Abstract

An efficient solvent-free protocol for the synthesis of 4,4′-(arylmethylene)-bis(3-methyl-1-phenyl-1H-pyrazol-5-ol)s via one-pot pseudo five-component condensation reaction of phenyl hydrazine, ethylacetoacetate, and aryl aldehydes in the presence of acetic acid functionalized pyridinium salt (1-(carboxymethyl)pyridinium chloride {[cmpy]Cl}) as reusable catalyst has been reported. Moreover,1 H and13C NMR, mass, CHN analysis, Fourier transform infrared spectroscopy, scanning electron microscope, X-ray diffraction analysis, and calculation of interplaner distance of the catalysts have been studied in this work.

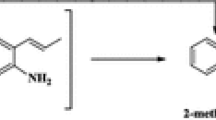

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ionic liquids (based on organic cations such as imidazolium or pyridinium) have received considerable interest as eco-friendly solvents, catalysts and reagents in organic synthesis due to their unique properties, including low volatility, non-flammability, high thermal stability, negligible vapor pressure, and ability to dissolve a wide range of materials [1–9]. Among them, Brønsted acidic ionic liquids, with the useful properties of solid acids and mineral liquid acids, have been introduced to replace the traditional mineral liquid acids like sulfuric acid and hydrochloric acid in chemical procedures [10–25].

Multi-component reactions (MCRs) have a significant role in combinatorial chemistry, in which three or more starting materials react to generate a product, where basically all or most of the atoms contribute to the newly obtained product. Also, MCRs offer some advantages of simplicity and formation ofthe main product without yield of side products and lead to the formation of interesting heterocyclic rings [26–31].

The most common protocol for the synthesis of 4,4′-(arylmethylene)bis(1H-pyrazol-5-ol)s is one-pot three-component condensation reaction of aldehydes with 3-methyl-1-phenyl-5-pyrazolone. This protocol was reported using various catalysts such as [Dsim] AlCl4 [18], [Pyridine–SO3H]Cl [25], THSB [32], SASPSPE [33], (AP-SiO2) [34], N-(3-Silicapropyl)-N-methyl imidazolium hydrogen sulfate ([Sipmim]HSO4) [35], 2-hydroxy ethylammonium propionate [36], N,N-diphenyl-N′-picrylhydrazyl (DPPH), 2,2′-azino-bis(3-ethylenzothiazoline-sulphonic acid), and diammonium salt (ABTS+) [37] . However, limited methods have been introduced for the preparation of these compounds via one-pot pseudo five-component condensation reaction of phenylhydrazine, acetoacetate derivatives, and arylaldehydes [38–40]. Because of the importance of these compounds, the introduction of a milder, faster, and more eco-friendly method accompanied with higher yields is still needed.

Herein, we have utilized acetic acid functionalized pyridinium salt (1-(carboxymethyl)pyridinium chloride {[cmpy]Cl}) (Scheme 1) as an efficient catalyst for the preparation of 4,4′-(arylmethylene)bis(3-methyl-1-phenyl-1H-pyrazol-5-ol)s by the one-pot pseudo five-component condensation reaction of phenyl hydrazine and β-ketoesters derivatives with aromatic aldehydes at 110 °C under solvent-free conditions (Scheme 2).

Experimental

Materials

All chemicals were purchased from Merck or Fluka Chemical Companies. The known products were identified by comparison of their melting points and spectral data with those reported in the literature.

Procedure for the synthesis of 1-(carboxymethyl)pyridinium chloride {[cmpy]Cl}

A mixture of pyridine (0.010 mol) and ethyl chloroacetate (0.010 mol) was stirred and heated at 70 °C for 24 h, during which time the reaction mixture turned to an orange viscous liquid. The liquid was washed with diethyl ether (3 × 30 mL) and dried under vacuum for 2 h. Then, a solution of HCl 37 % (0.011 mol) was added to the prepared liquid and refluxed for 30 min. Finally, the solvent was removed under reduced pressure and the remaining solid was washed with diethyl ether to give the product as a white powder.

1-(carboxymethyl)pyridinium chloride IR (Nujol): 696, 895, 1375, 2650–3550, 3056 cm−1; 1H NMR (400 MHz, DMSO-d6): δ (ppm) 5.72 (S, 2H), 8.23 (t, J = 7.00 Hz, 2H), 8.69 (t, J = 7.00 Hz, 1H), 8.94 (d, J = 6.80 Hz, 2H), 13.57 (s, 1H);13C NMR (75 MHz, DMSO-d6): δ (ppm) 61.0, 128.1, 146.6, 146.8, 168.0; MS: m/z = 173 (M+); CHN Analysis: Anal. Calcd for C7H8ClNO2: C, 48.93; H, 4.74; N, 8.14. Found: C, 48.43; H, 4.64; N, 8.07.

General procedure for the synthesis of 4, 4′-(arylmethylene)- bis (3-methyl-1-phenyl-1H-pyrazol-5-ol)s using 1-(carboxymethyl)pyridinium chloride {[cmpy]Cl}

A mixture of ethylacetoacetate (2 mmol), phenyl hydrazine (2 mmol), and [cmpy]Cl (10 mol%) in a 10 mL round-bottomed flask connected to a reflux condenser, was stirred at 110 °C for 30 s and then aromatic aldehyde (1 mmol) was added to the reaction mixture and continued for the appropriate time. After completion of the reaction, as monitored by TLC, the reaction mixture was cooled to room temperature and recrystallized from ethanol (95 %).

Results and discussion

1-(Carboxymethyl)pyridinium chloride {[cmpy]Cl} was prepared by the reaction of pyridine with ethyl chloroacetate at 70 °C and then hydrolysation the first product was done. The structure of it was identified by1 HNMR,13CNMR, IR and mass as well as elemental analysis in a great similarity with previous literature (Scheme 3).

The IR spectrum of [cmpy]Cl has been displayed in Fig. 1. The broad peak at 2408–3056 cm−1 can be related to O-H stretching of the COOH group. Moreover, the peak observed at 1375 cm−1 corresponds to vibrational modes of C=O bond of the COOH group. On the other hand, the C–H stretching vibrations of the pyridine ring in 1-(carboxymethyl)pyridinium chloride appeared at 3056 cm−1 and C–H bending vibrations of the pyridine ring in [cmpy]Cl observed at 696 and 895 cm−1. These mentioned peaks clearly confirmed the structure of [cmpy]Cl.

The structure of [cmpy]Cl was confirmed by NMR studies. The important peak in 1H NMR spectra of the [cmpy]Cl is related to the acidic hydrogen of COOH, which was observed at 13.57 ppm (Fig. 2). Also, in 13C NMR spectra of [cmpy]Cl, the peaks related to the methylene group and carbonyl group were observed at 61.08 and 168.01 ppm, respectively. The peaks related to pyridine ring were observed at 128.15, 146.69 and 146.85 ppm (Fig. 3).

XRD patterns of 1-(Carboxymethyl)pyridinium chloride {[cmpy]Cl} were studied in a domain of 3°–90° (Fig. 4). As shown in Fig. 4, XRD pattern of 1-(Carboxymethyl)pyridinium chloride {[cmpy]Cl exhibited diffraction lines of a highly crystalline nature at 2θ ≈ 8.9°, 18.2°, 20.4°, 24.7°, 25.4°, 27.4°, 28.7°, 29.9°, 31.8°, 32.0°, 33.1°, 35.1°, 37.9°, and several small lines in the 40°–80º range. Interplaner distance studies of the catalyst could be worked out in the 8.9°–37.9°, and results have been displayed in Table 1. As an example, calculations for the highest diffraction line 25.4° proved that an interplaner distance of 0.3502 nm (see the same highest diffraction line at 25.4°) was calculated to be via the Bragg equation:

(λ: Cu radiation (0.154178 nm) were obtained.

In another investigation, scanning electron microscope (SEM) of [cmpy]Cl was also studied. The SEM micrographs of the catalyst showed that the particles had not completely agglomerated. According to SEM micrographs, the particles of the catalyst were observed in micro scales (Fig. 5).

After characterization of [cmpy]Cl, we examined the catalytic activity of the catalyst for the preparation of 4, 4′-(arylmethylene)-bis(3-methyl-1-phenyl-1H-pyrazol-5-ol)s. In this regard, the condensation of ethylacetoacetate (2 mmol), phenyl hydrazine (2 mmol) with benzaldehyde (1 mmol), as a model reaction, was tested in the presence of different amounts of [cmpy]Cl, at a range of 60–120 °C under solvent-free conditions (Scheme 1). The results are depicted in Table 2. Table 2 indicates that higher yield and shorter reaction time were obtained using 10 mol% of catalysts at 110 °C under solvent-free conditions. No improvement in the reaction results was observed by increasing the amount of the catalysts and the temperature. The reaction was also tested without the catalyst. In this case the reaction proceeded with 15 % of yield after 120 min.

To compare the efficiency of the solution versus solvent-free conditions, a mixture of ethylacetoacetate (2 mmol), phenyl hydrazine (2 mmol) with benzaldehyde (1 mmol), as the model reaction, using [cmpy]Cl in some various solvents was heated in an oil-bath (50 °C). Low yields of the product were isolated, even after elongated reaction times. Using solvents, such as CHCl3, EtOAc, EtOH, H2O, and CH3CN, the product was obtained in low yields (Table 3).

After optimization of the reaction conditions, to explore the efficiency and the scope of the presented protocol, a mixture of ethylacetoacetate (2 mmol) and phenyl hydrazine (2 mmol) in the presence of [cmpy]Cl as catalyst were treated with aromatic aldehydes. The corresponding results are summarized in Table 4. As Table 4 indicates, all aldehydes (including benzaldehyde and arylaldehydes bearing halogens, electron-withdrawing and electron-releasing substituents) were successfully reacted with 3-methyl-1- phenyl-5-pyrazolone derivatives (obtained from reaction of β-ketoester and phenyl hydrazine) to produce the corresponding 4,4′-(arylmethylene)-bis (3-methyl-1-phenylpyrazol-5-ol) derivatives in good to excellent yields and in relatively short reaction times.

In a proposed mechanism, ethylacetoacetate (I) is activated by [cmpy]Cl (Scheme 4). Then, phenyl hydrazine attacks to I and intermediate II is obtained by removing of one molecule of H2O. By intramolecular attack in intermediate II and removing of one molecule of ethanol, 3-methyl-1- phenyl-5-pyrazolone (III) was prepared. III converts to IV after tautomerization. Intermediate V is generated via the condensation of IV with an activated aldehyde by the catalyst and converted to VI by removing of one molecule of H2O. VI as Michael acceptor is reacted with another intermediate of IV to obtain VII. Finally, after the tautomeric proton shift, the desired product is obtained.

In another study, recyclability of the catalyst was examined upon the condensation of ethylacetoacetate (2 mmol) and phenyl hydrazine (2 mmol) with benzaldehyde (1 mmol). After completion of the reaction, H2O was added to the reaction mixture, stirred, and refluxed for 5 min. Then the reaction mixture was filtered and the solvent of the filtrate (H2O) was removed under reduced pressure to separate the catalyst from crude product. Afterward, the reused catalyst was employed for another reaction. We observed that the catalytic activity of the catalyst was restored within the limits of the experimental errors for four successive runs.

Conclusions

In summary, we have introduced an efficient protocole for the 4,4′-(arylmethylene)-bis(3-methyl-1-phenylpyrazol-5-ols) via one-pot pseudo five-component condensation of phenyl hydrazine (2 mmol) and ethylacetoacetate (2 mmol) with aromatic aldehydes (1 mmol) using 1-(carboxymethyl)pyridinium chloride {[cmpy]Cl} as homogenous organic catalyst at 110 °C under solvent-free conditions. The catalyst is fully studied by IR, 1H and 13C NMR, XRD, and SEM as well as mass spectra. The advantages of the presented method are efficiency, generality, high yield, short reaction time, cleaner reaction profile, ease of product isolation, and simplicity.

References

P. Wasserscheid, W. Keim, Ionic liquids—New ‘solutions’ for transition metal catalysis. Angew. Chem. Int. Ed. 39, 3773 (2000)

V.I. Parvulescu, C. Hardacre, Catalysis in ionic liquids. Chem. Rev. 107, 2615 (2007)

M.J. Earle, S.P. Katdare, K.R. Seddon, Org. Lett. 6, 707 (2004)

B.C. Ranu, S. Banerjee, J. Org. Chem. 70, 4517 (2005)

B.C. Ranu, L. Adak, S. Banerjee, Can. J. Chem. 85, 366 (2007)

B. Pegot, G. Vo-Thanh, D. Gori, A. Loupy, Tetrahedron Lett. 45, 6425 (2004)

A. Zare, A.R. Moosavi-Zare, A. Hasaninejad, A. Parhami, A. Khalafi-Nezhad, M.H. Beyzavi, Synth. Commun. 39, 3156 (2009)

A. Zare, A. Parhami, A.R. Moosavi-Zare, A. Hasaninejad, A. Khalafi-Nezhad, M.H. Beyzavi, Can. J. Chem. 87, 416 (2009)

A. Hasaninejad, A. Zare, M. Shekouhy, J. Ameri Rad, J. Comb. Chem. 12, 844 (2010)

M.A. Zolfigol, A. Khazaei, A.R. Moosavi-Zare, A. Zare, Org. Prep. Proced. Int. 42, 95 (2010)

M.A. Zolfigol, A. Khazaei, A.R. Moosavi-Zare, A. Zare, J. Iran. Chem. Soc. 7, 646 (2010)

A.R. Moosavi-Zare, M.A. Zolfigol, E. Noroozizadeh, M. Tavasoli, V. Khakyzadeh, A. Zare, New J. Chem. 37, 4089 (2013)

M.A. Zolfigol, A. Khazaei, A.R. Moosavi-Zare, A. Zare, H.G. Kruger, Z. Asgari, V. Khakyzadeh, M. Kazem-Rostami, J. Org. Chem. 77, 3640 (2012)

M.A. Zolfigol, A. Khazaei, A.R. Moosavi-Zare, A. Zare, V. Khakyzadeh, Appl. Catal. A Gen. 400, 70 (2011)

A.R. Moosavi-Zare, M.A. Zolfigol, O. Khaledian, V. Khakyzadeh, M.D. Farahani, H.G. Kruger, New J. Chem. 38, 2342 (2014)

M.A. Zolfigol, V. Khakyzadeh, A.R. Moosavi-Zare, A. Zare, S.B. Azimi, Z. Asgari, A. Hasaninejad, C. R. Chimie 15, 719 (2012)

A. Zare, T. Yousofi, A.R. Moosavi-Zare, RSC Adv. 2, 7988 (2012)

A. Khazaei, M.A. Zolfigol, A.R. Moosavi-Zare, Z. Asgari, M. Shekouhy, A. Zare, A. Hasaninejad, RSC Adv. 2, 8010 (2012)

A.R. Moosavi-Zare, M.A. Zolfigol, O. Khaledian, V. Khakyzadeh, M.D. Farahani, M.H. Beyzavi, H.G. Kruger, Chem. Eng. J. 248, 122 (2014)

A. Zare, A.R. Moosavi-Zare, M. Merajoddin, M.A. Zolfigol, T. Hekmat-Zadeh, A. Hasaninejad, A. Khazaei, M. Mokhlesi, V. Khakyzadeh, F. Derakhshan-Panah, M.H. Beyzavi, E. Rostami, A. Arghoon, R. Roohandeh, J. Mol. Liq. 167, 69 (2012)

A.R. Moosavi-Zare, M.A. Zolfigol, V. Khakyzadeh, C. Bottcher, M.H. Beyzavi, A. Zare, A. Hasaninejad, R. Luque, J. Mater. Chem. A. 2, 770 (2014)

A. Zare, F. Abi, A.R. Moosavi-Zare, M.H. Beyzavi, M.A. Zolfigol, J. Mol. Liq. 178, 113 (2013)

A.R. Moosavi-Zare, M.A. Zolfigol, M. Zarei, A. Zare, V. Khakyzadeh, J. Mol. Liq. 186, 63 (2013)

A. Khazaei, M.A. Zolfigol, A.R. Moosavi-Zare, J. Afsar, A. Zare, V. Khakyzadeh, M.H. Beyzavi, Chin. J. Catal. 34, 1936 (2013)

A.R. Moosavi-Zare, M.A. Zolfigol, M. Zarei, A. Zare, V. Khakyzadeh, A. Hasaninejad, Appl. Catal. A Gen. 467, 61 (2013)

J. Zhu, H. Bienayme (eds.), Multicomponent Reactions (Wiley, Weinheim, 2005)

A. Khazaei, M.A. Zolfigol, A.R. Moosavi-Zare, F. Abi, A. Zare, H. Kaveh, V. Khakyzadeh, M. Kazem-Rostami, A. Parhami, H. Torabi-Monfared, Tetrahedron 69, 212 (2013)

A. Khazaei, M.A. Zolfigol, A.R. Moosavi-Zare, A. Zare, M. Khojasteh, Z. Asgari, V. Khakyzadeh, A. Khalafi-Nezhad, Catal. Commun. 20, 54 (2012)

A.R. Moosavi-Zare, M.A. Zolfigol, S. Farahmand, A. Zare, A.R. Pourali, R. Ayazi-Nasrabadi, Synlett 25, 193 (2014)

A.R. Moosavi-Zare, M.A. Zolfigol, M. Daraei, Synlett 25, 1173 (2014)

X.-C. Tu, H. Feng, M.-S. Tu, B. Jiang, S.-L. Wang, S.-J. Tu, Tetrahedron Lett. 53, 3169 (2012)

Z. Karimi-Jaberi, B. Pooladian, M. Moradi, E. Ghasemi, Chin. J. Catal. 33, 194 (2012)

Sh Tayebi, M. Baghernejad, D. Saberi, Kh Niknam, Chin. J. Catal. 32, 1477 (2011)

S. Sobhani, A. Hasaninejad, M. Faal Malek, Z. Pakdin Parizi, Synth. Commun. 42, 2245 (2012)

M. Baghernejad, Kh Niknam, Int. J. Chem. 4, 52 (2012)

Z. Zhoua, Y. Zhang, Green Chem. Lett. Rev. 7, 18 (2014)

X. Yang, P. Zhang, Y. Zhou, J. Wang, H. Liu, Chin. J. Chem. 30, 670 (2012)

A. Hasaninejad, M.R. Kazerooni, A. Zare, ACS Sustain. Chem. Eng. 1, 679 (2013)

S. Tayebi, K. Niknam, Iran. J. Catal. 2, 69 (2012)

A. Khazaei, F. Abbasi, A.R. Moosavi-Zare, New J. Chem. 38, 5287 (2014)

Acknowledgements

The authors gratefully acknowledge the Bu-Ali Sina University Research Council and Center of Excellence in Development of Environmentally Friendly Methods for Chemical Synthesis (CEDEFMCS) and University of Sayyed Jamaleddin Asadabadi for providing support to this work.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Moosavi-Zare, A.R., Zolfigol, M.A., Noroozizadeh, E. et al. Cyclocondensation-Knoevenagel–Michael Domino reaction of phenyl hydrazine, acetoacetate derivatives and aryl aldehydes over acetic acid functionalized ionic liquid. Res Chem Intermed 42, 4759–4772 (2016). https://doi.org/10.1007/s11164-015-2317-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2317-6