Abstract

Dynamic analysis of flexible body under large rotation becomes increasingly important in many engineering applications. This work takes rotating flexible beam as numerical example under assumptions of straight beam, small deformation and fixed axis rotation. Results of six finite element methods are compared: floating frame of reference formulation (FFRF), generalized component mode synthesis (GCMS), total Lagrangian formulation (TLF), linear Euler–Bernoulli beam (LEBB), nonlinear Euler–Bernoulli beam (NEBB) and absolute nodal coordinate formulation (ANCF). Due to the effect of geometric nonlinearity or centrifugal stiffening, the results of linear methods FFRF, GCMS and LEBB are different to geometrically nonlinear methods TLF, NEBB and ANCF. Three points of view are obtained through numerical result analysis. Firstly, based on the equivalence between FFRF and GCMS, a special type of parametrically excited nonlinear system is equivalent to linear system, so as to analyze the Lyapunov stability of its solution. Secondly, for the ANCF, the system invariant matrix is presented to calculate elastic force, which avoids element integration or assembling in each time step, and then the computational efficiency is improved by at least an order of magnitude when compared to adopting element invariant matrix. Thirdly, for GCMS, TLF and ANCF, the velocity of relative coordinate for deformation is adopted to calculate linear internal damping force, which gets different deflection result in comparison with adopting velocity of absolute coordinate for deformation, under large rotational speed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The finite element method [1,2,3,4,5,6] is widely applied for accurate dynamic analysis of flexible body under large rotation [7]. These finite element methods are usually categorized according to kinematic analysis approach: the FFRF [7], GCMS [2], LEBB [4] and NEBB [5] separate flexible deformation from rigid rotation, whereas the TLF [8] and ANCF [7] do not. The former categorized method is also known as hybrid coordinate method [9] or common flexible multibody dynamic method. According to deformation measurement approach, the four hybrid coordinate methods can be further categorized: the FFRF, LEBB and NEBB measure deformation by relative coordinate, whereas the GCMS by absolute coordinate [10]. Even under the same kinematic analysis approach and the same deformation measurement approach, there are more detailed categories; for example, the common FFRF interpolates deformation based on solid element, whereas the LEBB and NEBB base on beam element. Up to now, the comparison of these different finite element methods is necessary but still rare.

As an efficient flexible multibody dynamic method, the FFRF is already widely used in commercial softwares [11] and its performance is continuously enhanced by various new approaches. In order to avoid costly integral updates at each time step, the inertia and quadratic velocity force of FFRF are presented as a function of inertia shape integrals [7, 12]. Based on the Sherman-Morrison-Woodbury formula, the iterative equation of FFRF is solved with infinite penalty factor of joint constraint, and the factorization of unchanged mass and stiffness matrices part is reused [13]. To avoid using Lagrange multiplier of kinematic constraints, the absolute floating frame coordinates and local interface coordinates are transformed into absolute interface coordinate, and the tangent stiffness matrix is derived by variation of equilibrium equation [14]. By numerical examples, it is verified that three component mode synthesis methods both lead to correct numerical results: Guyan-Iron condensation method, modal truncation technique, Craig-Bampton synthesis approach [15]. After effect analysis of reference condition, it is proved there is no single set of reference conditions suited for all applications [16]. Through nodal-based treatment of FFRF, a concise equation of motion is derived without using inertia shape integrals or lumped mass approximation [11]. With the aid of inertia shape integrals method, component mode synthesis method and employment of reference condition, the method of FFRF is implemented in this work.

The GCMS is a promising alternative to flexible multibody dynamic analysis. The GCMS is based on absolute coordinate formulation, which measures deformation by absolute coordinate and partially linearizes the Green strain tensor with respect to co-rotated frame; the resulting mass and stiffness matrices are constant apart from a transformation based on rotation matrix [17]. For planar example, the component mode synthesis is applied to absolute coordinate formulation; although the number of deformation modes increases, the computational complexity for the system Jacobian factorization reduces from cubic to quadratic [18]. Through direct approximation of total displacements by global mode shapes, the total displacements are linearly dependent on reduced generalized coordinates, and the resulting equation of motion also preserves constant mass matrix, co-rotated stiffness matrix and avoids quadratic velocity vector [10]. For the flexible bodies with large rotations about one axis, the GCMS is formulated by reducing the number of flexible shape functions to three times the number of component mode synthesis shape functions [19]. To avoid the matrix ill condition which is caused by linear dependence and different Euclidean norm magnitude orders of generalized component modes, a “shortened” version of the classical Gram-Schmidt process is adopted to obtain desired independent set of generalized component modes [2]. In this work, the absolute coordinate formulation is organized in a comparative way to FFRF, and the global mode shapes are not given since they are already involved by previous work [20].

The TLF [8] is also called as a reference configuration formulation [21], which solves geometrically nonlinear problems with finite deformation. Except for problems with large mesh distortion, the TLF is widely applied in geometrically nonlinear problems of continua and structures, such as gear dynamics [3], rotating blade [22], car crash [23] and metal forming [24]. Via highly parallel graphics processing unit, the efficiency of biomechanical simulation based on TLF is increased by 16.8 times [25] and 20 times [26], respectively, in comparison with CPU implementations. The TLF is also the basis of constitutive equation for many complex nonlinear materials, such as silica-filled rubber material [27], viscoelastic plane structures [28], incompressible finite strain solid [29] and fiber composites [30]. For the TLF implementation in this work, the parallel computation [31] is regretfully not employed, the internal nodal force computation is less efficient than the procedure in section 4.9 of [8], and these two weaknesses restrict our result validity and our TLF implementation in this work only provides reference of numerical accuracy but not numerical efficiency.

The LEBB is based on Euler–Bernoulli beam assumption and linear elasticity assumption. A linear state-space model of flexible beam is established for single-link flexible manipulator simulation, it is shown the dominant parts of transient responses are characterized by only two flexible modes [4]. Through experiment and simulation comparisons, it is shown the LEBB based on linear elastic theory leads to a low vibration frequency and large vibration amplitude, along with the decrease of beam thickness and the increase of deflection [32]. Through separating the element motion into local system movement and elastic deflection, the dynamic equation of 3D beam element is formulated with lumped mass matrix, where the beam element is denoted by three lumped mass points [33]. Besides finite element method, the Euler–Bernoulli beam assumption and linear elasticity assumption are also used in analytical or semi-analytical method, such as inverse dynamics solution of slewing beam [34], dynamic analysis of single-link manipulator arm [35]. In this work, the inertia shape integrals are explicitly given for mass matrix calculation of LEBB.

The main difference between NEBB and LEBB is that NEBB adopts von Kármán strain–displacement relationship [36]. Through writing the equations of motion in terms of axial coordinate along the deformed axis, a constant stiffness matrix is obtained even if higher-order terms are retained in strain–displacement relationship [37]. A second-order approximation for the displacement field of flexible beam is proposed to account for dynamic stiffening, and the effects of tip mass and damping on dynamic behavior of the hub-beam system are analyzed on the basis of a finite element model [5]. Based on geometric nonlinear elastic theory and finite element method, the dynamic equations of elastic beams under large overall rotation are derived, and the effect of coupling deformation on system dynamic behavior is analyzed [38]. Using the fully nonlinear Green strain–displacement relationships, the coupling equation of motion for a rotating three-dimensional cantilever beam is established, and the effect of steady-state axial deformation and Coriolis term on coupling vibration is analyzed [39]. Besides finite element method, the Euler–Bernoulli beam assumption and von Kármán strain–displacement relationship are also used in analytical or semi-analytical method, such as parametric resonance of double-clamped micro-beams by electro-thermal heating [40], nonlinear resonant response of cable-stayed beam [41]. In pursuit of a uniform expression for geometrically nonlinear methods, the elastic force of NEBB is also calculated by system invariant matrix in this work.

As the same as TLF, the ANCF solves geometrically nonlinear problems with finite deformation; as the same as LEBB and NEBB, the ANCF attains finite element model with small degrees of freedom (DOF) [7]. The ANCF is proposed for large rotation and deformation analysis of shearable beam element with deformable cross section, it leads to constant mass matrix, zero centrifugal forces and zero Coriolis forces as the same as GCMS [42, 43]. In order to alleviate the Poisson locking caused by coupling between axial and transverse stress, the enhanced continuum method divides the elasticity matrix into two parts and only considers the Poisson effect at beam axis [44]; the enhanced assumed strain method enriches the displacement-dependent compatible strain by a set of additional independent enhanced strain [45]; the strain split method divides the Green-Lagrange strain into two parts and does not introduce additional variables [46]; the higher-order beam method enriches the interpolation polynomial basis to allow correct coupling between axial and transverse strain [47]. Different Poisson locking alleviation methods are compared and none of them are suitable for all ANCF element types [45, 46]. As for the alleviation of curvature thickness locking and shear locking, a new ANCF element with redefined interpolation polynomial expansion and reduced integration procedure is proposed [48]. In this work, the higher-order beam method [47] is adopted, and the computational efficiency of ANCF which adopts system invariant matrix is compared with ANCF which adopts element invariant matrix [49].

The above parts give separate illustrations for each single method. Because of the importance, the comparison of these different finite element methods is already concerned by many researches [5, 7, 10, 18, 19, 32, 43, 50]. Based on existing researches, this work tries to make a more comprehensive comparison of abovementioned six finite element methods. Some views are obtained after comparison; for example, the parametrically excited nonlinear system in GCMS can be transformed to linear system in FFRF. Besides advantages, simultaneous accommodation of six methods also brings weaknesses: only a rotating flexible beam example under centerline transverse load is considered; the narrations and notations may look weird due to the fact that they are different to classical researches and conventions; plenty of existing researches are not adopted to improve a single method to its extreme. This work attempts to deal with the conflict between these advantages and weaknesses.

The arrangement of this work is as follows. In Sect. 2, the three finite element methods FFRF, GCMS and TLF which base on solid element are introduced. In Sect. 3, the three finite element methods LEBB, NEBB and ANCF which base on beam element are introduced. In Sect. 4, numerical results of the six finite element methods under different rotational speeds are compared; the computational efficiencies of the six finite element methods are compared; the influence of system invariant matrix on computational efficiency is analyzed for TLF, NEBB and ANCF; the influence of damping on numerical results of GCMS, TLF and ANCF is analyzed. In Sect. 5, summaries and conclusions are given.

2 Methods based on solid element

2.1 The method of FFRF

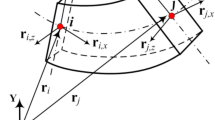

In order to describe the configuration of flexible body under large rotation, the FFRF establishes two reference frames: inertial frame \(o-xyz\) and floating frame \(O-XYZ\) as shown in Fig. 1. The inertial frame is fixed and the floating frame is rotating along with the body, and the motion of the flexible body point is then separated into two parts: rigid rotation and elastic deformation. The rigid rotation part can be represented by the motion of floating frame and measured in \(o-xyz\) as vector \(\varvec{u}_\mathrm{{r}} = {\left[ {\begin{array}{ccc} {{u_{\mathrm{{r}}x}}}&{{u_{\mathrm{{r}}y}}}&{{u_{\mathrm{{r}}z}}} \end{array}} \right] ^\mathrm{{T}}}\). The elastic deformation part can be measured in \(o-xyz\) as absolute coordinate vector \(\varvec{u}_\mathrm{{f}} = {\left[ {\begin{array}{ccc} {{u_{\mathrm{{f}}x}}}&{{u_{\mathrm{{f}}y}}}&{{u_{\mathrm{{f}}z}}} \end{array}} \right] ^\mathrm{{T}}}\) or measured in \(O-XYZ\) as relative coordinate vector \(\varvec{U}_\mathrm{{f}} = {\left[ {\begin{array}{ccc} {{U_{\mathrm{{f}}X}}}&{{U_{\mathrm{{f}}Y}}}&{{U_{\mathrm{{f}}Z}}} \end{array}} \right] ^\mathrm{{T}}}\) [10]. Measure the Cartesian coordinate of undeformed body point in frame \(O-XYZ\) as vector \({\varvec{X}_0} = {\left[ {\begin{array}{ccc} {{X_0}}&{{Y_0}}&{{Z_0}} \end{array}} \right] ^\mathrm{{T}}}\), vector \(\varvec{X}_0\) is constant and adopted to specify different body points. The total displacement vector \(\varvec{u} = {\left[ {\begin{array}{ccc} {{u_x}}&{{u_y}}&{{u_z}} \end{array}} \right] ^\mathrm{{T}}}\) of point \(\varvec{X}_0\) is measured in \(o-xyz\) as follows:

Different parameters are proposed to represent the rigid rotation of floating frame, such as Rodriguez parameters, Euler angles and direction cosines [7]. The direction cosines lead to linear dependence between reference coordinates and rigid rotation displacement, while additional constraints about reference coordinates are added [10]. This work only considers the fixed axis rotation case where rotational axis is z axis or Z axis, and rotational angle is \(\varphi \). Correspondingly, the rigid rotation displacement \(\varvec{u}_\mathrm{{r}}\) of point \(\varvec{X}_0\) and the reference coordinate constraint are given by

where matrix \({\varvec{N}_\mathrm{{r}}}({\varvec{X}_0}) = \left[ {\begin{array}{cc} {{\mathbf{{G}}_1} \cdot {\varvec{X}_0}{}}&{{\mathbf{{G}}_2} \cdot {\varvec{X}_0}} \end{array}} \right] \), \(\mathbf{{G}_1} = \left[ {\begin{array}{ccc} 1&{}0&{}0\\ 0&{}1&{}0\\ 0&{}0&{}0 \end{array}} \right] \), \({\mathbf{{G}}_2} = \left[ {\begin{array}{ccc} 0&{}{ - 1}&{}0\\ 1&{}0&{}0\\ 0&{}0&{}0 \end{array}} \right] \), reference coordinate vector \({\varvec{q}_\mathrm{{r}}} = {\left[ {\begin{array}{ccc} {\cos \varphi {\quad }}&{\sin \varphi } \end{array}} \right] ^\mathrm{{T}}}\) and vector \(\varvec{q}_{\mathrm{{r}}0}\) is the initial value of \(\varvec{q}_\mathrm{{r}}\).

The two measurements \(\varvec{u}_\mathrm{{f}}\) and \(\varvec{U}_\mathrm{{f}}\) of elastic deformation are correlated by the rotation matrix \(\varvec{A}\) as follows

When it is difficult to find analytical solution of governing equations for three-dimensional continuum elasticity problem, the integral or weak form equivalent to the governing differential equations is usually adopted to find approximate solution [21]. The finite element method subdivides the continuum domain as a finite number of elements, and the deformation vector \(\varvec{U}_\mathrm{{f}}\) of point \(\varvec{X}_0\) in the e-th element is approximated by interpolation of node deformation as follows

where \(\varvec{N}({\varvec{X}_0})\) is the shape function, element elastic coordinate vector \({\varvec{U}_{\mathrm{{f}}e}} = {\left[ {\begin{array}{cccc} {\varvec{U}_{\mathrm{{f}}e1}^\mathrm{{T}}}&{\varvec{U}_{\mathrm{{f}}e2}^\mathrm{{T}}}&{ \cdots }&{\varvec{U}_{\mathrm{{f}}em}^\mathrm{{T}}} \end{array}} \right] ^\mathrm{{T}}}\), \(\varvec{U}_{\mathrm{{f}}ei}\) is the deformation vector of the i-th node for the e-th element, m is the number of nodes for the e-th element.

To facilitate numerical integration, the Cartesian coordinate \(\varvec{X}_0\) is one-to-one mapped to local coordinate \(\varvec{\xi } = {\left[ {\begin{array}{ccc} {\xi {}}&{\eta {}}&\zeta \end{array}} \right] ^\mathrm{{T}}}, - 1 \le \xi ,\eta ,\zeta \le 1\), on the basis of shape function \(\varvec{N}(\varvec{\xi } )\) as follows

where \({\varvec{X}_{0e}} = {\left[ {\begin{array}{cccc} {\varvec{X}_{0e1}^\mathrm{{T}}}&{\varvec{X}_{0e2}^\mathrm{{T}}}&{\cdots }&{\varvec{X}_{0em}^\mathrm{{T}}} \end{array}} \right] ^\mathrm{{T}}}\) is the element Cartesian coordinate vector.

The 8-node brick isoparametric element is adopted in this work, and the shape functions \(\varvec{N}({\varvec{X}_0})\) and \(\varvec{N}(\varvec{\xi } )\) are the same and given by

where \({N_i} = \frac{{(1 + {\xi _i}\xi ) \cdot (1 + {\eta _i}\eta ) \cdot (1 + {\zeta _i}\zeta )}}{8}\), \(\mathbf{{I}}_3\) is \(3 \times 3\) identity matrix, \(\xi _i, \eta _i, \zeta _i\) are the local coordinate of the i-th node.

The derivative of displacement relative to time is velocity as follows

Due to the fact that components in matrix \(\dot{\varvec{A}}\) are identical with the components in vector \(\dot{\varvec{q}}_\mathrm{{r}}\), above velocity formula is transformed as

where matrix \({\varvec{N}_\mathrm{{r}}}({\varvec{X}}) = {\varvec{N}_{\mathrm{{r}}}}({\varvec{X}_0}) + \left[ {\begin{array}{cc} {\mathbf{{G}_1} \cdot {{\varvec{U}}_\mathrm{{f}}}{}}&{\mathbf{{G}_2} \cdot {{\varvec{U}}_\mathrm{{f}}}} \end{array}} \right] \), \(\varvec{X} = {\left[ {\begin{array}{ccc} {X {}}&{Y {}}&{Z} \end{array}} \right] ^\mathrm{{T}}}\) is the Cartesian coordinate of point \(\varvec{X}_0\) after deformation and it is also measured in frame \(O-XYZ\).

According to the velocity, the element kinetic energy \(T_e\) can be calculated through integration over element volume v as follows

where \(\rho \) is material density, element coordinate \({\varvec{q}_e} = {\left[ {\begin{array}{cc} {{\varvec{q}_\mathrm{{r}}}{}}&{{{\varvec{U}}_{\mathrm{{f}}e}}} \end{array}} \right] ^\mathrm{{T}}}\), the element mass matrix \({\varvec{M}_e} = \left[ {\begin{array}{cc} {{\varvec{M}_{\mathrm{{rr}}e}}}&{}{{\varvec{M}_{\mathrm{{rf}}e}}}\\ {\varvec{M}_{\mathrm{{rf}}e}^\mathrm{{T}}}&{}{{\varvec{M}_{\mathrm{{ff}}e}}} \end{array}} \right] \), \({\varvec{M}_{\mathrm{{rr}}e}} = \int _v {\rho \cdot \varvec{N}_\mathrm{{r}}^\mathrm{{T}}({\varvec{X}}) \cdot {\varvec{N}_\mathrm{{r}}}(\varvec{X} )\mathrm{{d}}v}\), \({\varvec{M}_{\mathrm{{rf}}e}} = \int _v {\rho \cdot \varvec{N}_\mathrm{{r}}^\mathrm{{T}}({\varvec{X}}) \cdot \varvec{A} \cdot \varvec{N}(\varvec{\xi } )\mathrm{{d}}v}\), \({\varvec{M}_{\mathrm{{ff}}e}} = \int _v \rho \cdot {\varvec{N}^\mathrm{{T}}}(\varvec{\xi } ) \cdot \varvec{N}(\varvec{\xi } )\mathrm{{d}}v\).

Under the assumption of small deformation, the strain vector \(\varvec{\varepsilon } = {\left[ {\begin{array}{cccccc} {{\varepsilon _X}{}}&{{\varepsilon _Y}{}}&{{\varepsilon _Z}{}}&{{\gamma _{XY}}{}}&{{\gamma _{YZ}}{}}&{{\gamma _{ZX}}} \end{array}} \right] } ^ \mathrm{{T}}\) of point \(\varvec{X}_0\) is linearly related to element elastic coordinate vector as follows [21]

where differential operator \(\varvec{L} = {\left[ {\begin{array}{cccccc} {\frac{\partial }{{\partial X}}}&{}0&{}0&{}{\frac{\partial }{{\partial Y}}}&{}0&{}{\frac{\partial }{{\partial Z}}}\\ 0&{}{\frac{\partial }{{\partial Y}}}&{}0&{}{\frac{\partial }{{\partial X}}}&{}{\frac{\partial }{{\partial Z}}}&{}0\\ 0&{}0&{}{\frac{\partial }{{\partial Z}}}&{}0&{}{\frac{\partial }{{\partial Y}}}&{}{\frac{\partial }{{\partial X}}} \end{array}} \right] ^\mathrm{{T}}}\), \(\varvec{B}_\mathrm{{L}}\) is linear strain matrix.

On account of small deformation assumption, the deformed coordinates X, Y, Z in operator \(\varvec{L}\) can also be replaced by undeformed coordinates \(X_0,Y_0,Z_0\). Then the components in strain matrix \(\varvec{B}_\mathrm{{L}}\) are calculated as follows

where vector \(\varvec{n} = {\left[ {\begin{array}{cccc} {{N_1}{}}&{{N_2}{}}&{\cdots {}}&{{N_m}} \end{array}} \right] ^\mathrm{{T}}}\).

According to the strain, the elastic potential energy \(V_e\) is calculated as follows

where \(\textbf{E}\) is elasticity matrix of moduli, element stiffness matrix \({\varvec{K}_{\mathrm{{L}}e}} = \int _v {\varvec{B}_\mathrm{{L}}^\mathrm{{T}} \cdot \mathbf{{E}} \cdot {\varvec{B}_\mathrm{{L}}}\mathrm{{d}}v}\).

As for the linear internal damping, it is assumed that the damping force is proportional to deformation velocity and its direction is opposite to deformation velocity [51]. Measure the damping force intensity of point \({\varvec{X}}_0\) in frame \(O-XYZ\) as \({\varvec{F}_\mathrm{{d}}}\); then \({\varvec{F}_\mathrm{{d}}}\) is proportional to the velocity of relative coordinate for deformation as follows

where c is damping coefficient.

Measure the damping force in frame \(o-xyz\) as \(\varvec{A} \cdot {\varvec{F}_\mathrm{{d}}}\); then the virtual work \(\delta {W_e}\) of damping force for the e-th element is as follows

where element damping matrix \({\varvec{D}_e} = \left[ {\begin{array}{c} {\tilde{\varvec{A}} \cdot {\varvec{D}_{\mathrm{{rf}}1e}} + {\varvec{D}_{\mathrm{{rf}}2e}}}\\ {{\varvec{D}_{\mathrm{{ff}}e}}} \end{array}} \right] \), \(\tilde{\varvec{A}} = \left[ {\begin{array}{cc} {\cos \varphi }&{}{ - \sin \varphi }\\ {\sin \varphi }&{}{\cos \varphi } \end{array}} \right] \), \({\varvec{D}_{\mathrm{{rf}}1e}} = c \cdot \int _v {\varvec{N}_\mathrm{{r}}^\mathrm{{T}}({\varvec{X}_0}) \cdot \varvec{N}(\varvec{\xi } )\mathrm{{d}}v}\), \({\varvec{D}_{\mathrm{{rf}}2e}} = c \cdot \left[ {\begin{array}{c} {\varvec{U}_{\mathrm{{f}}e}^\mathrm{{T}} \cdot {\varvec{D}_{\mathrm{{ff}}e}} \cdot \mathbf{{G}}_{1\textrm{d}}^\mathrm{{T}} \cdot {\varvec{A}_\mathrm{{d}}}}\\ {\varvec{U}_{\mathrm{{f}}e}^\mathrm{{T}} \cdot {\varvec{D}_{\mathrm{{ff}}e}} \cdot \mathbf{{G}}_{2\textrm{d}}^\mathrm{{T}} \cdot {\varvec{A}_\mathrm{{d}}}} \end{array}} \right] \), \(\varvec{D}_{\mathrm{{ff}}e} = c / \rho \cdot {\varvec{M}_{\mathrm{{ff}}e}}\), matrix \(\varvec{A}_\mathrm{{d}}\) is block-diagonal with each diagonal block equal to \(\varvec{A}\), \(\mathbf{{G}}_{1\textrm{d}}\) is block-diagonal with each diagonal block equal to \(\mathbf{{G}}_1\), \(\mathbf{{G}}_{2\textrm{d}}\) is block-diagonal with each diagonal block equal to \(\mathbf{{G}}_2\), and the dimensions of matrices \(\varvec{A}_\mathrm{{d}}\), \(\mathbf{{G}}_{1\textrm{d}}\) and \(\mathbf{{G}}_{2\textrm{d}}\) are dependent on the context.

The element damping matrix is composed of coupling part \(\tilde{\varvec{A}} \cdot {\varvec{D}_{\mathrm{{rf}}1e}} + {\varvec{D}_{\mathrm{{rf}}2e}}\) and elastic part \(\varvec{D}_{\mathrm{{ff}}e}\). The elastic part is proportional to elastic mass matrix \(\varvec{M}_{\mathrm{{ff}}e}\) as general Rayleigh proportional damping [52], and the coupling part emerges because the assumption of Eq. (15) means the deformation velocity of one point does not lead to dissipative force on another point [51]. In order to get an element damping matrix without coupling part, the internal damping model based on viscoelasticity [51] may be adopted.

According to the kinetic energy, elastic potential energy and damping virtual work, the generalized inertia force, generalized elastic force and generalized damping force can be obtained. Substituting them in the fundamental nonholonomic form of Lagrange’s equation [53], the following system dynamic equation is then obtained

where \(\varvec{M}\) is system mass matrix, system coordinate \(\varvec{q} = {\left[ {\begin{array}{cc} {\varvec{q}_\mathrm{{r}}^\mathrm{{T}}{}}&{\varvec{U}_{\mathrm{{fs}}}^\mathrm{{T}}} \end{array}} \right] ^\mathrm{{T}}}\), \(\varvec{U}_{\mathrm{{fs}}}\) is system elastic coordinate vector, \({\frac{{\partial \varvec{C}}}{{\partial \varvec{q}}}}\) is the Jacobian matrix of constraint vector \(\varvec{C}\), \(\varvec{\lambda }\) is the Lagrange multiplier vector of constraint, \(\varvec{Q}_\mathrm{{e}}\) is external force vector, quadratic velocity vector \({\varvec{Q}_v} = - \dot{\varvec{M}} \cdot \dot{\varvec{q}} + {\left( {\frac{{\partial T}}{{\partial \varvec{q}}}} \right) ^\mathrm{{T}}}\), T is system kinetic energy, damping force vector \({\varvec{Q}_\mathrm{{d}}} = \varvec{D} \cdot {\dot{\varvec{U}}_\mathrm{{fs}}}\), \(\varvec{D}\) is system damping matrix, system elastic force vector \({\varvec{Q}_k} = {\varvec{K}_\mathrm{{L}}} \cdot {\varvec{U}_\mathrm{{fs}}}\), \(\varvec{K}_\mathrm{{L}}\) is system stiffness matrix.

The quadratic velocity vector [7] is resulted from the differentiation of kinetic energy with respect to time and with respect to system coordinates. The gyroscopic and Coriolis force components are contained in this quadratic velocity vector. This term is also utilized by following researches [2, 10, 12, 18].

In combination with constraint equation, the above system dynamic equation composes a differential algebraic equation, which can be transformed into an ordinary differential equation [20]. There are different numerical methods to solve the ordinary differential equation, such as Runge–Kutta method and Adams method. Besides, the component mode synthesis method [15] is adopted to improve solution efficiency, and the eigenmode is calculated under reference condition [16]. Due to the order of matrix \(\varvec{D}_{\mathrm{{rf}}2e}\) cannot be reduced by component mode synthesis method, in order to improve calculation efficiency, this matrix is ignored on the basis of small deformation assumption, which means terms related to \(\delta \varvec{A}\) are ignored in virtual work calculation of damping force. Numerical result shows the influence of this ignorance on calculation accuracy is quite small.

2.2 The method of GCMS

Similar to FFRF, the GCMS establishes inertial frame \(o-xyz\) and floating frame \(O-XYZ\), and the total motion of flexible body point is separated into rigid motion part and elastic deformation part. However, different to FFRF, the GCMS adopts absolute coordinate vector \(\varvec{u}_\mathrm{{f}}\) rather than relative coordinate vector \(\varvec{U}_\mathrm{{f}}\) to measure the elastic deformation [10]. The elastic deformation \(\varvec{u}_\mathrm{{f}}\) of point \(\varvec{X}_\mathrm{{0}}\) in the e-th element is approximated by interpolation of node deformation as follows

where \({\varvec{u}_{\mathrm{{f}}e}} = {\left[ {\begin{array}{cccc} {\varvec{u}_{\mathrm{{f}}e1}^\mathrm{{T}}}&{\varvec{u}_{\mathrm{{f}}e2}^\mathrm{{T}}}&{ \cdots }&{\varvec{u}_{\mathrm{{f}}em}^\mathrm{{T}}} \end{array}} \right] ^\mathrm{{T}}}\) is element elastic coordinate vector.

In this case, the total velocity \(\dot{\varvec{u}}\) of point \(\varvec{X}_0\) is given by

The element kinetic energy \(T_e\) is correspondingly calculated by

where element coordinate \({\varvec{q}_e} = {\left[ {\begin{array}{cc} {{\varvec{q}_\mathrm{{r}}}{}}&{{{\varvec{u}}_{\mathrm{{f}}e}}} \end{array}} \right] ^\mathrm{{T}}}\), the element mass matrix \({\varvec{M}_e} = \left[ {\begin{array}{cc} {{\varvec{M}_{\mathrm{{rr}}e}}}&{}{{\varvec{M}_{\mathrm{{rf}}e}}}\\ {\varvec{M}_{\mathrm{{rf}}e}^\mathrm{{T}}}&{}{{\varvec{M}_{\mathrm{{ff}}e}}} \end{array}} \right] \), mass submatrices \({\varvec{M}_{\mathrm{{rr}}e}} = \int _v {\rho \cdot \varvec{N}_\mathrm{{r}}^\mathrm{{T}}({\varvec{X}}_0) \cdot {\varvec{N}_\mathrm{{r}}}(\varvec{X}_0 )\mathrm{{d}}v}\), \({\varvec{M}_{\mathrm{{rf}}e}} = \int _v {\rho \cdot \varvec{N}_\mathrm{{r}}^\mathrm{{T}}({\varvec{X}_0}) \cdot \varvec{N}(\varvec{\xi } )\mathrm{{d}}v}\), \({\varvec{M}_{\mathrm{{ff}}e}} = \int _v \rho \cdot {\varvec{N}^\mathrm{{T}}}(\varvec{\xi } ) \cdot \varvec{N}(\varvec{\xi } )\mathrm{{d}}v\).

Above equation shows the mass matrix of GCMS is constant which differs from FFRF. This means the quadratic velocity vector is avoided for calculation of generalized inertia force [10] and it usually improves calculation efficiency. Apologetically, the same notations \(\varvec{q}_e\), \(\varvec{M}_e\), \(\varvec{M}_{\mathrm{{rr}}e}\) and \(\varvec{M}_{\mathrm{{rf}}e}\) are used for both GCMS and FFRF, while their specific composition or calculation is different. In consideration of their same physical meaning, this kind of notation usage may be tolerable.

As for the element elastic potential energy \(V_e\), it is given by

Different to FFRF, the damping force intensity \(\varvec{F}_\mathrm{{d}}\) measured in \(O-XYZ\) for GCMS is expressed as follows

Virtual work \(\delta {W_e}\) of damping force for the e-th element is as follows

where element damping matrix \({\varvec{D}_e} = \left[ {\begin{array}{c} {{\varvec{D}_{\mathrm{{rf}}e}}}\\ {{\varvec{D}_{\mathrm{{ff}}e}}} \end{array}} \right] \), \({\varvec{D}_{\mathrm{{rf}}e}} = c / \rho \cdot {\varvec{M}_{\mathrm{{rf}}e}}\), \({\varvec{D}_{\mathrm{{ff}}e}} = c / \rho \cdot {\varvec{M}_{\mathrm{{ff}}e}}\).

According to the energy and virtual work, the generalized force can be obtained. Substituting them in the fundamental nonholonomic form of Lagrange’s equation, the following system dynamic equation is then obtained

where system coordinate \(\varvec{q} = {\left[ {\begin{array}{cc} {{\varvec{q}_\mathrm{{r}}}}&{{{\varvec{u}}_\mathrm{{fs}}}} \end{array}} \right] ^\mathrm{{T}}}\), \({\varvec{u}}_\mathrm{{fs}}\) is system elastic coordinate vector, damping force vector \({\varvec{Q}_\mathrm{{d}}} = \varvec{D} \cdot ({\varvec{A}_\mathrm{{d}}} \cdot \dot{\varvec{A}}_\mathrm{{d}}^\mathrm{{T}} \cdot {\varvec{u}_{\mathrm{{fs}}}} + {{\dot{\varvec{u}}}_{\mathrm{{fs}}}})\), system elastic force vector \({\varvec{Q}_k} = \left[ {\begin{array}{c} {\varvec{u}_{\mathrm{{fs}}}^\mathrm{{T}} \cdot {\mathbf{{G}}_{1\textrm{d}}} \cdot {\varvec{K}_\mathrm{{L}}} \cdot \varvec{A}_\mathrm{{d}}^\mathrm{{T}} \cdot {\varvec{u}_{\mathrm{{fs}}}}}\\ {\varvec{u}_{\mathrm{{fs}}}^\mathrm{{T}} \cdot {\mathbf{{G}}_{2\textrm{d}}} \cdot {\varvec{K}_\mathrm{{L}}} \cdot \varvec{A}_\mathrm{{d}}^\mathrm{{T}} \cdot {\varvec{u}_{\mathrm{{fs}}}}}\\ {{\varvec{A}_\mathrm{{d}}} \cdot {\varvec{K}_\mathrm{{L}}} \cdot \varvec{A}_\mathrm{{d}}^\mathrm{{T}} \cdot {\varvec{u}_{\mathrm{{fs}}}}} \end{array}} \right] \).

The solution method of above system dynamic equation is similar to FFRF, where component mode synthesis method is also adopted. As for the eigenmode of GCMS, it is transformed from the eigenmode of FFRF [10, 20].

2.3 The method of TLF

Different to the above two methods, the TLF only establishes inertial frame and the total motion of flexible body point is not separated. Before rigid rotation and elastic deformation, the configuration of flexible body is called the reference configuration; after rigid rotation and elastic deformation, the configuration of flexible body is called the current configuration [21]. The inertial frame is expressed by \(o-xyz\): the Cartesian coordinate for point of reference configuration is measured in inertial frame as vector \(\varvec{x}_0 = \left[ {\begin{array}{ccc} x_0&y_0&z_0 \end{array}} \right] ^\mathrm{{T}}\), the Cartesian coordinate for point of current configuration is measured in inertial frame as vector \(\varvec{x} = \left[ {\begin{array}{ccc} x&y&z \end{array}} \right] ^\mathrm{{T}}\). The vector \(\varvec{x}_0\) is constant and adopted to specify different body point, and the total displacement vector \(\varvec{u} = \left[ {\begin{array}{ccc} {u_x}&{u_y}&{u_z} \end{array}} \right] ^\mathrm{{T}}\) of point \(\varvec{x}_0\) is measured in inertial frame as

where t is time.

In finite element discretization, the Cartesian coordinate \(\varvec{x}\) is one-to-one mapped to local coordinate \(\varvec{\xi } = {\left[ {\begin{array}{ccc} \xi&\eta&\zeta \end{array}} \right] ^\mathrm{{T}}}, - 1 \le \xi ,\eta ,\zeta \le 1\) as follows

where \(\varvec{N}(\varvec{\xi } )\) is shape function and keeps the same as Eq. (8), \(\varvec{x}_{e}={\left[ {\begin{array}{cccc} {\varvec{x}_{e1}^\mathrm{{T}}}&{\varvec{x}_{e2}^\mathrm{{T}}}&\cdots&{\varvec{x}_{em}^\mathrm{{T}}} \end{array}} \right] ^\mathrm{{T}}}\) is element Cartesian coordinate vector.

The total displacement vector \(\varvec{u}\) of point \(\varvec{x}_0\) in the e-th element is approximated by interpolation of node displacement as

where \(\varvec{u}_e={\left[ {\begin{array}{cccc} {\varvec{u}_{e1}^\mathrm{{T}}}&{\varvec{u}_{e2}^\mathrm{{T}}}&\cdots&{\varvec{u}_{em}^\mathrm{{T}}} \end{array}} \right] ^\mathrm{{T}}}\) is element displacement vector.

The second derivative of displacement relative to time is acceleration as follows

According to the acceleration, the virtual work \(\delta T_e\) of inertia force for the e-th element is as follows

where \(\rho \) is material density under current configuration, v is element volume under current configuration, element mass matrix \({\varvec{M}_e} = \int _{v_0} {\rho _0 \cdot {\varvec{N}^\mathrm{{T}}}(\varvec{\xi } ) \cdot \varvec{N}(\varvec{\xi } )\mathrm{{d}}{v_0}}\), \(\rho _0\) is material density under reference configuration, \(v_0\) is element volume under reference configuration.

The TLF adopts Green-Lagrange strain to measure deformation [21, 54], which is invariant under rigid motion. The strain vector \(\varvec{\varepsilon } = \left[ {\begin{array}{cccccc} {{\varepsilon _x}}&{{\varepsilon _y}}&{{\varepsilon _z}}&{{\gamma _{xy}}}&{{\gamma _{yz}}}&{{\gamma _{zx}}} \end{array}} \right] ^\mathrm{{T}}\) of point \(\varvec{x}_0\) is nonlinearly related to element displacement vector as follows

where linear strain matrix \(\varvec{B}_\mathrm{{L}} = \varvec{L} \cdot \varvec{N}(\varvec{\xi })\) and \(\varvec{L} = {\left[ {\begin{array}{cccccc} {\frac{\partial }{{\partial x_0}}}&{}0&{}0&{}{\frac{\partial }{{\partial y_0}}}&{}0&{}{\frac{\partial }{{\partial z_0}}}\\ 0&{}{\frac{\partial }{{\partial y_0}}}&{}0&{}{\frac{\partial }{{\partial x_0}}}&{}{\frac{\partial }{{\partial z_0}}}&{}0\\ 0&{}0&{}{\frac{\partial }{{\partial z_0}}}&{}0&{}{\frac{\partial }{{\partial y_0}}}&{}{\frac{\partial }{{\partial x_0}}} \end{array}} \right] ^\mathrm{{T}}}\), the components of \(\varvec{B}_\mathrm{{L}}\) are calculated by \({\left( {\frac{{\partial \varvec{n}}}{{\partial \varvec{x}_0}}} \right) ^\mathrm{{T}}} = {\left[ {{{\left( {\frac{{\partial {\varvec{x}_0}}}{{\partial \varvec{\xi } }}} \right) }^\mathrm{{T}}}} \right] ^{ - 1}} \cdot {\left( {\frac{{\partial \varvec{n}}}{{\partial \varvec{\xi } }}} \right) ^\mathrm{{T}}}\), vector \(\varvec{n} = {\left[ {\begin{array}{cccc} {{N_1}}&{{N_2}}&\cdots&{{N_m}} \end{array}} \right] ^\mathrm{{T}}}\), nonlinear strain matrix \({\varvec{B}_\mathrm{{N}}} = {\varvec{B}_\mathrm{{N}1}} \cdot {\varvec{B}_\mathrm{{N}2}}\), \({\varvec{B}_\mathrm{{N}1}} = \left[ {\begin{array}{ccc} {{{\left( {\frac{{\partial \varvec{N}}}{{\partial x_0}} \cdot {\varvec{u}_e}} \right) }^\mathrm{{T}}}}&{}\varvec{0}&{}\varvec{0}\\ \varvec{0}&{}{{{\left( {\frac{{\partial \varvec{N}}}{{\partial y_0}} \cdot {\varvec{u}_e}} \right) }^\mathrm{{T}}}}&{}\varvec{0}\\ \varvec{0}&{}\varvec{0}&{}{{{\left( {\frac{{\partial \varvec{N}}}{{\partial z_0}} \cdot {\varvec{u}_e}} \right) }^\mathrm{{T}}}}\\ {{{\left( {\frac{{\partial \varvec{N}}}{{\partial y_0}} \cdot {\varvec{u}_e}} \right) }^\mathrm{{T}}}}&{}{{{\left( {\frac{{\partial \varvec{N}}}{{\partial x_0}} \cdot {\varvec{u}_e}} \right) }^\mathrm{{T}}}}&{}\varvec{0}\\ \varvec{0}&{}{{{\left( {\frac{{\partial \varvec{N}}}{{\partial z_0}} \cdot {\varvec{u}_e}} \right) }^\mathrm{{T}}}}&{}{{{\left( {\frac{{\partial \varvec{N}}}{{\partial y_0}} \cdot {\varvec{u}_e}} \right) }^\mathrm{{T}}}}\\ {{{\left( {\frac{{\partial \varvec{N}}}{{\partial z_0}} \cdot {\varvec{u}_e}} \right) }^\mathrm{{T}}}}&{}\varvec{0}&{}{{{\left( {\frac{{\partial \varvec{N}}}{{\partial x_0}} \cdot {\varvec{u}_e}} \right) }^\mathrm{{T}}}} \end{array}} \right] \), \({\varvec{B}_\mathrm{{N}2}} = \left[ {\begin{array}{cccc} {\frac{{\partial {N_1}}}{{\partial x_0}} \cdot {\mathbf{{I}}_3} \quad }&{}{\frac{{\partial {N_2}}}{{\partial x_0}} \cdot {\mathbf{{I}}_3} \quad }&{} {\cdots \quad } &{}{\frac{{\partial {N_m}}}{{\partial x_0}} \cdot {\mathbf{{I}}_3}}\\ {\frac{{\partial {N_1}}}{{\partial y_0}} \cdot {\mathbf{{I}}_3} \quad }&{}{\frac{{\partial {N_2}}}{{\partial y_0}} \cdot {\mathbf{{I}}_3} \quad }&{} {\cdots \quad } &{}{\frac{{\partial {N_m}}}{{\partial y_0}} \cdot {\mathbf{{I}}_3}}\\ {\frac{{\partial {N_1}}}{{\partial z_0}} \cdot {\mathbf{{I}}_3} \quad }&{}{\frac{{\partial {N_2}}}{{\partial z_0}} \cdot {\mathbf{{I}}_3} \quad }&{} {\cdots \quad } &{}{\frac{{\partial {N_m}}}{{\partial z_0}} \cdot {\mathbf{{I}}_3}} \end{array}} \right] \).

Above displacement and strain are expressed as function of the Lagrange coordinate \(\varvec{x}_0\) rather than the Euler coordinate \(\varvec{x}\), and this is the difference between TLF and updated Lagrangian formulation [8, 55].

Through matrix transformation, the nonlinear strain matrix \(\varvec{B}_\mathrm{{N}}\) is transformed as

where \(\varvec{B}_{\mathrm{{N}}5} = {\varvec{B}_{\mathrm{{N}}3}} \cdot {\varvec{B}_{\mathrm{{N}}4}}\), \({\varvec{B}_{\mathrm{{N}}3}} = \left[ {\begin{array}{ccc} {\frac{{\partial {\varvec{n}^\mathrm{{T}}}}}{{\partial x_0}}}&{}\varvec{0}&{}\varvec{0}\\ \varvec{0}&{}{\frac{{\partial {\varvec{n}^\mathrm{{T}}}}}{{\partial y_0}}}&{}\varvec{0}\\ \varvec{0}&{}\varvec{0}&{}{\frac{{\partial {\varvec{n}^\mathrm{{T}}}}}{{\partial z_0}}}\\ {\frac{{\partial {\varvec{n}^\mathrm{{T}}}}}{{\partial y_0}}}&{}{\frac{{\partial {\varvec{n}^\mathrm{{T}}}}}{{\partial x_0}}}&{}\varvec{0}\\ \varvec{0}&{}{\frac{{\partial {\varvec{n}^\mathrm{{T}}}}}{{\partial z_0}}}&{}{\frac{{\partial {\varvec{n}^\mathrm{{T}}}}}{{\partial y_0}}}\\ {\frac{{\partial {\varvec{n}^\mathrm{{T}}}}}{{\partial z_0}}}&{}\varvec{0}&{}{\frac{{\partial {\varvec{n}^\mathrm{{T}}}}}{{\partial x_0}}} \end{array}} \right] \), \({\varvec{B}_{\mathrm{{N}}4}} = \left[ {\begin{array}{cccc} {\frac{{\partial {N_1}}}{{\partial x_0}} \cdot {\mathbf{{I}}_m}{}}&{}{\frac{{\partial {N_2}}}{{\partial x_0}} \cdot {\mathbf{{I}}_m}{}}&{} {\cdots {}} &{}{\frac{{\partial {N_m}}}{{\partial x_0}} \cdot {\mathbf{{I}}_m}}\\ {\frac{{\partial {N_1}}}{{\partial y_0}} \cdot {\mathbf{{I}}_m}{}}&{}{\frac{{\partial {N_2}}}{{\partial y_0}} \cdot {\mathbf{{I}}_m}{}}&{} {\cdots {}} &{}{\frac{{\partial {N_m}}}{{\partial y_0}} \cdot {\mathbf{{I}}_m}}\\ {\frac{{\partial {N_1}}}{{\partial z_0}} \cdot {\mathbf{{I}}_m}{}}&{}{\frac{{\partial {N_2}}}{{\partial z_0}} \cdot {\mathbf{{I}}_m}{}}&{} {\cdots {}} &{}{\frac{{\partial {N_m}}}{{\partial z_0}} \cdot {\mathbf{{I}}_m}} \end{array}} \right] \), \(\mathbf{{I}}_m\) is \(m \times m\) identity matrix, \(\varvec{u}_{\mathrm{{d}}e}\) is block-diagonal with each diagonal block equal to \({\varvec{u}_{\mathrm{{B}}e}} = \left[ {\begin{array}{ccc} {{u_{xe1}}}&{}{{u_{ye1}}}&{}{{u_{ze1}}}\\ {{u_{xe2}}}&{}{{u_{ye2}}}&{}{{u_{ze2}}}\\ \vdots &{} \vdots &{} \vdots \\ {{u_{xem}}}&{}{{u_{yem}}}&{}{{u_{zem}}} \end{array}} \right] \).

The variation of Green-Lagrange strain \(\delta \varvec{\varepsilon }\) is as follows [21]

According to the Greed-Lagrange strain, the second Piola-Kirchhoff stress is calculated. The virtual work \(\delta V_e\) of elastic force for the e-th element is as follows [54]

where linear element stiffness matrix \({\varvec{K}_{\mathrm{{L}}e}} = \int _{v_0} \varvec{B}_\mathrm{{L}}^\mathrm{{T}} \cdot \mathbf{{E}} \cdot {\varvec{B}_\mathrm{{L}}}\mathrm{{d}}{v_0}\), nonlinear element stiffness matrix \({\varvec{K}_{\mathrm{{N}}e}} = {\varvec{K}_{\mathrm{{N}}1e}} \cdot {\varvec{u}_{\mathrm{{d}}e}} + \varvec{u}_{\mathrm{{d}}e}^\mathrm{{T}} \cdot {\varvec{K}_{\mathrm{{N}}2e}} + \varvec{u}_{\mathrm{{d}}e}^\mathrm{{T}} \cdot {\varvec{K}_{\mathrm{{N}}3e}} \cdot {\varvec{u}_{\mathrm{{d}}e}}\), matrices \(\varvec{K}_{\mathrm{{N}}1e}\), \(\varvec{K}_{\mathrm{{N}}2e}\) and \(\varvec{K}_{\mathrm{{N}}3e}\) are time-invariant, \({\varvec{K}_{\mathrm{{N}}1e}} = \frac{1}{2} \cdot \int _{v_0} {\varvec{B}_\mathrm{{L}}^\mathrm{{T}} \cdot \mathbf{{E}} \cdot {\varvec{B}_{\mathrm{{N}}5}}{\mathrm{{d}}{v_0}}}\), \({\varvec{K}_{\mathrm{{N}}2e}} = \int _{v_0} {\varvec{B}_{\mathrm{{N}}5}^\mathrm{{T}} \cdot \mathbf{{E}} \cdot {\varvec{B}_\mathrm{{L}}}\mathrm{{d}}{v_0}}\), \({\varvec{K}_{\mathrm{{N}}3e}} = \frac{1}{2} \cdot \int _{v_0} {\varvec{B}_{\mathrm{{N}}5}^\mathrm{{T}} \cdot \mathbf{{E}} \cdot {\varvec{B}_{\mathrm{{N}}5}}\mathrm{{d}}{v_0}}\).

The above equation provides a procedure to compute elastic force of element as \({{\varvec{Q}}_{ke}} = ({\varvec{K}_\mathrm{{L}e}} + {\varvec{K}_\mathrm{{N}e}}) \cdot {\varvec{u}_e}\). This procedure is different to the procedure in section 4.9 of [8]. While full quadrature is adopted, the number of arithmetic operations including addition and multiplication is analyzed for these two procedures. For the procedure based on above equation, the matrix multiplication order is implemented from right to left, and then the number of arithmetic operations is \(2 \cdot m^4 + 12 \cdot m^3 + 38 \cdot m^2 - 12 \cdot m\). For the procedure in section 4.9 of [8], the number of arithmetic operations is obtained as \(n_\mathrm{{m}} \cdot (39 \cdot m+174)\), where \(n_\mathrm{{m}}\) is the number of quadrature points. Under \(m = 8\) and \(n_\mathrm{{m}} = 3^3\), the numbers of arithmetic operations are, respectively, 16672 and 13122 for the two procedures. The presented procedure is less efficient but still adopted, and two reasons are: the element assembly in advance of solving system dynamic equation compensates efficiency; the time-invariant features of \(\varvec{K}_{\mathrm{{N}}1e}\), \(\varvec{K}_{\mathrm{{N}}2e}\) and \(\varvec{K}_{\mathrm{{N}}3e}\) reflect systemic inherent characteristics; for example, these three matrices are potential to provide possibly more accurate and efficient calculation of reduced quadratic and cubic stiffness coefficients in nonlinear reduced order model [56].

In order to not to damp rigid motion [51] or eliminate the influence of external damping [57], the total displacement is subtracted by rigid rotation displacement as deformation. The virtual work \(\delta W_e\) of damping force for the e-th element in TLF is similar to GCMS and given by

where element damping matrix \({\varvec{D}_e} = c / \rho \cdot {\varvec{M}_e}\), \(\varvec{u}_\mathrm{{r}e}\) is element displacement vector under only rigid rotation.

According to the virtual work statement [21], the following system dynamic equation is then obtained

where \(\varvec{u}_\mathrm{{s}}\) is system displacement vector, damping force vector \({\varvec{Q}_\mathrm{{d}}} = \varvec{D} \cdot \left[ {{\varvec{A}_\mathrm{{d}}} \cdot {\dot{\varvec{A}}}_\mathrm{{d}}^\mathrm{{T}} \cdot ({\varvec{u}_\mathrm{{s}}} - {\varvec{u}_{\mathrm{{rs}}}}) + ({{\dot{\varvec{u}}}_\mathrm{{s}}} - {{\dot{\varvec{u}}}_{\mathrm{{rs}}}})} \right] \), \(\varvec{u}_{\mathrm{{rs}}}\) is system displacement vector under only rigid rotation, system elastic force vector \({\varvec{Q}_k} = ({\varvec{K}_\mathrm{{L}}} + {\varvec{K}_\mathrm{{N}}}) \cdot {\varvec{u}_\mathrm{{s}}}\), nonlinear system stiffness matrix \({\varvec{K}_\mathrm{{N}}} = {\varvec{K}_{\mathrm{{N}}1}} \cdot {\varvec{u}_{\mathrm{{ds}}}} + \varvec{u}_{\mathrm{{ds}}}^\mathrm{{T}} \cdot {\varvec{K}_{\mathrm{{N}}2}} + \varvec{u}_{\mathrm{{ds}}}^\mathrm{{T}} \cdot {\varvec{K}_{\mathrm{{N}}3}} \cdot {\varvec{u}_{\mathrm{{ds}}}}\), matrices \(\varvec{K}_{\mathrm{{N}}1}\), \(\varvec{K}_{\mathrm{{N}}2}\), \(\varvec{K}_{\mathrm{{N}}3}\) and \(\varvec{u}_{\mathrm{{ds}}}\) are obtained by assembling \(\varvec{K}_{\mathrm{{N}}1e}\), \(\varvec{K}_{\mathrm{{N}}2e}\), \(\varvec{K}_{\mathrm{{N}}3e}\) and \(\varvec{u}_{\mathrm{{d}}e}\).

In the above equation, matrices \(\varvec{K}_{\mathrm{{N}}1}\), \(\varvec{K}_{\mathrm{{N}}2}\) and \(\varvec{K}_{\mathrm{{N}}3}\) are time-invariant, so they are called system invariant matrix. Once these matrices are obtained by element integration and assembly before solving system dynamic equation, they can be reused in every time step, which means there is no need of element integration and assembly in each time step. The similar method is also used by the inertia shape integrals method [7, 12] and the element invariant matrix method [49]: The former calculates system mass matrix for FFRF and the latter calculates components of element stiffness matrix for ANCF.

3 Methods based on beam element

3.1 The method of LEBB

Similar to FFRF, the LEBB also establishes inertial frame \(o-xyz\) and floating frame \(O-XYZ\), and the total motion of flexible body point is separated into rigid motion part and elastic deformation part. However, different from FFRF, the LEBB adopts deformation on one-dimensional centerline to determine deformation of three-dimensional beam. This work only considers the straight beam case, the X axis coincides with the undeformed straight beam centerline, and rotational axis is still z axis or Z axis. Measure the Cartesian coordinate of undeformed body point in frame \(O-XYZ\) as vector \(\varvec{X}_0 = \left[ {\begin{array}{ccc} X_0&Y_0&Z_0 \end{array}} \right] ^\mathrm{{T}}\); vector \(\varvec{X}_0\) is constant and adopted to specify different body points. For the point \(\varvec{X}_0\) of the three-dimensional beam, its deformation is measured in \(O-XYZ\) as relative coordinate vector \({\varvec{U}_\mathrm{{f}}}({\varvec{X}_0}) = {\left[ {\begin{array}{ccc} {{U_{\mathrm{{f}}X}}}&{{U_{\mathrm{{f}}Y}}}&{{U_{\mathrm{{f}}Z}}} \end{array}} \right] ^\mathrm{{T}}}\). For the cross section at \(X_0\), its configuration is measured in \(O-XYZ\) as relative coordinate vector \({\varvec{W}_\mathrm{{f}}}(X_0) = {\left[ {\begin{array}{cccccc} {{W_X}}&{{W_Y}}&{{W_Z}}&{{\theta _X}}&{{\theta _Y}}&{{\theta _Z}} \end{array}} \right] ^\mathrm{{T}}}\), where \(W_X\), \(W_Y\) and \(W_Z\) are translational displacement component, \(\theta _X\), \(\theta _Y\) and \(\theta _Z\) are rotational angle component. For most beam theories, the plane cross-section assumption [21] is adopted that a cross-section orthogonal to the centerline remains plane and keeps its shape throughout deformation process. In additional consideration of the small deformation assumption, the deformation \({\varvec{U}_\mathrm{{f}}}(\varvec{X}_0)\) of three-dimensional beam is then determined by deformation \({\varvec{W}_\mathrm{{f}}}(X_0)\) on one-dimensional centerline as follows

where matrix \({\varvec{N}_\mathrm{{c}}}(\varvec{X}_0) = \left[ {\begin{array}{cccccc} 1&{}0&{}0&{}0&{}Z_0&{}{ - Y_0}\\ 0&{}1&{}0&{}{ - Z_0}&{}0&{}0\\ 0&{}0&{}1&{}Y_0&{}0&{}0 \end{array}} \right] \).

When the ratio of length to cross-section dimension is not very high, the Euler–Bernoulli beam theory permits accurate solution [21]. The Euler–Bernoulli beam assumes that the rotated cross section keeps orthogonal to the deformed centerline throughout deformation process. In this case, the rotational angle \(\theta _Y(X_0)\) and \(\theta _Z(X_0)\) can be calculated by derivatives of deflection \(W_Y(X_0)\) and \(W_Z(X_0)\), the interpolations for deflection \(W_Y(X_0)\) and \(W_Z(X_0)\) should have \(C^1\) continuity, whereas interpolations for deformation \(W_X(X_0)\) and angle \(\theta _X(X_0)\) still use \(C^0\) interpolation. Then the deformation \({\varvec{W}_\mathrm{{f}}}(X_0)\) of cross section at \(X_0\) is approximated by interpolation of node deformation as

where shape function \({\varvec{N}_\mathrm{{E}} }(\xi ) = \left[ {\begin{array}{cc} {{\varvec{N}_{\mathrm{{E}} i}}(\xi )}&{{\varvec{N}_{\mathrm{{E}} j}}(\xi )} \end{array}} \right] \), \({\varvec{N}_{\mathrm{{E}} i}}(\xi ) = \left[ {\begin{array}{cccccc} {{N_{1\mathrm{{E}} i}}}&{}0&{}0&{}0&{}0&{}0\\ 0&{}{{N_{2\mathrm{{E}} i}}}&{}0&{}0&{}0&{}{{N_{3\mathrm{{E}} i}}}\\ 0&{}0&{}{{N_{2\mathrm{{E}} i}}}&{}0&{}{ - {N_{3\mathrm{{E}} i}}}&{}0\\ 0&{}0&{}0&{}{{N_{1\mathrm{{E}} i}}}&{}0&{}0\\ 0&{}0&{}{ - {N_{4\mathrm{{E}} i}}}&{}0&{}{{N_{5\mathrm{{E}} i}}}&{}0\\ 0&{}{{N_{4\mathrm{{E}} i}}}&{}0&{}0&{}0&{}{{N_{5\mathrm{{E}} i}}} \end{array}} \right] \), \({\varvec{N}_{\mathrm{{E}} j}}(\xi ) = \left[ {\begin{array}{cccccc} {{N_{1\mathrm{{E}} j}}}&{}0&{}0&{}0&{}0&{}0\\ 0&{}{{N_{2\mathrm{{E}} j}}}&{}0&{}0&{}0&{}{{N_{3\mathrm{{E}} j}}}\\ 0&{}0&{}{{N_{2\mathrm{{E}} j}}}&{}0&{}{ - {N_{3\mathrm{{E}} j}}}&{}0\\ 0&{}0&{}0&{}{{N_{1\mathrm{{E}} j}}}&{}0&{}0\\ 0&{}0&{}{ - {N_{4\mathrm{{E}} j}}}&{}0&{}{{N_{5\mathrm{{E}} j}}}&{}0\\ 0&{}{{N_{4\mathrm{{E}} j}}}&{}0&{}0&{}0&{}{{N_{5\mathrm{{E}} j}}} \end{array}} \right] \), \({N_{1\mathrm{{E}} i}} = 1 - \xi \), \({N_{1\mathrm{{E}} j}} = \xi \), \({N_{2\mathrm{{E}} i}} = 1 - 3{\xi ^2} + 2{\xi ^3}\), \({N_{2\mathrm{{E}} j}} = 3{\xi ^2} - 2{\xi ^3}\), \({N_{3\mathrm{{E}} i}} = {l_e} \cdot (\xi - 2{\xi ^2} + {\xi ^3})\), \({N_{3\mathrm{{E}} j}} = {l_e} \cdot ({\xi ^3} - {\xi ^2})\), \({N_{4\mathrm{{E}} i}} = ( - 6\xi + 6{\xi ^2})/{l_e}\), \({N_{4\mathrm{{E}} j}} = (6\xi - 6{\xi ^2})/{l_e}\), \({N_{5\mathrm{{E}} i}} = 1 - 4\xi + 3{\xi ^2}\), \({N_{5\mathrm{{E}} j}} = 3{\xi ^2} - 2\xi \), \(0\le \xi \le 1\), \(l_e\) is element length, element elastic coordinate vector \({\varvec{W}_{\mathrm{{f}}e}} = {\left[ {\begin{array}{cc} {{\varvec{W}_{\mathrm{{f}}ei}}}&{{\varvec{W}_{\mathrm{{f}}ej}}} \end{array}} \right] ^\mathrm{{T}}}\), \(\varvec{W}_{\mathrm{{f}}ei}\) and \(\varvec{W}_{\mathrm{{f}}ej}\) are the relative coordinate vector of the deformation for the two nodes i and j.

According to above deformation expression, the total displacement vector \(\varvec{u}\) of point \(\varvec{X}_0\) is measured in \(o-xyz\) and calculated similar to FFRF, and the corresponding velocity is given by

where matrix \({\varvec{N}_\mathrm{{r}}}({\varvec{X}})\) is the same as Eq. (10), matrix \({\varvec{N}_\mathrm{{f}}}({\varvec{X}_0}) = {\varvec{N}_\mathrm{{c}}}({\varvec{X}_0}) \cdot {\varvec{N}_\mathrm{{E}} }(\xi )\).

According to the velocity, the element kinetic energy \(T_e\) is calculated by

where element coordinate \({\varvec{q}_e} = {\left[ {\begin{array}{cc} {{\varvec{q}_\mathrm{{r}}}{}}&{{\varvec{W}_{\mathrm{{f}}e}}} \end{array}} \right] ^\mathrm{{T}}}\), the element mass matrix \({\varvec{M}_e} = \left[ {\begin{array}{cc} {{\varvec{M}_{\mathrm{{rr}}e}}}&{}{{\varvec{M}_{\mathrm{{rf}}e}}}\\ {\varvec{M}_{\mathrm{{rf}}e}^\mathrm{{T}}}&{}{{\varvec{M}_{\mathrm{{ff}}e}}} \end{array}} \right] \), \({\varvec{M}_{\mathrm{{rr}}e}} = \int _v {\rho \cdot \varvec{N}_\mathrm{{r}}^\mathrm{{T}}({\varvec{X}}) \cdot {\varvec{N}_\mathrm{{r}}}(\varvec{X} )\mathrm{{d}}v}\), \({\varvec{M}_{\mathrm{{rf}}e}} = \int _v \rho \cdot \varvec{N}_\mathrm{{r}}^\mathrm{{T}}({\varvec{X}}) \cdot \varvec{A} \cdot \varvec{N}_\mathrm{{f}}(\varvec{X}_0 )\mathrm{{d}}v\), \({\varvec{M}_{\mathrm{{ff}}e}} = \int _v {\rho \cdot {\varvec{N}_\mathrm{{f}}^\mathrm{{T}}}(\varvec{X}_0 ) \cdot \varvec{N}_\mathrm{{f}}(\varvec{X}_0 )\mathrm{{d}}v}\).

Mass matrices \(\varvec{M}_{\mathrm{{rr}}e}\) and \(\varvec{M}_{\mathrm{{rf}}e}\) can also be calculated by inertia shape integrals method [7, 12], and the relevant formulas are shown in “Appendix.”

The deformation in Eq. (36) is also adopted to calculate linear strain of three-dimensional beam. There are three nonzero strains \(\varepsilon _{X}\), \(\gamma _{XY}\) and \(\gamma _{XZ}\), and the strain vector \(\varvec{\varepsilon } = {\left[ {\begin{array}{ccc} {{\varepsilon _X}}&{{\gamma _{XY}}}&{{\gamma _{XZ}}} \end{array}} \right] ^\mathrm{{T}}}\) of point \(\varvec{X}_0\) is linearly related to element elastic coordinate as follows [21]

where matrix \({\varvec{L}_1} = \left[ {\begin{array}{cccc} 1&{}{ - {Z_0}}&{}{ - {Y_0}}&{}0\\ 0&{}0&{}0&{}{ - {Z_0}}\\ 0&{}0&{}0&{}{{Y_0}} \end{array}} \right] \), differential operator \({\varvec{L}_2} = \left[ {\begin{array}{cccccc} {\frac{\mathrm{{d}}}{{\mathrm{{d}}X}}}&{}0&{}0&{}0&{}0&{}0\\ 0&{}0&{}{\frac{{{\mathrm{{d}}^2}}}{{\mathrm{{d}}{X^2}}}}&{}0&{}0&{}0\\ 0&{}{\frac{{{\mathrm{{d}}^2}}}{{\mathrm{{d}}{X^2}}}}&{}0&{}0&{}0&{}0\\ 0&{}0&{}0&{}{\frac{\mathrm{{d}}}{{\mathrm{{d}}X}}}&{}0&{}0 \end{array}} \right] \), \(\varvec{B}_\mathrm{{L}}\) is linear strain matrix.

With the above nonzero strains, the beam is treated as orthotropic linear elastic material to calculate stress \({\sigma _X}\), \({\tau _{XY}}\) and \({\tau _{XZ}}\) [21]. The element elastic potential energy \(V_e\) is calculated as

where \(\textrm{E}\) is elastic modulus, \(\textrm{G}\) is shear moduli, element stiffness matrix \({\varvec{K}_{\mathrm{{L}}e}} = {l_e} \cdot \int _0^1 \varvec{N}_\mathrm{{E}}^\mathrm{{T}}(\xi ) \cdot \varvec{L}_2^\mathrm{{T}} \cdot \mathbf{{E}} \cdot {\varvec{L}_2} \cdot {\varvec{N}_\mathrm{{E}}}(\xi )\mathrm{{d}}\xi \), cross-section stiffness \(\mathbf{{E}} = \left[ {\begin{array}{cccc} {\mathrm{{E}} \cdot A}&{}{ - \mathrm{{E}} \cdot {S_Y}}&{}{ - \mathrm{{E}} \cdot {S_Z}}&{}0\\ { - \mathrm{{E}} \cdot {S_Y}}&{}{\mathrm{{E}} \cdot {I_Y}}&{}{\mathrm{{E}} \cdot {I_{YZ}}}&{}0\\ { - \mathrm{{E}} \cdot {S_Z}}&{}{\mathrm{{E}} \cdot {I_{YZ}}}&{}{\mathrm{{E}} \cdot {I_Z}}&{}0\\ 0&{}0&{}0&{}{\mathrm{{G}} \cdot J_X} \end{array}} \right] \), A is the area of cross section, \({S_Y} = \int _A {{Z_0}\mathrm{{d}}A}\) and \({S_Z} = \int _A {{Y_0}\mathrm{{d}}A}\) are the first-order moments of cross section, \({I_Y} = \int _A {Z_0^2\mathrm{{d}}A}\) and \({I_Z} = \int _A {Y_0^2\mathrm{{d}}A}\) are the inertia moment of cross section, \({I_{YZ}} = \int _A {{Y_0} \cdot {Z_0}\mathrm{{d}}A}\) is the inertia product of cross section, \(J_X=I_Y+I_Z\) is the polar inertia moment of cross section.

As the same as in FFRF, the virtual work \(\delta W_e\) of damping force for the e-th element is calculated by

where terms related to \(\delta \varvec{A}\) are ignored, element damping matrix \({\varvec{D}_e} = \left[ {\begin{array}{c} {{\tilde{\varvec{A}}} \cdot {\varvec{D}_{\mathrm{{rf}}e}}}\\ {{\varvec{D}_{\mathrm{{ff}}e}}} \end{array}} \right] \), \({\varvec{D}_{\mathrm{{rf}}e}} = c \cdot \int _v \varvec{N}_\mathrm{{r}}^\mathrm{{T}}({\varvec{X}_0}) \cdot {\varvec{N}_\mathrm{{f}}}({\varvec{X}_0})\mathrm{{d}}v\), \({\varvec{D}_{\mathrm{{ff}}e}} = c / \rho \cdot {\varvec{M}_{\mathrm{{ff}}e}}\).

As for the virtual work \(\delta W_e\) of load intensity \(\varvec{F}_\mathrm{{e}} = {\left[ {\begin{array}{cccccc} {F_{\mathrm{{e}}X}}&{F_{\mathrm{{e}}Y}}&{F_{\mathrm{{e}}Z}}&{T_{\mathrm{{e}}X}}&{T_{\mathrm{{e}}Y}}&{T_{\mathrm{{e}}z}} \end{array}} \right] ^\mathrm{{T}}}\) on beam centerline, it is calculated on the basis of small deformation assumption and given by

where terms related to \(\delta \varvec{A}\) are ignored, \(\varvec{\varphi } = {\left[ {\begin{array}{ccc} 0&0&\varphi \end{array}} \right] ^\mathrm{{T}}}\), \(\varvec{\theta } = {\left[ {\begin{array}{ccc} {{\theta _X}}&{{\theta _Y}}&{{\theta _Z}} \end{array}} \right] ^\mathrm{{T}}}\), \({\varvec{R}_e} = \left[ {\begin{array}{c} {\begin{array}{cc} {\varvec{N}_\mathrm{{r}}^\mathrm{{T}}({\varvec{X}_0}) \cdot \varvec{A} \quad }&{}{{\varvec{R}_{e1}}} \end{array}}\\ {\varvec{N}_\mathrm{{E}}^\mathrm{{T}}(\xi )} \end{array}} \right] \), \({\varvec{R}_{e1}} = \left[ {\begin{array}{ccc} 0&{}0&{}{ - \sin \varphi }\\ 0&{}0&{}{\cos \varphi } \end{array}} \right] \),

According to the energy and virtual work, the generalized force can be obtained. Substituting them in the fundamental nonholonomic form of Lagrange’s equation, the system dynamic equation is given by

where system coordinate \(\varvec{q} = {\left[ {\begin{array}{cc} {\varvec{q}_\mathrm{{r}}^\mathrm{{T}}{}}&{\varvec{W}_{\mathrm{{fs}}}^\mathrm{{T}}} \end{array}} \right] ^\mathrm{{T}}}\), \(\varvec{W}_{\mathrm{{fs}}}\) is system elastic coordinate vector, derivative \(\dot{\varvec{M}}\) and partial derivative \(\frac{{\partial {T}}}{{\partial \varvec{q}}}\) for calculation of \(\varvec{Q}_v\) are shown in “Appendix,” damping force vector \({\varvec{Q}_\mathrm{{d}}} = \varvec{D} \cdot {\dot{\varvec{W}}_\mathrm{{fs}}}\), system elastic force vector \({\varvec{Q}_k} = {\varvec{K}_\mathrm{{L}}} \cdot {\varvec{W}_\mathrm{{fs}}}\).

3.2 The method of NEBB

The kinematic analysis approach of NEBB is the same as LEBB, and then the calculations for kinetic energy and damping force virtual work in NEBB are also the same as in LEBB. Difference between NEBB and LEBB lies in the calculation of strain, and then their calculation for elastic potential energy is also different. In NEBB, the nonzero strain vector \(\varvec{\varepsilon } = {\left[ {\begin{array}{ccc} {{\varepsilon _X}}&{{\gamma _{XY}}}&{{\gamma _{XZ}}} \end{array}} \right] ^\mathrm{{T}}}\) of point \(\varvec{X}_0\) is nonlinearly related to element elastic coordinate as follows

where linear strain matrix \(\varvec{B}_\mathrm{{L}}\) is the same as in Eq. (40), nonlinear strain matrix \({\varvec{B}_\mathrm{{N}}} = \left[ {\begin{array}{c} {\varvec{W}_{\mathrm{{f}}e}^\mathrm{{T}}}\\ \varvec{0} \end{array}} \right] \cdot \varvec{N}_\mathrm{{E}}^\mathrm{{T}}(\xi ) \cdot \varvec{L}_3^\mathrm{{T}}\cdot {\varvec{L}_3}\cdot {\varvec{N}_\mathrm{{E}}}(\xi )\), differential operator \({\varvec{L}_3} = \left[ {\begin{array}{cccccc} 0&{}{\frac{\mathrm{{d}}}{{\mathrm{{d}}X}}}&{}0&{}0&{}0&{}0\\ 0&{}0&{}{\frac{\mathrm{{d}}}{{\mathrm{{d}}X}}}&{}0&{}0&{}0 \end{array}} \right] \).

Through matrix transformation, the nonlinear strain matrix \(\varvec{B}_\mathrm{{N}}\) is transformed as

where \({\varvec{B}_{\mathrm{{N}}3}} = \left[ {\begin{array}{c} {{\varvec{B}_{\mathrm{{N}}1}}}\\ \varvec{0} \end{array}} \right] \cdot {\varvec{B}_{\mathrm{{N}}2}}\), \({\varvec{B}_{\mathrm{{N}}1}} = \left[ {\begin{array}{cccccccc} {\frac{{\partial {N_{2\mathrm{{E}}i}}}}{{\partial X}}}&{\frac{{\partial {N_{3\mathrm{{E}}i}}}}{{\partial X}}}&{\frac{{\partial {N_{2\mathrm{{E}}j}}}}{{\partial X}}}&{\frac{{\partial {N_{3\mathrm{{E}}j}}}}{{\partial X}}}&{\frac{{\partial {N_{2\mathrm{{E}}i}}}}{{\partial X}}}&{\frac{{\partial {N_{3\mathrm{{E}}i}}}}{{\partial X}}}&{\frac{{\partial {N_{2\mathrm{{E}}j}}}}{{\partial X}}}&{\frac{{\partial {N_{3\mathrm{{E}}j}}}}{{\partial X}}} \end{array}} \right] \), \({\varvec{B}_{\mathrm{{N}}2}} = \mathrm{{diag}}({\varvec{B}_{\mathrm{{N}}2i}},{\varvec{B}_{\mathrm{{N}}2i}},{\varvec{B}_{\mathrm{{N}}2j}},{\varvec{B}_{\mathrm{{N}}2j}})\), \({\varvec{B}_{\mathrm{{N}}2i}} = \left[ {\begin{array}{cccccc} {\frac{{\partial {N_{2\mathrm{{E}}i}}}}{{\partial X}}}&{}0&{}0&{}{ - \frac{{\partial {N_{3\mathrm{{E}}i}}}}{{\partial X}}}&{}{\frac{{\partial {N_{3\mathrm{{E}}i}}}}{{\partial X}}}&{}0\\ 0&{}{\frac{{\partial {N_{2\mathrm{{E}}i}}}}{{\partial X}}}&{}{ - \frac{{\partial {N_{2\mathrm{{E}}i}}}}{{\partial X}}}&{}0&{}0&{}{\frac{{\partial {N_{3\mathrm{{E}}i}}}}{{\partial X}}} \end{array}} \right] \), \({\varvec{B}_{\mathrm{{N}}2j}} = \left[ {\begin{array}{cccccc} {\frac{{\partial {N_{2\mathrm{{E}}j}}}}{{\partial X}}}&{}0&{}0&{}{ - \frac{{\partial {N_{3\mathrm{{E}}j}}}}{{\partial X}}}&{}{\frac{{\partial {N_{3\mathrm{{E}}j}}}}{{\partial X}}}&{}0\\ 0&{}{\frac{{\partial {N_{2\mathrm{{E}}j}}}}{{\partial X}}}&{}{ - \frac{{\partial {N_{2\mathrm{{E}}j}}}}{{\partial X}}}&{}0&{}0&{}{\frac{{\partial {N_{3\mathrm{{E}}j}}}}{{\partial X}}} \end{array}} \right] \), \(\varvec{W}_{\mathrm{{d}}e}\) is block-diagonal with each diagonal block equal to \({\varvec{W}_{\mathrm{{B}}e}} = \left[ {\begin{array}{c} {{\varvec{W}_{\mathrm{{B}}ei}}}\\ {{\varvec{W}_{\mathrm{{B}}ej}}} \end{array}} \right] \), \({\varvec{W}_{\mathrm{{B}}ei}} = \left[ {\begin{array}{cccccc} 0&{}{{W_{Yi}}}&{}{{W_{Zi}}}&{}0&{}0&{}0\\ 0&{}{{\theta _{Zi}}}&{}0&{}0&{}0&{}0\\ 0&{}0&{}{{\theta _{Yi}}}&{}0&{}0&{}0\\ 0&{}0&{}0&{}0&{}{{W_{Zi}}}&{}0\\ 0&{}0&{}0&{}0&{}0&{}{{W_{Yi}}}\\ 0&{}0&{}0&{}0&{}{{\theta _{Yi}}}&{}{{\theta _{Zi}}} \end{array}} \right] \), \({\varvec{W}_{\mathrm{{B}}ej}} = \left[ {\begin{array}{cccccc} 0&{}{{W_{Yj}}}&{}{{W_{Zj}}}&{}0&{}0&{}0\\ 0&{}{{\theta _{Zj}}}&{}0&{}0&{}0&{}0\\ 0&{}0&{}{{\theta _{Yj}}}&{}0&{}0&{}0\\ 0&{}0&{}0&{}0&{}{{W_{Zj}}}&{}0\\ 0&{}0&{}0&{}0&{}0&{}{{W_{Yj}}}\\ 0&{}0&{}0&{}0&{}{{\theta _{Yj}}}&{}{{\theta _{Zj}}} \end{array}} \right] \).

The variation of nonlinear strain \(\delta \varvec{\varepsilon }\) is as follows

According to the nonlinear strain, stresses \({\sigma _X}\), \({\tau _{XY}}\) and \({\tau _{XZ}}\) are calculated as the same as LEBB. The virtual work \(\delta V_e\) of elastic force for the e-th element is as follows

where nonlinear element stiffness matrix \({\varvec{K}_{\mathrm{{N}}e}} = {\varvec{K}_{\mathrm{{N}}1e}} \cdot {\varvec{W}_{\mathrm{{d}}e}} + \varvec{W}_{\mathrm{{d}}e}^\mathrm{{T}} \cdot {\varvec{K}_{\mathrm{{N}}2e}} + \varvec{W}_{\mathrm{{d}}e}^\mathrm{{T}} \cdot {\varvec{K}_{\mathrm{{N}}3e}} \cdot {\varvec{W}_{\mathrm{{d}}e}}\), matrices \(\varvec{K}_{\mathrm{{N}}1e}\), \(\varvec{K}_{\mathrm{{N}}2e}\) and \(\varvec{K}_{\mathrm{{N}}3e}\) are time-invariant, \({\varvec{K}_{\mathrm{{N}}1e}} = \frac{1}{2} \cdot {l_e} \cdot \int _0^1 { {\varvec{N}_\mathrm{{E}}^\mathrm{{T}}(\xi ) \cdot \varvec{L}_2^\mathrm{{T}} \cdot {\mathbf{{E}}_1} \cdot {\varvec{B}_{\mathrm{{N}}3}}} \mathrm{{d}}\xi }\), \({\mathbf{{E}}_1} = \left[ {\begin{array}{ccc} {\mathrm{{E}}A}&{}0&{}0\\ { - \mathrm{{E}}{S_Y}}&{}0&{}0\\ { - \mathrm{{E}}{S_Z}}&{}0&{}0\\ 0&{}{ - \mathrm{{G}}{S_Y}}&{}{\mathrm{{G}}{S_Z}} \end{array}} \right] \), \({\varvec{K}_{\mathrm{{N}}2e}} = {l_e} \cdot \int _0^1 \varvec{B}_{\mathrm{{N}}3}^\mathrm{{T}} \cdot \mathbf{{E}}_1^\mathrm{{T}} \cdot {\varvec{L}_2} \cdot {\varvec{N}_\mathrm{{E}}}(\xi ) \mathrm{{d}}\xi \), \({\varvec{K}_{\mathrm{{N}}3e}} = \frac{1}{2} \cdot {l_e} \cdot \int _0^1 {\varvec{B}_{\mathrm{{N}}3}^\mathrm{{T}} \cdot {\mathbf{{E}}_3} \cdot {\varvec{B}_{\mathrm{{N}}3}}} \mathrm{{d}}\xi \), \({\mathbf{{E}}_3} = \left[ {\begin{array}{ccc} {\mathrm{{E}}A}&{}0&{}0\\ 0&{}{\mathrm{{G}}A}&{}0\\ 0&{}0&{}{\mathrm{{G}}A} \end{array}} \right] \).

The system dynamic equation of NEBB is similar to LEBB, and the only difference is that system elastic force vector \({\varvec{Q}_k} = ({\varvec{K}_\mathrm{{L}}} + {\varvec{K}_\mathrm{{N}}}) \cdot {\varvec{W}_\mathrm{{fs}}}\) in NEBB.

3.3 The method of ANCF

Similar to TLF, the ANCF only establishes inertial frame which is expressed by \(o-xyz\): The Cartesian coordinate for point of reference configuration is measured in inertial frame as vector \(\varvec{x}_0 = \left[ {\begin{array}{ccc} x_0&y_0&z_0 \end{array}} \right] ^\mathrm{{T}}\), and the Cartesian coordinate for point of current configuration is measured in inertial frame as vector \(\varvec{x} = \left[ {\begin{array}{ccc} x&y&z \end{array}} \right] ^\mathrm{{T}}\).

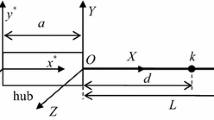

The main difference between ANCF and TLF lies in the displacement interpolation approach: Their element type, nodal coordinate and shape function are different. As shown in Fig. 2, coordinate \(\varvec{x}\) is one-to-one mapped to local coordinate \({\tilde{\varvec{X}}} = {\left[ {\begin{array}{ccc} {\tilde{X}}&{{\tilde{Y}}}&{{\tilde{Z}}} \end{array}} \right] ^\mathrm{{T}}}\), where \(\tilde{\varvec{X}}\) is local coordinate of a straight beam. Longitudinal coordinate \(\tilde{X}\) specifies different cross sections, and transverse coordinates \(\tilde{Y}\) and \(\tilde{Z}\) specify different points on cross section. The mapping from \(\varvec{x}\) to \({\tilde{\varvec{X}}}\) is given by

where \(\varvec{N}({\tilde{\varvec{X}}})\) is shape function, element coordinate vector \(\varvec{e} = {\left[ {\begin{array}{cc} {\varvec{e}_i^\mathrm{{T}}{}}&{\varvec{e}_j^\mathrm{{T}}} \end{array}} \right] ^\mathrm{{T}}}\), \(\varvec{e}_i\) and \(\varvec{e}_j\) are the nodal coordinate vector of nodes i and j.

The nodal coordinate vector simultaneously includes global position and gradient as follows

where \(g_{i,\alpha }\) is Pascal triangle polynomial about \(\tilde{Y}\) and \(\tilde{Z}\) [47], \(1 \le i \le (n + 1) \cdot (n + 2)/2\), the order \(\alpha \) of Pascal triangle satisfies \(0 \le \alpha \le n\), n is the order of the beam model and the beam model is called higher-order beam model if \(n>1\).

In order to prevent Poisson locking and hold high efficiency, the second order beam model of which \(n = 2\) is adopted [47]. Corresponding Pascal triangle polynomial is as follows

For positions and gradients only related to centerline, the interpolation polynomial is cubic in \(\tilde{X}\) direction; for gradients related to cross section, the interpolation polynomial is linear in \(\tilde{X}\) direction. Corresponding shape function \(\varvec{N}({\tilde{\varvec{X}}})\) is given by

where \({N_{1i}} = 1 - 3{\xi ^2} + 2{\xi ^3}\), \({N_{2i}} = {l_e} \cdot (\xi - 2{\xi ^2} + {\xi ^3})\), \({N_{3i}} = 1 - \xi \), \({N_{1j}} = 3{\xi ^2} - 2{\xi ^3}\), \({N_{2j}} = {l_e} \cdot ( - {\xi ^2} + {\xi ^3})\), \({N_{3j}} = \xi \), \(\xi = \tilde{X} / l_e\) and \(\xi \) linearly changes from 0 to 1 when centerline point moves from node i to j.

The total displacement vector \(\varvec{u} = \left[ {\begin{array}{ccc} {u_x}&{u_y}&{u_z} \end{array}} \right] ^\mathrm{{T}}\) of point \(\tilde{\varvec{X}}\) is then given by

where \(\varvec{e}_0\) is the initial value of \(\varvec{e}\).

According to total displacement in above equation, the virtual works of inertia force, elastic force and damping force are, respectively, calculated, in a similar way in Sect. 2.3. The resultant virtual work \(\delta T_e\) of inertia force for the e-th element is

where \({\varvec{M}_e} = \int _{v_0} {\rho _0 \cdot {\varvec{N}^\mathrm{{T}}}({\tilde{\varvec{X}}}) \cdot \varvec{N}({\tilde{\varvec{X}}})\mathrm{{d}}{v_0}}\).

The resultant virtual work \(\delta V_e\) of elastic force for the e-th element is

where \({\varvec{K}_{\mathrm{{L}}e}} = \int _{v_0} {\varvec{B}_\mathrm{{L}}^\mathrm{{T}} \cdot \mathbf{{E}} \cdot {\varvec{B}_\mathrm{{L}}}\mathrm{{d}}{v_0}}\), \({\varvec{K}_{\mathrm{{N}}e}} = {\varvec{K}_{\mathrm{{N}}1e}} \cdot {({\varvec{e}_\mathrm{{d}}} - {\varvec{e}_{\mathrm{{d}}0}})} + {({\varvec{e}_\mathrm{{d}}} - {\varvec{e}_{\mathrm{{d}}0}})^\mathrm{{T}}} \cdot {\varvec{K}_{\mathrm{{N}}2e}} + {({\varvec{e}_\mathrm{{d}}} - {\varvec{e}_{\mathrm{{d}}0}})^\mathrm{{T}}} \cdot {\varvec{K}_{\mathrm{{N}}3e}} \cdot {({\varvec{e}_\mathrm{{d}}} - {\varvec{e}_{\mathrm{{d}}0}})}\), \(\varvec{B}_\mathrm{{L}}\) is linear strain matrix as the same as Eq. (30), matrices \(\varvec{K}_{\mathrm{{N}}1e}\), \(\varvec{K}_{\mathrm{{N}}2e}\) and \(\varvec{K}_{\mathrm{{N}}3e}\) are time-invariant and the same as Eq. (33), matrix \(\varvec{B}_{\mathrm{{N}}5}\) for calculating \(\varvec{K}_{\mathrm{{N}}1e}\), \(\varvec{K}_{\mathrm{{N}}2e}\) and \(\varvec{K}_{\mathrm{{N}}3e}\) is the same as Eq. (31) where \(m = 2 + (n + 1) \cdot (n + 2)\), \(\varvec{e}_\mathrm{{d}}\) is block-diagonal with each diagonal block equal to \({\varvec{e}_\mathrm{{B}}} = \left[ {\begin{array}{ccc} {{e_1}}&{}{{e_2}}&{}{{e_3}}\\ {{e_4}}&{}{{e_5}}&{}{{e_6}}\\ \vdots &{} \vdots &{} \vdots \\ {{e_{3m-2}}}&{}{{e_{3m-1}}}&{}{{e_{3m}}} \end{array}} \right] \), \(e_k\) is the component in the k-th row of vector \(\varvec{e}\), \(\varvec{e}_{\mathrm{{d}}0}\) is the initial value of \(\varvec{e}_\mathrm{{d}}\).

In a similar way to TLF, the above equation provides a procedure to compute elastic force of element. Under \(m=14\) and \(n_\mathrm{{m}} = 5 \cdot 3 \cdot 3\), the numbers of arithmetic operations are, respectively, 117040 and 32400 for the presented procedure and the procedure in section 4.9 of [8]. The reason for adopting the presented procedure is the same as TLF.

The resultant virtual work \(\delta V_e\) of damping force for the e-th element is

where element damping matrix \({\varvec{D}_e} = c / \rho \cdot {\varvec{M}_e}\), \(\varvec{e}_\mathrm{{r}}\) is element coordinate vector under only rigid rotation.

According to the virtual work statement, the system dynamic equation of ANCF is given by

where \(\varvec{e}_\mathrm{{s}}\) is system coordinate vector, damping force vector \({\varvec{Q}_\mathrm{{d}}} = \varvec{D} \cdot \left[ {{\varvec{A}_\mathrm{{d}}} \cdot {\dot{\varvec{A}}}_\mathrm{{d}}^\mathrm{{T}} \cdot ({\varvec{e}_\mathrm{{s}}} - {\varvec{e}_{\mathrm{{rs}}}}) + ({{\dot{\varvec{e}}}_\mathrm{{s}}} - {{\dot{\varvec{e}}}_{\mathrm{{rs}}}})} \right] \), \(\varvec{e}_{\mathrm{{rs}}}\) is system coordinate vector under only rigid rotation, system elastic force vector \({\varvec{Q}_k} = ({\varvec{K}_\mathrm{{L}}} + {\varvec{K}_\mathrm{{N}}}) \cdot ({\varvec{e}_\mathrm{{s}}} - {\varvec{e}_{\mathrm{{s}}0}})\), nonlinear system stiffness matrix \({\varvec{K}_\mathrm{{N}}} = {\varvec{K}_{\mathrm{{N}}1}} \cdot {({\varvec{e}_\mathrm{{ds}}} - {\varvec{e}_{\mathrm{{ds}}0}})} + {({\varvec{e}_\mathrm{{ds}}} - {\varvec{e}_{\mathrm{{ds}}0}})^\mathrm{{T}}} \cdot {\varvec{K}_{\mathrm{{N}}2}} + {({\varvec{e}_\mathrm{{ds}}} - {\varvec{e}_{\mathrm{{ds}}0}})^\mathrm{{T}}} \cdot {\varvec{K}_{\mathrm{{N}}3}} \cdot {({\varvec{e}_\mathrm{{ds}}} - {\varvec{e}_{\mathrm{{ds}}0}})}\), \(\varvec{K}_{\mathrm{{N}}1}\), \(\varvec{K}_{\mathrm{{N}}2}\), \(\varvec{K}_{\mathrm{{N}}3}\), \(\varvec{e}_{\mathrm{{ds}}}\) and \(\varvec{e}_{\mathrm{{ds}}0}\) are obtained by element assembly.

In the above equation, matrices \(\varvec{K}_{\mathrm{{N}}1}\), \(\varvec{K}_{\mathrm{{N}}2}\) and \(\varvec{K}_{\mathrm{{N}}3}\) are time-invariant, so they are also called system invariant matrix. Once these matrices are obtained by element integration and assembly before solving system dynamic equation, they can be reused in every time step. Theoretically, system invariant matrix holds higher efficiency in comparison with element invariant matrix [49]. In every time step, the element invariant matrix method needs to calculate every component of element stiffness matrix at first; assembly from element to system is needed at next.

4 Numerical examples

This section takes a variable cross-section beam as numerical example, and its geometry is shown in Fig. 3a. The length of the beam is \(l=1\textrm{m}\), and the rectangular cross section linearly shrinks and rotates from left end to right end. The width and height of left end rectangle are \(l_\mathrm{{W}1}=0.06\textrm{m}\) and \(l_\mathrm{{H}1}=0.12\textrm{m}\), the width and height of right end rectangle are \(l_\mathrm{{W}2}=0.04\textrm{m}\) and \(l_\mathrm{{H}2}=0.08\textrm{m}\), and the rotation angle of right end rectangle relative to left end rectangle is \(\gamma =45^\circ \). The frame origin O locates at the center of the left end rectangle and the left end rectangle keeps rigid during rotation. As for material parameter, the elastic modulus is \(210\textrm{GPa}\), the Poisson’s ratio is 0.28, and the density is \(7.85 \times 10^3 \textrm{kg}\cdot \mathrm{{m}}^{-3}\). As for load, the centerline load intensity along z direction is \(-8\textrm{kN} \cdot \mathrm {m^{-1}}\); in order to avoid impact, the load intensity is linearly increased from \(0\textrm{kN} \cdot \mathrm {m^{-1}}\) to \(-8\textrm{kN} \cdot \mathrm {m^{-1}}\) by \(300{\upmu \textrm{s}}\). As for component mode synthesis, the number of eigenmodes for FFRF is 30, and the number of global eigenmodes for GCMS is 90. In all the following numerical calculations, these geometric, material, load and mode parameters keep unchanged.

There are three values for rotational speed: \({\dot{\varphi }}_1 = 1.0 \times 10^3 \textrm{rpm}\), \({\dot{\varphi }}_2 = 5.0 \times 10^3 \textrm{rpm}\), \({\dot{\varphi }}_3 = 1.0 \times 10^4 \textrm{rpm}\). There are three values for damping coefficient: \(c_1 = 1.0 \times 10^2 \textrm{kg}\cdot \textrm{s}^{-1}\cdot \textrm{m}^{-3}\), \(c_2 = 5.0 \times 10^2 \textrm{kg}\cdot \textrm{s}^{-1}\cdot \textrm{m}^{-3}\), \(c_3 = 1.0 \times 10^3 \textrm{kg}\cdot \textrm{s}^{-1}\cdot \textrm{m}^{-3}\). In the following calculations, these two parameters are changeable and only their symbols are used to refer to them.

For FFRF, GCMS and TLF, the number of solid elements is \(100 \times 6 \times 12\) as shown in Fig. 3b; for LEBB, NEBB and ANCF, the number of beam elements is 10. Numerical result shows these selected grid sizes are feasible for accuracy and efficiency. As for the solver of system dynamics differential equation, two solvers are adopted: Adams-Bashforth two-step method (AB) [58] for FFRF, GCMS, LEBB and NEBB, central difference method (CD) [59] for TLF and ANCF. These two solvers are explicit and convenient to implement, the AB is strongly stable [58], and the CD is conditionally stable [8, 31]. The time step sizes are \(0.5{\upmu \textrm{s}}\), \(0.3{\upmu \textrm{s}}\), \(0.5{\upmu \textrm{s}}\), \(0.4{\upmu \textrm{s}}\), \(0.4{\upmu \textrm{s}}\) and \(1.7{\upmu \textrm{s}}\) for FFRF-AB, GCMS-AB, TLF-CD, LEBB-AB, NEBB-AB and ANCF-CD, respectively. To confirm availability of the selected time step sizes, the following gives numerical result comparison under different time step sizes. Without clear indication, the collocations of grid size, solver and time step size are adopted for following calculations by default.

4.1 Results under different rotational speeds

This section compares the numerical results under different finite element methods and rotational speeds. Because the solver and time step size are different for different finite element methods, this section will not compare the efficiency of different methods. Under rotational speed \({\dot{\varphi }}_1\) and damping coefficient \(c_3\), the free end deflections obtained by different finite element methods are shown in Fig. 4. The longitudinal deflection means deflection along undeformed centerline direction, and the orthogonal transverse deflection means deflection orthogonal to both centerline and load direction. For all finite element methods, the value of deflection gradually goes convergent along with the increase of time. Before convergence, the oscillation of longitudinal deflection is much obvious than the other two deflections, and the reason is that larger tension stiffness requires larger critical damping than smaller bending stiffness. Although there is no load along the direction orthogonal to both centerline and load direction, the orthogonal transverse deflection is not zero, the reason is that nonzero cross-section rotation angle \(\gamma \) causes nonzero inertia product \(I_{YZ}\).

The FFRF-AB, GCMS-AB and LEBB-AB are linear method which holds linear form of strain–displacement equation, the TLF-CD, NEBB-AB and ANCF-CD are nonlinear method which holds nonlinear form of strain–displacement equation. From Fig. 4, the results of linear methods are close to each other, the results of nonlinear methods are close to each other, whereas the results of linear methods are different from nonlinear methods. Convergent deflections of the six methods are shown in Table 1. From the table, the results of FFRF-AB and GCMS-AB are almost the same, and the result difference rate of LEBB-AB relative to FFRF-AB is less than \(1.5\%\). The result difference rate of NEBB-AB relative to TLF-CD is less than \(1.3\%\), and the three result difference rates of ANCF-CD relative to TLF-CD are \(1.7\%\), \(4.0\%\) and \(1.5\%\). The difference rate for orthogonal transverse deflection of ANCF-CD relative to TLF-CD is a little large; however, when the number of beam elements for ANCF-CD increases to 20, this difference rate does not decrease. Due to the influence of geometric nonlinearity or dynamic stiffening, the three deflections of nonlinear methods are all smaller than corresponding deflections of linear methods; for example, the orthogonal transverse deflection of TLF-CD is \(12.7\%\) smaller than FFRF-AB, and the transverse deflection along z axis of TLF-CD is \(8.9\%\) smaller than FFRF-AB.

To confirm the availability of selected time step sizes, the orthogonal transverse deflections under different time step sizes are shown in Fig. 5, with rotational speed \({\dot{\varphi }}_1\) and damping coefficient \(c_3\). In the figure, the time step size equal to half of selected value is adopted, the time step size slightly larger than selected value is also adopted. From the figure, when the time step size reduces by half, the numerical result is still close to that under selected value; when the time step size is unsuitably large, the numerical result becomes infinite or apparently different from that under selected value. For example, the numerical results of FFRF-AB under \(0.5{\upmu \textrm{s}}\) and \(0.25{\upmu \textrm{s}}\) are close to each other, whereas the numerical result of FFRF-AB under \(0.6{\upmu \textrm{s}}\) goes numerically infinite. For calculations in this work, the selected time step size \(\mathrm{{\Delta }} t\) satisfies: if the numerical result is convergent under time step size \(\mathrm{{\Delta }} t\), then the result under \(\mathrm{{\Delta }} t / 2\) is also convergent and close to result under \(\mathrm{{\Delta }} t\); if the numerical result is divergent under time step size \(\mathrm{{\Delta }} t\), then the result under \(\mathrm{{\Delta }} t / 10\) is also divergent. Comparing the six methods, the selected time step size of ANCF-CD is the largest. Mathematically, the optimal time step size is subject to eigenvalues of the generalized amplification matrix [8].