Abstract

Oil refinery sludge (ORS) was mixed with shredded green wastes (GW) at ratios of 1:1 v/v (RI) and 1:3 v/v (RII). The mixtures, of approximately volumes of 1,020 l and 990 l respectively, were introduced in metal cubic containers of 1.0 m3 volume, opened at the top and with small holes punctured in the bottom and the side. The containers were additionally insulated with a layer of rockwool (20 mm). The boxes were emptied, the mixtures were turned and water was added occasionally, in one to two weeks intervals, simulating a windrow composting system. Temperature, physiochemical characteristics, mineral oil and grease (MOG) concentration, polycyclic aromatic hydrocarbons (PAHs) concentration, carbon dioxide emission, methane emission and microorganisms presence were recorded either daily or every time the mixtures were turned, for a period of 120 days. RII recorded temperatures as high as 62°C, reaching 56°C in Day 6 and retained temperatures above 50°C for more than 40 days. RI recorded its highest temperature of 53°C in Day 77. The reason why the two mixtures behaved so differently can be explained by: (i) extended co-digestion phenomena by the microorganisms decomposing the GW in RII, (ii) toxic effect of ORS in RI due to the far larger amounts used (840 kg in RI in comparison with the 460 kg in RII). After Day 36 temperature increased gradually in RI and MOG and PAHs reduction was first noted. At the end of the experiment MOG concentration in RI was 57.2 mg/kg dry weight (dw) (52.1% reduction) where in RII was 34.3 mg/kg dw (62.1% reduction). Emissions of methane and carbon dioxide support the concept of the toxic effect and the delay ignition of the decomposing process in RI. In total, CO2 and CH4 emissions from RI were recorded to be 30.8 kg and 18.5 g, respectively, where from RII 59.6 kg of CO2 and 6.4 g of CH4 were emitted. An effort was made to determine the effect of temperature alone (as an abiotic treating parameter) in both mixtures. It can be supported that about least 15% of the MOG and PAHs removal.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Petroleum storage and transportation facilities have often been a source of environmental pollution as they generate a number of hazardous wastes during the operation. Oily refinery sludge (ORS) is produced mainly from the accumulation of waste oily material in storage tank bottoms and from the water-oil separation systems. Due to its content of harmful organic compounds, ORS has been recognized as a potentially dangerous waste product (Karr and Lysyj 1983; Yang et al. 1991; Olajire et al. 2005). Particularly, petroleum-based oil wastes consist mainly of alkanes, paraffins, cycloalkanes, and aromatic hydrocarbons (Overcash and Pal 1979; Kirchman and Ewnetu 1998). Polycyclic aromatic hydrocarbons (PAH) constitute a small but important class of aromatic hydrocarbons, which are highly persistent compounds in the environment, recalcitrant to biodegradation and highly lipophilic, while some of them cause acute carcinogenic and mutagenic toxicity (Blanchard et al. 1999) and as a result, have been listed by regulatory agencies such as U.S.E.P.A. as top priority pollutants.

One of the most popular ORS treating method, due to its low cost and the simplicity of the treatment, was landfarming. Landfarming has traditional been the biological treatment method chosen to dispose ORS (Wilson and Jones 1993; Persson and Welander. 1994), even though low efficiencies in removing most toxic pollutants were achieved (Ferrari et al. 1996). Furthermore, the large surface area required for landfarming turned research to alternative biological methods such as composting (Williams and Keehan 1992; Kirchmann and Ewnetu 1998; Marin et al. 2006). Beaudin et al. (1996) showed that composting resulted in degradation of 77% of the mineral oil and grease (MOG) of a petroleum-hydrocarbon contaminated soil in six months while landfarming degraded less than 30% of the MOG in the same period. Studies were also performed by composting hydrocarbon-contaminated soil with other materials as biowaste (Van Gestel et al. 2003), activated sludge (Juteau et al. 2003) and tree leaves (Beaudin et al. 1999). A similar number of researches examined the composting of raw ORS with pig slurry (Marin et al. 2006); peat (Bengtsson et al. 1998) and horse manure (Kirchmann and Ewnetu 1998).

Green wastes (GW) have historically been disposed in landfills (Stentiford 2001). However, last years many governments have been trying to change this practice. In the EU, garden waste has been targeted for recycling, since a high proportion of civic-amenity waste is organic and it is produced free from contaminants relatively easily (Keeling et al. 1995).

The aim of this work is to examine systematic the composting treatment of oily waste sludge with GW in a pilot scale windrow system. The influence of mixing ratio to the reduction of oil content, PAHs concentration, microbial population and the production of greenhouse gases were examined.

Material and methods

Composters

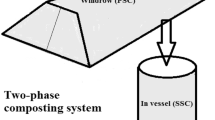

Two 1 m3 volume cubic shape (length × width × height, 1 × 1 × 1 m) metal containers were used as aerobic bioreactors, also known as composters. The boxes were completely opened at the top and small holes were punctured in the bottom and the sides. A layer of rockwool (20 mm) was used as additional insulation of the sides which however did allow the passive aeration through the holes. The boxes were introduced on the top of a small wooden structure that allowed air to enter from the bottom through the above mentioned small holes. As the mixtures inside the boxes were emptied and turned in one to two weeks intervals and water was occasionally added these systems simulated the windrow composting method. A presentation of the composters imitating the windrow composting system is provided in Fig. 1.

The mixtures

Oil refinery sludge (ORS) from the oil storage facilities in the outskirts of the city of Heraklion, in the island of Crete in Greece, was used together with shredded GW from the parks and roads of the city of Heraklion. Two mixtures were composed, one with a ratio of 1:1 v/v of ORS and GW named RI and a second with a ratio of 1:3 v/v respectively, named RII. During the synthesis of the mixtures the weights and volumes of each component added was measured and recorded. The mixtures were emptied from the composters and turned manually in 1–2 weeks intervals for a period of 120 days. In total 13 turnings took place. The initial moisture content of ORS and GW was found 34.7 and 43.1%, respectively. In order to maintain moisture levels between 50 and 60% which is identified for many investigators as suitable for efficient composting (Liang et al. 2003; Tiquia et al. 1996; Haug 1993; Suler and Finstein 1977), water was occasionally added in the mixtures manually.

Abiotic trials

Approximately 5 l of each mixture were further treated with 2% by weight HgCl2 in an effort to kill all the microorganisms present, as previous work on composting of oily sludge (Bengtsson et al. 1998). Each mixture was introduced in a drying oven with a digital temperature control. Each day, the temperature measured in each composter was used in each oven, achieving a very realistic temperature representation of the process. During the 120 days five samples were collected from the ovens (approximately in month intervals) and analyzed for MOG and PAHs.

MOG analysis

Oil and grease was determined by a gravimetric method. The sample was dried overnight at 60°C and homogenized by passing through a 20 mesh sieve in a grind (Pulverisette 14, Fritsch). Exactly 10 g of homogenized sample was mixed with 10 g anhydrous sodium sulfate in a mortar. The mixture was pulverized and 10 g of them were placed in an extraction thimble. The oil and grease were extracted in a Soxhlet apparatus using petroleum ether at a rate of 12 cycles h−1 for 8 h. The extraction solvent was filtered through glass wool containing anhydrous sodium sulfate, placed in a pre-weighed flask and evaporated. Mineral oil and grease was calculated by weighing the dry residue after solvent evaporation.

PAHs analysis

Concentrations of individual PAHs were determined by HPLC-DAD coupled with a fluorescence detector. The HPLC system consisted of a Solvent Delivery System from Agilent 1200 Series. The chromatographic separation was done using a reversed-phase Supelcosil LC-18 analytical column of 250 × 4.6 mm and 5 μm particle diameter from Supelco. The mobile phase initially consisted of 70% acetonitrile and 30% water. The analysis was run isocratically for 15 min and then programmed to 100% acetonitrile between 15 and 20 min. The mobile phase flow rate was 1.0 ml/min. The detection on the fluorescent detector was carried out at λex: 250 nm and at λem: 370 nm from 0 to 12 min and λex: 234 nm and at λem: 420 nm from 12 to 20 min.

Gas analysis

The closed chamber technique was used for estimating the emission rate from the composters. The specifically designed and constructed chambers were introduced in the top of the composters and were left open. The lead was introduced when sampling was conducted, in most cases in daily intervals. Four samples were collected (0, 15, 30, and 60 min) in gas tight syringes and were transferred to the gas chromatograph by sealing the needle with a butyl rubber stopper. Twenty microliters were injected into a gas chromatograph (Agilent 6890 N GC System) for analysis of methane and carbon dioxide. A thermal conductivity detector and a capillary column (GS Carbonplot, 30 m × 0.32 mm, 3 μm) were used. The column operated isothermally at 80°C and the detector port was operated at 150°C. Helium was used as the carrier gas at a flow rate 15 ml/min.

Mean values of the gas concentration measurements obtained between consecutive turnings for both piles, were calculated and used for further statistical analysis, according to Manios et al. (2007). Two-Way ANOVA on log-transformed gas concentration data was used in order to test the significance of differences in the mean gas concentration values between the two piles. Post Hoc Tukey tests were used to further investigate these differences (P < 0.05).

Microbial analysis

From the sample collected during turnings 10 g of were suspended in 90 ml sterile 0.1% ringer solution and agitated for 20 min on a reciprocal shaker at ambient temperature. One milliliter of each serial dilution of the suspensions was filter and the membrane was placed in triplicate on Rose Bengal Agar and Pseudomonas Agar, for enumeration of mesophilic fungi, and Pseudomonas after incubating at 25°C from 3 to 5 days and 37°C for 1 day, respectively.

Other physiochemical analysis

Temperature in the composters was measured in a daily bases at the core, meaning a depth of 40–60 cm. During turning composite samples were taken randomly at different places from the composting mixtures, were manually homogenized and used for further analysis. Percentage of humidity was estimated by determining the loss of weight of the sample after drying at 105°C (APHA 1985). The pH and electrical conductivity (EC) were measured in 1/1.5 solid/liquid aqueous extract (extraction time equal to 24 h). Volatile solids and total organic carbon (TOC) were analyzed by the ignition of sample at 600°C for 16 h (FCQAO 1996). Total nitrogen (TN) was determined by the micro-Kjeldal method (APHA 1995).

Results and discussion

The raw materials and their mixtures

Table 1 provides adequate information for the characterization of the two raw materials and their derived mixtures. For GW the physiochemical parameters are within the expected margins (Manios 2004). Regarding ORS it seems that there is a significant presence of soil together with oil residues since both TOC and MOG content (as well as TN) was smaller than that presented by other authors for similar materials (Marin et al. 2006). Since the ORS was not collected directly from the tanks, but from an exposed, temporary storage area, this was expected. The question was how the 12.5% TOC and the 0.51% TN of the ORS will affect the mixtures and their composting process.

Both RI and RII presented high electrical conductivity (especially RI) which even though will not effect the process considerably; it will affect the end product (Lasaridi et al. 2006). The pH value was also acceptable and the TOC was increased to 293 and 351 g/kg approximately for RI and RII, respectively. Organic matter wise there was a substantial substrate for the decomposing microorganisms to utilize in both mixtures, even though the TN content remained low (5.4 and 6.2 g/kg, respectively). MOG concentration drops also considerably in the mixtures, to 122 and 78 mg/kg, respectively. According to Table 1; Fig. 1 the probable limiting factors for successful composting of both mixtures in Day 1, were; (i) the relatively low moisture level, approximately 36 and 40% respectively for RI and RII, (ii) the very low carbon---nitrogen rate, and (iii) the unknown toxic effect of the petroleum hydrocarbons found in the two mixtures.

The C:N rate was approximately 54:1 for RI, where for RII (due to the larger presence of GW) was 56:1 where the optimum rate for composting is about 30:1 (Huang et al. 2004). Data from GW composting (shredded branches and leaves) indicate that the process can proceed with such high rates without the necessity of nitrogen addition (Manios and Stentiford 2004; Tai and He 2007). So that, it was decided to allow the process to develop before a final decision would be made.

Moisture levels for both ORS and GW were known the day when RI and RII were established and it was estimated that the mixture would have lower than the optimum moisture level, which is considered about 50–60% as previous reported. Furthermore, Antizar-Ladislao et al. (2006) studied the degradation of PAHs in an aged coal tar contaminated soil under in vessel composting conditions found that the optimal operational conditions occurred at moisture content of 60%. For this reason it was decided to add water during mixing as had happened with numerous other organic wastes in the past (Manios 2004). However, the texture of the ORS which looked extremely moist, far more than just 40%, confused the water addition process, which is in a large part rather empirical. As a result the water added was less than that required resulting to moisture levels presented in Fig. 2. Moisture loss was prominent throughout the composting as expected for open windrow systems (Haug 1993; Mohee et al. 2008). Adjustments of the water content performed and the moisture losses during experiment resulted to moisture content fluctuations among 30.3–53.4% and 38.6–58.7% for RI and RII, respectively. The mean moisture content value and the standard deviation for RI was 41.4 ± 6.7% and for RII was 46.9 ± 5.1%. Several researchers showed that as moisture content increased from 30% to 60% the metabolic and physiological activities of microorganisms were enhanced.

MOG concentration and its effect in the process was the biggest question mark since there was limited experience with ORS. The relevant literature as for example work conducted by Kirchmann and Ewnetu (1998); Van Gestel et al. (2003) and Marin et al. (2006) provide contrary results regarding a threshold value of MOG that would be able to delay or even cancel the composting process.

The composting behavior of RI and RII

Figure 3 presents the temperature fluctuation in the core of the two mixtures with time. Four days after establishment the temperature in RII was 50°C, a very good value for any organic waste in such short period of time. From that point onward RII behaved as most organic wastes both as temperature wise—recording more than 40 days with temperatures above 50°C and a maximum temperature of 62°C in Day 35—as well as pH, EC, TN, and TOC fluctuation (Fig. 2). RI behaves differently with the first 35 days straggling to increase temperature above 35°C. It does retain a medium temperature of above 40°C for a long period of time from that point onwards (as RII), These findings are in complete accordance to work presented by Marin et al. (2006) found that there are different thermal behavior between compost containing bulking agent and the other with no additives.

The presence of GW in larger amount in RII than in RI (Table 2) provides the bases for explaining the significant differentiation in the composting profile of the two mixtures. Better structure, provided by the 1:3 v/v rate of the bulking agent, allowed more air entrapment increasing the aerobic biodegradation of the mixture. This is strongly supported by the gases emission presented in Fig. 4 and statistically analyzed in Table 3. During the first 30 days of composting carbon dioxide flows out of RII in significant larger rates than in RI. Specifically until that day 13.6 kg of CO2 have been released from RII, in comparison with 2.2 kg of RI. Aerobic microorganisms in RII are predominant even though some anaerobic pockets exist producing small amounts of methane (and part of the carbon dioxide) as suggested by relevant published work (Atkinson et al. 1996; Ryckeboer et al. 2003).

If however density and absence of oxygen were the main reasons for the lower temperature, then as anaerobic microorganisms would become predominant methane and carbon dioxide should be produced and emitted from the RI composter. However, as can be easily spotted again through Fig. 4 and Table 3, this is not the case. The methane emission was higher but not significant than in RII. A simple and direct explanation to this phenomenon is the toxicity of MOG found in the ORS.

When used in the smaller rate (RII) the more easily decomposable GW managed to start their decomposing process. As temperature increased due to their decomposition two phenomena took place probably at the same time. First the thermophilic decomposing microorganisms co-digest the difficult to be decomposed and under ordinary situations toxic molecules. The use of co-substrate in order to enhanced biodegradation process has been well studied for various wastes under aerobic and anaerobic conditions (Rajaguru et al. 2000; Mata-Alvarez et al. 2000; Marin et al. 2006) and especially for oil refinery wastewaters in aerobic bioreactors (Lee et al. 2004). Slowly (or not) bacteria and fungi decompose the toxic molecules (here represented by the MOG and PAHs) as shows in Figs. 5 and 6. As these molecules decompose produce easier decomposable molecules (less toxic) providing additional substrate to the microorganisms (Antizar-Ladislao et al. 2004) and sustaining the co-digestion phenomenon.

Research into bioremediation of PAH contaminated wastes shown that fungi are an important microbial group for composting of a contaminated soil (Sasek et al. 2003; Bhatt et al. 2002). More specifically, the majority of these belong to the Basidiomycota, which contain the fungal genera responsible for wood decomposition and hence possess the necessary complex array of ligninolytic enzymes and nonenzymatic mechanisms for the degradation of lignin whose basic chemical structures are similar to the PAHs. Microorganisms degrading PAHs include fungi, such as Phanaerochaete chrysosporium, Bjerkandera sp. and Pleurotus ostreatus (Antizar-Ladislao et al. 2004; Canet et al. 2000). According to Fig. 6, fungi population in RII is larger than in RI, at least until Day 60. This observation may be explain the higher PAH degradation in RII than in RI. However, several researchers indicated that most common effect of fungi on PAHs degradation is not mineralization but mainly the activation and solubilization of PAHs by non-specific fungal enzymes (Johnsen et al. 2002). In addition, recent research on in-vessel composting of aged coal-tar contaminated soil showed no correlation between fungal to bacteria ratios and PAH losses (Antizar-Ladislao et al. 2008).

The heat released from the decomposing GW and the slowly decomposing ORS is entrapped inside the pile by the insulating capacity of the GW (Tai and He 2007). Temperature by its self as an abiotic treating parameter plays a part in the process as suggested by the relevant finding of the abiotic experiments presented in Table 4. The moderate abiotic treatment is added to the significant biotic in RII reducing the toxicity effect of the hydrocarbon pollutants to the decomposing microorganisms. As a result and as it is recorded in Figs. 5 and 6, pollutants are decreased faster and to lower final concentrations.

The toxic effect of the hydrocarbon pollutants can be further supported by the simultaneous MOG reduction and temperature increase in RI following the fourth turning. In Fig. 5 the concentration of MOG between the 29th day and the 38th day records a significant drop of approximately 20%, to a concentration lower than 100 g/kg. It is after that sudden drop that both the temperature profile and gases emissions change dramatically. From that point onwards RI records temperatures above 40°C and carbon dioxide and methane starting recording some important values (Fig. 4). Specifically and according to Fig. 4, carbon dioxide emission is increased almost to the level of RII where methane emission is now significant higher than RII (Table 4). Few days after PAHs concentration in RI starts dropping (Fig. 6) and finally Pseudomonas spp. and fungi population, both related to PAHs decomposition, do record a slight increase (especially the fungi).

It is rather clear that after more than 35 days of abiotic (temperature) and biotic (microorganisms) treatment, the toxicity level in RI has been reduced, probably through decomposition to simpler and less toxic molecules, in such way that allowed a larger variety of decomposing microorganisms to act. The capability of microorganisms to biodegrade specific contaminants depends on different reasons. The elevated temperatures of composting can increase the enzyme kinetics involved in biodegradation processes. Co-oxidation may be enhanced due to the range of alternative substrates present or modifications in the physical and chemical microenvironments within the composting mass can serve to increase the diversity of the microflora to which the contaminant is exposed (Williams and Keehan 1993).

Removing PAHs and MOG through composting

Tables 4 and 5 (the last was produced through Tables 1–3 as well as Fig. 2) together with Figs. 5 and 6 describe in a detailed manner the removal of MOG as well as phenanthrene (PHE), fluoranthene (FLU) and pyrene (PYR), constituting the PAHs monitored in these trials. According to them the reduction of MOG is 52.1% in RI and 62.1% in RII, where for PHE these values are 55.2% and 87.7%, for FLU 40.3 and 63.5% and for PYR 56.4% and 81.1% respectively. These removals were statistically significantly different (ANOVA—Tukey test) both for MOG and PAHs (P = 0.05). It is rather difficult to make direct comparison of these findings, with data published by other authors due to the quality of the ORS used and the nature of the bulking agent. For example Marin et al. (2006) reported 60% degradation of hydrocarbon content in similar ORS mixed with wood shavings. Since though, their mixtures were made based in mass rates and not volume rates, the comparability of the results is rather limited. However the removal percentage achieved at least in RII should be considered high compared with other composting efforts (Antizar-Ladislao et al. 2004).

As far the net amount of MOG removed, though composting, RI has a significant precedence with more than 41 g, where RII only slightly more than 17 g (Table 5). If the amount removed is compared with the volume of the mixture (or the volume of the bioreactor) then the efficiency rate is 0.41 for RI where for RII is 0.18. Also if the same amount is compared with the mass of GW required in each case (important for a cost benefit analysis) then again the efficiency rate for RI (0.30) is far better than for RII (0.09). Its obvious that this difference is a result of the initial concentrations, however does indicate in a rather strong way that if the aim is to remove/decompose/evaporate as much MOG as possible then mixtures like RI are far more productive. This is not the picture with PAHs. According to Table 5, there is rather small difference between the two mixtures, with RI recording slightly better values.

However, RII is superior to RI in regarding final concentration which more or less will determine how the end product will be handled further. In this case RII (Table 4) records far smaller values allowing the easier handling of the end product. The fact though that there was no total degradation of oil content, indicates (a) that there is some weakness in the composting treating process and (b) that the residual quantity is highly recalcitrant to biodegradation due to possible strong biosorption to the solids (non-bioavailable fraction) or to the nature of the remaining molecules (Artola-Caricano et al. 2003; Leonardi et al. 2007).

The abiotic treatment

Table 4 and Fig. 5 present some information regarding the effect of the temperature increase as a direct part of the treating process. According to the table MOG reduction due to temperature increase and the subquential evaporation of the lighter hydrocarbon is 15.3% for RI and 23.2% for RII. For all three PAHs the percentage removals were lower with the expectance of FLU which recorded similar values (14.1% and 19.4%, respectively). Antizar-Ladislao et al. (2005) found that abiotic losses of total PAH using non-amended soil was 20.8%, 42.0% and 66.3% at 38, 55 and 70°C, respectively. The mean temperature during experiment in RI was 37.2°C and for RII was 44.7°C. According to these temperatures, the observed abiotic losses are relatively close to this reported from Antizar-Ladislao et al. (2005). The effect of the abiotic parameter can be explained through the MOG composition. Many volatile compounds are part of the MOG. As temperature increase and remains high these molecules evaporates allowing a reduction in the overall MOG concentration (Bengtsson et al. 1998).

What however must be taken under consideration is the fact that during the abiotic experiments the mixtures were exposed to the temperature from the oven, where during composting the temperature was recorded in the core of the simulated windrow pile (Fig. 1). In the first case there was no physical barrier to the substances evaporation, where in the reality both the piled above materials as well as the drop of temperature in the outer layers might reduce the importance of abiotic treatment. Kirchman and Ewnetu (1998) support this idea showed that gaseous losses of oil compounds through volatilization from composts were not significant. It would be safe to suggest that microorganisms (similar to those monitored here—Fig. 6) are the main decomposing reason either by direct decomposition of the hydrocarbons and the decomposed bio-products or through co-digestion phenomena.

Previous research on remediation of PAH contaminated soil by in-vessel composting (Antizar-Ladislao et al. 2005) found that the biocidal effect of 2% HgCl2 were reduce over time, thus some foreign microorganisms may have been able to colonise the medium again. General, the technique of in-vessel composting providing in the reactors constant air-flow with air pump resulting to higher expose of medium to foreign microorganisms transported via air-flow. On the other hand in this experiment the HgCl2-inhibited reactor introduced in the oven without air or water supply amendment. So that, the abiotic losses represented by a non-amended medium as suggested (Antizar-ladislao et al. 2005) plus HgCl2 addition.

Conclusions

The 1:3 v/v mixing rate (RII) for the co-composting of ORS with GW should be considered as optimum, comparable to the 1:1 v/v (RI) mainly due to its overall behavior during the thermophilic stage of the process, as well as the lower final concentration of the MOG and PAHs. However, what seems more important than just the mixing rate, as a criterion for examining the composting potential of a mixture, is the concentration of the MOG that potentially inhibits the composting process. According to the findings presented, MOG concentration above 100 mg/kg of dry weight might potentially limit and delay composting. Mixing rates like 1:2 v/v should also be tested, as well as 1:3 v/v rates in which the initial MOG concentration would be higher than the above mentioned limiting value. Further investigation in the toxic effect of each MOG/PAHs component should also be conducted.

If and when this concentration is no longer a limiting factor, the ability of composting to remove MOG and PAHs should be considered as significant, with rates spreading between 50% and 85% depending the mixture and the pollutant. Most of this removal should be considered as a result of the decomposing microorganisms’ action, with a far smaller part as a result of the temperature increase and the consequent evaporation of the lighter hydrocarbons. This is difficult to be estimated accurately since it would be possible evaporated molecules due to temperatures in the core to be condensed in outer colder layers as flowing vertically.

Finally, monitoring methane and carbon dioxide emission during composting should be considered an important part of the process evaluation. In this case the emission profile of the two piles provided the required information for determining the toxic threshold of the MOG concentration.

References

Antizar-Ladislao B, Lopez-Real JM, Beck AJ (2004) Bioremediation of polycyclic aromatic hydrocarbon (PAH)-contaminated waste using composting approaches. Crit Rev Environ Sci Technol 34:249–289. doi:10.1080/10643380490434119

APHA AWWA & WEF (1995) Standard methods for the examination of water and wastewater, 19th edn. APHA Inc., Washington, DC, USA

Antizar-Ladislao B, Lopez-Real JM, Beck AJ (2005) Laboratory studies of the remediation of polycyclic aromatic hydrocarbon contaminated soil by in-vessel composting. Waste Manag 25:281–289. doi:10.1016/j.wasman.2005.01.009

Antizar-Ladislao B, Lopez-Real JM, Beck AJ (2006) Degradation of polycyclic aromatic hydrocarbons (PAHs) in an aged coal-tar contaminated soil under in-vessel composting conditions. Environ Pollut 141:459–468. doi:10.1016/j.envpol.2005.08.066

Antizar-Ladislao B, Spanova K, Beck AJ, Russell NJ (2008) Microbial community structure changes during bioremediation of PAHs in an aged coal-tar contaminated soil by in-vessel composting. Int Biodeter Biodegr Aticle 61:357–364

Atkinson CF, Jones DD, Gauthier JJ (1996) Putative anaerobic activity in aerated composts. J Ind Microbiol 16:182–188. doi:10.1007/BF01570002

Artola-Caricano E, Borkent I, Damen K, Jager T, Vaes WHJ (2003) Sorption kinetics and microbial biodegradation activity of hydrophobic chemicals in sewage sludge: model and measurements based on free concentrations. Environ Sci Technol 37:116–122. doi:10.1021/es020115y

Beaudin N, Caron RF, Legros R, Ramsay J, Lawlor L, Ramsay B (1996) Cocomposting of weathered hydrocarbon-contaminated soil. Compost Sci Util 4(2):37–45

Beaudin N, Caron RF, Legros R, Ramsay J, Ramsay B (1999) Identification of the key factors affecting composting of a weathered hydrocarbon-contaminated soil. Biodegradation 10:127–133. doi:10.1023/A:1008365832031

Bengtsson A, Quednau M, Haska G, Nilzen P, Persson A (1998) Composting of oily sludges-degradation, stabilized residues, volatiles and microbial activity. Waste Manag Res 16:273–284. doi:10.1177/0734242X9801600309

Bhatt M, Cajthaml T, Sasek V (2002) Mycoremediation of PAH-contaminated soil. Folia Microbiol (Praha) 47:255–258. doi:10.1007/BF02817647

Blanchard M, Teil MJ, Carru AM, Ollivon D, Garban B, Chesterikoff A et al (1999) PCB and PAH impacts on cytochrome P-450-dependent oxidases in roach (Rutilus rutilus) from the Seine river (France). Arch Environ Contam Toxicol 37:242–250. doi:10.1007/s002449900511

Canet R, Birnstingl JG, Malcolm DG, Lopez-Real JM, Beck AJ (2000) Biodegradation of polycyclic aromatic hydrocarbons (PAHs) by native microflora and combinations of white-rot fungi in a coal-tar contaminated soil. Bioresour Technol 76:113–117. doi:10.1016/S0960-8524(00)00093-6

FCQAO (1996) Methods book for the analysis of compost. Published by Federal Compost Quality Assurance Organization-Bundesgutegemeinschoft Kompost E.V., Abfall Now E.V. Publishing House, Stuttgart, Germany

Ferrari MD, Neirotti E, Albornoz C, Mostazo MR, Cozzo M (1996) Biotreatment of hydrocarbons from petroleum tank bottom sludges in soil slurries. Biotechnol Lett 18:1241–1246. doi:10.1007/BF00129947

Haug RT (1993) Compost engineering: principles and practice. Lewis Publishers, Boca Raton, FL

Huang GF, Wong JWC, Wuand QT, Nagar BB (2004) Effect of C/N on composting of pig manure with sawdust. Waste Manag 24:805–813. doi:10.1016/j.wasman.2004.03.011

Johnsen AR, Winding A, Karlson U, Roslev P (2002) Linking of microorganisms to phenanthrene metabolism in soil by analysis of 13C-labeled cell lipids. Appl Environ Microbiol 68:6106–6113. doi:10.1128/AEM.68.12.6106-6113.2002

Juteau P, Bisaillon JG, Lepine F, Ratheau V, Beaudet R, Villemur R (2003) Improving the biotreatment of hydrocarbons-contaminated soils by addition of activated sludge taken from the wastewater treatment facilities of an oil refinery. Biodegradation 14:31–40. doi:10.1023/A:1023555616462

Karr LA, Lysyj I (1983) Oily sludges: physical, chemical and toxicological characterization, vol 23. National Meeting—American Chemical Society, Division of Environmental Chemistry, pp 64–67

Keeling A, Griffiths B, Ritz K, Myers M (1995) Effects of compost stability on plant growth, microbiological parameters and nitrogen availability in media containing mixed garden-waste compost. Bioresour Technol 54:279–284. doi:10.1016/0960-8524(95)00138-7

Kirchmann H, Ewnetu W (1998) Biodegradation of petroleum-based oil wastes through composting. Biodegradation 9:151–156. doi:10.1023/A:1008355825404

Lasaridi K, Protopapa I, Kotsou M, Pilidis G, Manios T, Kyriacou A (2006) Quality assessment of composts in the Greek market: the need for standards and quality assurance. J Environ Manag 80:50–65. doi:10.1016/j.jenvman.2005.08.011

Lee LY, Hu JY, Ong SL, Ng WJ, Ren JH, Wong SH (2004) Two-stage SBR for treatment of oil refinery wastewater. Water Sci Technol 50(10):243–249

Leonardi V, Šašek V, Petruccioli M, D’Annibale A, Erbanovaì P, Cajthaml T (2007) Bioavailability modification and fungal biodegradation of PAHs in aged industrial soils. Int Biodeter Biodegr 60(170):165. doi:10.1016/j.ibiod.2007.02.004

Liang C, Das KC, McClendon RW (2003) The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour Technol 86:131–137. doi:10.1016/S0960-8524(02)00153-0

Madejoìn E, Jesuìs Diìaz M, Loìpez R, Cabrera F (2002) New approaches to establish optimum moisture content for compostable materials. Bioresour Technol 85:73–78. doi:10.1016/S0960-8524(02)00030-5

Manios T (2004) The composting potential of different organic solid wastes: experience from the island of Crete. Environ Int 29:1079–1089. doi:10.1016/S0160-4120(03)00119-3

Manios T, Stentiford EI (2004) Sanitary aspect of using partially treated landfill leachate as a water source in green waste composting. Waste Manag 24:107–110. doi:10.1016/S0956-053X(03)00130-2

Manios T, Maniadakis K, Boutzakis P, Naziridis Y, Lasaridi K, Markakis G et al (2007) Methane and carbon dioxide emission in a two-phase olive oil mill sludge windrow pile during composting. Waste Manag 27:1092–1098. doi:10.1016/j.wasman.2006.05.012

Marin JA, Moreno JL, Hernandez T, Garcia C (2006) Bioremediation by composting of heavy oil refinery sludge in semiarid conditions. Biodegradation 17:251–261. doi:10.1007/s10532-005-5020-2

Mata-Alvarez L, Mace S, Liabres P (2000) Anaerobic digestion of organic solid wastes: an overview of research achievements and perspectives. Bioresour Technol 74:3–16. doi:10.1016/S0960-8524(00)00023-7

Mohee R, Driver MFB, Sobratee N (2008) Transformation of spent broiler litter from exogenous matter to compost in a sub-tropical context. Bioresour Technol 99:128–136. doi:10.1016/j.biortech.2006.11.040

Olajire AA, Altenburger R, Küster E, Brack W (2005) Chemical and ecotoxicological assessment of polycyclic aromatic hydrocarbon-contaminated sediments of the Niger Delta, Southern Nigeria. Sci Total Environ 20:123–136. doi:10.1016/j.scitotenv.2004.08.014

Overcash MR, Pal D (1979) Design of land treatment systems for industrial wastes: theory and practice. Ann Arbor Science, Ann Arbor, MI, pp 152–219

Persson NA, Welander TG (1994) Biotreatment of petroleum hydrocarbons-containing sludges by landfarming. In: Hinchee RA, Alleman BC, Hoeppel RE, Miller RN (eds) Hydrocarbon bioremediation. Lewis Publishers, Boca Raton, FL, pp 335–342

Rajaguru P, Kalaiselvi K, Palanivel M, Subburam V (2000) Biodegradation of azo dyes in a sequential anaerobic–aerobic system. Appl Microbiol Biotechnol 54:268–273. doi:10.1007/s002530000322

Ryckeboer J, Mergaert J, Vaes K, Klammer S, De Clerq Q, Coosemans K et al (2003) A survey of bacteria and fungi occurring during composting and self-heating process. Ann Microbiol 53:349–410

Sasek V, Cajthaml T, Bhatt M (2003) Use of fungal technology in soil remediation: a case study. Water Air Soil Pollut 3:5–14

Stentiford EI (2001) Composting-optimising the process and keeping the neighbours happy. In: Lasaridi K, Paulopoulos K (eds) Proceeding of composting network conference, 12 June, Athens

Suler DJ, Finstein MS (1977) Effect of temperature, aeration, and moisture on CO2 formation in bench-scale, continuously thermophilic composting of solid waste. Appl Environ Microbiol 33:345–350

Tai HS, He WH (2007) A novel composting process for plant wastes in Taiwan military barracks. Res Conserv Rec 51:408–417. doi:10.1016/j.resconrec.2006.10.006

Tiquia SM, Tam NFY, Hodgkiss IJ (1996) Microbial activities during composting of spent pig-manure sawdust litter at different moisture contents. Bioresour Technol 55:201–206. doi:10.1016/0960-8524(95)00195-6

Van Gestel K, Mergaert J, Swing J, Coosemans J, Ryckeboer J (2003) Bioremediation of diesel oil-contaminated soil by composting with biowaste. Environ Pollut 125:361–368. doi:10.1016/S0269-7491(03)00109-X

Wilson SC, Jones KC (1993) Bioremediation of soil contaminated with polynuclear aromatic hydrocarbons (PAHs): a review. Environ Pollut 81:229–249. doi:10.1016/0269-7491(93)90206-4

Williams RT, Keehan KR (1992) Bioremediation using composting. In: Proceedings of National Waste Processing Conference, pp 429–433

Yang SYN, Connell DW, Hawker DW, Kayal SI (1991) Polycyclic aromatic hydrocarbons in air, soil and vegetation in the vicinity of an urban roadway. Sci Total Environ 102:229–240. doi:10.1016/0048-9697(91)90317-8

Acknowledgement

The authors would like to thank EKO Oil Company and especially K. Fotinakis for the supply of the oil refinery sludge.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fountoulakis, M.S., Terzakis, S., Georgaki, E. et al. Oil refinery sludge and green waste simulated windrow composting. Biodegradation 20, 177–189 (2009). https://doi.org/10.1007/s10532-008-9211-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-008-9211-5