Abstract

In this review, studies on petroleum sludge composting have been investigated in the aim to understand the sludge biotransformation and highlighting the points that need more attention. Total petroleum hydrocarbons (TPH) are the major contaminants present in the petroleum sludge they ranged from 0.204 to 521.12 g/kg of dry matter, indicating a potential risk to the environment if not correctly managed. In this case, composting of petroleum sludge with different bulking agents (soil, wood, green wastes and manure) have been used as an environmentally friendly treatment. The TPH removals ranged between 47 and 95% during the composting process. This difference between the TPH removals is due to divergence in TPH concentration, chemical characterization, mixing ratio and applying or not of ameliorated treatment. The enhanced treatment like the bioaugmentation and the biostimulation increased significantly the TPH degradation kinetic which ranged between 0.8 and 2%/day of TPH degradation, while in the unimproved composts it was below 0.66%/day of TPH degradation. Moreover, lack information on physico-chemical parameters in totally or partially of some studies restrain the better understanding of the whole petroleum sludge composting. The humic substances can absorb some hydrocarbons during their formation process, it is required to assess the interactions between these compounds throughout the composting. It is also important to know about the finality of the product from the composting process. In all, more researches are needed on the interactions between TPH and other organic matters, removal mechanisms, the toxicity and the stability of the final products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Petroleum sludge is produced throughout the petrochemical industry chain during the extraction, the transportation, the storage and the refining. At the storage tank level, sediments are formed in the bottom and these sludges are the most studied type in the literature (Hu et al. 2013). They are composed of oil, solid particles and water, and are commonly known as oily sludges (Hu et al. 2013). Sludge production in the petroleum refining industry also comes from oil/water separation operations at the wastewater treatment plant, especially the coagulation-flocculation treatment, the dissolved air flotation and the biological treatment (Van Oudenhoven et al. 1995; IPIECA 2010).

Sludge produced from oil refining continues to increase year after year as the global demand for fossil energy grows (Bhattacharyya and Shekdar 2003). As reported in the BP statistical review of world energy the global energy demand raised up in recent years, increasing the oil refining production all over the world (Fig. 1). It has been estimated that for each ton of crude oil, 3–5 kg of sludge is produced by refineries (Van Oudenhoven et al. 1995). Jean et al. (2001) reported that annually a petroleum refinery produces about 28,000 tons of sludges.

Global oil refining throughput in recent years (BP 2018)

Total petroleum hydrocarbons are one of the most abundant constituents in petroleum sludges. These compounds are responsible for the toxic nature of the sludges and can represent from 5 to 86% of the total sludge masse (da Silva et al. 2012; Hu et al. 2013). These hydrocarbons are rich in sulfur, nitrogen, oxygen, phosphorus and metallic elements. Hydrocarbons can be utilized as a source of carbon and energy and then degraded through the action of microorganisms (Sierra-Garcia and Oliveira 2013). Nevertheless, this biodegradation is influenced by several factors such as the concentration of hydrocarbons, the nutrients, the temperature, the oxygen and the humidity. Composting can improve the biodegradation by modifying some parameters such as the carbon/nitrogen/phosphorus ratio (C:N:P), the mixing ratio, and the moisture to maintain a high microbial activity (Ball et al. 2012).

Composting involves microbial strains that feed on waste while transforming organic substances into stable and humified products. In general, the composting takes place in two phases: a stabilization phase recognized by an intense microbiological activity which is accompanied by a rise in temperature (thermophilic phase), afterward the temperature gradually decreases and stabilizes indicating the depletion of the medium in simple molecules and is dominated by the humification process (maturation phase) and may last for months (Hassen et al. 2001). Composting can be done outdoors in the form of a pile or in a semi-closed system called bioreactor and the sludge is mixed with a bulking agent, e.g. green waste, straw, wood waste, household waste or other sources of easily biodegradable organic matter.

In this review, we have investigated the most relevant studies on petroleum sludge composting, in order to compare between the initial conditions, the processing system and the treatment enhancements. In addition, some points not stated in these studies have been highlighted to better assess the pollution transfer, in the aim to maximize preservation of the environment.

2 Composition and toxicity of the petroleum sludges

Due to their varied origins, which depend on the crude oil quality, the process refinery configuration and the wastewater treatment system, the composition of the petroleum sludge is very diverse and complex. Table 1 summarized the physico-chemical proprieties of the petroleum sludges and highlighting their content diversity. If the biological way of treatment is adopted for this kind of sludges, the carbon and the nitrogen amount can restrain the microbial growth and thus the all biological process. In this case, the addition of co-substrates or nutrition containing nitrogen and phosphorus can help to achieve an optimum C/N ratio and thus enhance the bioremediation. In addition to organic matter, petroleum sludges may contain from 4 to 7% of mineral sediments such as halite, calcite, kaolinite, quartz, silica, carbonate and hercynite (Monteiro et al. 2007; Aguelmous et al. 2016). Hu et al. (2013) reported that the most common forms of heavy metals in this type of sludge are zinc, lead, copper, nickel and chromium. Their concentrations vary from sludge to another and can reach very high values making this type of waste harmful to the environment (Table 1). However, microorganisms are capable to remove the heavy metals by different mechanisms such as biotransformation, bioaccumulation, biomineralization, bioadsorption, and bioleaching (Dixit et al. 2015). Microbial species have been reported to have the capacity to adsorb high amount of heavy metals, e.g. 567, 467, 270, 166 and 116 mg/g of Pb can be degraded, respectively by Corynebacterium glutamicum, Bacillus firmus, Pseudomonas putida, Rhizopus nigricans, Penicillium chrysogenum (Choudhary et al. 2017).

The total petroleum hydrocarbons (TPH) are the major toxic fraction in the oily sludges and can reach high values (Table 1). They are composed of carbon (83–90%), hydrogen (10–14%), sulfur (0.1–5.5%), nitrogen (0.05–2%), oxygen (0.1–4%) and traces of phosphorus and metallic elements (Okoh 2006; Zhang and Fan 2010). They are classified into four categories, aliphatic (> 50%), aromatic (26–30%), resins and asphaltenes (< 20%) (Lal and Khanna 1996; Kadali et al. 2012). Aliphatic hydrocarbons are the most appreciable TPH fraction by microorganisms. Fraction from C10 to C24 are the most easily biodegradable, while those with long or branched-chain are harder to degrade (Kunihiro et al. 2005). Dumped into the environment, this aliphatic fraction can easily penetrate the ground and reach the groundwater, but can also evaporate quickly (Alvarez and Illman 2005). Aromatic hydrocarbons are generally less volatile and less water-soluble than the aliphatic (Seo et al. 2009). The volatility and the solubility of the aromatic hydrocarbons decrease as the number of benzene rings increases (Mrozik et al. 2003). Polyaromatic hydrocarbons (PAH) are considered ubiquitous and persistent in the environment (Baklanov et al. 2007; Abdel-Shafy and Mansour 2016). The PAH can be photo-oxidized, chemical oxidized, biodegraded or bioaccumulated (Alebic-Juretic et al. 1990; Nadarajah et al. 2002). The PAH are probably mutagenic and carcinogenic to humans and can inflect lung cancer (Kim et al. 2013; Abdel-Shafy and Mansour 2016). Resins and asphaltenes are polar compounds with a high molecular weight (Viñas et al. 2002). Resins are generally dissolved compounds of nitrogen, oxygen and sulfur, while asphaltenes are large and complex colloidal molecules (Varjani and Upasani 2017).

Behind these physico-chemical parameters, the TPH can present a certain toxic degree. The contamination of the water sources, the marine environment, the soils and the air by TPH is one of the major environmental concerns. Water decontamination is complex and difficult given the low solubility of hydrocarbons and their relatively limited mass transfer rate (Paria 2008). Soil contamination can lead to a potentially long source of pollution, and subsequently destroys the plants, the microbial community, and the soil can lose its fertility (Osuji et al. 2006). Trapp et al. (2001) reported that the most biologically active substances in terms of toxicity have a logarithmic value of the octanol/water partition coefficient (Kow) between 2 and 6. Thus, several petroleum hydrocarbons fall into this category, such as hexane and decane which respectively have a Kow of 2.91 and 5.58 (Trapp et al. 2001).

Microorganisms are also affected by the toxic effect of petroleum hydrocarbons. Old previous studies have shown the toxic effect of the aliphatic and the aromatic hydrocarbons on microorganisms (Gill and Ratledge 1972; Calder and Lader 1976; Andrews et al. 1980). Uribe et al. (1990) have shown that this toxic effect on microorganisms is represented by the inhibition of oxygen and potassium uptake by cells, the isolation of mitochondria and the alteration of ATP synthesis. Petroleum hydrocarbons can also alter the cell membrane structure by changing their fluidity and their protein conformation, resulting in barrier disruption and energy transduction, in addition to enzymatic activity disruption (Van Hamme et al. 2003).

Light petroleum hydrocarbons can inhibit or decrease seed germination by easily entering the seeds cells or even by blocking the passage of oxygen and water (Adam and Duncan 2002). Sharifi et al. (2007) observed the phytotoxic effect of different concentrations ranging from 25 to 100 g/kg of hydrocarbons on the germination of certain seeds, the results showed germination between 2.7 and 63.5%. The hydrocarbon toxicity for plants has been demonstrated by several authors proving that at high concentration (> 10%) germination can be inhibited while specifying that some plant species have the capacity to withstand at high hydrocarbons percentages (Ogbo 2009; Saadoun and Al-Ghazawi 2010).

Given the composition of petroleum sludges in toxic elements, their disposal in nature may contaminate and pollute the receiving environment. Viscous compounds in petroleum sludges can alter and change the properties of the medium (Robertson et al. 2007), obstruct the soil pores, can be absorbed by mineral elements or form a film on the surface (Al-Mutairi et al. 2008). Tang et al. (2012) reported that residual chemical compounds that have been in the environment for a long time appear to be resistant to sorption and degradation. Generally, in oil refineries, the sludges are placed in drying beds and subsequently stored in an open space which can be seen as a source of atmospheric pollution by volatile organic compounds (Cheremisinoff and Rosenfeld 2009). Thus, to limit the environmental risks associated to the management of the petroleum sludges, several regulations have emerged such as the Resource Conservation and Recovery Act (RCRA) in the United States, which sets strict standards for the handling, storage and safe disposal of these wastes.

3 Petroleum sludge treatments

Petroleum sludge treatment is essential before their disposal in the natural environment. Different approaches can be used for treating the petroleum sludges: we can act at the production source for the reduction of the sludge produced volume, the extraction and reuse of the hydrocarbons contained in the sludges, and finally the disposal after the degradation of organic matter (Pinheiro and Holanda 2009; da Silva et al. 2012).

There exist various ways of petroleum sludge treatments. In general, the physical and chemical methods are applied in the main interest to recover the hydrocarbons present in the sludges, and thus to reduce the released wastes outside the company. The most used methods are solvent extraction, froth flotation, ultrasonic and microwave irradiation, pyrolysis, electrokinetic method, centrifugation and freeze/thaw (Hu et al. 2013). The oil recovery treatments are generally easy and short. However, these types of treatment are quite expensive given the machines applied, the large amount of solvent and water, persistence of heavy metals and the energy consumption, as well as the generation of another waste that will have to be treated later (Fig. 2). Moreover, residues from hydrocarbon recovery processes must undergo a stabilization treatment prior to the final discharge.

Overview of petroleum sludge treatments, with respective advantages and limitations (Hu et al. 2013)

The disposal of petroleum sludge can be done by incineration, biodegradation, oxidation and stabilization/solidification (Udotong et al. 2011; Hu et al. 2013). The incineration consists in the complete combustion of the petroleum sludge in incinerator over 700 °C (Scala and Chirone 2004). Even if the incineration is effective (99%), its feasibility is affected by the sludge humidity (> 51%) (Sankaran et al. 1998). In addition, hazardous gas emissions cause atmospheric pollution in plus of ash residue (Li et al. 1995). Stabilization/solidification treatment is applied to reduce the availability of contaminants (Malviya and Chaudhary 2006). However, some limitations of this method have been noticed, as some studies revealed that the product from this treatment may leach (Karamalidis and Voudrias 2007). The oxidation treatment is aimed to introduce chemical reactive to oxidize organic matter (Ferrarese et al. 2008). This treatment method will require a large quantity of chemical products with increasing quantity of petroleum sludge, in plus of some advanced equipment to enhance the TPH removal (Hu et al. 2013). The choice of the treatment method can be determined by the feasibility, the desired duration, the appropriate space, the targeted contaminants and the global cost (Fig. 2).

Bioremediation has been the most studying treatment of petroleum hydrocarbons, taking into account its low cost, large capacity and high efficiency. Biodegradation is a process by which microorganisms transform or mineralize organic compounds through metabolic or enzymatic processes into less harmful products, which are subsequently integrated into natural biogeochemical cycles (Maletić et al. 2013). Under aerobic conditions, microorganisms use hydrocarbons and thus form CO2, H2O and biomass. For more than a century, it has been reported that certain types of microorganisms have developed the ability to use aliphatic and aromatic hydrocarbons as a source of carbon and energy (Sierra-Garcia and Oliveira 2013). Some species such as Pseudomonas aeruginosa, Pseudomonas putida, Bacillus subtilis, Bacillus cereus, Bacillus licheniformis and Bacillus laterospor can modify the membrane surface of their cells to increase their affinity for hydrophobic substances and facilitate their absorption (Cybulski et al. 2003). Two mechanisms can be undertaken to activate the biodegradation of petroleum hydrocarbons: the interfacial adhesion by direct contact with the hydrocarbons, and by the adhesion to emulsified hydrocarbons via biosurfactants (Kaczorek et al. 2011; Varjani and Upasani 2017). The biodegradation of petroleum hydrocarbons involves metabolic reactions catalyzed by a multitude of enzymes. The enzymes that play an important role in this process are oxygenase, peroxidase, reductase, hydroxylase and dehydrogenase (Abbasian et al. 2015). In general, during the hydrocarbon biodegradation, the oxygen serves as an external acceptor of electrons, while an organic element from the substrate functions as an electron donor or energy source (Braddock et al. 1997). In the literature, several species of bacteria have proven their ability to degrade the petroleum hydrocarbons, such as Pseudomonas spp, Alcaligenes spp., Stenotrophomas maltohilia, Yersinia spp., Bacillus spp., Micrococcus and Enterobacteria (Lazar et al. 1999; Van Hamme et al. 2000). However, the Pseudomonas spp. species was the most reported in the TPH biodegradation studies, especially P. aeruginosa (Rocha and Infante 1997). On the other hand, fungal strains are also frequently used in the TPH biodegradation. These include Aspergillus spp., Penicillium spp., Mortierella spp., Trichoderma spp., Candida, Rodoturela, Aureobasidium and others (Riser-Roberts 1998; Bento and Gaylarde 2001).

4 Petroleum sludge composting

The composting helps to achieve an optimum C/N ratio around 20 which is not the case of petroleum sludge (Table 1), to enhance the growth of microorganisms. The composting takes place in two phases, the first called thermophilic is the short one (3–15 days) and it is characterized by the rise of temperature and degradation of light/micro-molecules; the second called maturation characterized by the long duration (3–12 months) in which degradation of heavy/macro-molecules occurs. The rise of the temperature over than 60 °C allows the sanitization but also the application of this treatment in extreme climatic conditions (Delille et al. 2007; Ball et al. 2012). The composting process can be done in piles/windrows, bioreactors or both successively (Fig. 3). The choice of the engineered composting system can be done by referring to the physico-chemical parameters of the petroleum sludge, area, duration and cost. The bioreactor is the most desirable composting mode since it allows the optimization of oxygen, temperature, humidity, nutrients and the control of gas emissions. In a novel arrangement of petroleum sludge treatment consisting in primary composting in piles followed by a secondary composting in bioreactor, revealed an improvement of 10% in TPH removal than composting in piles only (Koolivand et al. 2017). The removal of TPH in composting process can be affecting by several factors such as the physico-chemical parameters and the microbial community and their specific enzymes.

4.1 Abiotic factors

Varjani and Upasani (2019) recorded between 3.4 and 4.6% of TPH degradation in abiotic test during petroleum sludge composting with disappearance of lighter hydrocarbons, indicating the role of abiotic factors (i.e. physico-chemical proprieties) in this process.

The pH range between 6.5 and 8.5, may enhance microbial activity during the composting process of petroleum sludges (Koolivand et al. 2017). However, there are some microbial strains that can resist and adapt to extreme conditions, e.g. Candida digboiensis which was reported to biodegrade 95.7% of TPH in a pH at 3 (Sood et al. 2010).

Aerobic biodegradation is the most effective way for TPH degradation, which means that the presence of oxygen for this process is the key parameter for hydrocarbon catabolism (Van Hamme et al. 2003). The initial step in the degradation of aliphatic, cyclic and aromatic hydrocarbons by bacteria and fungi involves oxidation of substrates by oxygenase, for which the presence of oxygen is paramount (Leahy and Colwell 1990).

According to Viñas et al. (2005), the degradation rate of petroleum sludge compounds is also affected by the moisture content. However, very high humidity can disadvantage the microbial growth by limiting the oxygen supply. Otherwise, a study on the TPH bioremediation reported that moisture of 10% is sufficient to reach more than 70% of TPH removal in 270 days (Haghollahi et al. 2016).

The TPH characteristics may influence on the petroleum sludge composting. Minai-Tehrani et al. (2015) reported that in 31% of TPH degradation, aliphatic, aromatic, resin and asphaltene fractions decreased, respectively by 60, 42, 6 and 4%. In another TPH bioremediation study, the aromatic compounds increased by 2% while the aliphatic ones decreased by 28.7% (Wu et al. 2017b). PAH and chlorinated organic compounds present in petroleum sludge are very resistant to microbial attack (Arun et al. 2011). The TPH properties that may affect their biodegradation are chemical structure, substitution degree, viscosity, solubility, and concentration (Seo et al. 2009; Jain et al. 2011). Margesin et al. (2007) reported that increasing TPH concentration by 8 times can reduce the TPH removal by 6.75 times. However, decreasing the TPH concentration will not automatically rise up the removal rate. Ramadass et al. (2015) recorded the lowest removal rate in 27.8 g/kg of TPH, and assigned this to the fact that this sample was composed by 70% of recalcitrant hydrocarbons (C28–C40) and only 2 g/kg of bioavailable hydrocarbons. Even if Admon et al. (2001) and Huesemann et al. (2004) recommended a TPH concentration between 0.2 and 5.5% for better microbial activity, many studies have reached more than 90% of TPH removal with a TPH concentration exceeding 160 g/kg (Sood et al. 2010; Adetutu et al. 2015). In petroleum sludge composting the initial TPH concentration plays a role in the treatment effectiveness; as much as the concentration is high the TPH removal is low (Koolivand et al. 2017). However, a relatively low TPH concentration may have the opposite effect by limiting the carbon input required for the growth of microorganisms (Sayara et al. 2010).

Nutrients such as nitrogen (N) and phosphorus (P) limit the TPH biodegradation due to their limited availability (Wu et al. 2017a). Several authors have suggested biostimulation by adding N and P to improve the TPH biodegradation (Wang et al. 2012; Silva-Castro et al. 2013). Wu et al. (2016) recorded 60% of TPH removal in biostimulated treatment with an addition of ammonium sulfate ((NH4)2SO4) and dipotassium phosphate (K2HPO4), against only 16% of TPH removal for natural attenuation treatment. Roy et al. (2018) reported that addition of N and P simultaneously conduct to 55% of TPH removal, while adding N or P separately recorded respectively, 50 and 46% of TPH removal. Nevertheless, an excessive concentration of nutrients in the medium can inhibit the hydrocarbon biodegradation (Souza et al. 2014).

The temperature plays a vital role in the biodegradation process. It affects the physical properties of the petroleum hydrocarbons and the type of microorganisms responsible for the degradation (Chandra et al. 2013). Gibb et al. (2001) reported that the rise of temperature is proportional to the solubility of the contaminants and induces a high metabolic activity. High temperature increases the solubility of hydrophobic pollutants, decreases the viscosity, improves the diffusion, and transfers long-chain alkanes from solid to liquid phase (Aislabie et al. 2006). At high temperature, the enzymatic kinetic involved in the petroleum sludge biodegradation increases and thus affects positively the TPH removal efficiency (Koolivand et al. 2017). The TPH bioremediation can occur even in extreme cold-climate. As reported by Kim et al. (2018), TPH was removed by 58% in cold seasonal temperatures ranging from − 10 to 19 °C, and highlighted that Arthrobacter, Rhodococcus and Polaromas abundance was better throughout the wintry season than in summer.

4.2 Biotic factors

Firstly, microbial diversity and growth may influence positively on the petroleum sludge composting. It has been well reported that a microbial consortium leads to better biodegradation of complex hydrocarbons (Cerqueira et al. 2011; Shen et al. 2015). Ghazali et al. (2004) reported that a consortium constituted by three Bacillus, two Pseudomonas and one Micrococcus strains helped degrading more recalcitrant hydrocarbons than consortium of two Bacillus and one Pseudomonas. Otherwise, the bioaugmentation in petroleum hydrocarbons studies has revealed more TPH biodegradation against natural attenuation or biostimulation (Bidja Abena et al. 2019; Varjani and Upasani 2019). Moreover, hydrocarbon-degrading bacteria isolated from petroleum sludge compost, have been able to degrade toxic elements such as PAH (Ubani et al. 2016).

Bioavailability of hydrocarbons is such a key factor for biological uptake. For petroleum substrates, biological uptake can be done by direct contact with soluble fraction or by biosurfactant-mediated contact with heavier and insoluble hydrocarbons (Kapellos 2017). Biosurfactants consist of hydrophilic and hydrophobic segments and are classified in glycolipids, phospholipids, lipopeptides, lipoproteins and membranous vesicles (Desai and Banat 1997). These compounds are produced by microorganisms during the stationary phase (Yan et al. 2012), and enhance solubilization, desorption or emulsification of hydrocarbons (Dias et al. 2012; Kavitha et al. 2014). The main role of biosurfactants in petroleum biodegradation is reducing the repulsive force between hydrocarbons and microorganisms, helping mixing and interaction between them (Souza et al. 2014; Hua and Wang 2014). Microorganisms involved in petroleum hydrocarbons bioremediation have been largely reported to have the capacity of producing biosurfactants (Waigi et al. 2015; Varjani and Upasani 2016), which certainly affects the composting process. In plus of lipoprotein biosurfactant, a consortium of Shewanalla chilikensis, Bacillus firmus and Halomonas hamiltonii produced biocatalysts (lipase, catalase and oxidoreductase) which rise the TPH removal at 96% (Suganthi et al. 2018).

4.3 Co-substrates in petroleum sludge composting

Different natures of co-substrates were used in petroleum sludge composting. In general, these co-substrates called bulking agents are applied to increase porosity and oxygen diffusion and to form water-stable aggregates (Zahrim et al. 2015). This for interest to increase the aeration and the microbial activity (Eftoda and Mccartney 2004; Malińska and Zabochnicka-Świa̧tek 2013). To enhance the TPH remediation by composting, researchers seem that they have focused more on the aeration aspect, as most of the studies applied a mixture of petroleum sludge with soil, sand or wood chips. These co-substrates decrease the TPH concentration in the mixtures, increase microorganisms/sludge surface contact and ameliorate the bacterial activity. However, mixing the petroleum sludge with soil can be also in interest to bring an exo/indi-genous microbial consortium. In some case, the soil has been contaminated by hydrocarbons and so the microbial consortium has already been adapted to degrade the targeted contaminants (Ling and Isa 2006). In the same way, other authors have chosen to introduce more extraneous biomass by adding animal manures, while in some studies, we added directly a microbial consortium, which is known as hydrocarbon degrading (Milne et al. 1998; Ayotamuno et al. 2007). As reported in some studies, the carbon of TPH is more assimilated than the one from the co-substrates (Kirchmann and Ewnetu 1998; Koolivand et al. 2013; Asgari et al. 2017). This confirmed that the choice of the co-substrates in petroleum sludge composting is not like the one for the composting of sewage sludge or another kind of biodegradable waste. In the latter one, the choice of the co-substrates is based on the intake of a suitable assimilable carbon for microorganisms. In addition, the main aim of the petroleum sludge composting is to reduce or eliminate the TPH.

In this case, we can understand that composting of petroleum sludge needs a consensus between different parameters. The choice of the bulking agent for suitable aeration, not competing as the main carbon source, and the activation of microbial growth.

4.4 Sludge characteristics and composting system

Petroleum sludges used in composting studies are very diverse. The pH ranged from 5.8 to 8, except for the study of Asgari et al. (2017) which applied an acidic petroleum sludge with a pH of 1.35 (Table 1). These pH values are adequate with the optimum range of pH for the biodegradation of the TPH, and does not constitute an obstacle for the good running of the composting process. This represents an advantage for treating the petroleum sludge by composting process, with no adding of commercial products to maintain the pH in the range between 6.5 and 8.5. However, for acidic petroleum sludges, adding of a co-substrate with high pH can rise the composting mixture pH, as applied by Asgari et al. (2017).

The range diversity of the total organic carbon (TOC) and the total Kjeldahl nitrogen (TKN) of the petroleum sludges was too consequent. As the TOC concentration ranged between 4.9 and 542.44 g/kg, and for the TKN it varied between 0.02 and 16 g/kg (Table 1). This diversity in the TOC and the TKN concentrations is generally due to the initial oil quality and the refining system. This induces a certain vigilance against the composting method, as each type of petroleum sludge must be considered separately. Taking into account the C/N ratio, some type of petroleum sludge has to be supplemented with a nitrogen source and other with a carbon source, for redressing or diminishing the C/N value. It is known that a C/N value between 25 and 30 enhance the biodegradation (Huang et al. 2004; Ma et al. 2016).

The composting process for petroleum sludges was mainly conducted in a semi-closed system (reactor). This is generally to prevent the exhaust of the volatile compounds. Most of the studies have been applied at laboratory scale (0.5–49 kg) or semi-industrial scale (> 1000 kg), except Kriipsalu and Nammari (2010) who made a composting process at a very large scale (Table 2). The purpose of making compost at the laboratory or semi-industrial scale in the reactor system is the perfect control of the process (tilling, aerating, watering and sampling). It also helped to understand and ameliorate the biodegradation mechanism of TPH by adding nutrients or a microbial consortium and applying a different co-substrate in many ratios. In most of the studies, the ratios of petroleum sludge/co-substrate applied ranged between 1/1 and 1/100 in order to decrease the TPH concentration in the composting mixture. Except for the studies of Ayotamuno et al. (2007, 2010) and Atagana (2014) in which the petroleum sludge was 2 to 6 times the co-substrate. For Ayotamuno et al. (2007, 2010) the reason for applying much more petroleum sludge than the co-substrate can be explained by the low TPH concentration of 69.37 and 98 g/kg. For Atagana (2014) the reason can be the wish to keep a certain TPH concentration in the composting mixture after the successive dilution by applying five consecutive co-substrates.

4.5 Physico-chemical transformation during the composting process

Table 2 represents the physico-chemical parameters at the initial and the final stages of the mixture that indicates the highest TPH removal. In this case, we noted a certain lack of information. Most of the authors were not focalized on the assessment of the physico-chemical parameters during the composting process. This makes the comparison between the studies of petroleum sludge composting really difficult. In addition, the C/N ratio reported in some studies has evolved differently, in some its decrease and in others its increase (Table 2). Generally, the C/N ratio decreases in the composting process due to the assimilation of carbon by microorganisms (El Fels et al. 2014). However, in the petroleum sludge composting it has been reported that the C/N ratio can increase due to the preferential assimilation of carbon from TPH and quick consumption of nitrogen than carbon (Koolivand et al. 2013; Asgari et al. 2017). From this, we can afford to stipulate that in the petroleum sludge composting, the microorganisms can even target the main contaminant (TPH) or the organic matter from the co-substrate. That induces that the choice of the co-substrate, the addition of nutrition (biostimulation) or extraneous microorganism is critical for the rest of the composting process.

In general, the C/N ratio in the composting process of organic wastes is applied as an indicator of the maturity and stability of the final product. A C/N ratio between 10 and 15 designates a good degree of maturity and stability (El Fels et al. 2014). In petroleum sludge composting, all the authors have not extended their discussion on the maturity and stability of the final products. As reported in Table 2 most of the final C/N ratios were out of the range 10 and 15. Thereby, the final products from these studies are not stable and mature, and their storage in nature may cause a certain biological activity resumption.

4.6 TPH degradation during the composting process

In composting studies, the amount of TPH varied between 0.204 and 521.12 g/kg (Table 3). Comparing these studies, or in another term stating that a study is better than another isn’t an easy thing. This difference in the initial TPH concentration influence on the TPH removal and the process duration. Less TPH concentration or quantity doesn’t automatically mean that the biodegradation will be easy or more effective. Asgari et al. (2017) and Koolivand et al. (2017) observed a better TPH degradation kinetic and total removal in high mixing ratio compared to very low ones. As seen in some studies, the TPH removal rate reached more than 80% in 42 days, while in others it is just around 47% in 84 days (Table 3). However, by referring to the TPH degradation kinetic, the group of studies which haven’t received any enhanced treatment expressed less than 0.66%/day of TPH degradation. Except for Vasudevan and Rajaram (2001) and Ouyang et al. (2005) who applied the bioaugmentation and obtained just 0.8%/day of TPH degradation, the other ameliorated treatment recorded more than 1%/day of TPH degradation (Table 3). This can be related to the small amount of the bacterial consortium or also, the thing that this consortium was an extraneous inoculum to the TPH biodegradation. In contrary, the other studies which performed the bioaugmentation with an inoculum of hydrocarbon-degrading bacteria and a large amount between 7.4 × 1011 and 1.5 × 1012 CFU/g, have recorded 1.8 and 2%/day of TPH degradation (Table 3). It seems that the bioaugmentation affects more positively the TPH biodegradation and help to achieve quickly a high rate of TPH removal if it is done by inoculating hydrocarbon-degrading bacteria. The biostimulation enhanced also the biodegradation, as the four studies which applied it recorded between 1.04 and 1.15%/day of TPH degradation (Table 3). In addition, TPH consist of a mixture between aliphatic, aromatic, resin and asphaltene hydrocarbons, this chemical diversity can play an essential role in the biodegradation. More aliphatic hydrocarbons in a petroleum sludge than in another will facilitate furthermore the growth of the microbial community, helping to degrade more recalcitrant contaminants (cyclic alkanes, PAH or asphaltenes), and achieving a better TPH degradation result.

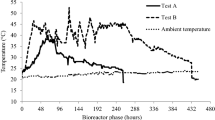

The rise of the temperature in petroleum composting studies doesn’t seem to be an indicator of the good process progress like for composting of other organic wastes, and in which we can base ourselves to affirm or predict the highest removal rate of TPH. In this case, four studies with the highest temperature peaks haven’t exceed 0.66%/day of TPH degradation. In addition to that, the study with the highest peak temperature of 77 °C has reached the less kinetic of TPH degradation (Table 3). It is recognized that high temperature increases the solubility of the TPH and facilitate their uptake by microorganisms, however surpassing an optimal value affects negatively the TPH degradation. Several studies have been focused on the relationship between temperature and hydrocarbons biodegradation. Margesin and Schinner (1997) studied the influence of temperature ranged between 4 and 30 °C on oil degradation by yeast, and found that the oil biodegradation was higher in 20 °C than in 30 °C. In another study, increasing temperature over the optimum has a restrained effect, as Coulon et al. (2005) reported that increasing temperature from 4 to 10 °C had a significant result while increasing from 10 to 20 °C slowed the TPH degradation kinetic. It is also reported that oil-degrading bacteria have a specific preferential temperature. Development of Pseudoalteromonas, Reinekea, Cycloclasticus and Sulfitobacter is favored at an incubation temperature of 4 °C, while a temperature of 24 °C is more suitable for Oleibacter, Thalassobius, Phaeobacter, and Roseobacter (Liu et al. 2017). By the way, even if the maximal value of temperature isn’t an indicator of a high TPH degradation, it affects it by influencing the microbial activity and also the physico-chemical structure of the TPH (Brakstad et al. 2004).

Some reported studies on petroleum sludge composting have addressed the effect on PAH, and found that PAH can be removed between 60 and 88% (Kirchmann and Ewnetu 1998; Kriipsalu et al. 2007; Fountoulakis et al. 2009; Atagana 2014; Ubani et al. 2016). Bacillus has been reported to be the most abundant bacteria in petroleum sludge composting and responsible for most PAH biodegradation (Ubani et al. 2016). Kirchmann and Ewnetu (1998) reported that aromatic hydrocarbons decreased slightly compared to aliphatic. However, all PAH decreased and were under detection limit (< 0.1 mg/kg), except pyrene, chrysene and anthracene. Atagana (2014) reported that lighter PAH were removed easily, whereas heavier ones were recalcitrant without manure addition. This fact was also reported by Kriipsalu et al. (2008a) which recorded an effective reduction of 2–4 ring PAH over 5–6 ring PAH. However, the same authors reported that biodegradation of 5–6 ring PAH can be enhanced by 69% in case of secondary thermophilic phase.

In the degradation of hydrocarbons, the biological activity can be assisted by chemical oxidation or volatilization. In this case, the control test helps to distinguish between the real part of TPH bioremediation and natural oxidation. In petroleum sludge composting, 50% of the studies have applied a control test, but not all of them with the aim to determine the percentage of the volatilization in the TPH removal. Four studies have applied the control test for estimating the volatilization fraction, three of them found a negligible value between 0 and 2.7% while for the other study 23% of volatilization was recorded (Table 3). In the last study, Fountoulakis et al. (2009) acted differently in their abiotic test, they applied it in a drying oven. According to them, direct exposition of the mixture to the heating from the oven with no physical barrier has increased the volatilization; while in reality the high temperatures are reached in the core of the mixture and the outer surface can reduce the volatilization (Fountoulakis et al. 2009). No biocide was applied in the other composting studies. The purpose, in this case, was to compare the treatments applied (bulking agents, bioaugmentation, biostimulation) and sludge biotransformation with no treatment practiced. Appreciable TPH removal rates between 12 and 45% were recorded in these studies (Table 3), considering that petroleum indigenous microorganisms have a great adaptation capacity.

In general, when it comes to talking about composting, we think about the humus which is the product from the natural organic matter biotransformation called the humification process. More the compost is rich in humic substances, more is benefic for soil and plants growth (El Fels et al. 2014). Reviewing the studies of petroleum sludge composting no one addressed the subject of the humification process. A study that focused on the bioremediation of waste mazut, had revealed the formation of the humic substances during the biodegradation of petroleum hydrocarbons (Jednak et al. 2017). Hafidi et al. (2008) and El Fels et al. (2016) have stipulated that the decrease of hydrocarbons in composting process was not at all due to biodegradation, as some of them can be assimilated into non-accessible sites or can form another type of hydrocarbons. A recent study on the distribution of aliphatic and aromatic hydrocarbons in soil found that these compounds can be bound to humic substances (Zhang and Fan 2016; Zhang et al. 2018). They reported that in soils 46% of the aliphatic hydrocarbons were HA-bound (Humic Acids), and 36% of the aromatic hydrocarbons were Humin-bound and FA-bound (Fulvic Acids). This interaction between hydrocarbons and humic substances is an essential part of the bioremediation process, and their assessment in petroleum sludge composting is important.

5 Conclusion

Bioremediation of petroleum sludge by composting has been widely used to reduce TPH quantity and minimize their impact. This biological process achieved between 47 and 95% of TPH removal during treatment from 30 to 373 days. This review underlined the importance of bioaugmentation and biostimulation as an effective way to ameliorate the composting process. In the case of bioaugmentation, it is recommended to apply a microbial consortium instead of one microorganism species, and even more indigenous than extraneous ones. In regards to initial compost parameters, the authors suggested adjusting the C/N ratio to 20 as biostimulation to the microbial community to enhance TPH removal. To our knowledge, a C/N ratio between 25 and 30 is more required, as in the compost not only the TPH are targeted. The diversity of the petroleum sludges has led to better assess the response of different TPH concentrations to biodegradation. Lack of information in the majority of studies on other physico-chemical parameters than just TPH restrained the full organic matrix assessment. Nevertheless, the majority of these studies were realized in lab-scale under controlled conditions, suggesting that pilot-scale studies are recommended to fully assess the composting process under the influence of both biotic and abiotic factors. As no one of the studies on petroleum sludges composting has addressed interest in evaluating the stability and the maturity degree of the final product. We think that this part is required to identify the natural obstacles that interrupt the TPH removal process, and also the plan for the product from the petroleum sludge composting. All of this, in order to overcome the negative impact of persistent hydrocarbons on soil and environment.

6 Scope of future researches

With the increasing energy demand and the unsatisfying of the green energies, the petroleum industry still has a bright future. This may engender more hazardous wastes which can contaminate the soil, the water and the air. The consequences on the environment and by the way human health can be disastrous. The researches on the treatment of petroleum wastes have taken a great interest and still in progress. Although, studies on the mechanisms, the persistence and the transfer of hydrocarbons are highly recommended to better assess their impact on the environment. Indeed, more research areas are needed:

-

Physico-chemical parameters (e.g. C/N ratio) that help better biodegradation of both targeted TPH and also all organic matrix.

-

Identification of microbial consortia capable to degrade the TPH and other organic matters at the same time to reduce the process duration.

-

Isolation of microorganisms able to assimilate recalcitrant TPH compounds and their introduction at the final stage of composting.

-

Discover the formation of humic substances (e.g. humic and fulvic acids) during the petroleum sludge composting, and their potential interactions with the TPH.

-

Highlighting the quality of the final compost in term of maturity and stability, which can eventually give an idea about the whole biotransformation leading to better find the right disposal into the environment.

References

Abbasian F, Lockington R, Mallavarapu M, Naidu R (2015) A comprehensive review of aliphatic hydrocarbon biodegradation by bacteria. Appl Biochem Biotechnol 176:670–699. https://doi.org/10.1007/s12010-015-1603-5

Abdel-Shafy HI, Mansour MSM (2016) A review on polycyclic aromatic hydrocarbons: source, environmental impact, effect on human health and remediation. Egypt J Pet 25:107–123. https://doi.org/10.1016/j.ejpe.2015.03.011

Adam G, Duncan H (2002) Influence of diesel fuel on seed germination. Environ Pollut 120:363–370. https://doi.org/10.1016/S0269-7491(02)00119-7

Adetutu EM, Bird C, Kadali KK et al (2015) Exploiting the intrinsic hydrocarbon-degrading microbial capacities in oil tank bottom sludge and waste soil for sludge bioremediation. Int J Environ Sci Technol 12:1427–1436. https://doi.org/10.1007/s13762-014-0534-y

Admon S, Green M, Avnimelech Y (2001) Biodegradation kinetics of hydrocarbons in soil during land treatment of oily sludge. Bioremediat J 5:193–209. https://doi.org/10.1080/20018891079285

Aguelmous A, Lahsaini S, El Fels L et al (2016) Assessment of organo-mineral fraction during storage of oil refinery sludge. Mor J Chem Mor J Chem 4:1029–1036

Aguelmous A, El Fels L, Souabi S et al (2018) Petroleum sludge bioremediation and its toxicity removal by landfill in gunder semi-arid conditions. Ecotoxicol Environ Saf 166:482–487. https://doi.org/10.1016/j.ecoenv.2018.09.106

Aislabie J, Saul DJ, Foght JM (2006) Bioremediation of hydrocarbon-contaminated polar soils. Extremophiles 10:171–179. https://doi.org/10.1007/s00792-005-0498-4

Alebic-Juretic A, Cvitas T, Klasinc L (1990) Heterogeneous polycyclic aromatic hydrocarbon degradation with ozone on silica gel carrier. Environ Sci Technol 24:62–66. https://doi.org/10.1021/es00071a005

Al-Mutairi N, Bufarsan A, Al-Rukaibi F (2008) Ecorisk evaluation and treatability potential of soils contaminated with petroleum hydrocarbon-based fuels. Chemosphere 74:142–148. https://doi.org/10.1016/j.chemosphere.2008.08.020

Alvarez PJ, Illman WA (2005) Fundamentals of groundwater flow and contaminant transport processes. In: Schnoor JL, Zehnder A, Alvarez PJ, Illman WA (eds) Bioremediation and natural attenuation. Wiley, New York, pp 115–167

Andrews RE, Parks LW, Spence KD (1980) Some effects of Douglas fir terpenes on certain microorganisms. Appl Environ Microbiol 40:301–304. https://doi.org/10.1157/13048914

Arun K, Ashok M, Rajesh S et al (2011) Crude oil PAH constitution, degradation pathway and associated bioremediation microflora: an overview. Int J Environ Sci 1:1420–1439. https://doi.org/10.6088/ijessi.00107020004

Asgari A, Nabizadeh R, Mahvi AH et al (2017) Biodegradation of total petroleum hydrocarbons from acidic sludge produced by re-refinery industries of waste oil using in-vessel composting. J Environ Heal Sci Eng 15:1–9. https://doi.org/10.1186/s40201-017-0267-1

Atagana HI (2014) Managing physicochemical parameters in compost systems to enhance degradation of petroleum wastes from a sludge dam. African J Biotechnol 13:857–865. https://doi.org/10.5897/AJB2013.12257

Ayotamuno MJ, Okparanma RN, Nweneka EK et al (2007) Bio-remediation of a sludge containing hydrocarbons. Appl Energy 84:936–943. https://doi.org/10.1016/j.apenergy.2007.02.007

Ayotamuno JM, Kogbara RB, Agele EA, Agoro OS (2010) Composting and phytoremediation treatment of petroleum sludge. Soil Sediment Contam Int J 19:686–695. https://doi.org/10.1080/15320383.2010.515627

Baklanov A, Hänninen O, Slørdal LH et al (2007) Integrated systems for forecasting urban meteorology, air pollution and population exposure. Atmos Chem Phys 7:855–874. https://doi.org/10.5194/acp-7-855-2007

Ball AS, Stewart RJ, Schliephake K (2012) A review of the current options for the treatment and safe disposal of drill cuttings. Waste Manag Res 30:457–473. https://doi.org/10.1177/0734242X11419892

Bento FM, Gaylarde CC (2001) Biodeterioration of stored diesel oil: studies in Brazil. Int Biodeterior Biodegrad 47:107–112. https://doi.org/10.1016/S0964-8305(00)00112-8

Bhattacharyya JK, Shekdar AV (2003) Treatment and disposal of refinery sludges: Indian scenario. Waste Manag Res 21:249–261. https://doi.org/10.1177/0734242X0302100309

Bidja Abena MT, Li T, Shah MN, Zhong W (2019) Biodegradation of total petroleum hydrocarbons (TPH) in highly contaminated soils by natural attenuation and bioaugmentation. Chemosphere 234:864–874. https://doi.org/10.1016/j.chemosphere.2019.06.111

BP (2018) BP statistical review of world energy. London 2018:22

Braddock JF, Ruth ML, Catterall PH et al (1997) Enhancement and inhibition of microbial activity in hydrocarbon-contaminated arctic soils: implications for nutrient-amended bioremediation. Environ Sci Technol 31:2078–2084. https://doi.org/10.1021/es960904d

Brakstad OG, Bonaunet K, Nordtug T, Johansen Ø (2004) Biotransformation and dissolution of petroleum hydrocarbons in natural flowing seawater at low temperature. Biodegradation 15:337–346

Calder JA, Lader JH (1976) Effect of dissolved aromatic hydrocarbons on the growth of marine bacteria in batch culture. Appl Environ Microbiol 32:95–101

Cerqueira VS, Hollenbach EB, Maboni F et al (2011) Biodegradation potential of oily sludge by pure and mixed bacterial cultures. Bioresour Technol 102:11003–11010. https://doi.org/10.1016/j.biortech.2011.09.074

Chandra S, Sharma R, Singh K, Sharma A (2013) Application of bioremediation technology in the environment contaminated with petroleum hydrocarbon. Ann Microbiol 63:417–431. https://doi.org/10.1007/s13213-012-0543-3

Cheremisinoff NP, Rosenfeld P (2009) Chapter 1—The petroleum industry. In: Handbook of pollution prevention and cleaner production—best practices in the petroleum industry. William Andrew Publishing, Oxford, pp 1–97

Choudhary M, Kumar R, Datta A et al (2017) Bioremediation of heavy metals by microbes. In: Arora S, Singh AK, Singh YP (eds) Bioremediation of salt affected soils: an Indian perspective. Springer, Cham, pp 233–255

Coulon F, Pelletier E, Gourhant L, Delille D (2005) Effects of nutrient and temperature on degradation of petroleum hydrocarbons in contaminated sub-Antarctic soil. Chemosphere 58:1439–1448. https://doi.org/10.1016/j.chemosphere.2004.10.007

Cybulski Z, Dziurla E, Kaczorek E, Olszanowski A (2003) The influence of emulsifiers on hydrocarbon biodegradation by pseudomonadacea and bacillacea strains. Spill Sci Technol Bull 8:503–507. https://doi.org/10.1016/S1353-2561(03)00068-9

da Rocha ORS, Dantas RF, Duarte MMMB et al (2010) Oil sludge treatment by photocatalysis applying black and white light. Chem Eng J 157:80–85. https://doi.org/10.1016/j.cej.2009.10.050

da Silva LJ, Alves FC, de França FP (2012) A review of the technological solutions for the treatment of oily sludges from petroleum refineries. Waste Manag Res 30:1016–1030. https://doi.org/10.1177/0734242X12448517

Delille D, Pelletier E, Coulon F (2007) The influence of temperature on bacterial assemblages during bioremediation of a diesel fuel contaminated subAntarctic soil. Cold Reg Sci Technol 48:74–83. https://doi.org/10.1016/j.coldregions.2005.09.001

Desai JD, Banat IM (1997) Microbial production of surfactants and their commercial potential. Microbiol Mol Biol Rev 61:47–64

Dias RL, Ruberto L, Hernández E et al (2012) Bioremediation of an aged diesel oil-contaminated Antarctic soil: evaluation of the “on site” biostimulation strategy using different nutrient sources. Int Biodeterior Biodegrad 75:96–103. https://doi.org/10.1016/j.ibiod.2012.07.020

Dixit R, Wasiullah Malaviya D et al (2015) Bioremediation of heavy metals from soil and aquatic environment: an overview of principles and criteria of fundamental processes. Sustainability 7:2189–2212. https://doi.org/10.3390/su7022189

Eftoda G, Mccartney D (2004) Determining the critical bulking agent requirement for municipal biosolids composting determining the critical bulking agent requirement for municipal biosolids composting. Compost Sci Util 12:208–218. https://doi.org/10.1080/1065657X.2004.10702185

El Fels L, Zamama M, El Asli A, Hafidi M (2014) Assessment of biotransformation of organic matter during co-composting of sewage sludge-lignocelullosic waste by chemical, FTIR analyses, and phytotoxicity tests. Int Biodeterior Biodegrad 87:128–137. https://doi.org/10.1016/j.ibiod.2013.09.024

El Fels L, Lemee L, Ambles A, Hafidi M (2016) Identification and biotransformation of aliphatic hydrocarbons during co-composting of sewage sludge-Date Palm waste using Pyrolysis-GC/MS technique. Environ Sci Pollut Res 23:16857–16864. https://doi.org/10.1007/s11356-016-6670-9

Ferrarese E, Andreottola G, Oprea IA (2008) Remediation of PAH-contaminated sediments by chemical oxidation. J Hazard Mater 152:128–139. https://doi.org/10.1016/j.jhazmat.2007.06.080

Fountoulakis MS, Terzakis S, Georgaki E et al (2009) Oil refinery sludge and green waste simulated windrow composting. Biodegradation 20:177–189. https://doi.org/10.1007/s10532-008-9211-5

Ghazali FM, Rahman RNZA, Salleh AB, Basri M (2004) Biodegradation of hydrocarbons in soil by microbial consortium. Int Biodeterior Biodegradation 54:61–67. https://doi.org/10.1016/j.ibiod.2004.02.002

Gibb A, Chu A, Wong RCK, Goodman RH (2001) Bioremediation kinetics of crude oil at 5 °C. J Environ Eng 127:818–824. https://doi.org/10.1061/(ASCE)0733-9372(2001)127:9(818)

Gill CO, Ratledge C (1972) Toxicity of n-Alkanes, n-Alk-1-enes, n-Alkan-1-ols and n-Alkyl-1-bromides towards Yeasts. J Gen Microbiol 72:165–172. https://doi.org/10.1099/00221287-72-1-165

Hafidi M, Amir S, Jouraiphy A et al (2008) Fate of polycyclic aromatic hydrocarbons during composting of activated sewage sludge with green waste. Bioresour Technol 99:8819–8823. https://doi.org/10.1016/j.biortech.2008.04.044

Haghollahi A, Fazaelipoor MH, Schaffie M (2016) The effect of soil type on the bioremediation of petroleum contaminated soils. J Environ Manage 180:197–201. https://doi.org/10.1016/j.jenvman.2016.05.038

Hassen A, Belguith K, Jedidi N et al (2001) Microbial characterization during composting of municipal solid waste. Bioresour Technol 80:217–225. https://doi.org/10.1016/S0960-8524(01)00065-7

Hu G, Li J, Zeng G (2013) Recent development in the treatment of oily sludge from petroleum industry: a review. J Hazard Mater 261:470–490. https://doi.org/10.1016/j.jhazmat.2013.07.069

Hua F, Wang HQ (2014) Uptake and trans-membrane transport of petroleum hydrocarbons by microorganisms. Biotechnol Biotechnol Equip 28:165–175. https://doi.org/10.1080/13102818.2014.906136

Huang GF, Wong JWC, Wu QT, Nagar BB (2004) Effect of C/N on composting of pig manure with sawdust. Waste Manag 24:805–813. https://doi.org/10.1016/j.wasman.2004.03.011

Huesemann MH, Hausmann TS, Fortman TJ (2004) Does bioavailability limit biodegradation? A comparison of hydrocarbon biodegradation and desorption rates in aged soils. Biodegradation 15:261–274. https://doi.org/10.1023/B:BIOD.0000042996.03551.f4

IPIECA (2010) Petroleum refining water/wastewater management. London, p. 22

Jain PK, Gupta VK, Gaur RK et al (2011) Bioremediation of petroleum oil contaminated soil and water. Res J Environ Toxicol 5:1–26

Jean DS, Chu CP, Lee DJ (2001) Freeze/thaw treatment of oily sludge from petroleum refinery plant. Sep Sci Technol 36:2733–2746. https://doi.org/10.1081/SS-100107222

Jednak T, Avdalović J, Miletić S et al (2017) Transformation and synthesis of humic substances during bioremediation of petroleum hydrocarbons. Int Biodeterior Biodegrad 122:47–52. https://doi.org/10.1016/j.ibiod.2017.04.009

John NM (2007) Heavy metals content of crude oil sludge/poultry manure and crude oil sludge/municipal solid waste composts. Agric J 2:281–284

Kaczorek E, Moszyńska S, Olszanowski A (2011) Modification of cell surface properties of Pseudomonas alcaligenes S22 during hydrocarbon biodegradation. Biodegradation 22:359–366. https://doi.org/10.1007/s10532-010-9406-4

Kadali KK, Simons KL, Skuza PP et al (2012) A complementary approach to identifying and assessing the remediation potential of hydrocarbonoclastic bacteria. J Microbiol Methods 88:348–355. https://doi.org/10.1016/j.mimet.2011.12.006

Kapellos GE (2017) Chapter 2—Microbial Strategies for Oil Biodegradation. In: Becker SMBT-M of MT in BP (ed). Academic Press, New York, pp 19–39

Karamalidis AK, Voudrias EA (2007) Cement-based stabilization/solidification of oil refinery sludge: leaching behavior of alkanes and PAHs. J Hazard Mater 148:122–135. https://doi.org/10.1016/j.jhazmat.2007.02.032

Kavitha V, Mandal AB, Gnanamani A (2014) Microbial biosurfactant mediated removal and/or solubilization of crude oil contamination from soil and aqueous phase: an approach with Bacillus licheniformis MTCC 5514. Int Biodeterior Biodegradation 94:24–30. https://doi.org/10.1016/j.ibiod.2014.04.028

Kim K-H, Jahan SA, Kabir E, Brown RJC (2013) A review of airborne polycyclic aromatic hydrocarbons (PAHs) and their human health effects. Environ Int 60:71–80. https://doi.org/10.1016/j.envint.2013.07.019

Kim J, Lee AH, Chang W (2018) Enhanced bioremediation of nutrient-amended, petroleum hydrocarbon-contaminated soils over a cold-climate winter: the rate and extent of hydrocarbon biodegradation and microbial response in a pilot-scale biopile subjected to natural seasonal freeze-thaw t. Sci Total Environ 612:903–913. https://doi.org/10.1016/j.scitotenv.2017.08.227

Kirchmann H, Ewnetu W (1998) Biodegradation of petroleum-based oil wastes through composting. Biodegradation 9:151–156

Koolivand A, Naddafi K, Nabizadeh R (2013) Biodegradation of petroleum hydrocarbons of bottom sludge from crude oil storage tanks by in-vessel composting. Toxicol Environ Chem 95:101–109

Koolivand A, Rajaei MS, Ghanadzadeh MJ et al (2017) Bioremediation of storage tank bottom sludge by using a two-stage composting system: effect of mixing ratio and nutrients addition. Bioresour Technol 235:240–249. https://doi.org/10.1016/j.biortech.2017.03.100

Kriipsalu M, Nammari D (2010) Monitoring of biopile composting of oily sludge. Waste Manag Res 28:395–403. https://doi.org/10.1177/0734242X09337749

Kriipsalu M, Marques M, Nammari DR, Hogland W (2007) Bio-treatment of oily sludge: the contribution of amendment material to the content of target contaminants, and the biodegradation dynamics. J Hazard Mater 148:616–622. https://doi.org/10.1016/j.jhazmat.2007.03.017

Kriipsalu M, Marques M, Hogland W, Nammari DR (2008a) Fate of polycyclic aromatic hydrocarbons during composting of oily sludge during composting of oily sludge. Environ Technol 29:43–53. https://doi.org/10.1080/09593330802008735

Kriipsalu M, Marques M, Maastik A (2008b) Characterization of oily sludge from a wastewater treatment plant flocculation-flotation unit in a petroleum refinery and its treatment implications. J Mater Cycles Waste Manag 10:79–86. https://doi.org/10.1007/s10163-007-0188-7

Kunihiro N, Haruki M, Takano K et al (2005) Isolation and characterization of Rhodococcus sp. strains TMP2 and T12 that degrade 2,6,10,14-tetramethylpentadecane (pristane) at moderately low temperatures. J Biotechnol 115:129–136. https://doi.org/10.1016/j.jbiotec.2004.07.018

Lal B, Khanna S (1996) Degradation of crude oil by Acinetobacter calcoaceticus and Alcaligenes odorans. J Appl Bacteriol 81:355–362. https://doi.org/10.1111/j.1365-2672.1996.tb03519.x

Lazar I, Dobrota S, Voicu A et al (1999) Microbial degradation of waste hydrocarbons in oily sludge from some Romanian oil fields. J Pet Sci Eng 22:151–160. https://doi.org/10.1016/S0920-4105(98)00064-3

Leahy JG, Colwell RR (1990) Microbial degradation of hydrocarbons in the environment. Microbiol Rev 54:305–315

Li C-T, Lee W-J, Mi H-H, Su C-C (1995) PAH emission from the incineration of waste oily sludge and PE plastic mixtures. Sci Total Environ 170:171–183. https://doi.org/10.1016/0048-9697(95)04705-X

Ling CC, Isa MH (2006) Bioremediation of oil sludge contaminated soil by co-composting with sewage sludge. J Sci Ind Res 65:364–369

Liu J, Bacosa HP, Liu Z (2017) Potential environmental factors affecting oil-degrading bacterial populations in deep and surface waters of the Northern Gulf of Mexico. Front Microbiol 7:1–14. https://doi.org/10.3389/fmicb.2016.02131

Ma J, Yang Y, Dai X et al (2016) Effects of adding bulking agent, inorganic nutrient and microbial inocula on biopile treatment for oil-field drilling waste. Chemosphere 150:17–23. https://doi.org/10.1016/j.chemosphere.2016.01.123

Maletić S, Dalmacija B, Rončevic S (2013) Petroleum hydrocarbon biodegradability in soil—implications for bioremediation. In: Kutcherov V, Anton Kolesnikov I (eds) Hydrocarbon. InTech, Rijeka

Malińska K, Zabochnicka-Świa̧te M (2013) Selection of bulking agents for composting of sewage sludge. Environ Prot Eng 39:91–103. https://doi.org/10.5277/EPE130209

Malviya R, Chaudhary R (2006) Factors affecting hazardous waste solidification/stabilization: a review. J Hazard Mater 137:267–276. https://doi.org/10.1016/j.jhazmat.2006.01.065

Margesin R, Schinner F (1997) Effect of temperature on oil degradation by psychotrophic yeast in liquid culture and in soil. FEMS Microbiol Ecol 24:243–249

Margesin R, Hämmerle M, Tscherko D (2007) Microbial activity and community composition during bioremediation of diesel-oil-contaminated soil: effects of hydrocarbon concentration, fertilizers, and incubation time. Microb Ecol 53:259–269. https://doi.org/10.1007/s00248-006-9136-7

Marín JA, Moreno JL, Hernández T, García C (2006) Bioremediation by composting of heavy oil refinery sludge in semiarid conditions. Biodegradation 17:251–261. https://doi.org/10.1007/s10532-005-5020-2

Milne BJ, Baheri HR, Hill GA (1998) Composting of a heavy oil refinery sludge. Environ Prog 17:24–27

Minai-Tehrani D, Rohanifar P, Azami S (2015) Assessment of bioremediation of aliphatic, aromatic, resin, and asphaltene fractions of oil-sludge-contaminated soil. Int J Environ Sci Technol 12:1253–1260. https://doi.org/10.1007/s13762-014-0720-y

Monteiro SN, Vieira CMF, Ribeiro MM, Silva FAN (2007) Red ceramic industrial products incorporated with oily wastes. Constr Build Mater 21:2007–2011. https://doi.org/10.1016/j.conbuildmat.2006.05.035

Mrozik A, Piotrowska-Seget Z, Labuzek S (2003) Bacterial degradation and bioremediation of polycyclic aromatic hydrocarbons. Polish J Environ Stud 12:15–25

Nadarajah N, Van Hamme J, Pannu J et al (2002) Enhanced transformation of polycyclic aromatic hydrocarbons using a combined Fenton’s reagent, microbial treatment and surfactants. Appl Microbiol Biotechnol 59:540–544. https://doi.org/10.1007/s00253-002-1073-x

Ogbo E (2009) Effects of diesel fuel contamination on seed germination of four crop plants—Arachis hypogaea, Vigna unguiculata, Sorghum bicolor and Zea mays. Afr J Biotechnol 8:250–253. https://doi.org/10.1109/CGO.2006.10

Okoh AI (2006) Biodegradation alternative in the cleanup of petroleum hydrocarbon pollutants. Biotechnol Mol Biol Rewie 1:38–50. https://doi.org/10.1002/9783527620999.ch6m

Osuji LC, Egbuson EJ, Ojinnaka CM (2006) Assessment and treatment of hydrocarbon inundated soils using inorganic nutrient (N-P-K) supplements: II. A case study of eneka oil spillage in Niger Delta, Nigeria. Environ Monit Assess 115:265–278. https://doi.org/10.1007/s10661-006-6552-6

Ouyang W, Liu H, Murygina V et al (2005) Comparison of bio-augmentation and composting for remediation of oily sludge: a field-scale study in China. Process Biochem 40:3763–3768. https://doi.org/10.1016/j.procbio.2005.06.004

Paria S (2008) Surfactant-enhanced remediation of organic contaminated soil and water. Adv Colloid Interface Sci 138:24–58. https://doi.org/10.1016/j.cis.2007.11.001

Pinheiro BCA, Holanda JNF (2009) Processing of red ceramics incorporated with encapsulated petroleum waste. J Mater Process Technol 209:5606–5610. https://doi.org/10.1016/j.jmatprotec.2009.05.018

Ramadass K, Smith E, Palanisami T et al (2015) Evaluation of constraints in bioremediation of weathered hydrocarbon-contaminated arid soils through microcosm biopile study. Int J Environ Sci Technol 12:3597–3612. https://doi.org/10.1007/s13762-015-0793-2

Riser-Roberts E (1998) Remediation of petroleum contaminated soils: biological, physical and chemical processes. CRC Press, Boca Raton

Robertson SJ, McGill WB, Massicotte HB, Rutherford PM (2007) Petroleum hydrocarbon contamination in boreal forest soils: a mycorrhizal ecosystems perspective. Biol Rev 82:213–240. https://doi.org/10.1111/j.1469-185X.2007.00012.x

Rocha C, Infante C (1997) Enhanced oily sludge biodegradation by a tensio-active agent isolated from Pseudomonas aeruginosa USB-CS1. Appl Microbiol Biotechnol 47:615–619. https://doi.org/10.1007/s002530050983

Roldan-Carrillo T, Castorena-Cortes G, Zapata-Penasco I et al (2012) Aerobic biodegradation of sludge with high hydrocarbon content generated by a Mexican natural gas processing facility. J Environ Manag 95:S93–S98. https://doi.org/10.1016/j.jenvman.2011.04.014

Roy A, Dutta A, Pal S et al (2018) Biostimulation and bioaugmentation of native microbial community accelerated bioremediation of oil refinery sludge. Bioresour Technol 253:22–32. https://doi.org/10.1016/j.biortech.2018.01.004

Saadoun I, Al-Ghazawi Z (2010) Toxicity of diesel fuel towards plant seeds as reflected by seed germination outcomes, sprout length and fresh weight. J Agric Environ Sci 8:167–172

Sankaran S, Pandey S, Sumathy K (1998) Experimental investigation on waste heat recovery by refinery oil sludge incineration using fluidised-bed technique. J Environ Sci Heal Part A 33:829–845. https://doi.org/10.1080/10934529809376764

Sayara T, Sarrà M, Sánchez A (2010) Optimization and enhancement of soil bioremediation by composting using the experimental design technique. Biodegradation 21:345–356. https://doi.org/10.1007/s10532-009-9305-8

Scala F, Chirone R (2004) Fluidized bed combustion of alternative solid fuels. Exp Therm Fluid Sci 28:691–699. https://doi.org/10.1016/j.expthermflusci.2003.12.005

Seo J-S, Keum Y-S, Li Q (2009) Bacterial degradation of aromatic compounds. Int J Environ Res Public Health 6:278–309

Sharifi M, Sadeghi Y, Akbarpour M (2007) Germination and growth of six plant species on contaminated soil with spent oil. Int J Environ Sci Technol 4:463–470. https://doi.org/10.1007/BF03325982

Shen T, Pi Y, Bao M et al (2015) Biodegradation of different petroleum hydrocarbons by free and immobilized microbial consortia. Environ Sci Process Impacts 17:2022–2033. https://doi.org/10.1039/C5EM00318K

Sierra-Garcia IN, de Oliveira VM (2013) Microbial hydrocarbon degradation: efforts to understand biodegradation in petroleum reservoirs. In: Chamy R, Rosenkranz F (eds) Biodegradation: engineering and technology. IntechOpen

Silva-Castro GA, Rodelas B, Perucha C et al (2013) Bioremediation of diesel-polluted soil using biostimulation as post-treatment after oxidation with Fenton-like reagents: assays in a pilot plant. Sci Total Environ 445–446:347–355. https://doi.org/10.1016/j.scitotenv.2012.12.081

Sood N, Patle S, Lal B (2010) Bioremediation of acidic oily sludge-contaminated soil by the novel yeast strain Candida digboiensis TERI ASN6. Environ Sci Pollut Res 17:603–610. https://doi.org/10.1007/s11356-009-0239-9

Souza EC, Vessoni-Penna TC, De Souza Oliveira RP (2014) Biosurfactant-enhanced hydrocarbon bioremediation: an overview. Int Biodeterior Biodegrad 88:88–94. https://doi.org/10.1016/j.ibiod.2014.01.007

Suganthi SH, Murshid S, Sriram S, Ramani K (2018) Enhanced biodegradation of hydrocarbons in petroleum tank bottom oil sludge and characterization of biocatalysts and biosurfactants. J Environ Manag 220:87–95. https://doi.org/10.1016/j.jenvman.2018.04.120

Tang J, Lu X, Sun Q, Zhu W (2012) Aging effect of petroleum hydrocarbons in soil under different attenuation conditions. Agric Ecosyst Environ 149:109–117. https://doi.org/10.1016/j.agee.2011.12.020

Trapp S, Köhler A, Larsen LC et al (2001) Phytotoxicity of fresh and weathered diesel and gasoline to willow and poplar trees. J Soils Sediments 1:71–76. https://doi.org/10.1065/j552001.07.018

Ubani O, Atagana HI, Thantsha MS, Rasheed A (2016) Identification and characterisation of oil sludge degrading bacteria isolated from compost. Arch Environ Prot 42:67–77. https://doi.org/10.1515/aep-2016-0021

Udotong IR, Udotong JI, Inam E, Kim KW (2011) Bioconversion of crude oil production sludge into soil conditioner using sawdust as organic amendment. Geosystem Eng 14:51–58. https://doi.org/10.1080/12269328.2011.10541330

Uribe S, Rangel P, Espinola G, Aguirre G (1990) Effects of cyclohexane, an industrial solvent, on the yeast Saccharomyces cerevisiae and on isolated yeast mitochondria. Appl Environ Microbiol 56:2114–2119

Van Hamme JD, Odumeru JA, Ward OP (2000) Community dynamics of a mixed-bacterial culture growing on petroleum hydrocarbons in batch culture. Can J Microbiol 46:441–450. https://doi.org/10.1139/w00-013

Van Hamme JD, Singh A, Ward OP (2003) Recent advances in petroleum microbiology. Microbiol Mol Biol Rev 67:503–549. https://doi.org/10.1128/MMBR.67.4.503-549.2003

Van Oudenhoven J, Cooper G, Cricchi G et al (1995) Oil refinery waste, disposal methods and costs 1993 survey. CONCAWE, Brussels Report 1/95

Varjani SJ, Upasani VN (2016) Biodegradation of petroleum hydrocarbons by oleophilic strain of Pseudomonas aeruginosa NCIM 5514. Bioresour Technol 222:195–201. https://doi.org/10.1016/j.biortech.2016.10.006

Varjani SJ, Upasani VN (2017) A new look on factors affecting microbial degradation of petroleum hydrocarbon pollutants. Int Biodeterior Biodegrad 120:71–83. https://doi.org/10.1016/j.ibiod.2017.02.006

Varjani S, Upasani VN (2019) Influence of abiotic factors, natural attenuation, bioaugmentation and nutrient supplementation on bioremediation of petroleum crude contaminated agricultural soil. J Environ Manag 245:358–366. https://doi.org/10.1016/j.jenvman.2019.05.070

Vasudevan N, Rajaram P (2001) Bioremediation of oil sludge-contaminated soil. Environ Int 26:409–411

Viñas M, Grifoll M, Sabaté J, Solanas AM (2002) Biodegradation of a crude oil by three microbial consortia of different origins and metabolic capabilities. J Ind Microbiol Biotechnol 28:252–260. https://doi.org/10.1038/sj/jim/7000236

Viñas M, Sabaté J, Espuny MJ, Solanas AM (2005) Bacterial community dynamics and polycyclic aromatic hydrocarbon degradation during bioremediation of heavily creosote-contaminated soil. Appl Environ Microbiol 71:7008–7018. https://doi.org/10.1128/AEM.71.11.7008-7018.2005

Waigi MG, Kang F, Goikavi C et al (2015) Phenanthrene biodegradation by sphingomonads and its application in the contaminated soils and sediments: a review. Int Biodeterior Biodegradation 104:333–349. https://doi.org/10.1016/j.ibiod.2015.06.008

Wang X, Wang Q, Wang S et al (2012) Effect of biostimulation on community level physiological profiles of microorganisms in field-scale biopiles composed of aged oil sludge. Bioresour Technol 111:308–315. https://doi.org/10.1016/j.biortech.2012.01.158

Wu M, Dick WA, Li W et al (2016) Bioaugmentation and biostimulation of hydrocarbon degradation and the microbial community in a petroleum-contaminated soil. Int Biodeterior Biodegradation 107:158–164. https://doi.org/10.1016/j.ibiod.2015.11.019

Wu M, Li W, Dick WA et al (2017a) Bioremediation of hydrocarbon degradation in a petroleum-contaminated soil and microbial population and activity determination. Chemosphere 169:124–130. https://doi.org/10.1016/j.chemosphere.2016.11.059

Wu M, Ye X, Chen K et al (2017b) Bacterial community shift and hydrocarbon transformation during bioremediation of short-term petroleum-contaminated soil. Environ Pollut 223:657–664. https://doi.org/10.1016/j.envpol.2017.01.079

Yan P, Lu M, Yang Q et al (2012) Oil recovery from refinery oily sludge using a rhamnolipid biosurfactant-producing Pseudomonas. Bioresour Technol 116:24–28. https://doi.org/10.1016/j.biortech.2012.04.024

Zahrim AY, Asis T, Hashim MA et al (2015) A review on the empty fruit bunch composting: life cycle analysis and the effect of amendment(s) BT. In: Ravindra P (ed) Advances in bioprocess technology. Springer, Cham, pp 3–15

Zhang J, Fan S (2016) Influence of PAH speciation in soils on vegetative uptake of PAHs using successive extraction. J Hazard Mater 320:114–122. https://doi.org/10.1016/j.jhazmat.2016.08.024

Zhang Z, Gai L, Hou Z et al (2010) Characterization and biotechnological potential of petroleum-degrading bacteria isolated from oil-contaminated soils. Bioresour Technol 101:8452–8456. https://doi.org/10.1016/j.biortech.2010.05.060

Zhang J, Fan S, Zhang M et al (2018) Aliphatic hydrocarbons recovered in vegetables from soils based on their in situ distribution in various soil humus fractions using a successive extraction method. J Hazard Mater 346:10–18. https://doi.org/10.1016/j.jhazmat.2017.12.012

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aguelmous, A., El Fels, L., Souabi, S. et al. The fate of total petroleum hydrocarbons during oily sludge composting: a critical review. Rev Environ Sci Biotechnol 18, 473–493 (2019). https://doi.org/10.1007/s11157-019-09509-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11157-019-09509-w