Abstract

The transformation reaction of 1-(2-aminophenyl)propan-2-ol was studied at 200 °C under argon pressure. A range of catalysts was applied including carbon, titania and zeolite supported Ru, Pd, Pt, Rh, and Ir, as well as metal free zeolites. The highest conversion was obtained with H-Beta-150 and H-Beta-25 and the highest selectivity to 2-methylindoline was achieved with 0.3 % Ir–H-Beta-150 and H-Beta-25. Although the selectivity to 2-methylindole was high for all catalysts, formation of the final product 2-methylindoline only took place over the most acidic catalysts.

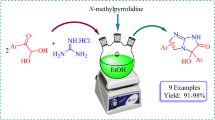

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Amines are intermediates and products of great importance for chemical and life science applications. Secondary amines can be synthesized through N-alkylation of primary amines or through additions to imines, aziridines and carbonyls in the case of alkyl amines, as well as through N-alkylation of primary aryl amines and through addition to imines (reductive alkylation) in the case of aromatic amines [1]. For secondary aromatic amines, the N-alkylation can be achieved starting from nonactivated aryl amines using either alkyl halides or alcohols, or the N-alkylation can be accomplished by metal-catalyzed reactions or using protected aromatic amines [1]. Hydrogen borrowing reaction with alcohols is an environmentally friendly alternative for synthesis of secondary amines [2–4], where the first step is the removal of hydrogen from the alcohol by the catalyst to form an aldehyde, after which the amine reacts with the aldehyde forming an imine and water, and finally hydrogen is returned by the catalyst to the imine resulting in an amine (Scheme 1).

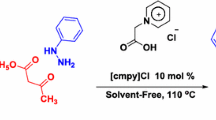

Hydrogen borrowing reactions have previously been studied using homogeneous metal complexes [5–13], although heterogeneous catalysts containing metals such as ruthenium [14–16], gold [17–19], silver [20], nickel [21], palladium [22], platinum [23], platinum–tin [24] and copper [25] have also been used. In this work, the dehydrogenation-cyclization and hydrogen borrowing of 1-(2-aminophenyl)propan-2-ol to 2-methylindole and 2-methylindoline was investigated. Both products are known to be used as intermediates for synthesizing pharmaceuticals, and can be applied also for synthesis of dyes, pigments and optical brighteners. The hydrogen borrowing of 1-(2-aminophenyl)propan-2-ol, not reported previously in the literature, was carried out in an autoclave under argon pressure at 200 °C using a range of supported noble metal catalysts and zeolites without any metal. Heterogeneous catalysts have not been used previously for cyclization of 1-(2-aminophenyl)propan-2-ol to 2-methylindole (the dehydrogenation-cyclization reaction), which has been reported previously using iridium complexes under oxidative conditions [26], not directly relevant for hydrogen borrowing methodology.

2 Experimental

2.1 Catalysts

Commercial catalysts from Degussa, 5 % Ru/C (H105 XB/W 5 %), 10 % Pd/C (E101 NE/W 10 %), 5 % Rh/C (G106 B/W 5 %), 5 % Pt/C (F105 N/W 5 %) were used.

Mesoporous graphite-like carbon material of the Sibunit family was used as a support material to prepare Ir/Sibunit. The preparation procedures and properties of Sibunit carbons are described elsewhere [27]. Prior to use, the support was washed to remove any impurities, first by boiling Sibunit with distilled water to remove suspended coal dust, then washing with HCl (2 M) under reflux for 4 h, and finally washed with distilled water and dried at 120 °C. The iridium catalysts used in the experiments were prepared using solutions of reagent grade IrCl4·nH2O in HCl (0.5 M) (Ir content 52.9 %, JSC “The Gulidov Krasnoyarsk non-ferrous metals plant”) by deposition–precipitation. To prepare the catalyst, the carbon support was dispersed in water. An appropriate amount of an aqueous solution of H2IrCl6 was added dropwise under moderate stirring, followed by addition of Na2CO3 (1 M) aqueous solution, dried overnight at 120 °C and reduced by hydrogen at temperature ramp 2 °C/min up to 350 °C.

The Rh/TiO2, Ru/TiO2, and Pd/TiO2 catalysts were prepared by incipient wetness impregnation technique. The nominal metal loading was 2 wt%. An aqueous solutions of RhCl3·nH2O (40 %, Sigma Aldrich), RuCl3·nH2O (40.49 %, Johnson Matthey), and PdCl2 (59.2 %, Reachim, Russia) were used as metal precursors and TiO2 (Sachtleben Chemie GmbH, 100 % anatase phase) was used as the support. The rhodium and ruthenium metal precursors dissolved in distilled H2O, as well as palladium chloride dissolved in HCl were then added dropwise to the support. The solid was dried at room temperature overnight, reduced in hydrogen at 350 °C (1 °C/min) for Ru and Rh, and at 300 °C (1 °C/min) in case of Pd precursors.

Synthesis of Ir–H-Beta-150-IE (SiO2/Al2O3 molar ratio 150) zeolite catalyst was carried out by ion-exchange method and Ir–H-Beta-150-IMP by evaporation-impregnation in a rotavapour using aqueous solution of iridium chloride. NH4-Beta-150 zeolite obtained from Zeolyst International was transformed to H-Beta-150 by step calcination procedure in a muffle oven. Ir modified H-Beta-150 zeolite catalyst was dried at 100 °C in an oven and calcined at 400 °C. Ru-MCM-41 mesoporous catalyst was prepared using in situ method by direct addition of aqueous ruthenium (III) chloride in the gel solution of MCM-41 mesoporous material. The detail description for the synthesis of Ru-MCM-41 mesoporous catalysts is given in Ref. [28].

The H-Beta-25 zeolite catalyst was modified with platinum using aqueous solution of hexachloroplatinic acid (Merck). The modification of H-Beta-25 catalyst with Pt was carried out using evaporation impregnation method in a rotator evaporator for 24 h. The catalyst was recovered after the completion of synthesis, dried at 100 °C and calcined in a muffle oven at 400 °C.

NH4-Beta-25 and NH4-Beta-300 zeolites (SiO2/Al2O3 molar ratio 25 and 300 respectively) were obtained from Zeolyst International and were transformed to proton forms by step calcinations at 450 °C in a muffle oven.

2.2 Experimental Procedure

The experiments were carried out in a 300 ml autoclave (Parr instruments) under argon pressure (99.999 %, AGA). Synthesis of 1-(2-aminophenyl)propan-2-ol was carried out as described in the literature [26]. Toluene was purchased from J.T. Baker (“Baker analyzed”). 2-Methylindole and 2-methylindoline were purchased from Sigma Aldrich (98 % purity), Before the experiment, the catalyst was reduced, in case of Ru, Pt, Rh, and Ir ex situ at 400 °C (for 1 h, heating rate 5 °C/min) in hydrogen, for 10 % Pd/C in situ at 200 °C for 1 h and 2 % Pd/TiO2 in situ at 100 °C for 1 h under hydrogen. The ex situ reduced catalysts were also pre-treated in situ at 100 °C for 30 min under hydrogen, after which the reactor was flushed with argon. The reactor containing catalyst and 70 ml solvent was heated to the reaction temperature under argon at 1,650 rpm. The reactant and 50 ml solvent was degassed in the bubbling unit for 5 min using argon and then added to the reactor. The total pressure in the reactor were 12 bar. The reaction time was set to zero and the experiment was started.

Samples were taken at different time intervals and analyzed by a gas chromatograph (GC). The samples were prepared for GC using 0.5 ml of the sample taken from the reactor and to this 0.5 ml of an internal standard, consisting of 0.02 M undecane in toluene, was added. An aliquot of 1 µl of the sample was injected with an autosampler to the GC. The injector temperature was 220 °C and the split ratio 50:1. A Supelco B-Dex-225 column was used with the helium gas flow of 0.9 ml/min. The following temperature program was applied: 130 °C for 60 min and 10 °C/min to 160 °C, where it maintained for 10 min. The flame ionization detector (FID) was kept at 300 °C.

2.3 Catalyst Characterization

To determine the metal particle size and dispersion, catalysts were analyzed by CO pulse chemisorption (Autochem 2910, Micrometrics). In these experiments, 0.05–0.1 g of the sample was placed into a quartz U-tube containing silica wool, the tube was inserted to the system and the sample was dried in a stream of helium gas at 50 °C for 30 min. Next, the sample was reduced at the same temperature and time as in the reduction before the experiment in hydrogen, using helium as a carrier gas, after which it was flushed with helium (retained at the reduction temperature) for 1 h, cooled to room temperature, placed on water bath, and subsequently the CO pulses were introduced (10 % CO in helium, helium as a carrier gas) until the adsorption was complete. The dispersion was calculated from the amount of CO consumed, assuming the metal:CO stoichiometry to be unity.

X-ray fluorescence (XRF) technique was used in this work to determine the metal loading (ARL with Rh anode) for the TiO2 supported catalysts. As synthesized Ir–H-Beta-150 zeolite and Ru-MCM-41 mesoporous catalysts were characterized using X-ray powder diffraction for determination of phase purity and nitrogen adsorption for measurement of surface area.

A Perkin-Elmer PHI 5400 spectrometer with a monochromatized Al Kα X-ray source operated at 14 kV and 300 W was used in the XPS analysis of zeolite supported metal catalysts. The pass energy of the analyzer was 17.9 eV and the energy step 0.1 eV. The binding energy calibration was based on the Si 2p peak at 103.3 eV. The sensitivity factors used in the quantitative analysis for Si 2p, O 1s, Ir 4f 7/2, and Ru 3d 5/2 were 0.283, 0.711, 2.402 and 2.208 respectively.

The platinum content of H-Beta-25 was analyzed using inductively coupled plasma atomic emission spectroscopy (ICP-AES). Around 50 mg of the catalyst was dissolved using 4 ml aqua regia and 2 ml of hydrofluoric acid in a microwave oven. The dissolved sample was diluted to 100 ml with de-ionized water and further diluted to 1:5, after which it was analyzed.

2.4 Thermodynamic Calculations

To estimate the reaction thermodynamic characteristics the quantum chemical calculations were carried out by using the molecular modeling program HyperChem 8.0. Initial molecular geometry was optimized by semi-empirical PM3 method. Based on vibrational analysis and statistical thermodynamics, standard thermodynamic functions such as enthalpy, entropy and heat capacity at different temperatures were obtained.

3 Results and Discussion

3.1 Thermodynamics

Thermodynamic calculations made for the overall hydrogen borrowing reaction neglected the temperature effect on the enthalpy and entropy for hydrogen and water. The enthalpy was zero for hydrogen and −241.84 kJ/mol for water and the entropy was 130.52 J/mol K for hydrogen and 188.74 J/mol K for water. The enthalpy for a compound at temperature T was calculated in the following way

where cp is heat capacity.

The thermodynamic properties for the reactant and products at 298 K are given in Table S1 (Supporting information). Table S2, S3 and S4 (Supporting information) give the thermodynamic properties as a function of temperature for 1-(2-aminophenyl)propan-2-ol, 2-methylindole, and 2-methylindoline respectively. Gibbs free energy calculated for the hydrogen borrowing reaction and presented in Table S5 (Supporting information) is clearly negative (ca.–90 kJ/mol) increasing its value with temperature.

3.2 Catalyst Characterization

According to XRF analysis Ru-MCM-41 contains 3.3 wt% of ruthenium, Ir–H-Beta-150-IE 0.3 wt% of iridium, and Ir–H-Beta-150-IMP 0.5 wt% of iridium. The results for Pt–H-Beta-25 were not reliable since the platinum and aluminum peaks overlapped. The ICP-OES gave 4.5 % of platinum for Pt–H-Beta-25.

X-ray powder diffraction patterns of Ru-MCM-41 mesoporous catalyst exhibited presence of RuO2 and MCM-41 phase. Direct introduction of Ru to MCM-41 did not influence the parent structure of the mesoporous materials [27]. Ir–H-Beta-150 catalyst exhibited patterns similar to that of pristine H-Beta-150 zeolite catalyst, indicating the integrity of Beta zeolite structure after IrCl3 modification.

The catalysts were characterized by CO chemisorption to determine the metal dispersion and metal particle size, and the results are given in Table 1.

5 % Rh/C and 5 % Pt/C had the smallest metal particle size. 3.3 % Ru-MCM-41 had the largest metal particles, followed by 5 % Ru/C, 10 % Pd/C and 0.5 % Ir–H-Beta-150-IMP, 1 % Ir/Sibunit and finally by 0.3 % Ir–H-Beta-150-IE and 4.5 % Pt–H-Beta-25.

TiO2 supported catalysts were characterized using XRF and TEM. XRF confirmed that the catalyst loading was 2 wt%. The aim was to determine the metal particle size using TEM, but as seen from the micrographs on Fig. S1–S3 (Supporting information), it was difficult to see the metal particles contour while the presence of metal on the catalyst was definitely confirmed by EDX.

3.3 Catalytic Activity

If transformations of 1-(2-aminophenyl)propan-2-ol are in line with the hydrogen borrowing reaction path then they should follow the reaction sequence presented in Scheme 2.

Since no ketone was observed among the products the first step, e.g. the one giving 2-methylindole, involves in fact dehydrogenation and cyclization, as well as the formation of water, and can be further denoted as dehydrogenation-cyclization reaction. In the second step the intermediate 2-methylindole is hydrogenated by hydrogen that has been “borrowed” by the catalyst giving 2-methylindoline. Besides the main compounds N-propyl-benzene amine was also formed in small amounts.

Various metal catalysts on carbon and titania support were tested in order to see which metal would be active in the hydrogen borrowing reaction. Because only dehydrogenation-cyclization reaction took place, metals supported on Beta zeolite and MCM-41 were also tested. It turned out that these catalysts were active and Beta zeolite per se with varied acidity was used to elucidate behaviour of metal free catalysts.

The results from the experiments using carbon and mesoporous carbon Sibunit supported catalysts are shown in Fig. 1.

Transformations of 1-(2-aminophenyl)propan-2-ol: filled square = 5 % Ru/C, Degussa H105 XB/W 5 %, filled triangle = 10 % Pd/C, Degussa E101 NE/W 10 %, filled diamond = 5 % Pt/C, Degussa F105 N/W 5 %, open square = 5 % Rh/C, Degussa G106 B/W 5 %, open triangle = 1 % Ir/Sibunit, a conversion versus time and b selectivity to 2-methylindole versus conversion. Reaction conditions: 0.02 M in 120 ml toluene, 0.5 g catalyst, 200 °C, 12 bar total pressure (argon), 1,650 rpm

As can be seen from Fig. 1 10 % Pd/C gave the highest conversion in 4 h, followed by 5 % Pt/C, 5 % Ru/C, 5 % Rh/C, and 1 % Ir/Sibunit (Fig. 1a). Selectivity to 2-methylindole was almost 100 % (Fig. 1b) while 2-methylindoline was completely absent. Figure 2 displays the results for titania supported catalysts. The highest conversion was obtained for 2 % Rh/TiO2, followed by 2 % Pd/TiO2, and 2 % Ru/TiO2 (Fig. 2a). The selectivity to 2-methylindole was above 80 % (Fig. 2b) while selectivity to 2-methylindoline was equal to zero.

Transformations of 1-(2-aminophenyl)propan-2-ol: filled square = 2 % Pd/TiO2, filled triangle = 2 % Ru/TiO2, filled diamond = 2 % Rh/TiO2, a conversion versus time and b selectivity to 2-methylindole versus conversion. Reaction conditions: 0.02 M in 120 ml toluene, 0.5 g catalyst, 200 °C, 12 bar total pressure (argon), 1,650 rpm

The results for metal catalysts supported on zeolites and mesoporous materials are presented in Fig. 3. The highest conversion was obtained for 4.5 % Pt–H-Beta-25, followed by 0.5 % Ir–H-Beta-150-IMP, 0.3 % Ir–H-Beta-150-IE, and 3.3 % Ru-MCM-41 (Fig. 3a). The highest selectivity to 2-methylindoline was obtained with 0.3 % Ir–H-Beta-150-IE, followed by 0.5 % Ir–H-Beta-150-IMP, 3.3 % Ru-MCM-41, and 4.5 % Pt–H-Beta-25 (Fig. 3b). The selectivity decreased with conversion whereas the selectivity to 2-methylindole increased with conversion (Fig. 3c).

Transformations of 1-(2-aminophenyl)propan-2-ol: filled square = 0.5 % Ir–H-Beta-150-IMP, filled triangle = 3.3 % Ru-MCM-41, filled diamond = 0.3 % Ir–H-Beta-75-IE, open square = Pt–H-Beta-25 a conversion versus time, b selectivity to 2-methylindoline versus conversion, and c selectivity to 2-methylindole versus conversion. Reaction conditions: 0.02 M in 120 ml toluene, 0.5 g catalyst, 200 °C, 12 bar total pressure (argon), 1,650 rpm

In order to elucidate the role of metal, Beta zeolites per se without any metal were tested (Fig. 4).

Transformations of 1-(2-aminophenyl)propan-2-ol: filled square = H-Beta-25, filled diamond = H-Beta-150, filled triangle = H-Beta-300, a conversion versus time, b selectivity to 2-methylindoline versus conversion, c selectivity to 2-methylindole versus conversion, and d yield to 2-methylindoline versus time. Reaction conditions: 0.02 M in 120 ml toluene, 0.5 g catalyst, 200 °C, 12 bar total pressure (argon), 1,650 rpm

The most acidic zeolite (H-Beta-25) together with the second most acidic (H-Beta-150) demonstrated the highest conversion (Fig. 4a). The highest selectivity to the desired product 2-methylindoline obtained for H-Beta-25 was almost 70 % (Fig. 4b) decreasing with conversion. Interestingly, the selectivity to 2-methylindole increased with conversion (Fig. 4c). The yield of 2-methylindoline went through a maximum, with the highest yield of 34 % obtained for H-Beta-25 (Fig. 4d). Reddy et al. [29] used zeolites ZSM-5 with varied acidity, H-Mordenite and H-Y in the cyclocondensation of 5-amino-1-pentanol to piperidine at 350 °C. The yield of piperidine increased with increasing Si/Al ratio, meaning that a less acidic zeolite gave higher yield to piperidine contrary to the results in the present study. Since it was noticed that the yield of 2-methylindoline passes through a maximum, dehydrogenation of 2-methylindoline to 2-methylindole over H-Beta-25 under argon at 200 °C was also tested and as seen from Fig. 5, the conversion was 91 % in 4 h.

The conversion in 4 h, the turnover frequency (TOF) at 1 h reaction time as well as the selectivity to 2-methylindole and 2-methylindoline at 30 % conversion are presented in Table 2.

Conversion was 100 % in 4 h for 0.5 % Ir–H-Beta-150-IMP, 4.5 % Pt–H-Beta-25, H-Beta-25, and H-Beta-150. The TOF was the highest for Beta zeolite supported iridium catalysts, but since the reaction also takes place on only support material, such comparison based on exposed site of Ir is not a fair one. Selectivity to the desired product 2-methylindoline at 30 % conversion was the highest for 0.3 % Ir–H-Beta-150-IE followed by H-Beta-25. Acidic support itself gave high yields of the desired product, while the acidic support combined with the metal afforded even higher yields.

Transformations of the starting substrate to methylindole take place in the presence of all catalysts investigated, while generation of 2-methylindoline proved to be more challenging proceeding only with the acidic catalysts. Some traces of 2-methylindoline were obtained with 2 % Ru/TiO2. If the overall reaction follows the hydrogen borrowing path then experimental results should be discussed addressing a feasibility to hydrogenate 2-methylindole to 2-methylindoline. In some recent publications hydrogenation of 2-methylindole to 2-methylindoline has been studied showing that addition of an acid is needed to enhance the reaction rate [30, 31] of the hydrogenation reaction.

Scheme 1 illustrates the concept of hydrogen borrowing reactions for primary alcohols. For secondary alcohols this scheme should be modified and account for formation of ketones (Scheme 2). The reaction mechanism for the hydrogen borrowing reaction under inert atmosphere in the case of 1-(2-aminophenylpropan-2-ol should thus include: (i) removal of hydrogen and formation of a ketone, (ii) cyclization and removal of water to form an imine in the liquid phase, (iii) protonation of imine and subsequent hydrogenation forming an amine. Typically hydrogenation–dehydrogenation steps require presence of metal sites, while amination in principle can occur at least in the case of aldehydes even without any catalyst [32]. As already mentioned in the current work no formation of ketone was observed by GC analysis. Moreover, dependence of selectivity to 2-methylindole and 2-methylindoline on conversion as well an experimental evidence on 2-methylindoline dehydrogenation to 2-methylindole (Fig. 5) are not in line with Scheme 2, but rather fitted with an alternative reaction network presented in Scheme 3.

It should be noted that transformation of 1-(2-aminophenyl)propan-2ol to 2-methylindoline through the path presented in Scheme 3 is thermodynamically feasible as the Gibbs energy for this reaction is the same as was calculated for the overall hydrogen borrowing reaction. Dehydration of various alcohols to olefins in the presence of zeolites is well known [33, 34]. The main argument against formation of an intermediate olefin, which in fact was not observed experimentally, is that olefins are mainly used for C-alkylation being typically not applied for N-alkylation as well as O- and S-alkylation due to low reactivity. At the same time even direct acid promoted cyclodehydration of amino alcohols should not be ruled out as demonstrated recently for similar homogeneous acid catalyzed reactions [35, 36].

4 Conclusions

Transformations of 1-(2-aminophenyl)propan-2-ol to 2-methylindoline and 2-methylindole were studied using carbon, titania and zeolite supported Ru, Pd, Pt, Rh, and Ir as well as zeolites without any metal sites at 200 °C in argon (12 bar total pressure). High yields of 2-methylindole were obtained with the majority of tested catalysts, while acidic zeolite catalysts with or even without metal can also result in formation of 2-methylindoline. Reaction network was proposed which comprised dehydration–cyclization and dehydrogenation steps.

References

Salvatore RN, Yoon CH, Jung KW (2001) Tetrahedron 57:7785–7811

Hamid MHSA, Slatford PA, Williams JMJ (2007) Adv Synth Catal 349:1555–1575

Guillena G, Ramón DJ, Yus M (2010) Chem Rev 110:1611–1641

Watson AJA, Williams JMJ (2010) Science 329:635–636

Blank B, Michlik S, Kempe R (2009) Chem Eur J 15:3790–3799

Blank B, Madalska M, Kempe R (2008) Adv Synth Catal 350:749–758

Fujita K, Li Z, Ozeki N, Yamaguchi R (2003) Tetrahedron Lett 44:2687–2690

Fujita K, Enoki Y, Yamaguchi R (2008) Tetrahedron 64:1943–1954

Gnanamgari D, Sauer ELO, Schley ND, Butler C, Incarvito CD, Crabtree RH (2009) Organometallics 28:321–325

Hamid MHSA, Allen CL, Lamb GW, Maxwell AC, Maytum HC, Watson AJA, Williams JMJ (2009) J Am Chem Soc 131:1766–1774

Lamb GW, Watson AJA, Jolley KE, Maxwell AC, Williams JMJ (2009) Tetrahedron Lett 50:3374–3377

Prades A, Corberán R, Poyatos M, Peris E (2008) Chem Eur J 14:11474–11479

Tillack A, Hollmann D, Mevius K, Michalik D, Bähn S, Beller M (2008) Eur J Org Chem 28:4745–4750

Kim JW, Yamaguchi K, Mizuno N (2009) J Catal 263:205–208

Shi F, Tse MK, Zhou S, Pohl M-M, Radnik J, Hüber S, Jähnisch K, Brückner A, Beller M (2009) J Am Chem Soc 131:1775–1779

Yamaguchi K, He J, Oishi T, Mizuno N (2010) Chem Eur J 16:7199–7207

Ishida T, Kawakita N, Akita T, Haruta M (2009) Gold Bull 42:267–274

Zotova N, Roberts FJ, Kelsall GH, Jessiman AS, Hellgardt K, Hii KK (2012) Green Chem 14:226–232

He L, Lou X-B, Ni J, Liu Y-M, Cao Y, He H-Y, Fan K-N (2010) Chem Eur J 16:13965–13969

Liu H, Chuah G-K, Jaenicke S (2012) J Catal 292:130–137

Alonso F, Riente P, Yus M (2011) Acc Chem Res 44:379–391

Corma A, Ródenas T, Sabater MJ (2010) Chem Eur J 16:254–260

Shimizu K-I, Ohshima K, Tai Y, Tamura M, Satsuma A (2012) Catal Sci Technol 2:730–738

He W, Wang L, Sun C, Wu K, He S, Chen J, Wu P, Yu Z (2011) Chem Eur J 17:13308–13317

Lihar PR, Arundhathi R, Kantam ML, Prathima PS (2009) Eur J Org Chem 31:5383–5389

Fujita K, Yamamoto K, Yamaguchi R (2002) Org Lett 4:2691–2694

Kumar N, Mäki-Arvela P, Hajek J, Salmi T, Murzin DYu, Heikkilä T, Laine E, Laukkanen P, Väyrynen J (2004) Microporous Mesoporous Mater 69:173–179

Miyazaki E (1980) J Catal 65:84–94

Reddy BN, Kulkarni SJ, Subrahmanyam M (1994) Appl Catal A 119:23–32

Kulkarni A, Zhou W, Török B (2011) Org Lett 13:5124–5127

Wang D-S, Chen Q-A, Li W, Yu C-B, Zhou Y-G, Zhang X (2010) J Am Chem Soc 132:8909–8911

Demidova YuS, Simakova IL, Wärnå J, Simakov A, Murzin DYu (2014) Chem Eng J 238:164–171

Bryant DE, Kranich WL (1967) J Catal 8:8–13

Minachev KhM, Garanin VI, Isakov YaI (1964) Russ Chem Bull 13:1635–1636

Kang KH, Do J, Park YS (2012) J Org Chem 77:808–812

Hwang S, Park H, Kwon Y, Kim S (2014) RSC Adv 4:60017–60024

Acknowledgments

This work is a part of activities at the Åbo Akademi Process Chemistry Centre (PCC), a Centre of Excellence financed by Åbo Akademi University. Financial support from European Union through the Seventh Framework Programme (Project 246095-2) is gratefully acknowledged. Mr. Markku Reunanen and Dr. Annika Smeds are acknowledged for analysis by GC–MS.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bernas, H., Demidova, Y.S., Aho, A. et al. Transformations of 1-(2-Aminophenyl)propan-2-ol to 2-Methylindoline. Catal Lett 145, 955–963 (2015). https://doi.org/10.1007/s10562-014-1474-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-014-1474-3