Abstract

Commercial-scale synthesis of (S)-N-Boc-3-hydroxyadamantylglycine (I), which is the key intermediate of saxagliptin, can be achieved from 2-(3-hydroxy-1-adamantyl)-2-oxoacetic acid (6) by reductive amination with phenylalanine dehydrogenase. The biological enzyme used in the original medicinal chemistry route is expensive and not easily obtained, making it unsuitable for further development. In this work, we developed a conventional chemical approach to give the corresponding oxime from oxoacetic acid followed by reduction of oxime and protected amino with (Boc)2O to afford the racemic mixture of N-Boc-3-hydroxyadamantylglycine (III). Utilizing this route, N-Boc-3-hydroxyadamantylglycine was prepared in six linear chemical steps with 38 % overall yield.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Type 2 diabetes mellitus (T2DM) is a global epidemic with estimated prevalence of 5 % (346 million people) worldwide in 2012; without intervention this number is likely to more than double, and around 470 million people are projected to have prediabetes by 2030 [1]. The health, social, and economic burdens of T2DM are significant [2–4]. Consequently, T2DM presents a major challenge to healthcare systems around the world.

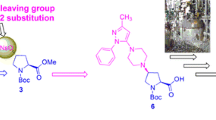

Saxagliptin (Onglyza) is a highly potent, orally available reversible dipeptidyl peptidase IV (DPP-IV) inhibitor (in comparison with other dipeptidyl peptidase enzymes) which is given once daily, being approved by the Food and Drug Administration (FDA) for treatment of type 2 diabetes mellitus in 2009. (S)-N-Boc-3-Hydroxyadamantylglycine (I) as a key intermediate of saxagliptin (Scheme 1) was originally prepared using an expensive and technically demanding enzyme-catalyzed reaction from oxoacetic acid 6 by reductive amination with phenylalanine dehydrogenase (Scheme 2) [5, 6]. Thereafter, various new routes without using enzymes were developed (Scheme 3). Vu et al. [5] (route 1) reported a new method to synthesize the racemic mixture of N-Boc-3-hydroxyadamantylglycine (III), followed by resolution of III to afford I. Route 2 [7] uses an asymmetric synthesis to obtain I, requiring harsh conditions and highly toxic reagent. A relatively simple route has also been developed to prepare III, as shown in route 3 [8], representing the latest research progress regarding III, but the use of expensive metal catalysts [Cp*RhCl2]2 made it unsuitable for large-scale production. A new synthetic approach to III was developed starting from the inexpensive and commercially available 1-adamantanecarboxylic acid (1) (Scheme 5). The synthesis of 1-adamantyl methyl ketone (2) had been reported by our team [9], and we had optimized the synthesis conditions to improve the yield. Compound 2 was converted into 2-(1-adamantyl)-2-oxoacetic acid (3) by oxidation with potassium permanganate in aqueous NaOH. Then, we have two routes to get the final product. In one, the keto acid 3 is treated with hydroxylamine hydrochloride to get 1-adamantyl-2-hydroxyimino acetic acid (4), with reduction of oxime 4 with Raney-Ni and oxidation of 2-(1-adamantyl)glycine (5) with H2SO4/HNO3 to give the racemic mixture of 3-hydroxyadamantylglycine (8). In another, preferred embodiment, 8 is directly obtained from 3 by hydroxylation of the adamantane ring using KMnO4 in hot aqueous NaOH, with reduction of 2-(3-hydroxy-1-adamantyl)-2-hydroxyimino acetic acid (7) to get 8. Alternatively, the Boc-protected amino acid III can be prepared by treatment of 8 with (Boc)2O and NaOH.

Experimental

Method for preparation of 1-adamantyl methyl ketone (2)

A mixture of 20 g (0.11 mol) 1 and 40 mL thionyl chloride was stirred under reflux for 4 h, the excess SOCl2 was removed under reduced pressure, and the residue was 1-adamantanecarbonyl chloride. To a solution of 3.83 g (0.17 mol) sodium in 100 mL petroleum ether at room temperature, we added dropwise over a period of 1 h a mixture of 26.7 mL (0.17 mol) diethyl malonate and 50 mL petroleum ether, and the mixture was stirred until sodium was consumed completely. A solution of 1-adamantanecarbonyl chloride in 50 mL petroleum ether was added slowly (duration 1 h) to the resulting suspension. The mixture was stirred overnight at room temperature. Distilled water (200 mL) was added, and the organic layer was separated; after concentration under vacuum, a mixture of acetic acid (80 mL), distilled water (24 mL), and concentrated sulfuric acid (8 mL) was added and reflux for 6 h, then the reaction solution was poured into 600 mL ice-water for crystallization; the white needle crystal was filtered off and dried to afford 1-adamantyl methyl ketone (2) (yield 18.41 g, 93 %); m.p. 53–54 °C (53–55 °C [10]); IR (KBr, cm−1): 2,930, 2,913, 2,851, 1,698, 1,451, 1,345; ESI-MS: m/z 177 [M-H]−; 1H NMR (300 MHz, CDCl3) δ: 2.09 (s, 3H), 2.07–1.56 (m, 15H).

Method for preparation of 2-(1-adamantyl)-2-oxoacetic acid (3)

Sodium hydroxide solution (2 %, 100 mL), t-butanol (30 mL), and 2 (8.9 g, 0.05 mol) were charged into a 250-mL three-neck round-bottom flask; the contents were heated with an oil bath to 40–45 °C, then potassium permanganate (15.8 g, 0.1 mol) was added over a 1-h period; following the addition, the reaction was stirred for an additional 2 h at 40 °C. The mixture was quenched with 10 % Na2SO3 (10 mL) and filtered through Celite; the filter cake and reaction flask were rinsed with 20 mL hot water. The filtrate was adjusted to pH 1 using concentrated hydrochloric acid, and a large amount of white solid appeared; the white solid was filtered off and dried to afford 3 (yield 9.37 g, 90 %); m.p. 98–101 °C (102–104 °C [11]); IR (KBr, cm−1): 2,906, 2,887, 2,848, 2,675, 2,557, 1,717; ESI-MS: m/z 207 [M-H]−; 1H NMR (300 MHz, MEOH-d4) δ: 2.05 (s, 3H), 1.92–1.739 (m, 12H).

Method for preparation of 1-adamantyl-2-hydroxyimino acetic acid (4)

3 (8.32 g, 0.04 mol) and sodium hydroxide (1.6 g, 0.04 mol) were added to 500 mL aqueous solution and stirred at room temperature until completely dissolved to give a clear solution, then hydroxylamine hydrochloride (3.34 g, 0.048 mol) was added and the reaction solution was stirred in an ice-water bath for 2 h; the white solid was filtered off and dried to afford 4 (yield 7.93 g, 89 %); m.p. 147–149 °C (152–153 °C [12]); IR (KBr, cm−1): 3,280, 2,905, 2,850, 2,527, 1,651, 1,702; ESI-MS: m/z 222 [M-H]−; 1H NMR (300 MHz, DMSO) δ: 2.51–2.44 (m, 1H), 1.93 (s, 3H), 1.79–1.56 (m, 12H).

Method for preparation of 2-(1-adamantyl)glycine (5)

A solution of 4 (4.46 g, 0.02 mol) in alcohol (40 mL) was shaken with hydrogen in the presence of Raney-Ni as catalyst [prepared from 2 g Ni–Al alloy (50–50)] at 50 °C under ordinary pressure for 7 h. After the catalyst had been removed by filtration, the filtrate was dried over anhydrous Na2SO4 and the solvent was removed under vacuum to obtain the crude product, then 20 mL methanol was added in and concentrated hydrochloric acid was added dropwise until the solution became clear; the pH of the solution was adjusted to the isoelectric point with 10 % NaOH, and the precipitate was filtered off and washed with alcohol; the white solid was dried to obtain 5 (yield 3.68 g, 88 %). 5 (0.5 g) was suspended in 10 mL methanol, then concentrated hydrochloric acid was added until giving a clear solution; the solvent was removed to obtain the hydrochloride salt of 5. IR (as hydrochloride salt, KBr, cm−1): 3,449, 3,173, 3,053, 2,903, 2,849, 1,724; ESI-MS: m/z 208 [M-H]−; 1H NMR (as hydrochloride salt, 300 MHz, DMSO-d6) δ: 8.32(s, 3H), 3.25 (d, J = 5.1 Hz, 1H), 1.96 (s, 3H), 1.66–1.51 (m, 12H).

Method for preparation of 2-(3-hydroxy-1-adamantyl)-2-oxoacetic acid (6)

3 (8.32 g, 0.04 mol) was added to a solution of 2 % sodium hydroxide (360 mL). The mixture was stirred and heated to 80 °C, then potassium permanganate (11.4 g, 0.072 mol) was added portionwise to the mixture over a 1-h period; following the addition, the reaction was stirred for an additional 3 h at this temperature. The mixture was quenched with 10 % Na2SO3 (10 mL) and was filtered through Celite; the filter cake and reaction flask were rinsed with 20 mL hot water. The filtrate was adjusted to pH 1 by concentrated hydrochloric acid and extracted with ethyl acetate (3 × 200 mL). The extracts were washed with brine, dried over anhydrous sodium sulfate, and concentrated to give colorless oil, which was recrystallized from ethyl acetate and heptane to give 6 as colorless solid (yield 6.09 g, 68 %); m.p. 162–163 °C (164–165 °C [13]); IR (KBr, cm−1): 3,401, 2,932, 2,861, 2,482, 1,876, 1,713, 1689; ESI-MS: m/z 223 [M-H]−; 1H NMR (300 MHz, DMSO-d6) δ: 3.32 (br s, 1H), 2.16 (s, 2H), 1.74–1.42 (m, 12H).

Method for preparation of 2-(3-hydroxy-1-adamantyl)-2-hydroxyimino acetic acid (7)

6 (8.96 g, 0.04 mol) and sodium hydroxide (1.6 g, 0.04 mol) were added to 100 mL aqueous solution and stirred at room temperature until completely dissolved to give a clear solution, then hydroxylamine hydrochloride (3.34 g, 0.048 mol) was added and the reaction solution was stirred in an ice-water bath for 2 h; the white solid was filtered off and dried to afford 7 (yield 8.63 g, 90 %). m.p. 172–174 °C; IR (KBr, cm−1): 3,429, 3,282, 2,913, 2,864, 1,744, 1,706; ESI-MS: m/z 238 [M-H]−; 1H NMR (300 MHz, DMSO-d6) δ: 10.70 (br s, 1H), 2.13 (s, 2H), 1.71–1.41 (m, 12H).

Method for preparation of 3-hydroxyadamantylglycine (8)

5 (2.09 g, 0.01 mol) was added portionwise to a cooled mixture of HNO3 (65 %, 1.33 mL, 0.019 mol) and H2SO4 (98 %, 32 mL, 0.59 mol) over a 0.5-h period at 0 °C; the reaction was stirred at room temperature overnight and added dropwise to 80 mL ice-water; the pH of the solution was set to 1 by concentrated hydrochloric acid, and the solvent was removed under vacuum to obtain a white solid; 30 mL anhydrous ethanol was added, after which the precipitated inorganic salts were filtered off, the pH of the filtrate was adjusted to the isoelectric point with 10 % NaOH, and the precipitate was filtered off to afford 8 (yield 1.69 g, 75 %).

A solution of 7 (4.78 g, 0.02 mol) in alcohol (40 mL) was shaken with hydrogen in the presence of Raney-Ni as catalyst [prepared from 2 g Ni–Al alloy (50–50)] at 50 °C under ordinary pressure for 7 h. After the catalyst had been removed by filtration, the filtrate was dried over anhydrous Na2SO4 and the solvent was removed under vacuum to obtain the crude product, then 20 mL methanol was added in and concentrated hydrochloric acid was added dropwise until the solution became clear; the pH of the solution was adjusted to the isoelectric point with 10 % NaOH, and the precipitate was filtered off and washed with alcohol; the white solid was dried to obtain 8 (yield 3.86 g, 86 %). 8 (0.5 g) was suspended in 10 mL methanol, then concentrated hydrochloric acid was added until giving a clear solution; the solvent was removed to obtain the hydrochloride salt of 8. IR (as hydrochloride salt, KBr, cm−1): 3,351, 3,187, 3,050, 2,924, 2,903, 2,853, 1,724; ESI-MS: m/z 224 [M-H]−; 1H NMR (as hydrochloride salt, 300 MHz, DMSO-d6) δ: 8.32 (s, 2H), 5.52 (bs, 2H), 3.32 (d, J = 5.2 Hz, 1H), 2.12 (s, 2H), 1.60–1.39 (m, 12H).

Method for preparation of N-Boc-3-hydroxyadamantylglycine (III)

The pH of a mixture of 8 (2.25 g, 0.01 mol) and water (40 mL) was adjusted to 10 with 10 % NaOH, then the reaction mixture was treated with (Boc)2O (2.62 g, 0.012 mol) in tetrahydrofuran (THF, 40 mL). The reaction was stirred at room temperature overnight, and the THF layer was discarded; the aqueous layer was adjusted to pH 3 with concentrated hydrochloric acid. After extracting with ethyl acetate (3 × 30 mL), the aqueous layer was separated and the combined organic layers were washed with brine and dried over Na2SO4, and the solvent removed in vacuo to leave oil, which was recrystallized to obtain III (yield 2.86 g, 88 %). m.p. 177–179 °C; IR (KBr, cm−1): 3,407, 3,288, 2,977, 2,926, 2,595, 1,718, 1,696; ESI-MS: m/z 324 [M-H]-; 1H NMR (300 MHz, CDCl3) δ: 5.18 (d, J = 8.3 Hz, 1H), 4.08 (d, J = 8.8 Hz, 1H), 2.25 (s, 2H), 1.59 (dd, J = 44.4, 22.8 Hz, 12H), 1.44 (s, 9H).

Results and discussion

The original route presents a very attractive pathway based on a key biological enzyme, phenylalanine dehydrogenase (Scheme 2). Although this enzyme catalysis method can afford saxagliptin intermediate I from keto acid 6 efficiently and specifically, the biological enzyme used in this method is expensive and not easily obtained, resulting in high production costs of the final product and thereby increasing the economic burden of diabetics. In addition, the keto acid 6, which could be afforded by several methods [5] as described in Scheme 4, is the raw material of the biological enzyme-catalyzed synthesis. As shown in Scheme 4, 6 can be prepared in five linear chemical steps from 1-bromoadamantane via route 1, but the usage of toxic reagents (such as oxalyl chloride) and harsh reaction conditions (−78 °C) limits its further development and large-scale application. Route 2 also needs long linear chemical steps to afford 6, and the operation is complex. Route 3 was developed as a method to afford compound 6 by reacting 1-adamantanecarboxylic acid with methyl lithium, followed by oxidation of adamantane tertiary–H to hydroxyl with dimethyldioxirane and oxidation of methyl to carboxyl with sodium permanganate. Due to the above limitations, it has become a challenge for us to develop an alternative method for rapid access to intermediate I in good yield.

Some solutions to these problems are shown in Scheme 3. There is no doubt that these routes are not perfect and have various disadvantages, so we developed the new route shown in Scheme 5. In our route, 6 is prepared in three linear chemical steps with good yields from commercially available adamantane intermediate 1-adamantanecarboxylic acid. Compared with the reported routes, our route is not very complicated, the operation is simpler, and the reaction conditions milder; we can further reduce the cost of production by avoiding use of biological enzyme. The highlights of this new synthesis include readily available raw materials, low cost, high yield, mild reaction conditions, and its potential for large-scale industrial application. However, it also showed a few issues; e.g., we can only afford the racemic mixture of intermediate III but not saxagliptin intermediate I. So, in further studies, we need to choose an appropriate method for chiral separation of intermediate III to intermediate I. Despite the issues, we feel that the oxime approach described in Scheme 5 still represents a very attractive and potentially industrial approach to saxagliptin intermediate I.

Previous work showed that compound 2 was converted into compound 6 by oxidation with potassium permanganate with yield of only 36 % [14] and 47 % [9]. Our research indicates potassium permanganate oxidation of methyl into carboxyl with simultaneous oxidation of adamantane tertiary–H into hydroxyl. The electron-withdrawing effect of the carbonyl group made the oxidation of methyl comparatively easy. Therefore, this oxidation reaction was divided into two steps: first using potassium permanganate oxidation of compound 2 to obtain compound 3 in 90 % yield at 40–45 °C, then oxidation of compound 3 at 80 °C to afford compound 4 with yield of 68 %. The total yield of the two-step reaction reached 61.2 %, representing a great improvement compared with literature. In the other route, we used H2SO4/HNO3 to oxidize the adamantane tertiary–H of compound 5 into hydroxyl to give compound 8 in 75 % yield.

Initially, we chose Zn/AcOH as the reducing agent for the reaction of the oxime to amino because of its low cost. Moreover, we found that the reaction was complete and almost no by-product appeared from thin-layer chromatography (TLC); however, the final separation yield was only about 50 %. We believe that maybe the amino and carboxyl groups of the amino acid formed a coordination compound with Zn2+, which led to lower yield (Scheme 6). So we chose Raney-Ni as the reducing agent to afford the corresponding amino acid in high yield [15].

Conclusions

We have developed an efficient and chromatography-free route for preparation of saxagliptin intermediate N-Boc-3-hydroxyadamantylglycine (III). In consideration of the economic costs, a traditional chemical reduction process was utilized to avoid using biological enzyme, we chose the compound 1-adamantanecarboxylic acid (1) as the starting material, and other reagents used in this route were cheap and commercially available. Our route considerably lowers the cost and delivery time required to prepare saxagliptin intermediate N-Boc-3-hydroxyadamantylglycine (III). In the optimized process, the overall yield from the proposed starting materials was approximately 38 %.

References

S. Kang, Diabetes 2012, The Lancet (2012)

M. De Groot, R. Anderson, K.E. Freedland, R.E. Clouse, P.J. Lustman, Psychosom. Med. 63, 619–630 (2001)

D. Wanless, Securing our future health: taking a long-term view. HM Treasury (2002)

A.M. Jacobson, Endocr. Pract. 10, 502–508 (2004)

T. C. Vu, D. B. Brzozowski, R. Fox, Methods and compounds for producing dipeptidyl peptidase IV inhibitors and intermediates thereof. WO 2004/052850 A2 2004

L. Ronald Hanson, L. Steven Goldberg, B. David Brzozowski, Adv. Synth. Catal. 349, 1369–1378 (2007)

J. David Augeri, A. Jeffery Robl, A. David Betebenner, J. Med. Chem. 48, 5025–5037 (2005)

D. Benito-Garragori, W. Felzmann, K. Knepper, T. Wilhelm, Process for the reductive amination of α-keto carboxylic acids, WO 2012028721 A1 2012

J. Li, S. Zhang, H. Zhou, J. Peng, Y. Feng, X. Hu, Lett. Org. Chem. 9, 347–350 (2012)

H. Stetter, E. Rausher, Chem. Ber. 103, 863–865 (1970)

W. C. Jefford, J-C. Flossier, J. Boukouvalas, J. Chem. Soc. Chem. Commun. 23, 701–1702 (1986)

C. E. Hermann, A. N. Jack, Snyder, Alpha-amino-1-adamantylmethyl penicillins, US Patent 3,325,478, 1967

D. Jollie, J.R. Godfrey, Z. Jack, D. Jollie, Gougoutas, J. Org. Chem. 71, 8647–8650 (2006)

M. Berner, R. Partanen, A. Salakka, Process for the preparation of adamantine derivatives. WO 2006/128952 A1 May 6 2006

A. Sakurai, M. Igarashi, H. Midorikawa, Bull. Chem. Soc. Jpn. 38(6), 1030–1032 (1965)

Acknowledgments

This work was supported by the Natural Science Foundation of Chongqing (CSTC, 2006BB5286). We furthermore thank Chongqing Medical University for partial financial support of this work. We are grateful to Yue Feng and Jun Pen for helpful discussions related to this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Y., Wang, A., Tao, Z. et al. A facile synthesis of saxagliptin intermediate N-Boc-3-hydroxyadamantylglycine. Res Chem Intermed 41, 4113–4121 (2015). https://doi.org/10.1007/s11164-013-1515-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-013-1515-3