Abstract

This chapter reviews the Life Cycle Assessment (LCA) and the effect of amendment(s) for empty fruit bunches composting. A Life Cycle Assessment (LCA) of empty fruit bunches EFB composting as a solid waste processing is presented. The LCA study by various investigators confirmed that composting is more really environmentally friendly based on the greenhouse gas reduction measurement. Successful composting of empty fruit bunches (EFB) and suitable amendment(s) and obtaining a product of horticultural value may increase the viability of this recycling approach. The EFB composting with suitable amendments has shown acceptable quality of compost and simultaneously accelerates the process to less than 60 days. Finally, a case study on utilization of banana skins as amendments is discussed. In the case study, the addition of banana skin could enhance rapid EFB decomposition and increase nutrients such as P and K. A 45 days experiment was conducted at a ~100 kg scale to observe decomposition processes in empty fruit bunch (EFB) amended with two different percentages of banana skins (BS) (H5 and H10, 5 % and 10 % of BS by weight, respectively) in comparison with the control (unamended EFB, i.e. H0). The temperature in the three points of the piles was recorded throughout the experiment. By day 3, the temperature in the substrates H10 exceeded 45 °C while the highest temperature recorded in the control during the experiment was 39 °C (day 22). In conclusion, banana skins have potential as amendment for enhancing EFB composting.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

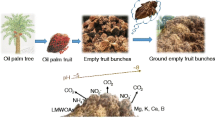

Palm oil industry significantly contributes to the national economy in Malaysia and currently accounts for RM53 billion (Kabbashi et al. 2014). The empty fruit bunches (EFB) of oil palm is one of the major wastes from oil palm industry. It is reported that about 3.0 million tons of oil palm empty fruit bunch (EFB) fibers are produced every year (Sajab et al. 2013). The typical physicochemical analysis for EFB is shows in Table 1.1. Due to the fact that EFB are generated daily and every year its disposal becoming a great concern, thus sustainable technology for EFB disposal is vital to be developed. Composting is regarded as a proven technology for processing EFB from the palm oil mill (Zahrim and Asis 2010). Composting is an accelerated bioconversion of organic matter to humic substances known as compost. Furthermore, composting could reduce the volume and initial weight of the fresh EFB by 85 % and 50 % respectively (Saletes et al. 2004).

The compost can be applied as a soil amendment (Yaser et al. 2007) or mulching as well other non-agricultural usage such as biofilter. Recently, indigenous micro-organisms from EFB compost were developed into advanced or multifunctional biofertilizer products (Phua et al. 2012). Among others, the quality of compost depends on the raw material itself (Zahrim and Asis 2010) as well as turning frequency (Tiquia et al. 2002).

Life Cycle Assessment (LCA)

Life cycle assessment (LCA) has been used to evaluate and compare the impacts of different waste disposal scenarios, including composting. By using a common metric, LCA methodology allows for the quantification and comparison of environmental impacts between stages of a product or service throughout its life cycle, including raw material acquisition, processing, distribution, use, and end of life. Several LCA studies have reported that composting is more advantageous, i.e. less environmental impacts, than other organic waste disposal scenarios, such as landfill and incineration (Saer et al. 2013).

Stichnothe and Schuchardt (2010) studied a detailed life cycle model has been used to calculate the environmental impacts of POME and EFB treatment. The authors investigated several options, i.e. (1) dumping EFB and storing POME and ponds, (2) returning EFB to the plantation and POME as before, (3) using EFB and POME for co-composting and returning the produced compost to the plantation, (4) generating biogas from POME and thereafter as in (3). The sensitivity analysis has been carried out in order to estimate the influence of good and poor management practice on the environmental performance. From this study, Stichnothe and Schuchardt (2010) stated that the main contributor to the Global Warming Potential (GWP) is methane from POME and EFB dumping. The GWP of palm oil mill waste treatment can be reduced from 245 kg CO2eq per ton FFB to up to 5 kg CO2eq per ton FFB due to the reduction of methane emissions and nutrient recycling. Co-composting of POME and EFB leads to considerable nutrient recovery, in addition to GWP reduction (Stichnothe and Schuchardt 2010). Recently, Chiew and Shimada (2013) analysed seven technologies for EFB management: ethanol production, methane recovery, briquette production, biofuel for combined heat and power (CHP) plants, composting, medium density fiberboard (MDF) production, and pulp and paper production. The authors reported that the methane recovery and composting are more environmentally friendly than other technologies, as measured by reduction of greenhouse gas emissions (Chiew and Shimada 2013). In another study, Norhasmillah et al. (2013) compared the life cycle inventory (LCI) obtained from three commercial oil palm biomass composting projects in Malaysia which use the open windrow composting system. Interestingly, the authors found that composting saved 65 % of time required for a complete degradation of POME when compared to ponding system, and 89 % of time required for a complete degradation of EFB compared to mulching (Norhasmillah et al. 2013).

The advantages of EFB composting not only reduces environmental burdens; it also leads to net environmental benefit regarding most environmental impact categories, e.g., acidification potential, eutrophication potential, ozone layer depletion potential, etc. due to the avoided emissions from inorganic fertilizer production (Stichnothe and Schuchardt 2010). Yoshizaki et al. (2013) reported that the compost production using shredded empty fruit bunch (EFB) and POME anaerobic sludge obtained from the anaerobic digester is equivalent of 579 tonnes, 151 tonnes and 761 tonnes per year of nitrogen, phosphorus and potassium respectively (Yoshizaki et al. 2013).

A Review on the Effect of Different Amendment(s)

Rapid decomposition of empty fruit bunch (EFB) can be obtained by adding suitable material(s) such as animal waste and palm oil mill effluent (Table 1.2). The effects of composting EFB alone, EFB-poultry layer deep-litter-urea, and EFB-poultry broiler floor-litter-urea were studied by Thambirajah and Kuthubutheen (1989). The initial C: N ratios of the three mixtures were 40:1, 33:1 and 26:1, respectively. After 8 weeks of composting the C: N ratios of the mixtures were 26:1, 17:1 and 16:1, respectively (Thambirajah and Kuthubutheen 1989). The composting of EFB alone, EFB-goat dung, EFB-cow dung and EFB-chicken manure were studied by Thambirajah et al. (1995). The initial C:N ratios (52:1, 35:1, 48:1, 47:1) for the four compost heaps were significantly reduced to 24:1, 14:1, 18:1 and 12:1, respectively, after 60 days of composting (Thambirajah et al. 1995). In this study, the maximum heap temperature of 70 °C was maintained for 3 days during composting phase. Both mesophilic and thermophilic bacteria showed consistent activity throughout the process, whereas fungal activity was completely suppressed during the peak heating phase (Thambirajah et al. 1995). Saletes et al. (2004) have added urea and/or ripe compost to amend the initial C/N of EFB. They reported that after 70 days, the compost could be considered matured. However, almost 50 % of the phosphorus, 70 % of the potassium, 45 % of the magnesium and between 10 % and 20 % of the calcium theoretically applied were lost during composting period. The authors suggested that the better distribution of the effluent applications, combined with a system to recover the leachings, should substantially reduce these losses, while maintaining suitable humidity for microbial degradation (Saletes et al. 2004).

Schuchardt et al. (2005) reported that the conventional ponding system of palm oil mill effluent (POME) treatment is not only contribute highest pollution of the environment also the system with the lowest profit. The authors recommended utilisation of nutrients from POME and EFB for composting process (Schuchardt et al. 2005). The investigation of co-composting EFB with partially treated palm oil mill effluent (POME) was carried out by Baharuddin et al. (2009). The temperature was increased up to 58.5 °C at day three of treatment, after that fluctuated between 50 and 62 °C and then decreased in the latter stage of the process. The pH of the system (7.75–8.10) did not vary significantly during the treatment period while moisture content was reduced horn 65–75 % to about 60 % at the end of the treatment. The initial C/N ratio of 45 was significantly reduced to 12 after 60 days of composting. The final cured compost contained a considerable amount of nutrients (carbon, nitrogen, phosphorus, potassium, calcium, magnesium, sulfur and iron) and trace amounts of manganese, zinc, copper. In addition, very low levels of heavy metals were detected in the compost. The number of bacteria involved in the composting process was decreased at the end of the composting period. The compost product may useful in palm oil plantation as fertilizer and soil amendment (Baharuddin et al. 2009).

The co-composting of pressed-shredded EFB and palm oil mill effluent (POME) anaerobic sludge from 500 m3 closed anaerobic methane digested tank was investigated by Baharuddin et al. (2010). High nitrogen and nutrients content were observed in the POME anaerobic sludge. The sludge was subjected to the pressed-shredded EFB to accelerate the co-composting treatment. The co-composting treatment was completed in a short time within 40 days with a final C/N ratio of 12.4. The co-composting process exhibited a higher temperature (60–67 °C) in the thermophilic phase followed by curing phase after 4 weeks of treatment. Meanwhile, pH of the composting pile (8.1–8.6) was almost constant during the process and moisture content was reduced from 64.5 % (initial treatment) to 52.0 % (final matured compost). The use of pressed-shredded EFB as a main carbon source and bulking agent contributed to the optimum oxygen level in the composting piles (10–15 %). The biodegradation of composting materials is shown by the reduction of cellulose (34.0 %) and hemicellulose (27.0 %) content towards the end of treatment. In addition, considerable amount of nutrients and low level of heavy metals were detected in the final matured compost (Baharuddin et al. 2010). Baharuddin et al. (2011) reported that shredding-pressing treatment on EFB gave better results in removing the debris and silica bodies as compared to only shredding treatment. With the aspiration of reducing the composting yard area and energy consumption, the production of non-shredded EFB-POME compost in industrial scale windrow was reported by Zahrim and Asis (2010). The authors reported that the total composting time including preparation of the windrow was about 40–45 days and the windrow was turned every 10 days. Compost quality i.e. moisture content, pH, nitrogen and other nutrients, was evaluated during 6 months operations, and it was found that the nutrient in compost is acceptable for soil conditioner (Zahrim and Asis 2010). A study on EFB-POME- non-food cassava starch was carried out by Mohammad et al. (2015). The authors reported that the total period of composting was 35–40 days and found that the 2-mm particle size of EFB was most suitable to grow microbes, gave the highest protein of 85 g kg−1 and degraded fastest (lowest C/N ratio of 16). In addition, substrate ratio 1:3 (EFB and POME) and pH 5.0 were found to be favorable for mature compost (Mohammad et al. 2015).

Decanter cake (DC) is generated by palm oil milling plant from three-phase CPO purification. The production rate of DC is about 4–5 wt% of fresh fruit bunch processed and consuming a lot of space. Moreover when dried, the DC could becoming fire hazard and contribute toward increasing the amount of suspended particles in the vicinities of mills (Dewayanto et al. 2014). Composting EFB-decanter cake (DC)-palm oil mill effluent (POME) was reported by Yahya et al. (2010). The addition of decanter cake slurry has accelerated the composting process of the EFB. The C/N ratio after 51 days for the mature compost with the decanter cake slurry was 18.65 while that of the matured compost without the decanter cake slurry remained high at 28.96. The compost formed from the addition of decanter cake (DC) to EFB and POME had 46.4 % nitrogen, 17.9 % phosphorus, 17.7 % potassium and 23.1 % calcium more than that without decanter cake (Yahya et al. 2010). Nutongkaew et al. (2014a) investigated the composting of EFB-palm oil mill sludge (POMS)-DC. The compost appeared dark brown in color, crumbly, attained an ambient temperature and had the C/N ratio of 11:1 after 40 days fermentation, indicating the maturity of the compost. The authors also reported that the compost quality complied with the national compost standard set by the Ministry of Agriculture, Thailand (Nutongkaew et al. 2014a). In another study, Nutongkaew et al. (2014b) investigated a composting study on EFB-DC-palm oil mill biogas sludge (POMS)-palm oil fuel ash (POFA). The authors found that the compost piles turned dark brown and attained an ambient temperature after 40 days incubation. The pH values were stable in the range of 6.9–7.8 throughout the process whereas the moisture content tended to decrease till the end with the final value around 30 %. After 60 day’s incubation, the mixture ratio of POMS:PEFB:DC at 2:1:1 with the addition of biogas effluent gave the highest quality of the compost. Its nitrogen content was 31.75 % higher than the other treatments that may be a result of growth of ink cap mushroom (Coprinus sp.). This is the first report on the occurrence of this mushroom during composting. In addition, its nutrients (3.26 % N, 0.84 % P and 2.03 % K) were higher than the level of the Organic Fertilizer Standard (Nutongkaew et al. 2014b). However, in another study Kananam et al. (2011) reported that the use of decanter sludge did not have an effect on any biochemical conditions of either aerobic or anaerobic EFB composting. Moreover, the oil palm EFB compost with decanter sludge in an aerobic condition completed within 30 days whereas compost in the anaerobic condition failed to complete composting within 90 days. By adding red soil to the compost pile, it does not affected the composting time, but it reduced the odour generated from the pile (Kananam et al. 2011). In another study, Kabbashi et al. (2014) studied composting of EFB-POME-DC-sawdust. The maturity of the composting could be reflected by the best C/N ratio obtained was run 6 which are 16.51, pH, and germination index result of 154 %. This simple technology urge to enhance the productivity and sustainability of the Malaysian palm oil milling industry by improving the local isolated fungal strains and increasing composting utilization (Kabbashi et al. 2014).

Addition of recycled paper mill sludge (RPMS) to EFB for the production of compost was investigated by Rosazlin et al. (2011). Then, the EFB-RPMS compost mixtures were evaluated for physical, chemical, phytotoxicity and short term plant growth effects. These composts mixtures had no toxicity effects on plants, had 100 % seed germination, high in nutrient contents, low in C/N ratio and had fine particle size of <18 mm. The concentrations of heavy metals were also within the recommended level of the Council of European Communities (CEC) for compost (Rosazlin et al. 2011). Composting oil palm wastes (EFB-frond-trunk) with sewage sludge was carried out by Kala et al. (2009). Shredded oil palm wastes were mixed with sewage sludge in three different ratios (1:0, 3:1 and 4:1 ratio). Oil palm wastes with sewage sludge at 4:1 ratio was found to be the most optimum compost as potting media for ornamental plants because of its texture suitable for potting media, not stringent or stiff, had high nutrient contents (2.05 % N, 0.640 % P, 1.39 % K, 0.705 % Ca, 0.229 % Mg), pH 6.2 and low C/N ratio, 19 (Kala et al. 2009). The efficiency of EFB-frond- poultry litter composting was investigated by Vakili et al. (2012). From the study, the 1:3 ratio of EFB-frond and poultry litter had the lowest C/N ratio, TOC and the highest value of TKN, 18, 27 % and 1.48 %), respectively (Vakili et al. 2012).

An investigation of several organic materials in Malaysia as additives/amendments for composting EFB was carried out by Chai et al. (2013). The authors found that the organic waste materials with a C/N ratio of <30 can be applied as a nitrogen source in EFB co-composting. The outcome of this study suggested that the percentage of EFB ranged between 50 % and 60 %, which is considered as the ideal mixing ratio in EFB co-composting (Chai et al. 2013). Talib et al. (2014) the composting of EFB-rabbit manure using forced-aeration system and reported that aeration rate of 0.26 L min−1 dry matter−1 provided enough oxygen level (10 %) for the rest of composting period, showing 40.5 % of OM reduction that is better than other aeration rates (Talib et al. 2014). From the above review, selection and dosage of amendments are critical for the enhancement of EFB composting. In the next section, a new amendment for EFB composting i.e. banana skins is discussed.

Case Study: Addition of Banana Skin as Amendment

As one of the most consumed fruits in the world, banana is a very common fruit. The main banana residue is the fruit skin, which accounts for 30–40 % of the total fruit weight. It was reported that several tons of banana peels are produced daily in small-medium food processing industry, marketplaces, household garbage and restaurants (Mohammed and Chong 2013). In Malaysia, banana skins have not been fully utilized for production of useful by-products.

Co-composting of banana skins with empty fruit bunch could reduce waste management problems and conserve plant nutrients. Nasreen and Qazi (2012) investigated composting of banana skins in glass jars. The authors found that the seed germination indices for the compost is 63 %, indicated the conversion of the wastes into value added phytotoxin free fertilizer, which can escalate the agricultural output (Nasreen and Qazi 2012). In another study, Kalemelawa et al. (2012) evaluated the efficacy of aerobic and anaerobic composting of inoculated banana peels, and assess the agronomic value of banana peel-based compost. The study suggested that the final composts contained high K (>100 g kg−1) and TN (>2 %), indicating high potential as a source of K and N fertilizer (Kalemelawa et al. 2012). Recently, a co-composting banana stem-swine manure-eucalyptus bark was carried out by Deng et al. (2014). The authors reported that when C/N ratio of the composting material was 25–27, the heaps of compost were the highest in temperature, reaching up to 56 °C or higher and maintained the high temperature for 10–11 days, respectively, and they were also higher in content of nutrients, and the pot experiment also shows that composts had a certain growth-promoting effect on banana seedlings (Deng et al. 2014).

The aim of this study was to evaluate the effect of amount of banana skin on the heap temperature and final nutrient of EFB-POME compost. Results from this study could give valuable insight on the effect of banana skin as an amendment for enhancing composting performance.

Methodology

The palm oil mill effluent (POME) from an anaerobic digestion pond No. 1 and empty fruit bunch were collected from Merotai Palm Oil Mill, Tawau, Sabah. Banana skin was collected from various small food stall around Tawau, Sabah. One hundred kilograms of EFB was mixed with different percentage of banana skins (BS) as indicated in Table 1.2. The 28 m3/h POME (from day 0 to day 35) was sprayed carefully so that the banana peel does leached from the compost heap. The composting process was performed over the course of 45 days. Turning of the compost was carried out at day 5, 10, 15, 20, 25, 30 and 35. This study was carried out at Merotai Composting Plant, Tawau, Sabah. All experiments were carried out in duplicate.

Physicochemical Analysis

During the whole co-composting process, the temperatures at three points along the length of the middle of composting mixtures (5 cm, 10 cm deep and at the core of the compost heap) were measured almost daily. The three readings per composting mixture were averaged. Ambient temperature was also recorded. Sampling for nutrients analysis was made on ten randomly selected points on each compost heap. The chemical analysis was carried out by Sime Darby Research Sdn. Bhd. Method used for moisture content burn at 103 °C. The nitrogen content was analyzed using distillation method (MS 677: Part 1–VIII:1980). The organic matter (OM) content (volatile solids) was determined with a furnace at 550 °C (MS 417: Part 8:1997). The total P was estimated using spectrophotometric molybdovanadophosphate (MS417: Part 4:1994). The potassium and magnesium were determined using atomic absorption spectroscopy (AAS) (MS417: Part 5 and Part 6:1994).

Result and Discussion

Temperature Profile

The temperature monitoring is a very simple way to follow the progress of composting (Yaser et al. 2007). In this study, the oxygen content for all heaps i.e. H0, H5 and H10, is maintained around 19–20 %, which is necessary for maximum biodegradation (Baharuddin et al. 2009). The trends of the temperatures in the H0, H5 and H10 were not similar indicating different effect of percentage of BS addition. Stentiford (1996) suggested that temperatures higher than 55 °C maximized sanitation, those between 45 and 55 °C maximized the biodegradation rates, and between 35 and 40 °C maximized microbial diversity in the composting process. Throughout the experimental period, the ambient temperature ranged from 24 to 29 °C. During the composting period, at day 3, the H10 achieved the maximum temperature of 47.5 °C while the H0 and H5 only achieved temperature of 36.0 and 40.5 °C (Fig. 1.1). The sharp increase in temperature to greater than 45 °C for H10 in the first 3 days of composting reflects the rapid initiation of the composting process (Placha et al. 2013; Stentiford 1996). Both H0 and H5 did not achieve temperature for maximum biodegradation rates. The maximum temperature for the H0 is 40.5 °C and was achieved at day 8 while the H5’s maximum temperature is 42 °C (day 35). However, it can be seen also that the large drop in temperature also experienced by the H10 might be due to the limited ability of BS to adsorb heat.

From Fig. 1.1, the temperature in H10 can be raised again by turning the heap. After biodegradation process, the structure of compost e.g. porosity, may change. The turning operation improves the aeration of the compost materials by increasing its porosity. Therefore, the availability of more air within the composting materials favors the renewal of microbial activities which indirectly increase the decomposition process of the composting materials (Yahya et al. 2010). In this study, the effect of turning was very significant especially for H10. It can be seen that at day 5, the temperature drop to 33 °C, but after turning process, the temperature is rise again to 41.5 °C. Similar trend also found after each turning process until after day 35 (i.e. last turning was carried out), the temperature for the H10 is around 34 °C due to lack of carbon that has been fully utilized by the microorganisms and consequently, minimize the metabolism and the heat production (Zahrim and Asis 2010).

Moisture Content, pH and Nutrients

The final physicochemical compositions of the final compost are shown in Table 1.3. From the table, it could be seen that the value for moisture content, pH, phosphorus, and potassium of the compost material with banana skin slurry are greater than un-amended compost (control). In comparison with others studies (Table 1.3), the potassium in this study is greater than others, indicating positive improvement by adding banana skin as amendments.

Increasing of the final moisture content due to addition of banana skin might be due to the ability of banana skin to adsorb water. Due to the fact that the protein content in banana is around 8–11 % (Happi Emaga et al. 2007) while only 2–3 % for EFB (Abdullah et al. 2009), as expected, the final pH (protein degradation) for both H5 and H10 were higher than the control.

The addition of banana skin contributes little effect on the final N content based on R2 value in Eq. (1.1). The best equation to describe the correlation for mass of banana skin (x) and nitrogen content is as follows:

From Table 1.3, it is suggested the addition of sludge from anaerobic digestion system to improve the N content (Yaser et al. 2007; Baharuddin et al. 2010; Nutongkaew et al. 2014b). While the best equation to describe the correlation for mass of banana skin (x) and K2O is given as:

The banana skin increases the potassium content from 2.7 % to around 3.0 %, however the addition of more than 5 % BS did not increases the K content might be due to the solubilisation of K in compost leachate as shown in Eq. (1.2). However, the addition of banana skin highly affected the final P2O5 and MgO (data not shown) as shown in Eqs. (1.3) and (1.4).

Conclusion

-

(1)

LCA study by various investigators confirmed that composting is more really environmentally friendly based on the greenhouse gas reduction measurement.

-

(2)

The EFB composting with suitable amendments give acceptable quality of compost and accelerate the process to less than 60 days.

-

(3)

In the case study, the addition of banana skin could enhance rapid EFB decomposition and increase nutrients such as P and K.

References

Abdullah, S. S. S., Hassan, M. A., Shirai, Y., Funaoka, M., Shinano, T., & Idris, A. (2009). Effect of solvent pretreatment on lignophenol production from oil palm empty fruit bunch fibres. Journal of Oil Palm Research, 21, 700–709.

Baharuddin, A. S., Hock, L. S., Yusof, M. Z. M., Rahman, N. A. A., Shah, U. K. M., Hassan, M. A., et al. (2010). Effects of palm oil mill effluent (POME) anaerobic sludge from 500 m3 of closed anaerobic methane digested tank on pressed-shredded empty fruit bunch (EFB) composting process. African Journal of Biotechnology, 9, 2427–2436.

Baharuddin, A. S., Rahman, N. A. A., Shah, U. K. M., Hassan, M. A., Wakisaka, M., & Shirai, Y. (2011). Evaluation of pressed shredded empty fruit bunch (EFB)-palm oil mill effluent (POME) anaerobic sludge based compost using Fourier transform infrared (FTIR) and nuclear magnetic resonance (NMR) analysis. African Journal of Biotechnology, 10, 8082–8089.

Baharuddin, A. S., Wakisaka, M., Shirai, Y., Abd-Aziz, S., Abdul-Rahman, N. A., & Hassan, M. A. (2009). Co-composting of empty fruit bunches and partially treated palm oil mill effluents in pilot scale. International Journal of Agricultural Research, 4, 69–78.

Chai, E. W., H'ng, P. S., Peng, S. H., Wan-Azha, W. M., Chin, K. L., Chow, M. J., et al. (2013). Compost feedstock characteristics and ratio modelling for organic waste materials co-composting in Malaysia. Environmental Technology, 34, 2859–2866.

Chiew, Y. L., & Shimada, S. (2013). Current state and environmental impact assessment for utilizing oil palm empty fruit bunches for fuel, fiber and fertilizer—A case study of Malaysia. Biomass and Bioenergy, 51, 109–124.

Deng, X. K., Dong, C. M., Xin, K., Zhao, N., Yang, J. M., & Ruan, Y. Z. (2014). Comparative study on effects of composting of banana stem, eucalyptus bark and swine manure relative to ratio of ingredients. Journal of Ecology and Rural Environment, 30, 658–663.

Dewayanto, N., Isha, R., & Nordin, M. R. (2014). Use of palm oil decanter cake as a new substrate for the production of bio-oil by vacuum pyrolysis. Energy Conversion and Management, 86, 226–232.

Happi Emaga, T., Andrianaivo, R. H., Wathelet, B., Tchango, J. T., & Paquot, M. (2007). Effects of the stage of maturation and varieties on the chemical composition of banana and plantain peels. Food Chemistry, 103, 590–600.

Kabbashi, N. A., Alam, Z., & Ainuddin, M. (2007). Bio-composting process development by SSF for utilization agro-industrial wastes. In Third Kuala Lumpur international conference on biomedical engineering, 2006 (Vol. 15, pp. 464–468).

Kabbashi, N. A., Noruldin, N., & Mirghani, M. E. (2014). Studies of locally effective microorganisms (EM) to enhance the degradation of empty fruit bunches, pome and cake during composting process. Journal of Pure and Applied Microbiology, 8, 815–819.

Kala, D. R., Rosenani, A. B., Fauziah, C. I., & Thohirah, L. A. (2009). Composting oil palm wastes and sewage sludge for use in potting media of ornamental plants. Malaysian Journal of Soil Science, 13, 77–91.

Kalemelawa, F., Nishihara, E., Endo, T., Ahmad, Z., Yeasmin, R., Tenywa, M. M., et al. (2012). An evaluation of aerobic and anaerobic composting of banana peels treated with different inoculums for soil nutrient replenishment. Bioresource Technology, 126, 375–382.

Kananam, W., Suksaroj, T. T., & Suksaroj, C. (2011). Biochemical changes during oil palm (Elaeis guineensis) empty fruit bunches composting with decanter sludge and chicken manure. ScienceAsia, 37, 17–23.

Mohammad, N., Alam, M. Z., & Kabashi, N. A. (2015). Optimization of effective composting process of oil palm industrial waste by lignocellulolytic fungi. Journal of Material Cycles and Waste Management, 17, 91–98.

Mohammed, R. R., & Chong, M. F. (2013). Treatment and decolorization of biologically treated Palm Oil Mill Effluent (POME) using banana peel as novel biosorbent. Journal of Environmental Management, 132, 237–249.

Nasreen, Z., & Qazi, J. I. (2012). Lab scale composting of fruits and vegetable waste at elevated temperature and forced aeration. Pakistan Journal of Zoology, 44, 1285–1290.

Norhasmillah, A. H., Puah, C. W., Ibrahim, N. A., Baharuddin, A. S., & Choo, Y. M. (2013). Life cycle inventory of the commercial production of compost from oil palm biomass: A case study. Environment, Development and Sustainability, 15, 1663–1670.

Nutongkaew, T., Duangsuwan, W., Prasertsan, S., & Prasertsan, P. (2014a). Effect of inoculum size on production of compost and enzymes from palm oil mill biogas sludge mixed with shredded palm empty fruit bunches and decanter cake. Songklanakarin Journal of Science and Technology, 36, 275–281.

Nutongkaew, T., Duangsuwan, W., Prasertsan, S., & Prasertsan, P. (2014b). Physicochemical and biochemical changes during composting of different mixing ratios of biogas sludge with palm oil mill wastes and biogas effluent. Journal of Material Cycles and Waste Management, 16, 131–140.

Phua, C. K. H., Abdul Wahid, A. N., & Abdul Rahim, K. (2012). Development of multifunctional biofertilizer formulation from indigenous microorganisms and evaluation of their N2-fixing capabilities on Chinese cabbage using 15N tracer technique. Pertanika Journal of Tropical Agricultural Science, 35, 673–679.

Placha, D., Raclavska, H., Kucerova, M., & Kucharova, J. (2013). Volatile fatty acid evolution in biomass mixture composts prepared in open and closed bioreactors. Waste Management, 33, 1104–1112.

Rosazlin, A., Fauziah, C. I., Wan Rasidah, K., Rosenani, A. B., & Kala, D. R. (2011). Assessment on the quality of Recycled Paper Mill Sludge mixed with oil palm empty fruit bunch compost. Malaysian Journal of Soil Science, 15, 49–62.

Saer, A., Lansing, S., Davitt, N. H., & Graves, R. E. (2013). Life cycle assessment of a food waste composting system: environmental impact hotspots. Journal of Cleaner Production, 52, 234–244.

Sajab, M. S., Chia, C. H., Zakaria, S., & Khiew, P. S. (2013). Cationic and anionic modifications of oil palm empty fruit bunch fibers for the removal of dyes from aqueous solutions. Bioresource Technology, 128, 571–577.

Saletes, S., Siregar, F. A., Caliman, J. P., & Liwang, T. (2004). Ligno-cellulose composting: Case study on monitoring oil palm residuals. Compost Science and Utilization, 12, 372–382.

Schuchardt, F., Wulfert, K., & Darnoko, D. (2005). New process for combined treatment of waste (EFB) and waste water (POME) from palm oil mills—Technical, economical and ecological aspects. Landbauforschung Volkenrode, 55, 47–60.

Stentiford, E. T. (1996). Composting control: Principles and practice. London, UK: Chapman & Hall.

Stichnothe, H., & Schuchardt, F. (2010). Comparison of different treatment options for palm oil production waste on a life cycle basis. International Journal of Life Cycle Assessment, 15, 907–915.

Talib, A. T., Mokhtar, M. N., Baharuddin, A. S., & Sulaiman, A. (2014). Effects of aeration rate on degradation process of oil palm empty fruit bunch with kinetic-dynamic modeling. Bioresource Technology, 169, 428–438.

Thambirajah, J. J., & Kuthubutheen, A. J. (1989). Composting of palm press fiber. Biological Wastes, 27, 257–269.

Thambirajah, J. J., Zulkali, M. D., & Hashim, M. A. (1995). Microbiological and biochemical changes during the composting of oil palm empty fruit bunches—Effect of nitrogen supplementation on the substrate. Bioresource Technology, 52, 133–144.

Tiquia, S. M., Richard, T. L., & Honeyman, M. S. (2002). Carbon, nutrient, and mass loss during composting. Nutrient Cycling in Agroecosystems, 62, 15–24.

Vakili, M., Haque, A. A. M., Hosseini, S. M., & Salamatinia, B. (2012). Evaluation of maturation and stability some indexes of mixed palm oil biowaste composting process and poultry litter. World Applied Sciences Journal, 19, 234–240.

Yahya, A., Sye, C. P., Ishola, T. A., & Suryanto, H. (2010). Effect of adding palm oil mill decanter cake slurry with regular turning operation on the composting process and quality of compost from oil palm empty fruit bunches. Bioresource Technology, 101, 8736–8741.

Yaser, A. Z., Abd Rahman, R., & Kalil, M. S. (2007). Co-composting of palm oil mill sludge-sawdust. Pakistan Journal of Biological Science, 10, 4473–4478.

Yoshizaki, T., Shirai, Y., Hassan, M. A., Baharuddin, A. S., Raja Abdullah, N. M., Sulaiman, A., et al. (2013). Improved economic viability of integrated biogas energy and compost production for sustainable palm oil mill management. Journal of Cleaner Production, 44, 1–7.

Zahrim, A. Y., & Asis, T. (2010). Production of non shredded empty fruit bunch semi-compost. The Journal of the Institution of Engineers, Malaysia, 71, 11–17.

Acknowledgement

A.Y. Zahrim would like to thank to Universiti Malaysia Sabah and Prestige Central Management Sdn. Bhd. for giving permission in conducting 1 year industrial internship.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Zahrim, A.Y., Asis, T., Hashim, M.A., Al-Mizi, T.M.T.M.A., Ravindra, P. (2015). A Review on the Empty Fruit Bunch Composting: Life Cycle Analysis and the Effect of Amendment(s). In: Ravindra, P. (eds) Advances in Bioprocess Technology. Springer, Cham. https://doi.org/10.1007/978-3-319-17915-5_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-17915-5_1

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-17914-8

Online ISBN: 978-3-319-17915-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)