Abstract

In this work, an oxovanadium(IV) complex supported on the surface of modified Fe3O4 with a silica shell has been synthesized. The obtained nanostructures were characterized using FT-IR, XRD, SEM, EDX, VSM, TGA and ICP-AES analyses. The synthesized magnetic nanocatalyst has been applied as an efficient catalyst for the synthesis of 2-amino-4H-benzo[h]chromenes via three-component one-pot reaction and also selective oxidation of sulfides to sulfoxides under solvent-free conditions. The synthesized nanocatalyst could be easily separated from the reaction mixture using an external magnet and reused several consecutive runs for both reactions without noticeable reducing in its catalytic activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heterogeneous supported nanocatalysts are an important, versatile reagents and emerging field in catalysis science, because of the small size, the active metal atoms are exposed to the surface and thus minimize the specific cost per function [1,2,3]. Despite the high activity and selectivity of homogeneous catalysts, the use of heterogeneous catalytic systems has been favored over the use of homogeneous ones. The major disadvantage of metal-based homogeneous catalyst systems is their difficult separation from the reaction solution by classical methods as well as they may possibly leave toxic traces of heavy metals in the products. Hence, such drawbacks can be overcome by immobilization of a catalytically active molecule on a solid support [4,5,6,7,8,9,10,11,12,13]. From the various solid supports, magnetic nanoparticles (MNPs) such as Fe3O4 are valuable supports for the immobilization of inorganic and organic catalysts due to their unique advantages including high dispersion, low toxicity, good degree of chemical stability and high active surface for adsorptions or immobilization of metals and ligands. On the other hand, MNPs can be separated by magnetic decantation after the reaction, which is easier rather than cross flow filtration and centrifugation, thus making it a more sustainable nanosupprt [14,15,16,17,18].

Although numerous developments have been achieved in the synthesis and application of magnetic nanoparticles but unfortunately, they sometimes tend to aggregate in a liquid phase due to the anisotropic dipolar attraction. Hence, it is crucial to develop efficient strategies to strengthen the chemical stability of magnetic nanoparticles. In order to resolve such problems, the magnetic cores are usually protected with an outer stabilizing or coating materials, such as organic (polymers and surfactants) and inorganic (silica and carbon-based materials) stabilizers [19,20,21]. These coating materials not only provide stability to the magnetic nanoparticles but they also generate a type of high-performance composite materials that can be used in a wide range of research protocols, such as Mannich type reactions, carbon–heteroatom bond formation, coupling reactions, alkylation, oxidation, reductions, asymmetric synthesis and biology related ones [22,23,24,25,26,27,28]. Hence, many efforts have been devoted to immobilize various metal complexes (e.g., Sc, Cu, Fe, Mn, Co, Ni, Mo and V) on magnetite with silica shell as heterogeneous nanocatalysts for various organic transformations [29,30,31,32,33,34,35,36,37,38].

The selective oxidation of sulfides as environmental pollutants to sulfoxides is an important transformation in organic chemistry. Moreover, a basic obstacle during the oxidation of sulfides is overoxidation of the sulfoxides to their corresponding sulfones. Therefore, it is very important that the catalyst has a high selectivity. Some of biologically active sulfoxides play an important role as therapeutic agents such as antifungal, antibacterial, anti-atherosclerotic, anti-ulcer, antihypertensive and anti-atherosclerotic as well as psychotropic and vasodilators [39, 40].

Multi-component reactions (MCRs) have recently gained prime interest in field of organic synthesis due to their ability of building up the complex molecules in a single step. Nowadays, MCRs are considered as a substantial route in the synthesis of many important heterocyclic compounds such as chromene derivatives. 2-Amino-4H-chromenes are an important class of natural oxygen-containing heterocyclic compounds, which are extensively found in edible fruits, vegetables and used in cosmetics and pigments. Derivatives of these compounds are known to possess antibacterial, antifungal, antioxidant, antitumor, important pharmaceutical and other bioorganic properties [41,42,43].

Owing to the context of green chemistry and heterogeneous nanocatalysis, we herein report an oxovanadium(IV) complex supported on modified Fe3O4 by a stepwise procure and study its catalytic performance for preparation of 2-amino-4H-benzo[h]chromene derivatives in an one-pot three-component reaction and also selective oxidation of sulfides under solvent-free condition.

Experimental section

Materials and measurements

All the chemicals and solvents without any further purification were analytical reagent grade where purchased from Aldrich, Merck or Fluka. FT-IR spectra of nanostructures were recorded using KBr disks on a Bruker vector 22 instrument in the spectral range 4000–400 cm−1. Thermogravimetric (TGA) analysis was performed on a Perkin Elmer analyzer under nitrogen atmosphere from room temperature to 800 °C. Ultrasonic irradiation was carried out with a SONICA-2200 Ep, input 50–60 Hz/305 W. The nanoparticles were analyzed using a Holland Philips X Pert X-ray diffraction diffractometer with Cu Kα radiation (λ = 1.5404 Å) in the 2θ range of 10°–70° at room temperature. Scanning electron microscopy (SEM) images were recorded with a VEGA/TESCAN KYKY-EM3200 microscope. Magnetic properties of samples were detected at room temperature from − 10,000 to \(+\) 10,000 Oe using a vibrating sample magnetometer (VSM, Meghnatis Kavir Kashan Co., Kashan, Iran). The metal content of the catalysts was measured by inductively coupled plasma atomic emission analysis (ICP-AES, Varian company VISTA-PRO model).

Synthesis of oxovanadium complex supported on modified Fe3O4 nanoparticles (Fe3O4@SiO2@VO) as nanocatalyst

Iron oxide magnetic nanoparticles (Fe3O4), silica-coated Fe3O4 nanoparticles (Fe3O4@SiO2) and functionalized Fe3O4 nanoparticles with amine group (Fe3O4@SiO2-amine) were synthesized according to the literature method [14, 44, 45]. For synthesis of the nanocatalyst, brown solid Fe3O4@SiO2-amine (0.3 g) and VO(acac)2 (5 mmol, 1.32 g) were sonicated in 30 mL dry toluene for 5 min. Then, the suspended mixture was refluxed for 24 h under N2 atmosphere. The final product was isolated by magnetic decantation and washed with ethanol/dry toluene and then dried at 80 °C. In the next step, in order to remove the unreacted VO(acac)2, Soxhlet extraction was carried out with ethanol.

General procedure for the synthesis of 2-amino-4H-benzo[h]chromenes

A mixture of aldehyde (1 mmol), 1-naphthol (1 mmol), malononitrile (1 mmol), and Fe3O4@SiO2@VO(IV) (0.2 g) was heated to 125 °C under solvent-free conditions. Using TLC, the progress of the reaction was controlled until the aldehyde had disappeared. After completion of the reaction, the resulting mixture was cooled to room temperature and the nanocatalyst separated using an external magnet, washed with ethanol, dried and then reused in next run. The obtained products were filtered and washed with ethanol to remove any unreacted starting materials. The synthesized 2-amino-4H-benzo[h]chromene derivatives were crystallized from hot ethanol in order to gain pure products.

General procedure for oxidation of sulfides

In a typical experiment, a mixture of sulfide (1.0 mmol), TBHP (2 mmol) and the nanocatalyst (50 mg) were added in a round-bottom flask and stirred under solvent-free condition in room temperature. Then, the mixture was stirred for the appropriate time at room temperature. The progress of the reaction was monitored by TLC. After completion of the reaction, the nanocatalyst was separated by magnetic decantation, washed with water/ethanol and reused for subsequent recycling runs. Also, the corresponding product was dried over anhydrous Na2SO4. All the experiments were carried out three times and mean value for each experiment was reported in this study for accuracy of the results.

Selected spectral data

All obtained products were characterized by FT-IR and melting point [46,47,48]. Also, 1H and 13C NMR spectra for some of 2-amino-4H-benzo[h]chromenes are reported (see the supporting information). Some of selected spectroscopic data is provided as below.

2-Amino-4-(4-chlorophenyl)-4H-benzo[h]chromene-3-carbonitrile: νmax (KBr) 3468, 3327, 2192,1669, 1599, 1407,1374, 1101 cm−1; δH (400 MHz, CDCl3): 4.82 (br s, 2H, NH2), 4.88 (s,1H, CH), 7.01–8.20 (10H, Ar).

2-Amino-4-(4-nitrophenyl)-4H-benzo[h]chromene-3-carbonitrile: νmax (KBr) 3473, 3349, 2191,1650, 1624,1511,1402,1350, 1099 cm−1; δH (400 MHz, CDCl3): 4.90 (br s, 2H, NH2), 5.0 (s,1H, CH), 6.96–8.22 (10H, Ar).

2-Amino-4-(3-nitrophenyl)-4H-benzo[h]chromene-3-carbonitrile: νmax (KBr) 3470, 3328, 2192,1666, 1601,1525,1406,1375, 1102 cm−1; δH (400 MHz, CD3CN): 5.73 (br s, 2H, NH2), 5.09 (s,1H, CH), 7.04–8.30 (10H, Ar).

Results and discussion

Preparation and characterization of the nanostructures

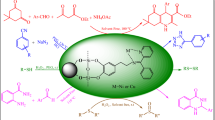

The procedure for the covalent attachment of oxovanadium(IV) complex immobilized on the surface of modified Fe3O4 nanoparticles is depicted in Scheme 1. In the first step, bare Fe3O4 nanoparticles were synthesized using Fe(III) and Fe(II) salts via a co-precipitation method. Subsequently, in order to protect the Fe3O4 nanoparticles from oxidation and agglomeration, silica shell was used. Then, modified Fe3O4 nanoparticles with a silica shell were functionalized with 3-aminopropyltriethoxysilane (APTES). Finally, VO(acac)2 was reacted with functionalized Fe3O4 nanoparticles to obtain Fe3O4@SiO2@VO as nanocatalyst.

The structural features of the prepared nanostructures were characterized by FT-IR, TGA, XRD, EDX, SEM, ICP-AES and VSM.

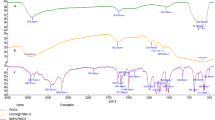

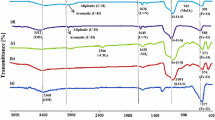

The FT-IR spectra of the nanostructures are shown in Fig. 1. In the FT-IR spectrum of the Fe3O4 (Fig. 1a), an intense broad band characteristic of the Fe–O at 578 cm−1 is observed. The broad band appearing around 3390 cm−1 is ascribed to O–H stretching of FeOH groups or adsorbed water of the magnetic surface. In the spectrum of Fe3O4@SiO2 peaks at 577, 800 and 1089 cm−1 is assigned to the stretching mode of Fe–O, symmetric Si–O–Si and asymmetric Si–O–Si. These peaks have been indicated the formation of a silica layer on Fe3O4 nanoparticles (Fig. 1b). The FT-IR spectrum of Fe3O4@SiO2-amine (Fig. 1c) shows a peak at 584 cm−1 assigned to Fe–O stretching vibration and bands at 799 and 1082 cm−1 are attributed to the symmetric and asymmetric of Si–O–Si, respectively. The presence of C–H vibration band at 2924 cm−1 confirmed the anchored APTES group on the surface of the silica. In the FT-IR spectrum of the Fe3O4@SiO2@VO peaks at 581, 1093, 1630 and 2931 cm−1 are observed, which are due to Fe–O, Si–O–Si, C=N and –CH2 group vibrations.

Fig. 2 shows the powder XRD patterns of Fe3O4, Fe3O4@SiO2 and Fe3O4@SiO2@VO. In the XRD pattern of Fe3O4 (Fig. 2a) observes six characteristic peaks at 2θ of 30.2°, 35.5°, 43.2°, 53.6°, 57.1°, and 62.7°, which is correspond to (220), (311), (400), (422), (511), and (440) reflections, respectively. These results were in agreement with standard data (JCPDS Card No. 19-629) and reveal that the Fe3O4 nanoparticles have inverse cubic spinel structured without impurity phases. The XRD pattern of Fe3O4@SiO2 (Fig. 2b) reveals the same diffraction peaks to that of Fe3O4 nanoparticles. However, the observed broad peak about 2 = \(\theta\)20°–24° can be attributed to existence of amorphous silica. Compared with XRD pattern of Fe3O4 (Fig. 2a), almost no additional peaks are observed in XRD pattern of Fe3O4@SiO2@VO (Fig. 2c) and just a slight decrease in the intensity of the diffraction peaks is observed. According to the obtained results, the comparison of Fig. 2a–c shows that the characteristic peaks of Fe3O4 nanoparticles did not change after coating with silica and grafting of metal complex.

To investigate the morphology and sizes of the prepared nanostructure, SEM images were studied (Fig. 3). As it can be seen in Fig. 3a, Fe3O4 nanoparticles have approximately spherical morphology. The morphology of the nanocatalyst was also observed by FE-SEM, which contains a fairly uniform spherical shape and narrow size distributions (Fig. 3b). It is obvious that nanocatalyst still has the morphological features of the support except for a slightly larger particle size.

The EDX analysis of Fe3O4@SiO2@VO indicate the presence of C, N, O, Si, Fe and V which provides further evidence for attachment of the vanadium complex on the surface of Fe3O4@SiO2 (Fig. 4).

The magnetic properties of Fe3O4, Fe3O4@SiO2 and Fe3O4@SiO2@VO nanocatalyst were investigated by VSM at room temperature (Fig. 5). As can be observed, magnetization curves of the materials exhibited no remanence effect, which indicate superparamagnetic nature of the synthesized nanostructures. The specific saturation magnetization values for Fe3O4, Fe3O4@SiO2 and Fe3O4@SiO2@VO are 56.12, 38.59 and 30.04 emu g−1. The decrease of magnetic saturation of the nanocatalyst indicates anchoring the metal complex on the surface of Fe3O4@SiO2. Nevertheless, by using an external magnetic field and then removed it, the nanocatalyst can still be well re-dispersed, indicating that nanocatalyst possess good redispersibility and magnetic responsivity.

TGA analysis was carried out under N2 atmosphere and the profiles are exhibited in Fig. 6. The profile of Fe3O4 shows a small weight loss (~ 3%) at about 100 ºC owing to the removal of physically adsorbed solvent and surface hydroxyl groups. As it can be seen, there is no significant weight loss in the range of 100–800 °C. Nonetheless, the profile of Fe3O4@SiO2@VO shows two step weight losses. Initially shows a very similar weight loss in the range of 80–120 °C, which corresponds to removal of physically adsorbed solvents. Second mass loss happens above 210 °C (~ 21%), which is due to thermal decomposition of the organic chemicals (Fig. S1 in the Supplementary Information). Additionally, the loaded vanadium of the magnetic nanocatalyst was found to be 1.37 mmol g−1 based on ICP-AES analysis.

Catalytic performance of the synthesized nanocatalyst

Part A: Catalytic performance of Fe3O4@SiO2@VO for the synthesis of 2-amino-4H-benzo[h]chromenes

After synthesis and characterization of Fe3O4@SiO2@VO, we have been investigated its catalytic activity for the synthesis of 2-amino-4H-benzo[h]chromenes via the one-pot, three-component reaction of aldehydes, malononitrile and 1-naphthol. For this aim, the reaction of 2-chlorobenzaldehyde with malononitrile and 1-naphthol was chosen as a model reaction to obtain the optimization of the conditions. In order to investigate the effects of catalytic active centers, background reactions were performed (Table 1, entries 1–4). The use of Fe3O4, Fe3O4@SiO2, and Fe3O4@SiO2-amine instead of the nanocatalyst, the reaction did not proceed after 24 h. Also, this reaction was examined in the absence of the catalyst. It was found that when the reaction occurred without catalyst, it showed poor yield even after 24 h. Therefore, the existence of nanocatalyst is necessary for this reaction. To study optimum reaction conditions, the influences of various factors such as solvents, amount of the nanocatalyst and temperature, were studied. Initially, the effect of various solvents such as H2O, EtOH, CH3CN and also solvent-free condition were studied; highest catalytic activity was observed when solvent-free condition was employed (Table 1, entries 5–8). In the next step, amount of the nanocatalyst on catalytic activity was studied; which the best catalytic performance was obtained using 0.2 g of Fe3O4@SiO2@VO. Increasing the amounts of the nanocatalyst obtain no further improvement (Table 1, entries 9–12). Also, The effect of temperature on the performance of the nanocatalyst was investigated. Among them, 110 °C was selected as the optimum temperature. At the above 110 °C, yield was decreased (Table 1, entries 13–16).

Finally, after optimization of different parameters in three-component reaction of 2-chlorobenzaldehyde, malononitrile and 1-naphthol (0.2 g of the nanocatalyst under solvent free condition at 110 °C), we used the optimized reaction conditions to different aldehydes. As can be seen from Table 2, the electronic impacts indicate a minor effect on the reaction yield and this method tolerates various electron-poor and electron-rich aldehydes. The corresponding products obtain in good to excellent yields. However, the presences of electron-withdrawing substituents on the benzene ring were obtained the best results.

Nanocatalyst recycling and leaching test

The reusability and stability of the anchored catalysts are a very important issue from practical, environmental and sustainability viewpoints [49]. The recyclability of the catalyst was surveyed using the reaction of 2-chloro benzaldehyde, malononitrile and 1-naphthol under the optimized conditions. In order to regenerate the nanocatalyst, after each run, it was separated by an external magnet, then washed several times with deionized water/EtOH and finally dried under vacuum for reuse. Fe3O4@SiO2@VO could be recycled for at least five times without significant change in its activity (Fig. 6).

Study of metal leaching by ICP technique after the reusability test is an important issue. After the nanocatalyst was separated, the filtrate was used for ICP analysis as leaching test. The vanadium leaching in the first and 5th run were 0.0012 (~ 0.14%) and 0.0029 mmol g−1 (~ 0.34%), respectively. Leaching experiments confirmed that the nanocatalyst is truly heterogeneous and that no catalytically active oxovanadium species are dissolved in the solution. It seems that strong interactions between the oxovanadium complex and magnetic support play a significant role in preventing metal leaching during the reaction.

SEM and FT-IR of the reused nanocatalyst after the 5th run in order to check the stability were studied. Based on SEM image, the morphology and structure of the reused nanocatalyst has been maintained during the recycling reaction (Fig. S2 in the Supplementary Information). Furthermore, FT-IR spectrum of the reused nanocatalyst was similar to that of fresh one and showed expected C–H, C=N, Si–O–Si and Fe–O vibration bands (Fig. S3 in the Supplementary Information). These results confirm the good stability and strong attachment of the oxovanadium complex on the surface of magnetic nanoparticles.

Proposed catalytic mechanism

On the basis of some related literatures [50, 51], a plausible mechanism was proposed for the preparation of 2-amino-4H-benzo[h]chromenes using Fe3O4@SiO2@VO (Scheme 2). According to the mechanism, the nanocatalyst could be attached to the carbonyl groups of the aldehyde and cyano group and activates it for nucleophilic attack. First, the reaction between malonitrile and aldehyde give an α,β-unsaturated nitrile (I) which reacts with 1-naphthol to form the dicyano compound (II). The rapid nucleophilic addition of phenolic hydroxyl group to the C=N group, and intramolecular cyclization to gives intermediate (III), after tautomerization of intermediate (III) forms the 2-amino-4H- benzo[h]chromenes (IV).

Part B: Catalytic performance of the nanocatalyst in the oxidation of sulfides

In continuation of our research in the area of developing homogeneous metal complexes supported onto surface of the magnetic support and their applications as catalyst in organic transformations [52,53,54,55], we were interested in finding a simple and efficient procedure for the selective oxidation of sulfides using synthesized nanocatalyst. The oxidation of sulfides was investigated in detail by optimizing the reaction variables such as solvent, substrate/oxidant molar ratio and amount of nanocatalyst. For this purpose, methyl phenyl sulfide was used as a sample.

At the first stage for optimization, the model reaction was carried out in the absence of nanocatalyst or oxidant (blank run). The result showed that reaction was incomplete even after prolonging the reaction time, which confirms the importance of the nanocatalyst and oxidant for the reaction completion (Table 3, entries 1–2). In continue the reaction was done in different solvents and also in solvent -free conditions (Table 3, entries 3–7 and 10). The results show that the highest conversion and selectivity is obtained under solvent-free condition within 2 h. However, it is noteworthy that the nanocatalyst is capable to act selectively in different solvents, which is a noticeable advantage. To optimize the amounts of nanocatalyst, different amounts of Fe3O4@SiO2@VO (10, 30, 50 and 100 mg) were used in the oxidation of methyl phenyl sulfide using tert-butyl hydrogenperoxide (TBHP) under solvent-free condition (Table 2, entries 8–11). As observed, when 10 and 50 mg of catalyst were used, conversion was increased from 59 to 99% under same reaction conditions respectively. A further increase in the catalyst amount decreases the selectivity which is undesired. The effect of TBHP/substrate mole ratio on model reaction was investigated at regular intervals of time (Table 3, entries 10, 12 and 13). The maximum conversion and selectivity was observed at 2:1 mol ratio of TBHP/methyl phenyl sulfide. It should be noted that the use of Fe3O4, Fe3O4@SiO2 and Fe3O4@SiO2-amine instead of Fe3O4@SiO2@VO gives a trace yield of the corresponding product even after 12 h (Table 3, entries 14–16).

According to the experimental results (as it was shown in Table 3), solvent-free condition at room temperature using 50 mg of nanocatalyst and 2:1 mol ratio of TBHP to methyl phenyl sulfide during 2 h is the best choice for the model reaction (Table 3, entry 10). After optimization of different parameters for methyl phenyl sulfide reaction as model substrate, the catalytic activity of Fe3O4@SiO2@VO was examined in the oxidation of other sulfides under the optimized conditions. The results have been summed up in Table 4. As it is clear, in all of the reactions, different sulfides were oxidized selectively to their corresponding sulfoxides in excellent yield in the short reaction times and no any by-products were observed. However, the lower activity of diaryl sulfide than arylalkyl sulfides seems to be due to the steric hindrance of the diaryl group. Therefore, the obtained results show that this methodology will be applicable for the oxidation of a wide range of other sulfides.

Reusability and leaching test in the reaction of sulfides

As the recyclability of a heterogeneous nanocatalyst is a significant factor, we investigated the recyclability and reusability of Fe3O4@SiO2@VO was investigated under the optimized conditions. After the magnetic separation of nanocatalyst from the reaction mixture, the nanocatalyst was washed with ethanol/H2O and dried to remove any remaining solvent, and then reused in the further reactions for several times. Results indicated that nanocatalyst is recyclable during six consecutive runs with preserving catalytic activity (Fig. 7).

Similar to previous section, a leaching test for methyl phenyl reaction under the optimized conditions was carried out. Only a low amount of vanadium leaching is observed (only 0.61% after 6th reaction run). Negligible amount of leaching during oxidation process confirms a strong interaction between magnetic support and metal complex and heterogeneous character of the synthesized nanocatalyst.

Comparison of catalytic efficiency with the previous works

In order to further investigate the eligibility of the present work, we compared this procedure with the previously reported catalysts for both reaction of 2-chlorobenzaldehyde, malononitrile and 1-naphtol for the preparation of corresponding product and oxidation of methyl phenyl sulfide, as shown in Table 5 [56,57,58,59,60,61,62,63] As can be seen, our catalytic system operated under mild conditions such as room temperature with minimum amounts of used catalyst in the oxidation of sulfides. Additionally, good stability of nanocatalyst, high product purity, commercially available materials and easy separation of the nanocatalyst are other advantages of this protocol.

Conclusions

In summary, we have reported a green, efficient and environmentally method for the synthesis of 2-amino-4H-benzo[h] chromene derivatives and selective oxidation of sulfide in the presence of oxovanadium(IV) complex immobilized on the surface of modified Fe3O4 nanoparticles as a nanocatalyst. The structure, morphology and chemical composition of the prepared nanostructures and nanocatalyst were confirmed by different spectroscopic and microscopic techniques like FT-IR, XRD, SEM, EDX, VSM, TGA, and ICP-AES analyses. Mild reaction conditions, use the green and non-toxic materials, good to excellent product yields, good stability of the nanocatalyst, ease of separation and recyclability of the catalyst and also use of solvent-free reaction conditions are the advantageous features of the presented work. It is noteworthy that the nanocatalyst also acted selectively in the oxidation of sulfide. Furthermore, the leaching experiments in the reaction of chromenes and sulfides proved that the oxovanadium complex was anchored firmly to the magnetic support. In addition, the results demonstrate that the nanocatalyst could be reused for several times in both reactions without significant loss in its activity.

References

Bell AT (2003) Sciencece 299:1688–1691

Astruc D (2008) Nanoparticles and catalysis. Wiley, Weinheim, pp 1–48

Lu F, Astruc D (2020) Coord Chem Rev 408:213180

de Jong K (2009) Synthesis of solid catalysts. Wiley, Weinheim

Gupta K, Sutar AK, Lin C-C (2009) Coord Chem Rev 253:1926–1946

Aghajani M, Safaei E, Karimi B (2017) Synth Met 233:63–73

Saberikia I, Safaei E, Karimi B et al (2017) Chem Sel 2:11164–11171

Latypova AR, Tarasyuk IA, Filippov DV et al (2019) Reac Kinet Mech Cat 127:741–755

Kaluža L, Karban J, Gulková D (2019) Reac Kinet Mech Cat 127:887–902

Glotov A, Stavitskaya A, Chudakov Y et al (2019) Bull Chem Soc Jpn 92:61–69

Imaoka T, Yamamoto K (2019) Bull Chem Soc Jpn 92:941–948

Lin B, Lin Z, Chen S et al (2019) Dalton Trans 48:8279–8287

Kwak K, Lee D (2018) Acc Chem Res 52:12–22

Teja AS, Koh P-Y (2009) Prog Cryst Growth Charact Mater 55:22–45

Wang D, Astruc D (2014) Chem Rev 114:6949–6985

Rossi LM, Costa NJ, Silva FP, Wojcieszak R (2014) Green Chem 16:2906–2933

Schneider MGM, Lassalle VL (2017) Biomed Pharmacother 93:1098–1115

Bilal M, Zhao Y, Rasheed T et al (2018) Int J Biol Macromol 120:2530–2544

Tsang SC, Yu CH, Gao X, Tam K (2006) J Phys Chem B 110:16914–16922

Lien Y-H, Wu T-M (2008) J Colloid Interface Sci 326:517–521

Lu Y, Yin Y, Mayers BT, Xia Y (2002) Nano Lett 2:183–186

Reddy LH, Arias JL, Nicolas J, Couvreur P (2012) Chem Rev 112:5818–5878

Karimi B, Mansouri F, Mirzaei HM (2015) ChemCatChem 7:1736–1789

Lim CW, Lee IS (2010) Nano Today 5:412–434

Ghorbani-Choghamarani A, Darvishnejad Z, Norouzi M (2015) Appl Organomet Chem 29:170–175

Gawande MB, Branco PS, Varma RS (2013) Chem Soc Rev 42:3371–3393

Baig RN, Nadagouda MN, Varma RS (2015) Coord Chem Rev 287:137–156

Keshavarz M, Abdoli-Senejani M, Hojati SF et al (2018) Reac Kinet Mech Cat 124:757–766

Tamoradi T, Irandoust A, Ghadermazi M (2019) J Iran Chem Soc 16:1723–1733

Li Z, Wu S, Zheng D et al (2014) ChemPlusChem 79:716–724

Martins NM, Pombeiro AJ, Martins LM (2019) Catal Commun 125:15–20

Karimpour T, Safaei E, Karimi B, Lee YI (2018) ChemCatChem 10:1889–1899

Bezaatpoura A, Askarizadehb E, Akbarpoura SH, Amiria M, Babaei B (2017) Mol Catal 436:199–209

Zhou Q, Wan Z, Yuan X et al (2016) Appl Organomet Chem 30:215–220

Bhat PB, Rajarao R, Sahajwalla V et al (2015) J Mol Catal A 409:42–49

Bagherzadeh M, Bahjati M, Mortazavi-Manesh A (2019) J Organomet Chem 897:200–206

Veisi H, Rashtiani A, Rostami A et al (2019) Polyhedron 157:358–366

Khaledian D, Rostami A, Rouhani S (2019) Catal Commun 124:46–50

Fernández I, Khiar N (2003) Chem Rev 103:3651–3706

Kazemi M, Ghobadi M (2017) Nanotechnol Rev 6:549–571

Weber L (2002) Drug Discov Today 7:143–147

Chen M-N, Mo L-P, Cui Z-S et al (2019) Curr Opin Green Sustain Chem 15:27–37

Kohzadian A, Zare A (2019) Res Chem Intermed 45:5473–5485

Wang Z, Shen B, Aihua Z, He N (2005) Chem Eng J 113:27–34

Masteri-Farahani M, Tayyebi N (2011) J Mol Catal A 348:83–87

Kumar D, Reddy VB, Mishra BG, Rana R, Nadagouda MN, Varma RS (2007) Tetrahedron 63:3093–3097

Khurana JM, Nand B, Saluja P (2010) Tetrahedron 66:5637–5641

Weast RC, Astle MJ, Beyer WH (1989) CRC handbook of chemistry and physics, vol 1990. CRC Press, Boca Raton

Polshettiwar V, Luque R, Fihri A, Zhu H, Bouhrara M, Basset J-M (2011) Chem Rev 111:3036–3075

Ren Y-M, Cai C (2008) Catal Commun 9:1017–1020

Khoobi M, Ma’mani L, Rezazadeh F, Zareie Z, Foroumadi A, Ramazani A, Shafiee A (2012) J Mol Catal A 359:74–80

Aghajani M, Monadi N (2017) J Iran Chem Soc 14:963–975

Monadi N, Moradi E (2018) Transit Met Chem 43:161–170

Aghajani M, Monadi N (2018) Appl Organomet Chem. https://doi.org/10.1002/aoc.4433

Aghajani M, Monadi N (2019) J Chin Chem Soc 66:775–784

Farahi M, Karami B, Alipour S, Moghadam LT (2014) Acta Chim Slov 61:94–99

Jin TS, Zhang JS, Liu LB, Wang AQ, Li TS (2006) Synth Commun 36:2009–2015

Heravi MM, Bakhtiari Kh, Zadsirjan V, Bamoharram FF, Heravi MO (2007) Bioorg Med Chem Lett 17:4262–4265

Divsalar N, Monadi N, Tajbaksh M (2016) J Nanostruct 6:312–321

Ghorbani-Choghamarani A, Ghasemi B, Safari Z, Azadi G (2015) Catal Commun 60:70–75

Nikoorazm M, Ghorbani-Choghamarani A, Mahdavi H, Esmaeili SM (2015) Microporous Mesoporous Mater 211:174–181

Islam SM, Roy AS, Mondal P, Tuhina K, Mobarak M, Mondal J (2012) Tetrahedron Lett 53:127–131

Hajjami M, Kolivand S (2016) Appl Organomet Chem 30:282–288

Acknowledgements

Authors gratefully acknowledge the University of Mazandaran Research Councils for financial support of this research project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Monadi, N., Davoodi, H. & Aghajani, M. Oxovanadium(IV) complex supported on the surface of magnetite as a recyclable nanocatalyst for the preparation of 2-amino-4H-benzo[h]chromenes and selective oxidation of sulfides. Reac Kinet Mech Cat 129, 659–677 (2020). https://doi.org/10.1007/s11144-020-01749-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-020-01749-0