Abstract

A novel series of 4-(substituted phenyl)-6-ferrocenyl-3,4-dihydropyrimidin- 2(1H)-ones has been synthesized by the Biginelli reaction between different substituted aromatic aldehydes, acetylferrocene and urea in the presence of boric acid as a catalyst. In addition, the effects of different conditions on the reaction were explored. The structures of all the target compounds were confirmed by FT-IR, 1H NMR, and 13C NMR.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

3,4-Dihydropyrimidinones (DHPMs) are important nitrogenous heterocyclic compounds [1], which have attracted considerable interest because of their wide range of biological and pharmacological activities such as anticancer activity [2, 3], antivirus [4], antifungal [5], anticonvulsant [6], antihepatitis [7], antitumor [8, 9], urease inhibition [10], anti-inflammatory and calcium channel blockers [11, 12]. Duing to their broad spectrum of pharmacological activities, researchers have performed an extensive and in-depth research theoretically and methodologically on the synthesis of DHPMs [13, 14]. The Biginelli condensation reaction is a classical method to obtain DHPMs. This ternary condensation of urea, aldehydes, and 1,3-dicarbonyl compounds results in the synthesis of 3,4-dihydropyrimidin-2(1H)-ones derivatives. This method has been widely used for the synthesis of dihydropyrimidin-2-ones because of its good results as a simple one-pot and stable method to get DHPMs. However, this method sustains the drawbacks such as the lower yields of the desired products especially in case of substituted aldehydes and loss of benign functional groups during the reaction. Therefore, in the recent years several improved methodologies mainly using CeCl3·7H2O [15], Bi(NO3)3 [16], FeCl3/nanopore Silica [17], ZrCl4 or ZrOCl2·8H2O [18], Y(NO3)3·6H2O [19], TaBr5 [20], Yb(PFO)3 [21], ClCH2COOH [22], sulfated tungstate [23], TsOH [24], HCl [25], DBSA [26], TEAA [27], PEt@Fe/IL [28], AlKIT-5 [29], Fe3O4/SMPA [30], CD-SO3H [31], SCM [32], NH4H2PO4/MCM-41 [33], SBNPSA [34], SBSSA [35], NSPVPC [36], [Cbmim]Cl [37], trypsin [38], l-proline [39], TMSCl [40], P(4-VPH)HSO4 [41] have been employed as heterogeneous catalyst for the synthesis of dihydropyrimidinones.

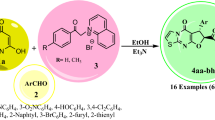

Ferrocenyl compounds have good biological activity in drug fields. Our group previously has synthesized a series of ferrocene derivatives [42,43,44], such as ferrocenylchalcone, ferrocenyl Schiff bases and ferrocenyl Mannich bases, etc. We started to search for the synthesis of Biginelli derivatives containing ferrocenyl, because of some prospective medicinal value from the ferrocenyl derivatives [45, 46], which were synthesized by the Biginelli reaction. Our team selected a green, environmentally friendly and economical method to synthesize a number of 3,4-dihydropyrimidinone derivatives containing ferrocenyl groups (Scheme 1).

Experimental

Materials and methods

All the chemicals and reagents used are of analytical grade, and were used without further purification. The target compounds were isolated and characterized by FT-IR, 1H NMR and 13C NMR. NMR tests were run on Bruker Avance 400 MHz in CDCl3 with tetramethylsilane as an internal standard. Infrared spectra (400–4000 cm−1) were recorded on Bruker Vector-22 FT-IR with samples prepared as KBr pellets. Melting points were recorded on an X-4 micro-melting point apparatus and uncorrected. Acetylferrocene were synthesized according to the procedures reported by Liu [47].

Synthesis of 3,4-dihydropyrimidin-2(1H)-one containing ferrocenyl

A mixture of acetylferrocene (1 mmol), urea (1.2 mmol), aromatic aldehydes (1 mmol), boric acid (0.8 mmol), acetic acid (10 mL) was stirred at 100°C. The reaction progress was monitored by TLC. After completion of the reaction, the mixture was cooled to room temperature and poured into ice water, filtered and washed with water. The crude product was purified by column chromatography on silica gel/ethyl acetate/petroleum ether (2:1) to give the title compounds (1a–1h).

4-Phenyl-6-ferrocenyl-3,4-dihydropyrimidin-2(1H)-one (1a)

IR(KBr,cm−1)v:3303(νN–H),3187(νC=C–H),2960,2925(ν–CH),1699(νsC=O),1590,1543(ν–C=C,Ar),1268(νC–N),1101(νasC–C,Fc), 746, 696(γC–H, Ar–R);

1HNMR(400 MHz,CDCl3):δ9.37(s,1H,N–H),7.59(d,1H,N–H),7.41(m,2H,Ar–H),7.28(d,3H,Ar–H),6.86(d,1H,C=C–H),6.12(s,1H, –CH), 5.54–5.01(m, 4H, Fc–H);

13C NMR(100 MHz, CDCl3):δ 189.63,140.76,140.28,135.18,131.05,129.35,128.95,126.13,102.67,54.53.

4-(4-Methylphenyl)-6-ferrocenyl-3,4-dihydropyrimidin-2(1H)-one (1b)

IR(KBr,cm−1)v:3298,3275(νN–H),3033(νC=C–H),2924,2854(ν–CH),1680(νC=O),1597,1537,1461(ν–C=C,Ar),1383(δs–CH3),1271(νC–N),1100(νasC–C, Fc),843(γC–H, Ar–R);

1HNMR(400 MHz,CDCl3):δ9.35(s,1H,N–H),7.58(d,1H,N–H),7.29(d,2H,Ar–H),7.09(d,2H,Ar–H),6.84(d,1H, C=C–H),6.07(s,1H,–CH),5.55–5.15(m,4H,Fc–H),2.28(s,3H,–CH3);

13CNMR(101 MHz,CDCl3):δ189.69,155.41,140.69,138.88,137.44,135.17,131.20,129.98,126.05,102.54,54.34, 21.32.

4-(4-methoxyphenyl)-6-ferrocenyl-3,4-dihydropyrimidin-2(1H)-one (1c)

IR(KBr,cm−1)v:3443,3302(νN–H),3007(νC=C–H),2924,2854(ν–CH),1694(νC=O),1669(νC=C),1593,1540,1513,1461(ν–C=C,Ar),1373(δs–CH3),1250(νC–N),1101(νasC–C,Fc),821(γC–H,Ar–R);

1HNMR(400 MHz,CDCl3):δ9.35(s,1H,N–H),7.55(d,1H,N–H),7.33(d,2H,Ar–H),6.86–6.80(m,2H,Ar–H),6.79(s,1H,C=C–H),6.06(s,1H,–CH),5.51–5.31(m,4H,Fc–H),3.74(s,3H,–OCH3);

13CNMR(100 MHz,CDCl3):δ189.69,159.99,155.43,140.49,135.08,132.68,131.31,131.12,127.50,114.55,102.43, 55.46,54.01.

4-(4-hydroxyphenyl)-6-ferrocenyl-3,4-dihydropyrimidin-2(1H)-one (1d)

IR(KBr,cm−1)v:3552(νO–H),3414,3235(νN–H),3007(νC=C–H),2923(ν–CH),1676(νC=O),1640(νC=C),1613,1541,1513,1412(νC=C, Ar),1265(νC–N),1113(νasC–C,Fc),832(γC–H,Ar–R);

1HNMR(400 MHz,CDCl3):δ9.43(s,1H,–OH),9.36(s,1H,N–H),7.40(d,1H,N–H),7.16(d,1H,Ar–H),7.05(d,2H,Ar–H), 7.00(s,1H,Ar–H),6.63(d,1H,C=C–H),6.26(s,1H,–CH),5.78–5.22(m,2H,Fc–H);

13CNMR(100 MHz,CDCl3):δ190.09,156.85,154.69,141.38,134.98,131.47,130.10,127.53,114.80,102.57, 49.81.

4-(4-Fluorophenyl)-6-ferrocenyl-3,4-dihydropyrimidin-2(1H)-one (1e)

IR(KBr,cm−1)v:3387,3186(νN–H),3076(νC=C–H),2924(ν–CH),1697(νC=O),1642(νC=C),1609,1546,1504,1461(νC=C, Ar), 1271(νC–N),1105(νasC–C,Fc),842(γC–H,Ar–R);

1HNMR(400 MHz,CDCl3):δ9.38(s,1H,N–H),7.51(d,1H,N–H),7.41–7.35(m,2H,Ar–H),6.97(t,2H,Ar–H),6.88(d,1H, C=C–H),6.14(s,1H,–CH),5.62–5.07(m,4H,Fc–H);

13CNMR(100 MHz,CDCl3):δ189.61,140.63,136.16,136.13,134.81,131.13,128.16,128.08,116.24,116.03,102.99z53.58.

4-(4-Chlorophenyl)-6-ferrocenyl-3,4-dihydropyrimidin-2(1H)-one (1f)

IR(KBr,cm−1)v:3236,3189(νN–H),3099(νC=C–H),2923(ν–CH),1696(νC=O),1537,1455(νC=C,Ar),1267(νC–N),1096(νasC–C,Fc),843(γC–H,Ar–R);

1HNMR(400 MHz,CDCl3):δ9.38(s,1H,N–H),7.51(d,1H,N–H),7.33(d,2H,Ar–H),7.25(s,2H,Ar–H),6.88(d,1H,C=C–H), 6.15(s,1H,–CH),5.58–5.17(m,4H,Fc–H);

13CNMR(100 MHz,CDCl3):δ189.58,155.04,140.79,138.65,134.84,134.73,129.38,127.69,103.12,53.52.

4-(4-Bromophenyl)-6-ferrocenyl-3,4-dihydropyrimidin-2(1H)-one (1 g)

IR(KBr,cm−1)v:3415,3319(νN–H),3097(νC=C–H),2923(ν–CH),1684(νC=O),1537,1484(ν–C=C,Ar),1267(νC–N),1103(νasC–C,Fc),837(γC–H, Ar–R);

1HNMR(400 MHz,CDCl3):δ9.38(d,1H,N–H),7.51(d,1H,N–H),7.41(d,2H,Ar–H),7.27(d,2H,Ar–H),6.88(d,1H,C=C–H),6.14(s,H,–CH),5.59–5.15(m,4H,Fc–H);

13CNMR(100 MHz,CDCl3):δ189.58,155.02,140.80,139.13,134.82,132.35,127.99,122.89,103.15,53.58.

4-(4-Isopropylphenyl)-6-ferrocenyl-3,4-dihydropyrimidin-2(1H)-one(1 h)

IR(KBr,cm−1)v:3174,3104(νN–H),3035(νC=C–H),2956,2924(ν–CH),1702(νC=O),1645,1543(νC=C,Ar),1379(δs–CH3), 1271(νC–N),1103(νasC–C,Fc),832(γC–H,Ar–R);

1HNMR(400 MHz,CDCl3):δ9.36(s,1H,N–H),7.58(d,1H,N–H),7.32(d,2H,Ar–H),7.13(d,2H,Ar–H),6.84(d,1H,C=C–H),6.08(s,1H,–CH),5.56–5.28(m,3H,Fc–H),2.82(m,1H,–CH),1.18(d,6H,C2H6);

13CNMR(100 MHz,CDCl3):δ189.68,155.57,149.69,140.62,137.70,135.16,131.19,127.37,126.08,102.56,54.36, 33.96, 24.04.

Results and discussion

To optimize the reaction conditions, various catalysts, solvent, addition of the catalyst, and temperatures were explored (Table 1). Catalyst plays a significant role in this reaction. To evaluate the effect of the catalyst, we perform the reaction with various catalysts (entries1–12). Initially, the mixture of aldehydes, acetylferrocene and urea under the reflux temperature in 10 h in the absence of catalyst or in the presence of TMSCl and L-proline all led to trace yield (entries 1–3). We also tested other catalysts that provide rather low yield (entries 4–11). But the good results were achieved in the presence of boric acid (60% entry 12). We further studied the influence of solvent, as shown in Table 1. We explored the reaction in ethanol, acetonitrile, dimethylformamide, acetic acid and methanol at reflux temperature (entries 12–16). The results showed that the highest yield of the products was achieved in the presence of acetic acid(entry 16). Next, we explored the effect of temperatures on the reaction in the presence of boric acid and acetic acid (Table 1). It was found that an increase in the temperature (entries 16–21) increased the yield of the target compound. Higher temperatures (above 100℃) (entry 22) had no obvious effect on the yield,while it even increased the reaction time. Therefore, 100°C was selected as a suitable temperature for all the reactions. Meanwhile, the addition of the catalyst was also studied, and the 0.8 mmol amount of catalyst was chosen as suitable addition.

In order to evaluate the generality of this methodology, we examined the reaction of urea with a variety of aromatic aldehydes containing electron donating or withdrawing groups and acetyl ferrocene, the results are summarized in Table 2. All the target compounds were obtained in good yields (Compd.1–8). Compounds 1b and 1c showed high yields (86–87%). We speculated that it was because of the presence of strong electron donating group (–CH3 and –OCH3). Interestingly, halogenated group decreased the yield slightly, although these groups theoretically increased the reactivity of aldehyde toward the condensation reaction (Compd.4–6). Compound 1g showed moderate yields which has –OH group. Compounds 1h also obtained the product in moderate yields. We have found a green and economical way to get the target compounds, such as low energy consumption, convenient operation and low cost.

Scheme 2 shows a plausible mechanism for this Biginelli reaction, which is a typical nucleophilic addition reaction. First of all, the aromatic aldehydes are protonated under the acid condition, the nitrogen of urea attacks the protonated carbonyl groups of the aromatic aldehydes to occur nucleophilic addition, then looses H2O to form imine intermediates, which is stabilized by boric acid. Then it further reacts with the activated acetyl ferrocene to produce an open-chain ureide. Finally, the target products are obtained by subsequent cyclization and dehydration.

Conclusion

In conclusion, we synthesized eight kinds of novel 4-(substituted phenyl)-6-ferrocenyl-3,4-dihydropyrimidin-2 (1H)-ones. The optimal reaction conditions were explored. The optimal protocol provides some advantages, such as mild reaction conditions, short reaction times, and good yields. The target products can be obtained above 81%. We hope that these novel target products can provide a theoretical basis for enriching 3,4-dihydropyrimidinones derivatives databases and drug research and development.

References

R. Olinski, D. Gackowski, M. Cooke, s. Biochim. Biophys. Acta 1869(1), 29 (2018)

F.A.F. Ragab, S.M. Abou-Seri, S. Abdel-Aziz, a. Eur. J. Med. Chem. 138, 140 (2017)

D. Kumarasamy, B.G. Roy, J. Rocha-Pereira, Bioorg. Med. Chem. Lett. 27(2), 139 (2017)

A.M. Maharramov, M.A. Ramazanov, G.A. Guliyeva, J. Mol. Struct. 1141, 39 (2017)

M. Sahu, N. Siddiqui, R. Iqbal, Bioorg. Chem. 74, 166 (2017)

Q. Ren, X. Liu, Z. Luo, Bioorg. Med. Chem. 25(3), 1042 (2016)

A. Manos-Turvey, H.A. Al-Ashtal, P.G. Needham, Bioorg. Med. Chem. Lett. 26(20), 5087 (2016)

K. Singh, H. Kaur, K. Chibale, Eur. J. Med. Chem. 66, 314 (2013)

F. Iftikhar, Y. Ali, F.A. Kiani, Bioorg. Chem. 74, 53 (2017)

M. Teleb, F.X. Zhang, J. Huang, Bioorg. Med. Chem. 25(6), 1926 (2017)

M. Teleb, F.X. Zhang, A.M. Farghaly, Tetrahedron Lett. 57(47), 5135 (2016)

P. Singh, A. Singh, M.A. Quraishi, J. Taiwan Inst. Chem. Eng. 60(5), 588 (2016)

A. Dhandapani, S. Manivarman, S. Subashchandrabose, J. Mol. Struct. 1127, 212 (2017)

B.K. Banik, A.T. Reddy, A. Datta, Tetrahedron Lett. 48(41), 7392 (2007)

B.J. Ahn, M.S. Gang, K. Chae, Ind. Eng. Chem. 14(3), 401 (2008)

J.C. Rodríguez-Domínguez, B. Dan, G. Kirsch, Tetrahedron Lett. 48(33), 5777 (2007)

N.S. Nandurkar, M.J. Bhanushali, M.D. Bhor, J. Mol. Catal. A Chem. 271(1), 14 (2007)

N. Ahmed, Lier. JEV. Tetrahedron Lett. 48(31), 5407 (2007)

M. Wu, J. Yu, W. Zhao, J. Fluor Chem. 132, 155 (2011)

Y. Yu, D. Liu, C. Luo, Bioorg. Med. Chem. Lett. 17(12), 3508 (2007)

S.D. Salim, K.G. Akamanchi, Catal. Commun. 12(12), 1153 (2011)

P.A. Solovyev, A.A. Fesenko, A.D. Shutalev, J. Fluor Chem. 182(25), 28 (2016)

A.M. Abdou, S. Botros, R.A. Hassan, Tetrahedron 71(1), 139 (2015)

M.A. Bigdeli, G. Gholami, E. Sheikhhosseini, Chin. Chem. Lett. 22(8), 903 (2011)

P. Attri, R. Bhatia, J. Gaur, Arabian J. Chem. 10(2), 206 (2017)

D. Elhamifar, F. Shojaeipoor, J. Mol. Catal. A Chem. 426, 198 (2017)

D. Shobha, M.A. Chari, A. Mano, Tetrahedron 65(51), 10608 (2009)

F. Zamani, S.M. Hosseini, S. Kianpour, Solid State Sci. 26(23), 139 (2013)

S. Asghari, M. Tajbakhsh, B.J. Kenari, Chin. Chem. Lett. 22(2), 127 (2011)

S. Moghaddas, A. Davoodnia, M.M. Heravi, Chin. J. Catal. 33(4), 706 (2012)

R. Tayebee, M. Ghadamgahi, Arabian J. Chem. 10, S757 (2017)

K. Niknam, N. Jafarpour, E. Niknam, Chin. Chem. Lett. 22(1), 69 (2011)

G. Sivagamisundari, A.M. Pushpalatha, S.J. Ranee, Int. J. Sci. Eng. Technol. 3(7), 852 (2014)

F. Shirini, M. Abedini, R. Pourhasan-Kisomi, Chin. Chem. Lett. 45(1), 111 (2014)

F. Heidarizadeh, E.R. Nezhad, S. Sajjadifar, Sci. Iran. 20(3), 561 (2013)

Z.B. Xie, N. Wang, W.X. Wu, J. Biotechnol. 170, 1 (2014)

J. Pandey, N. Anand, R.P. Tripathi, Tetrahedron 65(45), 9350 (2009)

M.A. Kolosov, O.G. Kulyk, M.J.K. Al-Ogaili, Tetrahedron Lett. 56(32), 4666 (2015)

J. Banothu, S. Basavoju, R. Bavantula, Tetrahedron Lett. 55(1), 224 (2014)

Y. Liu, H. Zhang, D. Yin, Res. Chem. Intermed. 41(6), 3793 (2015)

Y. Liu, G. Lian, D. Yin, Spectrochim. Acta Part A 100(1), 131 (2013)

Y. Liu, G. Lian, D. Yin, Res. Chem. Intermed. 38, 1043 (2012)

Y. Liu, L. Feng, D. Yin, J. Chem. Soc. Pak. 34(3), 702 (2012)

Y. Liu, J. Sheng, D. Yin, J. Organomet. Chem. 856, 27 (2018)

M. Tengfei, Y. Lei, L. Guoqiang, W. Yen, G. Yanzi, W. Jun, T. Lei, ACS Macro lett. 8(6), 639 (2019)

A. Csámpai, A.Z. Györfi, G.I. Turos, P. Sohar, J. Organomet. Chem. 694(22), 3667 (2009)

Y. Liu, H. Xin, D. Yin, J. Mol. Struct. 1157, 482 (2018)

Acknowledgements

The authors are indebted to Prof. Baojian Liu for his support and encouragement. The authors are thankful to Shaanxi University of Science & Technology for FT-IR spectroscopy and NMR spectroscopy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Dang, Y., Yin, D. et al. One-pot, multi-component synthesis of 3,4-dihydropyrimidin-2(1H)-one derivatives containing ferrocenyl. Res Chem Intermed 46, 547–555 (2020). https://doi.org/10.1007/s11164-019-03966-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-019-03966-2