride and trimethylchlorosilane as reagents, and the condition of Swern oxidation required quite low temperature (−78 °C), which was not adequate for the application of industry process. Meanwhile, method two [23] employed exceedingly high-priced 1,1-dichloro-2,2-bis(trimethylsilyloxy) ethylene that potentially blocked its further study. Method three [24] was previously carried out by our group, however, the ultimate step of oxidation was hard to reproduce and greatly decreased the total yield, which was only 27.5 %. According to analyzing these methods, we found the hydroxylation of adamantane ring was the key factor affecting the total yield and putting it in the last step always decreased the yield. Therefore, in order to remedy those limitations, our team brought forward an entirely moderate route, based on the method three, to provide compound 4. In this route, we advanced the hydroxylation of adamantane ring by sulfuric acid/nitric acid and chose the VHA reagent (SOCl2/DMF) to substitute the quondam acylation reagent, which consequently increased the yield of compound 4 and shortened the duration of reactions. Moreover, we optimized the hydroxylation of adamantane ring through central composite design-response surface methodology [25] focused on three important factors (X 1: the volume ratio of H2SO4–HNO3, X 2: reaction temperature and X 3: reaction time) after single factor test study of compound 2 (Fig. 1) [26].The result of central composite design-response surface methodology was depicted in Table 1 and the corresponding response surface of compound 2 was described in Fig. 2. Each factor has been conducted multiple linear regression and binomial fitting by the software of Design-Expert 8.0.6.1. Multiple linear regression equation was: Y (yield) = + 74.30 + 1.42X 1−0.74X 2 + 0.79X 3 (r 1 = 0.1396), the binomial equation was: Y (yield) = −285.50 + 26.17X 1−0.49X 2 + 4.9635.16X 3 + 0.06X 1 X 2−0.11X 1 X 3−0.008X 2 X 3−1.49\(X_{1}^{2}\)−0.11\(X_{2}^{2}\)−1.13\(X_{3}^{2}\) (r 2 = 0.8432). The correlation coefficient of binomial equation (r 2) was bigger than that of multiple linear regression (r 1), so the binomial model was ultimately the successful model. Figure 2 which was drawn based on the binomial equation showed within a certain range, the yield increased as the volume ratio of H2SO4–HNO3 increased and the reaction temperature rose, as well as the reaction time increased. Each response surface has its preferable area, and the yield of product could reach maximum in this area. The optimized range of producing compound 2 which was obtained by overlap of each response surface was: X 1:5.63–10.37, X 2: −5.96–5.95 °C, X 3: 13–17 h. After comprehensive consideration, the finally got optimum process conditions were: the volume ratio of H2SO4 to HNO3 (8/1), reaction temperature (0 °C), reaction time (15 h), with a good yield of 89 %.

As for the chiral separation of compound 6 and racemization of compound II, we produced diastereoisomeric salts through the combination between racemic compound 6 and various chiral alkaloids, and then separated the enantiomer from these salts by crystallization because the diastereoisomers differed in solubility in a same solvent. We screened a variety of alkaloids such as ephedrine, cinchonine, cinchonidine, S-(-)-α-phenylethylamine, quinine, quinidine, 1-deoxy-1-(octylamino)-d-glucitol, levamisole, l-arginine and d-(−)- threo-2-amino-1-(p-nitrophenyl)-1,3-propanediol chloramphenicol base, and eventually decided on quinidine as the chiral separator of compound I and quinine as the chiral separator of compound II. Moreover, we preliminarily optimized the reaction conditions to improve the final yield of compound I from three aspects. First of all, we researched the impact of the mole ratio of quinidine to substrate on the yield (Table 2). In the process of chiral separation, the mole ratio of separator to substrate has relatively large impact on the effect of separation, which is commonly among 0.5–1 times, therefore, we discussed the ratio in this range and found one-fold amount of quinidine could obtain satisfactory yield and optical purity. Secondly, we discussed the impact of the volume of solvent on the yield. As obviously revealed in Table 3, when the volume of solvent less than 8 times of the mass of substrate, the optical purity of product could not meet the requirements, while, when the volume of solvent over 8 times of the mass of substrate, the yield decreased with the increase of solvent. And eventually when the ratio of volume of solvent to mass of substrate was 8, the effect of separation was best. Finally, we discussed the impact of crystallization temperature on the yield (Table 4). The crystallization process is very important for the chiral separation and the temperature is often the key factor affecting the quality of the crystal. Generally speaking, low temperature is conductive to crystallization, however, the purity may be declined with the decrease of temperature. Therefore, we researched the crystallization temperature among 0–25 °C and got a good yield at 10 °C. Thus, taking all these factors into consideration, we eventually opted the mole ratio of quinidine to substrate was 1, the ratio of volume of solvent to mass of substrate was 8 and the crystallization temperature was 10 °C as comparatively optimal conditions to achieve the preparation of compound I. And in the process of racemization of compound II, we referenced the method of patent WO2011/117393 A1 [27], which combined compound II with N,N′-carbonyldiimidazole (CDI) to form an amide compound, then was afterwards racemized by NaH and hydrolyzed to afford compound 6 that could be recycled to get compound I. In order to save the cost, we made the DCC to substitute the CDI and found it also could get a satisfactory result. In a word, this method not only avoided using very expensive and highly unstable enzyme, but also made the yield of compound I over 77 % and the enantiomeric excess (ee) reach to 99 %, which was completely in conformity with the quality requirements for saxagliptin intermediate. Besides, the consideration of racemization of compound II greatly decreased the cost and highly increased the availability of compound 6.

Experimental section

General information

Unless otherwise indicated, reagents and solvents were obtained from commercial provenience and utilized without further purification. Organic solvents were evaporated with reduced pressure by the rotary evaporator. Melting points were ensured by RY-1 capillary melting point meter.IR spectra were registered on a spectrophotometer Nicolet FTIR 5700 in the range 550–3600 cm−1. 1H spectra were recorded on a Bruker Avance 400 NMR spectrometer. ESI–MS spectra were obtained with a Finnigan LCQ Advantage Max spectrometer.

3-Hydroxy-1-adamantanecarboxylic acid (2): A solution of concentrated sulfuric acid (20 mL) and nitric acid (2.5 mL, 65 % w/w aqueous solution) was stirred at 0 °C, then 1-adamantanecarboxylic acid(1) (5.0 g, 0.028 mol) was added portion-wise during half an hour. Thereafter, the mixture was stirred at 0 °C for 15 h. Afterwards, distilled water (100 mL) was added at 10 °C and stirred for another 4 h to produce a lot of white solid, which was filtered and recrystallized from propanone/water, then dried to afford compound 2 (4.88 g, 89 % yield). M.p. 199–200 °C; IR(KBr, cm−1): 3450, 2900, 1700, 1250, 1100, 580; ESI -MS (m/z): 195[M]−.

3-Hydroxy-1-acetyladamantane (3): A mixture of anhydrous N, N-dimethylformamide (DMF) (0.5 mL) and thionyl chloride (SOCl2) (20 mL) were stirred at a temperature range of 40–50 °C for 30 min, then compound 2 (5.0 g, 0.026 mol) was added and this solution was stirred at 80 °C for 4 h. After that, the superfluous SOCl2 was drawn over under reduced pressure, and the remainder was 3-chloride -1-adamantanecarbonyl chloride. To a solution of diethyl malonate (10 mL, 0.057 mol) and petroleum ether (20 mL) was added dropwise to metallic sodium (1.28 g, 0.056 mol) in petroleum ether (10 mL) at room temperature, and the mixture was then stirred until the metallic sodium was consumed completely. Subsequently, the 3-chloride-1-adamantanecarbonyl chloride with petroleum ether (15 mL) was tardily added to the consequent suspension and the solution was then stirred at room temperature for 12 h. Distilled water (60 mL) was added to the resulting white mixture, and then the organic layer was separated, which was distilled off under reduced pressure to afford luminous yellow oil residue. Afterwards, a mixture of acetic acid (20 mL), distilled water (6 mL) and concentrated sulfuric acid (2 mL) was added to the residue, and then refluxed for 6 h. The reaction solution was refrigerated to room temperature, and poured into 150 mL cold water, which was then extracted with ethyl acetate (4 × 10 mL), and the combined organic phases were removed by reduced pressure, and 10 % KOH (aq) (40 mL) was added to the residue, then the mixture was heated to reflux and stirred for 6 h. The reaction liquid was cooled to room temperature and extracted with ethyl acetate (4 × 10 mL), and the combined organic phases were removed by reduced pressure. The residue was recrystallized from methylene chloride/hexane and dried to afford compound 3 (3.96 g, 80 % yield). M.p. 89–90 °C (lit. [28] 89–91 °C); IR(KBr, cm−1): 3401, 2900, 1700, 1100, 1410, 600; 1H NMR (400 MHz, DMSO) δ 4.48 (s, 1H), 2.13 (s, 2H), 2.04 (s, 3H), 1.63–1.46 (m, 12H).

2-(3-Hydroxy-1-adamantyl)-2-oxoacetic acid (4): The tert-butanol (10 mL) was added to a mixture of compound 3 (5.0 g, 0.026 mol) and 3 % KOH(aq) (100 mL),then the solution was heated to 35 °C and potassium permanganate (8.6 g, 0.054 mol) was added by several times during half an hour. After that, the mixture was heated to 45 °C and stirred for 4 h. Then, anhydrous sodium sulfite (3.5 g, 0.024 mol) was added and the solution was filtered afterwards. The filtrate was adjusted to pH = 2 with concentrated hydrochloric acid and extracted with ethyl acetate (4 × 10 mL), and the combined organic phases were removed by reduced pressure. The residue was recrystallized from ethyl acetate/petroleum ether and dried to give compound 4 (5.0 g, 86.6 % yield). M.p. 163–165 °C (lit. [29] 164–165 °C); IR(KBr, cm−1): 3401, 2932, 2861, 2482, 1876, 1713, 1689; 1H NMR(400 MHz, DMSO-d6)δ: 3.32 (br s, 1H), 2.16 (s, 2H), 1.74-1.42 (m 12H); ESI–MS (m/z):223[M–H]−.

2-(3-Hydrox-1-adamantyl)-2- hydroxyimino acetic acid (5): A mixture of compound 4 (11.2 g, 0.05 mol) and distilled water (125 mL) were stirred at room temperature and the solution was adjusted to pH = 7 with 10 %NaOH (aq). Until the solution was clear, hydroxylamine hydrochloride (4.175 g, 0.06 mol) was added and it was stirred in an ice bath for 2 h. Then the white sediment was filtered and dried to afford compound 5 (10.79 g, 90 % yield). M.p. 172–174 °C; IR(KBr, cm−1):3429, 3282, 2913, 2864, 1744, 1706; 1H NMR (400 MHz, DMSO-d6) δ: 10.70(br s,1H), 2.13(s, 2H), 1.71–1.41(m, 12H); ESI–MS (m/z): 238 [M–H]−.

N-Boc-3′-hydroxyadamantylglycine (6): A solution of compound 5 (4.78 g, 0.02 mol), absolute ethyl alcohol (40 mL) and 10 % NaOH(aq) (20 mL) was stirred at the temperature of 50 °C, then nickel aluminum (Ni–Al) alloy (2.4 g) was added in a period of half an hour and the mixture was stirred at 50 °C until the reaction was completed. Thereafter, the undissolved substance was filtered and the filtrate was evaporated to afford white solid, which was dissolved in 30 mL water and adjusted to pH = 10 with concentrated hydrochloric acid. Then a mixture of (Boc)2O (5.23 g, 0.024 mol) and tetrahydrofuran (THF, 30 mL) was added and the solution was stirred at room temperature for 12 h and filtered afterwards. The filtrate was adjusted to pH = 2 with concentrated hydrochloric acid and extracted with ethyl acetate (4 × 10 mL), and the combined organic phases were washed with saturated salt water and dried with sodium sulphate (Na2SO4), then the menstruum was removed under reduced pressure and the residue was recrystallized from ethyl acetate/petroleum ether and dried to give compound 6 (5.27 g, 81 % yield). M.p. 178–179 °C; IR(KBr, cm−1): 3407, 3288, 2977, 2926, 2595, 1718, 1696; 1H NMR (400 MHz, CDCl3) δ 6.48 (s, 1H), 5.18 (d, J = 8.8 Hz, 2H), 4.08 (d, J = 8.6 Hz, 1H), 2.25 (s, 2H), 1.59 (dd, J = 44.4, 22.8 Hz, 12H), 1.44 (s, 9H); ESI–MS (m/z): 324 [M–H]−.

(S)-N-Boc-3′-hydroxyadamantylglycine (I): To a solution of compound 6 (2.5 g, 0.08 mol), quinidine (2.5 g, 0.06 mol) and absolute ethyl alcohol (20 mL) was stirred and refluxed for 5 min, then the mixture was cooled and filtered to give white solid, which was dissolved in ethyl acetate (20 mL). Afterwards, 20 mL water was added, and the solution was adjusted to pH = 2 with hydrochloric acid and the organic phase was isolated. Then the water phase was extracted with ethyl acetate (10 mL × 3) and the combined organic solvent was distilled off under depressurization. Eventually, the residue was recrystallized from ethyl acetate/petroleum ether and dried to give compound I (0.96 g, 77 % yield). M.p. 179–180 °C; 99 % ee (HPLC conditions: Daicel ChiralpakAD-H 250 × 4.6 mm, 5 μm; n-hexane/isopropanol = 85/15; flow rate: 1 mL/min; T = 25 °C; 210 nm); \([\alpha ]_{{\text{D}}}^{{20}}\) = + 25° (C = 1, CH3OH).

(R)-N-Boc-3′-hydroxyadamantylglycine: To a solution of compound 6 (2.5 g, 0.08 mol), quinine (2.0 g, 0.06 mol) and butanone (15 mL) was stirred and refluxed for 5 min, then the mixture was recrystallized at room temperature to give white solid, which was dissolved in ethyl acetate (20 mL). Afterwards, 20 mL water was added, and the solution was adjusted to pH = 2 with hydrochloric acid and the organic phase was isolated. Then the water phase was extracted with ethyl acetate (10 mL × 3) and the combined organic solvent was distilled off under reduced pressure to give compound II (0.73 g, 58 % yield). 99 % ee (HPLC conditions: Daicel ChiralpakAD-H 250 × 4.6 mm, 5 μm; n-hexane/isopropanol = 85/15; flow rate: 1 mL/min; T = 25 °C; 210 nm); \([\alpha ]_{{\text{D}}}^{{20}}\)[α]20 D = −25° (C = 1, CH3OH).

Racemization of compound II: A mixture of compound II (2.0 g, 0.06 mol, 99 % ee) and dimethyl sulfoxide (40 mL) was stirred at room temperature, then DCC (1.40 g, 0.07 mol) was added and stirred for 5 h, followed by NaH (0.37 g, 0.09 mol, 60 % in Oleum) was added portion-wise during an hour and stirred at 50 °C for 4 h, then continued to stirred at room temperature for 48 h. Thereafter, the solution was hydrolyzed by adding 30 mL 1 M NaOH (aq) and stirring for 2 h. To a mixture of water (40 mL) and methyl tert-butyl ether (80 mL) was added and the solution was adjusted to pH = 3 with hydrochloric acid. The organic phase was separated and distilled off under reduced pressure to get white solid identified as racemic compound 6 (1.4 g, 70 %, 14.2 % ee).

Conclusions

To summarize, we have put forward a facile and economic method to synthesize (S)-N-Boc-3′-hydroxyadamantylglycine (I) in 35 % overall yield from 1-adamantanecarboxylic acid over six steps. Compared with other previously reported methods, our route not only features moderate reaction conditions, high yields and easily available reagents but also has a prospect for the application of industry process. To the best of our knowledge, the chiral separator used in our study has not been published before and possesses great significance for further academic study.

References

International Diabetes Federation-Key Findings, IDF Diabetes Atlas Seventh Edition Poster Update 2015. http://www.diabetesatlas.org/(2015)

M.L. Mohler, Y. He, Z. Wu et al., Recent and emerging anti-diabetes targets [J]. Med. Res. Rev. 29(1), 125–195 (2009)

B.M. Squibb, ONGLYZA (saxagliptin) Tablets Prescribing Information (Bristol-Myers Squibb, Princeton, 2011)

V.A. Soloshonok, C. Cai, V.J. Hruby, Stereochemically defined C-substituted glutamic acids and their derivatives. 1. An efficient asymmetric synthesis of (2S,3S)-3-methyl- and -3-trifluoromethylpyroglutamic acids[J]. Tetrahedron 55, 12031–12044 (1999)

J.L. Aceña, A.E. Sorochinsky, V.A. Soloshonok, Recent advances in asymmetric synthesis of a-(trifluoromethyl)-containing amino acids. Synthesis 44, 1591–1602 (2012)

P. Etayo, A. Vidal-Ferra´n, Rhodium-catalyzed asymmetric hydrogenation as a valuable synthetic tool for the preparation of chiral drugs. Chem. Soc. Rev. 42, 728–754 (2013)

J. Wang, X. Liu, X. Feng, Asymmetric strecker reactions. Chem. Rev. 111, 6947–6983 (2011)

K. Undheim et al., The Scho¨llkopf chiron and transition metal mediated reactions, a powerful combination for stereoselective construction of cyclic a-quaternary-a-amino acid derivatives. Amino Acids 34, 357–402 (2008)

A.E. Sorochinsky et al., Asymmetric synthesis of a-amino acids via homologation of Ni(II) complexes of glycine Schiff bases. Part: 1 alkyl halide alkylations. Amino Acids 45, 691–718 (2013)

A.E. Sorochinsky et al., Asymmetric synthesis of a-amino acids via homologation of Ni(II) complexes of glycine Schiff bases. Part 2: Aldol, Mannich addition reactions, deracemization and (S) to (R) interconversion of a-amino acids. Amino Acids 45, 1017–1033 (2013)

J.L. Aceña et al., Asymmetric synthesis of a-amino acids via homologation of Ni(II) complexes of glycine Schiff bases Part 3 Michael addition reactions and miscellaneous transformations. Amino Acids 46, 2047–2073 (2014)

Y. Nian et al., Recyclable ligands for the non-enzymatic dynamic kinetic resolution of challenging a-amino acids. Angew. Chem. Int. Ed. 54, 12918–12922 (2015)

T.C. Vu, D.B. Brzozowski, R. Fox, Methods and compounds for producing dipeptidyl peptidase IV inhibitors and intermediates thereof [P]. WO 2004/052850 A2 (2004)

R.L. Hanson, S.L. Goldberg, D.B. Brzozowski, Preparation of an amino acid intermediate for the dipeptidyl peptidase IV inhibitor, saxagliptin, using a modified phenylalanine dehydrogenase [J]. Adv. Synth. Catal. 349, 1369–1378 (2007)

D.J. Augeri, J.A. Robl, D.A. Betebenner et al., Discovery and preclinical profile of saxagliptin (BMS-477118): a highly potent, long-acting, orally active dipeptidyl peptidase IV inhibitor for the treatment of type 2 diabetes [J]. J. Med. Chem. 48, 5025–5037 (2005)

D Benito-Garragori, W Felzmann, K Knepper et al., Process for the reductive amination of α-keto carboxylic acids. WO 2012/028721 A1 (2012)

Y. Chen, A. Wang, Z. Tao et al., A facile synthesis of saxagliptin intermediate N-Boc-3′-hydroxyadamantylglycine [J]. Res. Chem. Intermed. 41, 4113–4121 (2015)

A. Wang, Y. Deng et al., A convenient method for the synthesis of (S)-N-boc-3-hydroxyadamantylglycine: a key intermediate of saxagliptin [J]. Lett. Org. Chem. 11, 627–663 (2014)

T.C. Vu, D.B. Brzozowski, R. Fox et al. Methods and compounds producing dipeptidyl peptidase IV inhibiors and intermediates thereof. WO 2004/052850 A2 (2004)

V Reddy, R Mitra, A Kumar, P. Ramakrishna, A process for industrial preparation for [(S)-N-tert butoxycarbonyl-3-hydroxy]adamantylglycine. WO 2014/057495 A1 (2014)

J. Dong, Y. Gong, J. Liu, X. Chen, X. Wen, H. Sun, Synthesis and biological evaluation of all eight stereoisomers of DPP-IV inhibitor saxagliptin. Bioorg. Med. Chem. 22, 1383–1393 (2014)

M. Politino, M.M. Cadin, P.M. Skonezny, J.G. Chen, Process for preparing dipeptidyl IV inhibitors and intermediates therefor [P]. WO 2005106011 (2005)

S.A. Savage, G.S. Jones, S. Kolotuchin, S.A. Ramrattan, T. Vu, R.E. Waltermire, Preparation of saxagliptin, a novel DPP-IV inhibitor. Org. Process Res. Dev. 13(6), 1169–1176 (2009)

J.K. Li, H.R. Zhou, J. Peng et al., Synthesis of 2-(3-hydroxy-1-adamantyl)-2-glyoxylic Acid. Chin. J. Pharm. 43(4), 251–253 (2012)

Y. Feng, Y.J. Chen, J. Peng et al., Optimization of the synthesis process of 2- (3- hydroxy- 1- adamantyl)- 2-oxoacetic acid by the central composite design- response surface methodology. Chem. Res. Appl. 2, 194–199 (2013)

S.L. Ferreira, R.E. Bruns, J.M. David et al., Statistical designs and response surface techniques for the optimization of chromatographic systems. J. Chromatogr. A 1158(1–2), 2–14 (2007)

W Thorsten, Racemisation of (R)-N-BOC-3-hydroxyadamantyl glycine [P]. WO 2011/117393 A1 (2011)

V.V. Pozdnyakov, I.K. Moiseev, Synthesis of 3-R-1-acetyladamantanes by substitution in 3-chloro- and 3-hydroxy-1-acetyladamantanes. Russ. J. Org. Chem. 39(5), 739–741 (2003)

J.D. Godfrey Jr., R.T. Fox et al., Novel 1,4-homofragmentation via an α-lactone [J]. J. Org. Chem. 71, 8647–8650 (2006)

Acknowledgments

We deeply appreciate the financial support of this research by a grant from the graduate scientific research and innovation projects of Chongqing Education Committee (No. CYS15142). We are also grateful for all that Chongqing Medical University and Chongqing Research Center for Pharmaceutical Engineering have done for accomplishing this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, J., Jiang, X., Gan, R. et al. A facile and economic method for the synthesis of (S)-N-Boc-3′-hydroxyadamantylglycine. Res Chem Intermed 42, 5709–5721 (2016). https://doi.org/10.1007/s11164-015-2398-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2398-2