Abstract

A series of ferrocene-containing dihydropyrimidines (DHPs) were prepared by the one-pot Biginelli reaction of formylferrocene, 1,3-dicarbonyl component and urea/thiourea. The reaction was catalyzed by a commercial Keggin heteropolyacid (H4SiMo12O40) as a safe, clean and recyclable catalyst. Three different synthetic protocols were examined in order to improve the yields of the reaction and to elucidate its mechanism. Intermediates of the competitive Knoevenagel reaction were also isolated. The methodology is operationally simple and provides access to highly substituted dihydropyrimidines containing ferrocene in very good yields. The catalyst can be used and recycled without appreciable loss of the catalytic activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, there has been increasing interest in the design of suitable protocols leading to both typical and new compounds. Green procedures seek to reduce contamination through the use of some strategies that include obtaining products through multicomponent reactions (MCRs), using recyclable catalysts, and reducing the use of solvents and auxiliary substances, among others [1].

One of the most important MCRs is the Biginelli reaction that involves the cyclocondensation reaction between a 1,3-dicarbonyl compound, a substituted aldehyde, and urea in the presence of a catalyst to obtain dihydropyrimidinones (DHPMs). DHPMs contain a heterocyclic system of remarkable pharmacological efficiency due to a range of biological effects, including antiviral, antitumor, antibacterial, antihypertensive and anti-inflammatory activities [2–4]. Monastrol is a DHPM considered as a new lead for the development of anticancer drugs [5]. In addition, during the last two decades, many methodologies involving the synthesis of DHPMs have been reported in a recent review article [6]. One of us has studied the Biginelli reaction, in sustainable conditions, using heteropolyacids as catalysts [7, 8].

On the other hand, ferrocene derivatives have attracted the attention of the scientific community on account of their interesting chemistry. Ornelas [9] has written an exhaustive and interesting review showing different ferrocene derivatives, as well as describing their most relevant applications. Due to the electronic properties and easy functionalization of ferrocene, the ferrocene-containing compounds have found several applications in materials science including as catalysts [10–15], sensors [16–18], and electroactive materials [11, 19, 20]. Their use in medicinal chemistry is also an active research area. Studies describing their activity as antifungal and antibacterial [21, 22], antitumoral [23–25], and against malaria [26, 27] and human immunodeficiency virus (HIV) [28] have been reported.

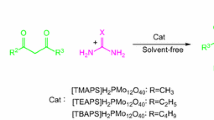

Heteropolyacids with different transition metals such as Ag1H2PW [29], Fe3O4@SiO2-HPW [30], and MCM-41-supported phosphotungstic acid [31], among others, have been used as environmental friendly catalysts. Furthermore, several Lewis acid catalysts, including FeCl3/HCl, BF3·OEt2, LaCl3·7H2O, Ytterbium triflate, InX3 [32], H3BO3/AcOH [33, 34], and FeCl3/TMSCl/CH3CN [35], have been employed to improve the synthesis of ferrocenyl-substituted DHPs using the Biginelli reaction.

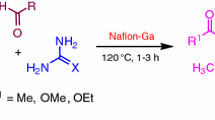

In this paper, we report a simple and convenient one-pot synthesis of ferrocenyl-pyrimidones using a commercial and recyclable heteropolyacid (H4SiMo12O40) with Keggin structure (Scheme 1).

Experimental

General and instrumentation

Chemicals were purchased from Aldrich, Fluka and Merck, and were freshly used after purification by standard procedures (distillation and recrystallization). The used catalyst, molibdosilicic acid hydrate (>99.9 %; Aldrich) was fully characterized by one of us in previous works [36–38].

All the reactions were monitored by TLC on precoated silica gel plates (254 mm). Flash column chromatography was performed with silicagel (230–400 mesh). All the yields were calculated from crystallized products. All the products were identified by comparison of physical data (mp, TLC and NMR) with those reported. Melting points (uncorrected) of the compounds were determined in sealed capillary tubes (Büchi apparatus). The 1H-NMR and 13C-NMR spectra were performed on a Bruker Avance DPX-400 spectrometer using standard Bruker software. The chemical shifts were expressed in δ units with Me4Si (TMS) as the internal standard.

Catalytic test

Procedure A

A solution of 1 mmol of ethylacetoacetate, 1 mmol of formylferrocene, 1.5 mmol of urea and 1 % of the commercial heteropolyacid (H4SiMo12O40) was added to 5 ml of the selected solvent and then heated with stirring in an argon atmosphere under reflux of the solvent (or 100 °C for acetic acid) for the required time (see Table 1). The reaction mixture was cooled to room temperature and then poured into ice water (50 ml). The precipitated solid was filtered, washed with the cold solvent used in the reaction, dried in vacuum and subjected to flash column chromatography on silica using DCM-EtOH (79:1) as solvent to obtain products with different retention times that were recrystallized in EtOH.

Procedure B

A solution of 1 mmol of formylferrocene, 1.5 mmol of urea and 1 % of the commercial heteropolyacid (H4SiMo12O40) was added to 5 ml of the selected solvent and then heated with stirring in an argon atmosphere under reflux of the solvent (or 100 °C for acetic acid) for 1 h. The reactor was removed from the heating bath and allowed to cool to room temperature, then 1 mmol of ethylacetoacetate was added and the reaction was continued with heating as in procedure A.

Procedure C (recovery of the catalyst)

The reaction was conducted as in procedure B. After consumption of the reactants (TLC), the solvent was evaporated and the residue was extracted with CH2Cl2 (2 × 3 ml). The catalyst was filtered and the filtered solution was concentrated in vacuum. The residue was subjected to flash column chromatography and recrystallized as in procedure A.

Catalyst reuse

Stability tests of the bulk PA catalysts were carried out by running four consecutive experiments using procedure C under the same reaction conditions. After each test, the separated catalyst was washed with CH2Cl2 (2 × 2 ml), dried under vacuum, and then reused.

Physical properties of compound 1

Yellow pale powder; m.p. 228–229 (decomp.). 1H NMR (d6-DMSO): 9.13 (1H, s, 1-NH), 7.50 (1H, s, 3-NH), 4.96 (1H, d, J = 4 Hz, 4-CH), 4.14–3.93 (m, C5H4), 4.19 (5H, s, C5H5), 4.11 (2H, q, J = 7 Hz, CH2), 2.15 (3H, s, 6-CH3), 1.23 (3H, t, J = 7 Hz, CH3); 13C NMR (d6-DMSO): 166.7 (OCO), 153.8 (NCON), 148.4 (6-C), 101.6 (5-C), 94.5 (1′-C), 68.0 and 67.7 (3′ and 4′-C), 66.8 and 65.8 (2′ and 5′-C), 60.3 (CH2O), 49.6 (4-C), 18.4 (4-CH3), 15.2 (CH3).

Results and discussion

Optimum reaction conditions were examined employing formylferrocene, ethylacetoacetate and urea as the test reaction and using the procedures A and B described above. In procedure A, all components were added together with the catalyst at the beginning of the reaction. In procedure B, ethylacetoacetate was added after heating the other components and catalyst for 1 h.

The optimal reaction condition for 1 was obtained using procedure B and acetic acid as solvent. In this condition, a yield of 65 % of ferrocene derivative 1 was obtained (Table 1, entry 8). When H3PMo12O40 was used, the yield fell to 54 % (Table 1, entry 9). A general trend observed with Brønsted acid catalyzed reactions is that the yields decrease with the decreasing of the acid strength in the following order: H3PW12O40 > H3PMo12O40 = H4SiW12O40 > H4SiMo12O40. Furthermore, H3PW12O40 is cheaper than H4SiMo12O40. However, when we used the former catalyst under the same conditions as H4SiMo12O40 (Table 1, entry 9), several unidentified byproducts were detected by TLC (in the present work) causing a lower yield. Although yield loss is not significant, the byproducts generated by the use of the most acidic catalyst of the series, made the separation and purification of the final product more difficult and expensive. For this last reason, we selected H4SiMo12O40 as the catalyst to obtain ferrocenyl-substituted DHPs.

Table 2 shows the yields of 1 as a function of reaction time employing procedure B. The yield of 1 rises to 73 % with the additional reaction time of 2 h (Table 2, entry 4). A further increment does not show yield improvements (72 %; Table 2, entry 5).

Table 3 shows the effect of the amount of catalyst on the yield of ferrocene derivative 1 (blank experiment: entry 1). When we performed the reaction without the catalyst, a yield of only 31 % was obtained. It can also be seen that the yields increased from 57 to 73 % when the amount of catalyst increased from 0.5 to 1 % (Table 3, entries 2 and 3), and no relevant changes of the reaction yield were observed with a further increase in the amount of catalyst (2 %) (72 %; Table 3, entry 4). Thus, 1 % of catalyst is a suitable amount for performing this reaction.

The reuse of the catalyst was investigated in the consecutive reaction of formylferrocene, ethylacetoacetate and urea. For this study, we used procedure C. This method is the same as B but the isolation procedure is changed in order to recover the catalyst. After completion of the reaction, the solvent was evaporated and the residue was extracted with CH2Cl2 (2 × 3 ml). The catalyst was filtered, dried in vacuum, and reused in the next experiment. The results shown as yields of ferrocene derivative 1 are summarized in Table 4. The catalyst was reused three runs under the same conditions without appreciable loss of its catalytic activity.

Using the optimized condition, a dissolution of formylferrocene (1 mmol), dicarbonyl component (1 mmol), urea or thiourea (1.5 mmol), acetic acid (5 ml) and H4SiMo12O40 (50 mg, 1 %) was heated at 100 °C with stirring during 1 + 2 h (Scheme 1) to obtain seven substituted ferrocene derivatives (Table 5). The NMR data of the 4-ferrocenyl-3,4-dihydropyrimidiones 1, 2 [32] and 5 [33] and -thiones 3, 4, 6 and 7 [34] match very well with the values reported in the literature. Melting points were used as test control (see Table 5). In all the experiments, the desired compounds were obtained as unique products.

Scheme 2 displays a plausible reaction mechanism for the ferrocene derivative 1 synthesis. In a previous work [8], we found that the mechanism proposed by Kappe [39] is the most appropriate when Bronsted acid was used. Kappe observed the formation of bis-ureide with no other detectable intermediates and proposed the N-acyliminium pathway (Scheme 2) for the Biginelli reaction. This mechanism has been further supported by mass spectrometry and density functional theory calculations [40]. The bis-ureide was also detected by us in the reaction between benzaldehyde and N-methyl urea by 1H-NMR and 13C-NMR spectroscopy [8]. The first step involves the nucleophilic attack of urea on the electron-deficient carbon of the aldehyde function under acidic conditions (I-H +), giving the two tautomeric N-acyliminium ion intermediates (IIa and IIb). The second step begins with the nucleophilic addition of the enol form of 1,3-carbonyl compound (IIIb) over the positive imine carbon atom of the resonance form (IIc), joining the three components and giving the keto and imino carbocations (IVa and IVb). This carbocation site suffers an intramolecular nucleophilic addition and produces the cyclization of the structure (Va and Vb). Subsequent interchanges of protons and loss of water and H+ form product 1.

To obtain further evidence of this mechanism, we alternatively performed the procedures A and B. Following procedure A, two secondary products with lower retention times were isolated after flash chromatography. The compounds were identified as the E/Z isomers of 3-ferrocenyl-2-methylcarbonyl-2-propenoic acid ethyl ester (compounds 8 and 9) as a result of the Knoevenagel condensation of formylferrocene with ethylacetoacetate (see Scheme 3). In this competitive reaction, the ethylacetoacetate enol form IIIb adds to the electrophilic carbon atom of the protonated formylferrocene I-H +. This well-established mechanism ends with the double-bond formation and consequent loss of water (Scheme 3). In this condition, 50 % yield of ferrocene derivative 1 together with 15 and 25 % yields of intermediates 8 (E-isomer) and 9 (Z-isomer), respectively, were obtained.Footnote 1

To minimize the formation of this product, we performed procedure B. In this procedure, formylferrocene and urea are first put together to form the N-acyliminium ion intermediates (IIa and IIb) and, after 1 h of heating, the third component (ethylacetoacetate) is added. In this condition, the reaction yield improved to 65 % (Table 1, entry 8) and only traces of Knoevenagel intermediates were formed (yield of both isomers below 5 %).

Conclusions

A novel, efficient and environmentally friendly one-pot multicomponent procedure for the synthesis of 4-ferrocenyl-3,4-dihydropyrimidiones and thiones in acetic acid at 100 °C was developed based on the use of commercial H4SiMo12O40 as recyclable catalyst. Seven examples of 4-ferrocenyl-3,4-dihydropyrimidiones and thiones 2-arylpyridines were obtained with very good yields (63–73 %). Although these yields were similar to the other procedures previously reported, the present methodology has the advantage of the separation and reuse of the catalyst. Also, its activity remains constant after three cycles, representing a friendly alternative environment. The E/Z isomers produced by the condensation between the diketo and formyl components were isolated and identified as secondary products, showing that Knoevenagel condensation was a competitive mechanism. Moreover, when the reaction was performed in two steps and the diketo component added after the formation of the iminium ion, the yield of the desired product improved. To the best of our knowledge, this is the first report on the synthesis of ferrocenyl-appended dihydropyrimidiones and thiones using heteropolyacids as catalyst.

Notes

8: 1H NMR (CDCl3): 7.48 (1H, s, =CH), 4.46 (2H, m, 2′ and 5′), 4.42 (m, 3′ and 4′), 4.26 (2H, q, J = 7.1 Hz, CH2), 4.21 (5H, s, C5H5), 2.41 (3H, s, COCH3), 1.33 (3H, t, J = 7.1 Hz, CH3); 13C NMR (CDCl3): 203.6 (CO), 164.7 (OCO), 142.1 (=CH), 129.0 (=C), 75.6 (1′-C), 71.9 (2′ and 5′-C), 70.7 (3′ and 4′-C), 69.9 (C5H5), 61.1 (CH2), 31.2 (COCH3), 14.2 (CH3); 9: 1H NMR (CDCl3): 7.46 (1H, s, = CH), 4.51 (2H, m, 2′ and 5′), 4.48 (m, 3′ and 4′), 4.37 (2H, q, J = 7.1 Hz, CH2), 4.21 (5H, s, C5H5), 2.34 (3H, s, COCH3), 1.38 (3H, t, J = 7.1 Hz, CH3); 13C NMR (CDCl3): 193.8 (CO), 168.5 (OCO), 143.2 (=CH), 130.1 (=C), 75.3 (1′-C), 72.3 (2′ and 5′-C), 70.7 (3′ and 4′-C), 70.0 (C5H5), 61.4 (CH2), 26.5 (COCH3), 14.1 (CH3).

References

P.T. Anastas, J.C. Warner, Green Chemistry: Theory and Practice (Oxford University Press, Oxford, 1998)

C.O. Kappe, Acc. Chem. Res. 33, 879 (2000)

C.O. Kappe, Tetrahedron 49, 6937 (1993)

K.S. Atwal, B.N. Swanson, S.E. Unger, D.M. Floyd, S. Moreland, A. Hedberg, B.C. O’Reilly, J. Med. Chem. 34, 806 (1991)

S.J. Haggarty, T.U. Mayer, D.T. Miyamoto, R. Fathi, R.W. King, T.J. Mitchison, S.L. Schreiber, Chem. Biol. 7, 275 (2000)

S. Suresh, J.S. Sandhu, Arkivoc i, 66 (2012)

G.P. Romanelli, A.G. Sathicq, J.C. Autino, G. Baronetti, H.J. Thomas, Synth. Commun. 37, 3907 (2007)

O. D´allessandro, G. Sathicq, V. Palermo, L.M. Sanchez, H. Thomas, P. Vázquez, T. Constantieux, G. Romanelli, Curr. Org. Chem. 16, 2763 (2012)

C. Ornelas, New J. Chem. 35, 1973 (2011)

C. Ornelas, J.R. Aranzaes, L. Salmon, D. Astruc, Chem. Eur. J. 14, 50 (2008)

D. Astruc, C. Ornelas, J. Ruiz, Acc. Chem. Res. 41, 841 (2008)

C. Ornelas, J. Ruiz, C. Belin, D. Astruc, J. Am. Chem. Soc. 131, 590 (2008)

A. Wang, C. Ornelas, D. Astruc, P. Hapiot, J. Am. Chem. Soc. 131, 6652 (2009)

D. Astruc, C. Ornelas, J. Ruiz, Chem. Eur. J. 15, 8936 (2009)

C. Ornelas, J. Ruiz Aranzaes, E. Cloutet, S. Alves, D. Astruc, Angew. Chem. Int. Ed. 46, 872 (2007)

D. Astruc, C. Ornelas, J. Ruiz Aranzaes, J. Inorg. Organomet. Polym Mater. 18, 4 (2008)

C. Ornelas, J. Ruiz, D. Astruc, Organometallics 28, 4431 (2009)

R. Djeda, A. Rapakousiou, L. Liang, N. Guidolin, J. Ruiz, D. Astruc, Angew. Chem. Int. Ed. 49, 8152 (2010)

M.-C. Daniel, A. Sakamoto, J. Ruiz, D. Astruc, H. Nishihara, Chem. Lett. 35, 38 (2006)

J.D. Megiatto, K. Li, D.I. Schuster, A. Palkar, M.A.n. Herranz, L. Echegoyen, S. Abwandner, G. de Miguel, D.M. Guldi, J. Phys. Chem. B 114, 14408 (2010)

C. Biot, N. François, L. Maciejewski, J. Brocard, D. Poulain, Bioorg. Med. Chem. Lett. 10, 839 (2000)

J. Zhang, Appl. Organomet. Chem. 22, 6 (2008)

L.V. Snegur, V.N. Babin, A.A. Simenel, Y.S. Nekrasov, L.A. Ostrovskaya, N.S. Sergeeva, Russ. Chem. Bull. 59, 2167 (2010)

M.F.R. Fouda, M.M. Abd-Elzaher, R.A. Abdelsamaia, A.A. Labib, Appl. Organomet. Chem. 21, 613 (2007)

E. Hillard, A. Vessières, G. Jaouen, in Medicinal Organometallic Chemistry, ed. G. Jaouen and N. Metzler-Nolte (Springer, Berlin, 2010), pp. 81–117

L. Delhaes, C. Biot, L. Berry, L.A. Maciejewski, D. Camus, J.S. Brocard, D. Dive, Bioorg. Med. Chem. 8, 2739 (2000)

T. Itoh, S. Shirakami, N. Ishida, Y. Yamashita, T. Yoshida, H.-S. Kim, Y. Wataya, Bioorg. Med. Chem. Lett. 10, 1657 (2000)

A.K. Kondapi, N. Satyanarayana, A.D. Saikrishna, Arch. Biochem. Biophys. 450, 123 (2006)

Y. Ren, B. Liu, Z. Zhang, J. Lin, J. Ind. Eng. Chem. 21, 1127 (2015)

S. Wang, Z. Zhang, B. Liu, J. Li, Cat. Sci. Technol. 3, 2104 (2013)

A. Liu, Z. Zhang, Z. Fang, B. Liu, K. Huang, J. Ind. Eng. Chem. 20, 1977 (2014)

N.-Y. Fu, Y.-F. Yuan, M.-L. Pang, J.-T. Wang, C. Peppe, J. Organomet. Chem. 672, 52 (2003)

A. Csámpai, A.Z. Györfi, G.I. Túrós, P. Sohár, J. Organomet. Chem. 694, 3667 (2009)

K. Kiss, A. Csámpai, P. Sohár, J. Organomet. Chem. 695, 1852 (2010)

Z.-T. Wang, L.-W. Xu, C.-G. Xia, H.-Q. Wang, Tetrahedron Lett. 45, 7951 (2004)

P. Vázquez, L. Pizzio, C. Cáceres, M. Blanco, H. Thomas, E. Alesso, L. Finkielsztein, B. Lantaño, G. Moltrasio, J. Aguirre, J. Mol. Catal. A: Chem. 161, 223 (2000)

M.E. Chimienti, L.R. Pizzio, C.V. Cáceres, M.N. Blanco, Appl. Catal. A 208, 7 (2001)

D. Bennardi, G. Romanelli, J. Autino, L. Pizzio, P. Vázquez, C. Cáceres, M. Blanco, Reac Kinet Mech Cat 100, 165 (2010)

C.O. Kappe, J. Org. Chem. 62, 7201 (1997)

R.O.M.A. De Souza, E.T. da Penha, H.M.S. Milagre, S.J. Garden, P.M. Esteves, M.N. Eberlin, O.A.C. Antunes, Chem. Eur. J. 15, 9799 (2009)

Acknowledgments

We thank Universidad Nacional de La Plata, CONICET and ANPCyT for financial support. GR is member of CONICET. J.L.J. acknowledges the Deutscher Akademischer Austauschdienst, Germany (DAAD), for a scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jios, J.L., Metzler-Nolte, N., Vázquez, P.G. et al. One-pot synthesis of ferrocenyl-pyrimidones using a recyclable molibdosilicic H4SiMo12O40 heteropolyacid. Res Chem Intermed 42, 977–986 (2016). https://doi.org/10.1007/s11164-015-2067-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2067-5