Abstract

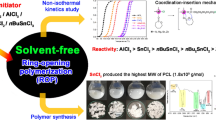

The structure–reactivity relationship of titanium(IV) alkoxides (Ti(OR)4; R = n-propoxide, n-butoxide, tert-butoxide and 2-ethylhexoxide) in the ring-opening polymerization of ε-caprolactone (ε-CL) has been successfully investigated by differential scanning calorimetry (DSC) technique. Based on isothermal method, the kinetic results demonstrated that the polymerization rate decreased with increasing chain length and bulkiness of alkoxy group of Ti(OR)4. The determined activation energy (Ea) from autocatalytic model (f(α) = αm(1 − α)n) for titanium(IV) n-propoxide, n-butoxide, tert-butoxide and 2-ethylhexoxide were found to be 77.7, 97.2, 105.2 and 97.9 kJ/mol. From thermodynamics analysis of transition state (TS) formulation, the obtained activation enthalpy (∆H≠) values revealed that the titanium(IV) n-propoxide required the lowest energy to form the TS with ε-CL. From the obtained activation entropy (∆S≠) values, it was found that the stability of TS of ε-CL with titanium(IV) n-propoxide was higher than n-butoxide, 2-ethylhexoxide and tert-butoxide. From the overall results, it is clearly indicated that the steric hindrance of Ti(OR)4 initiators plays an important role on the kinetics and thermodynamics of polymerization process. The reactivity of Ti(OR)4 initiators was determined in the order of: titanium(IV) n-propoxide > n-butoxide ≈ 2-ethylhexoxide > tert-butoxide. The polymerization mechanism of all Ti(OR)4 initiators with ε-CL was proposed through the coordination-insertion mechanism.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

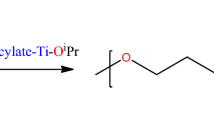

Recently, the biodegradable polymers such as poly(ε-caprolactone) (PCL), poly(l-lactide) (PLL), poly(d-lactide) (PDL) and polyglycolide (PGA) have become the most attractive biodegradable polymeric materials which are studied and developed by many researchers [1,2,3]. These polymers can be utilized in versatile applications in which their chemical, physical and mechanical properties can be controlled by synthesis conditions [4, 5]. The ring-opening polymerization (ROP) through the coordination-insertion mechanism is an effective synthetic route that can provide a good molecular architecture, microstructure and molecular weight of biodegradable polymers [4, 6]. A large number of metal-containing initiator has been developed for utilizing as coordination initiator which can effectively control the molecular weight and molecular architecture of polymer products [7,8,9,10,11]. Metal alkoxides (MOR) and carboxylates (MCOOR) with active metal centers such as Al [7], Sm [8], Zr [9] and Zn [10] and etc. can be used as coordination initiator for the ROP of cyclic esters monomers, especially tin(II) octoate (Sn(Oct)2) which is the most popular initiating system [12]. Nowadays, the modern trend has concerned about the toxicity of Sn residual in the polymers due to its toxicity to human body and environment. Yamada et al. [13] reported that Sn(Oct)2 is cytotoxic to astrocytes from in vitro study. They found that Sn(Oct)2 reduced the mitochondrial activity about 16%. Furthermore, the presence of Sn in the biodegradable foil and wrapping material based on poly(lactic acid) (PLA) causes the increasing of Sn residual in the environment that toxic to aquatic organism [14]. This impacts our attention for developing the Sn-free initiator. From literatures review, we found that titanium(IV) alkoxide (Ti(OR)4) is one of interesting candidates that can be used as initiator for the ROP of cyclic esters. This type of initiator shows some advantages such as: (i) high polymerization rate, (ii) high solubility in monomers and organic solvents and (iii) it can be used to create the advance structure of polymer (star branch polymer). Li et al. [15] reported the preparation of well define titanium(IV) alkoxides based on benzotriazol phenoxide ligands as initiator for the ROP of ε-caprolactone (ε-CL). These designed Ti-initiators gave the low molecular weight of PCL. The polymerization kinetics was investigated by the proton-nuclear magnetic resonance spectroscopy (1H-NMR) technique. The results showed the increasing polymerization rate with initiator concentration. Kim et al. [16] studied the ROP of l-lactide (LL) with heterogeneous silica supported titanium alkoxide catalysts. They found that these combined initiating systems produced the higher molecular weight polymer than titanium alkoxides. Furthermore, the increasing of reaction temperature also increases the polymerization rate. Li et al. [17] reported the new titanium alkoxide bifunctional initiator for the ROP of ε-CL and radical polymerization of n-butyl acrylate. The synthesized Ti(OCCH2CCl3)4 could be used as initiator for synthesizing the copolymer derived from ε-CL and n-butyl acrylate. The kinetic parameters were determined from first order reaction model. The results demonstrated that the polymerization proceeded through the coordination-insertion mechanism and all four alkoxide groups in \({\text{Ti[OCH}}_{{\text{2}}} {\text{CCl}}_{{\text{3}}} {\text{]}}_{{\text{4}}}\) share a similar activity on initiating the polymerization of ε-CL. Li et al. [18] investigated the kinetics of the ROP of ε-CL with the synthesized Ti(O(CH2)4OCH=CH2)4 initiator using differential scanning calorimetry (DSC) technique. They found that the polymerization rate depended on initiator concentration and temperature. The polymerization activation energy (Ea) obtained from both non-isothermal and isothermal methods are in the same trend. Our previous work, we have compared the polymerization rate of Ti(OR)4 (R = n-propoxide, n-butoxide, tert-butoxide and 2-ethylhexoxide) initiators in the ROP of ε-CL using non-isothermal DSC technique [19]. Under the dynamic condition, the Ea values of titanium(IV) n-propoxide is lower than n-butoxide, 2-ethylhexoxide and tert-butoxide. Therefore, it is obvious that the kinetics information is necessary to shed more light on the catalytic behavior of initiator in the ROP of cyclic esters. The ROP of cyclic esters initiated by metal alkoxides initiator are generally occurred through the coordination-insertion mechanism [4, 6, 20, 21]. From mechanistic consideration, the ROP of ε-CL initiated by all Ti(OR)4 initiators was also proceeded through this well-known mechanism. The example of the coordination-insertion ROP of ε-CL with titanium(IV) n-propoxide is illustrated in Fig. 1. The polymerization occurred by the coordination of ε-CL with the reactive Ti–O bond resulting in the more reactive carbonyl carbon of monomer. Then, the alkoxy group (OR) of initiator attacked this carbonyl carbon of ε-CL yielding acyl-oxygen bond cleavage. Then, the opened cyclic monomer inserted into this Ti–O bond forming the propagating species that still contain the reactive Ti–O bond. The propagation step was also occurred through this mechanism and the PCL was obtained after the propagation step was completed. However, the thermodynamics can also be considered as the supportive information for comparing the reactivity of initiator in the ROP of cyclic esters. We found that the thermodynamics of titanium(IV) alkoxides initiated the ROP of cyclic esters has not been mentioned and discussed before.

adapted from literature [19]

A plausible reaction mechanism of the coordination-insertion ROP of ε-CL initiated by titanium(IV) n-propoxide

Therefore, the objective of this work is to expand more understanding on the effect of alkoxy group of titanium(IV) alkoxides (Ti(OR)4; R = n-propoxide, n-butoxide, tert-butoxide and 2-ethylhexoxide) on the ROP of ε-CL. The kinetics and thermodynamics of transition state formulation are investigated by isothermal DSC technique. The catalytic performance of all Ti(OR)4 initiators in the ROP of ε-CL will be compared and discussed using the obtained apparent rate constant (kapp), Ea, activation enthalpy (∆H≠) and activation entropy (∆S≠).

Experimental

Material preparations

Commercial ε-caprolactone (ε-CL) (Acros Organics, 99.0%) was purified by vacuum distillation before used. Titanium(IV) alkoxides (Ti(OR)4) such as titanium(IV) n-propoxide (Fluka, 99%), titanium(IV) n-butoxide (Fluka, 99%), titanium(IV) tert-butoxide (Sigma-Aldrich, 99%) and titanium(IV) 2-ethylhexoxide (Fluka, 99%) were used as received. The chemical structures of all Ti(OR)4 initiators are summarized in Table 1.

Isothermal DSC polymerization

Kinetics and thermodynamics of the ROP of ε-CL initiated by all Ti(OR)4 initiators were investigated on a Perkin-Elmer DSC-7. The polymerization mixtures were prepared by mixing of ε-CL (2 g) with 1.0 mol% of Ti(OR)4 initiators in a dry vials and stirred vigorously for 10 min. For each DSC run, the sample (7–8 mg) was weighed into aluminum pan and sealed. The sample was placed at standby temperature of 20 °C for 3 min and then heated up to 150–180 °C at a heating rate of 100 °C/min. The sample was held at the designed temperatures for 120 min under a flowing nitrogen atmosphere (20 ml/min) without sample mass loss. The data was processed under the Pyris DSC-7 program.

Results and discussion

Generally, the ROP of cyclic ester is an exothermic process because the monomer converts to polymer by the covalent bond formation. This process can be observed by the occurrence of polymerization exotherms in DSC measurement under non-isothermal and isothermal mode [18, 19, 22]. In this work, the progress of ROP of ε-CL with all Ti(OR)4 initiators is investigated by isothermal DSC technique. In this technique, the polymerization occurs under a constant temperature as shown in Fig. 2.

The results show the dependency of polymerization exotherms with temperature. They occurred and completed in a short period of time as temperature increases [18]. The obtained polymerization exotherm is board when the temperature decreases indicating the slower polymerization is obtained. When compare the polymerization exotherms at an identical temperature as illustrated in Fig. 3, the polymerization exotherm for the ROP of ε-CL obtained from titanium(IV) n-propoxide occurs at lower temperature than titanium(IV) n-butoxide, 2-ethylhexoxide and tert-butoxide.

From the results obtained from Figs. 2 and 3, the heat of polymerization can be obtained by integrating the DSC exotherms. In isothermal DSC experiment, the heat liberated from polymerization reaction can be used to determine the progress of reaction. The conversion of monomer (α) can be determined from the heat released at any time (∆Ht) divided by heat of polymerization (∆H) as described in literatures [18, 23]. Generally, the obtained polymerization exotherm from DSC is directly related to the rate of reaction (dα/dt) [24]. After obtaining dα/dt, α can be determined. The extent of polymerization can be determined from the ratio of ∆Ht and ∆H for a given temperature as shown in the following equations [23].

The plots of monomer conversion against time for the ROP of ε-CL initiated by Ti(OR)4 initiators are displayed in Fig. 4. The results from Fig. 4a show that the polymerization of ε-CL initiated by titanium(IV) n-propoxide completed faster at high temperature. From Fig. 4b, it is found that the conversion for the ROP of ε-CL at 165 °C with titanium(IV) n-propoxide approaches 1 faster than n-butoxide, 2-ethylhexoxide and tert-propoxide, respectively.

To support the results from Fig. 4, the rate of polymerization (dα/dt) is used to compare the reactivity of Ti(OR)4 initiators in the ROP of ε-CL. The plots of dα/dt against time for the ROP of ε-CL initiated by Ti(OR)4 initiators at a temperature of 165 °C are illustrated in Fig. 5. The results clearly demonstrate that the performance of Ti(OR)4 initiators in the ROP of ε-CL is found to be in the following order: titanium(IV) n-propoxide > n-butoxide ≈ 2-ethylhexoxide > tert-butoxide. From the obtained results, it is obvious that the chemical structure affects the polymerizability and reactivity of Ti(OR)4 initiators in the ROP of ε-CL. The high steric hindrance Ti(OR)4 initiator, the low polymerization rate of ε-CL is obtained. To clearify the influence of Ti(OR)4 structure on the reactivity, the kinetics and thermodynamics information are utilized.

For kinetics study by isothermal DSC, the progress of polymerization can be investigated by measuring the liberated heat at different time under a constant temperature. To derive the rate equation for the polymerization of ε-CL with Ti(OR)4, the M, I and P are represented as the monomer, initiator and polymer. The polymerization reaction of ε-CL with Ti(OR)4 is displayed in the following equation. Generally, the ROP of ε-CL is the first order with respect to monomer concentration. Therefore, the rate equation can be written as Eq. 3.

Here rp, kp, [M], [I] and n are the polymerization rate, the polymerization rate constant, the monomer concentration, the initiator concentration and the reaction order with respect to initiator concentration. By combining the constant of kp with [I]n, the new rate expression is written as Eq. 4:

Here kapp is the apparent rate constant of polymerization. In DSC kinetics study, the [M] can be replaced by the function of monomer conversion (f(α)) as shown in Eq. 5.

This f(α) depends on the nature of polymerization reaction. The plots of monomer conversion against time (Fig. 4) for the ROP of ε-CL with all Ti(OR)4 initiators show a sigmoidal curve. These indicate that the polymerization occurred with autocatalytic behavior as described in literatures [25, 26]. Therefore, the f(α) is replaced by the autocatalytic model (f(α) = αm(1 − α)n) similar to our previous work [25]. The rp can also be replaced by dα/dt therefore the new rate expression is obtained as shown in Eq. 6.

By taking the natural logarithm to the both side of Eq. 6 yielding Eq. 7. The value of n is obtained from the slope of the plots of ln(dα/dt) against ln(1 − α). By rearranging Eq. 6, the value of m and kapp can be determined from the slope and intercept of the ln((dα/dt)/(1 − α)n) − lnα plots (based on Eq. 8). The example of the plots of ln(dα/dt) against lnα and ln(1 − α) for the ROP of ε-CL initiated by titanium(IV) n-propoxide initiator are illustrated in Fig. 6 and the determined kinetic parameters are summarized in Table 2.

From the obtained results, it is found that the overall reaction order of monomer (m + n) close to 1 which is obvious for the ROP of cyclic esters as described. Furthermore, the kapp values are found to increase with increasing temperature due to the higher driving force in system at high temperature. At identical temperature, the kapp value obtained from the ROP of ε-CL with titanium(IV) n-propoxide is higher than those of Ti(OR)4 initiators. This suggests that the titanium(IV) n-propoxide is the most reactive initiator in this work. From the obtained kapp values at different temperatures, the polymerization activation energy (Ea) can be determined by replacing kp with Arrhenius equation as shown in Eq. 9 [27]. Taking the natural logarithm into Eq. 9, the value of Ea can be determined from the slope of the plot of lnkapp against 1/T based on Eq. 10. The plot of lnkapp against 1000/T for the ROP of ε-CL initiated by titanium(IV) n-propoxide is illustrated in Fig. 7.

From the results, it is important that the Ea value for the ROP of ε-CL initiated by titanium(IV) n-propoxide is lower than n-butoxide, 2-ethylhexoxide and tert-butoxide. This reveals that the high steric hindrance of Ti(OR)4 yields the lower polymerization rate of ε-CL. The results from this work close to the ROP of ε-CL with tributyltin(IV) alkoxides (Bu3SnOR) initiator reported in our previous work [22]. The steric hindrance around reactive Ti–O center reduces the coordination ability with monomer resulting in the decreasing of polymerization rate. From kinetics consideration, the reactivity of Ti(OR)4 alkoxide initiators is determined in the following order: tintanium(IV) n-propoxide > n-butoxide ≈ 2-ethylhexoxide > tert-butoxide. The obtained Ea values for all Ti(OR)4 in the ROP of ε-CL are in the similar trend to the non-isothermal DSC kinetics analysis reported by Meelua et al. [19].

To support the results obtained from kinetic information, the thermodynamics of transition state (TS) formulation between ε-CL and Ti(OR)4 initiators is investigated to describe the stability of transition state. In this work, the obtained values of kapp are utilized to calculate the thermodynamic parameters of activation. In the most of kinetics works, the rate constant of reaction is frequently replaced by Arrhenius equation. In our previous study, we have replaced the rate constant by the Eyring equation [28] resulting the equation that can be used to determine the activation parameters from isothermal DSC polymerization as shown in Eq. 11.

Here kB is the Boltzmann constant, h is the Plank’s constant, \(\Delta H^{ \ne }\) is the activation enthalpy, \(\Delta S^{ \ne }\) is the activation entropy and [I]0 is the initial concentration of initiator. From the Eq. 11, the values of \(\Delta H^{ \ne }\) and \(\Delta S^{ \ne }\) can be calculated from the slope and intercept of the linear plot of − ln(kapp/T) versus 1000/T. The plots of ln(kapp/T) against 1000/T for the ROP of ε-CL initiated by Ti(OR)4 initiators are illustrated in Fig. 8 and the obtained thermodynamic parameters are summarized in Table 3.

The ∆H≠ value shown in Eq. 11 is the heat required to form the TS between ε-CL and Ti(OR)4. The higher ∆H≠ value indicates that the system (monomer + initiator) needs higher energy to form the TS. From the obtained results, it is found that the ∆H≠ value for the ROP of ε-CL initiated by titanium(IV) n-propoxide is lower than n-butoxide, 2-ethylhexoxide and tert-butoxide. This clearly demonstrates that the chemical structure of Ti(OR)4 is not only affect the kinetics but also the thermodynamics of transition state formulation. The TS of ε-CL with titanium(IV) n-propoxide has lower energy than n-butoxide, 2-ethylhexoxide and tert-butoxide. Therefore, the conversion of ε-CL to PCL is rapidly occurred when titanium(IV) n-propoxide is utilized as intiator. From the obtained ∆S≠ values, it is found that the values of ∆S≠ for the ROP of ε-CL with all Ti(OR)4 are negative indicating the high order of the TS between ε-CL and Ti(OR)4 [29]. From the obtained results, the ∆S≠ of the TS of ε-CL with titanium(IV) n-propoxide is lower (more negative) than n-butoxide, 2-ethylhexoxide and tert-butoxide. This reveals that the highest order TS is obtained when the titanium(IV) n-propoxide is used. This may be caused by the lower steric hindrance of titanium(IV) n-propoxide than orther Ti(OR)4 initiators. In the case of titanium(IV) tert-butoxide, the lowest order of TS is obtained due to its highest steric hindrance around Ti–O active center that dramatically reduces the coordination ablility with ε-CL. From these, the long or bulky alkoxy group (–OR) of Ti(OR)4 initiator can reduce the electron density around Ti–O active center resulting in the lower reactivity than short or small OR group. When comparing the reactivity of titanium(IV) n-propoxide and titanium(IV) n-butoxide, the lower reactivity of titanium(IV) n-butoxide may be attributed to the more prevention in the coordination of ε-CL with Ti–O active center due to the flexible bond in n-butoxy group.

The obtained kinetics and thermodynamics results can be supported by the results obtained from computational technique reported by Silawanich et al. [30]. They reported the comparison for the reactivity of Ti(OR)4 initiators in the ROP of ε-CL by the density functional theory (DFT). Basing on B3LYP/LANL2DZ calculation, they found that the potential energy barrier for the TS1, the rate determining step, of ε-CL and Ti(OR)4 was in the following order: titanium(IV) n-propoxide (14.22 kcal/mol) < n-butoxide (15.58 kcal/mol) < 2-ethylhexoxide (22.82 kcal/mol) < tert-butoxide (28.47 kcal/mol). This reveals that the high steric hindrance of Ti(OR)4 increases the potential energy barrier which is caused by the blocking of Ti–O reactive center with ε-CL. Furthermore, the lowest potential energy barrier of titanium(IV) n-propoxide results in the highest stability of reaction intermediate (the lowest energy of intermediate (INT)) which corresponds to the ∆S≠ values obtained in this work. From the thermodynamics analysis, it is found that the steric hindrance of Ti(OR)4 initiators destabilizes the TS of ε-CL and Ti(OR)4 resulting the lower rate of polymerization.

Conclusions

The effect of steric hindrance of Ti(OR)4 (R = n-propoxide, n-butoxide, tert-butoxide and 2-ethylhexoxide) on the ROP of ε-CL was completely investigate by isothermal DSC technique. Kinetics and thermodynamics information were completely utilized to evaluate the relationship of Ti(OR)4 chemical structure and reactivity in the ROP of ε-CL. From kinetics analysis, the kapp and Ea values obtained from autocatalytic model revealed that the reactivity of titanium(IV) n-propoxide was higher than n-butoxide, 2-ethylhexoxide and tert-butoxide. From thermodynamics analysis, the steric hindrance around reactive Ti–O bond of Ti(OR)4 initiators destabilizes the transition state. For the higher steric hindrance of Ti(OR)4, the higher value of ∆H≠ of the transition state formulation was obtained. Moreover, the values of ∆S≠ demonstrated that the order of transition state decreased with increasing bulkiness of alkoxy group of Ti(OR)4 initiators. The overall results demonstrated that the steric hindrance of Ti(OR)4 affects both of kinetics and thermodynamics of the ROP of ε-CL. The results obtained from this work will be useful for describing the reactivity of others initiating systems in the ROP of cyclic esters.

References

Cabaret OD, Vaca BM, Bourissou D (2004) Controlled ring-opening polymerization of lactide and glycolide. Chem Rev 101:6147–6176

Hamad K, Kaseem M, Yang HW, Deri F, Ko YG (2015) Properties and medical applications of polylactic acid: a review. Express Polym Lett 5:435–455

Girdthep S, Worajittiphon P, Leejarkpai T, Molloy R, Punyodom W (2016) Effect of silver-loaded kaolinite on real ageing, hydrolytic degradation, and biodegradation of composite blown films based on poly(lactic acid) and poly(butylene adipate-co-terephthalate). Eur Polym J 82:244–259

Stridsberg KM, Ryner M, Albertsson AC (2002) Controlled ring-opening polymerization: polymers with designed macromolecular architecture. Adv Polym Sci 157:41–65

Pretula J, Slomkowski S, Penczek S (2016) Polylactides—methods of synthesis and characterization. Adv Drug Deliv Rev 107:3–16

Albertsson AC, Varma IK (2003) Recent developments in ring opening polymerization of lactones for biomedical applications. Biomacromolecules 4:1466–1486

Hao P, Yang Z, Li W, Ma X, Roesky HW, Yang Y, Li J (2015) Aluminum complexes containing the C-O–Al–O–C framework as efficient initiators for ring-opening polymerization of ε-caprolactone. Organometallics 34:105–108

Contreras JM, Medina D, Carrasquero DL, Contreras RR (2013) Ring-opening polymerization of ε-caprolactone initiated by samarium acetate. J Polym Res 20:244

Chmura AJ, Cousins DM, Davidson MG, Jones MD, Lunn MD, Mahon MF (2008) Robust chiral zirconium alkoxide initiators for the room-temperature stereoselective ring-opening polymerisation of rac-lactide. Dalton Trans 11:1437–1443

Jedrzkiewicz D, Czelusniak I, Wierzejewska M, Szafert S, Ejfler J (2015) Well-controlled, zinc-catalyzed synthesis of low molecular weight oligolactides by ring opening reaction. J Mol Catal A 396:155–163

Routaray A, Nath N, Mantri S, Maharana T, Sutar AK (2015) Synthesis and structural studies of copper(II) complex supported by –ONNO– tetradentate ligand: efficient catalyst for the ring-opening polymerization of lactide. Chin J Catal 36:764–770

Karidi K, Mantourlias T, Seretis A, Pladis P, Kiparissides C (2015) Synthesis of high molecular weight linear and branched polylactides: a comprehensive kinetic investigation. Eur Polym J 72:114–128

Yamada T, Jung D, Sawada R, Tsuchiya T (2008) Intracerebral microinjection of stannous 2-ethylhexanoate affects dopamine turnover in cerebral cortex and locomotor activity in rats. J Biomed Mater Res B 87B(2):381–386

Cooney JJ (1995) Organotin compounds and aquatic bacteria: a review. Helgoländer Meeresun 49:663–677

Li CY, Yu CJ, Ko BT (2013) Facile synthesis of well-defined titanium alkoxides based on benzotriazole phenoxide ligands: efficient catalysts for ring-opening polymerization of cyclic esters. Organometallics 32:172–180

Kim E, Shin EW, Yoo IK, Chung JS (2009) Ring-opening polymerization of l-lactide with silica supported titanium alkoxide catalysts. Macromol Res 17:346–351

Li P, Zerroukhi A, Chen J, Chalamet Y, Jeanmaire T, Xia Z (2009) Synthesis of poly(ɛ-caprolactone)-block-poly(n-butyl acrylate) by combining ring-opening polymerization and atom transfer radical polymerization with Ti[OCH2CCl3]4 as difunctional initiator: I. Kinetic study of Ti[OCH2CCl3]4 initiated ring-opening polymerization of ɛ-caprolactone. Polymer 50:1109–1117

Li P, Zerroukhi A, Chen J, Chalamet Y, Jeanmaire T, Xia Z (2008) Kinetics study of Ti[O(CH2)4OCH=CH2]4 initiated ring-opening polymerization of ε-caprolactone by differential scanning calorimetry. J Appl Polym Sci 110:3990–3998

Meelua W, Molloy R, Meepowpan P, Punyodom W (2012) Isoconversional kinetic analysis of ring-opening polymerization of ε-caprolactone: steric influence of titanium(IV) alkoxides as initiators. J Polym Res 19:9799

Limwanich W, Meepowpan P, Kungwan N, Punyodom W (2020) Influence of butyl group of tin chloride initiators on the non-isothermal DSC ring-opening polymerization of ε-caprolactone: the studies of kinetics, mechanism and polymer synthesis. Thermochim Acta 683:178458

Limwanich W, Meepowpan P, Kungwan N, Punyodom W (2016) Kinetic and mechanistic investigation of the ring-opening polymerization of l-lactide initiated by nBu3SnOnBu using 1H-NMR. Reac Kinet Mech Cat 119:381–392

Limwanich W, Khunmanee S, Kungwan N, Punyodom W, Meepowpan P (2015) Effect of tributyltin alkoxides chain length on the ring-opening polymerization of ε-caprolactone: kinetics studies by non-isothermal DSC. Thermochim Acta 599:1–7

Hernandez AR, Richa AM (2010) Ring opening polymerization of ε-caprolactone initiated by decamolybdate anion: determination of kinetic and thermodynamic parameters by DSC and 1H-NMR. J App Polym Sci 115:2288–2295

Punyodom W, Limwanich W, Meepowpan P (2017) Tin(II) n-butyl l-lactate as novel initiator for the ring-opening polymerization of ε-caprolactone: kinetics and aggregation equilibrium analysis by non-isothermal DSC. Thermochim Acta 655:337–343

Limwanich W, Punyodom W, Kungwan N, Meepowpan P (2015) DSC kinetics analysis for the synthesis of three-arms poly(ε-caprolactone) using aluminum tri-sec-butoxide as initiator. Int J Chem Kinet 47:734–743

Su YC, Yei DR, Chang FC (2005) The kinetics of B-a and P-a type copolybenzoxazine via the ring opening process. J App Polym Sci 95:730–737

Vyazovkin S, Burnham AK, Criado JM, Perez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19

Eyring H (1935) The activated complex in chemical reactions. J Chem Phys 3:107–115

Sedush NG, Chvalun SN (2015) Kinetics and thermodynamics of l-lactide polymerization studied by differential scanning calorimetry. Eur Polym J 62:198–203

Silawanich A, Muangpil S, Kungwan N, Meepowpan P, Punyodom W, Lawan N (2016) Theoretical study of efficiency comparison of Ti(IV) alkoxides as initiators for ring-opening polymerization of ε-caprolactone. Comput Theor Chem 1090:17–22

Acknowledgements

The authors wish to thanks the financial supports from Chiang Mai University (WP and PM), the Thailand Research Fund (TRF) (MRG6080164) (WL) and Office of the Higher Education Commission (OHEC) (WL). The Department of Chemistry and Materials Science Research Center, Faculty of Science, Chiang Mai University, Faculty of Sciences and Agricultural Technology, Rajamangala University of Technology Lanna and University of Phayao are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Limwanich, W., Meelua, W., Meepowpan, P. et al. Kinetics and thermodynamics studies of the ring-opening polymerization of ε-caprolactone initiated by titanium(IV) alkoxides by isothermal differential scanning calorimetry. Reac Kinet Mech Cat 135, 881–895 (2022). https://doi.org/10.1007/s11144-022-02184-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-022-02184-z