Abstract

The article presents a structure of the algorithm and mathematical and software systems. The general characteristics of the algorithm for determining heat losses in the hearth of a blast furnace based on the use of the heat balance of the lower zone are presented. External heat losses in the process of melting occurring through the tuyere belt, barrel, and bosh, are determined by the difference between the input and output components of the zonal heat balance for the lower part of heat transfer. The determination of heat losses by the heat balance in the lower heat transfer part allows their value to be estimated according to the current information about the operation of the furnace under specific raw materials and operating parameters. The information support of the system is presented, the software architecture is described, the characteristics of the software modules are given, and fragments of its work are illustrated. The information modeling system is distinguished by taking into account the basic physical and chemical laws of the processes of the control object, the principles of system analysis, and the use of modern principles for the development and construction of mathematical models and software. Heat loss control is necessary to assess the condition of the blast furnace refractory lining and rational gas distribution, as well as to adjust the coke rate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Control of heat losses during blast furnace melting is considered the third most crucial means to control and automate the blast-furnace process, following the control of the charge and quality of iron ore raw materials and coke, as well as the processing technology of smelting products [1,2,3,4,5,6,7]. Heat losses vary over the course of the blast furnace (BF) operation due to factors such as flame erosion of the lining, the formation of scull with the potential for its destruction, and the development of either peripheral or axial gas streams. For example, in Japan, in order to conserve coke, the excessive development of the peripheral gas stream is controlled and eliminated using heat removal data from barrel and bosh refrigerators [8].

The main heat losses occur in the lower part of the blast furnace, which determines its performance, while their magnitude depends on the specific design and operating parameters of the furnace [5,6,7,8,9,10,11,12,13]. During melting, external heat losses occurring through the tuyere belt, barrel, and bosh, are determined as the difference between the input and output components of the zonal heat balance for the lower heat exchange part [14,15,16]. A block for calculating the heat balance of the lower heat transfer part included in the mathematical model of the UrFU-MMK [17, 18] blast furnace process allows the input and output heat balance components to be identified based on the current data of the melting process and the calculation results to be analyzed, along with forecasting a decrease in coke rate when varying the parameters of the BF operation. Through the analysis of the heat balance of the lower heat transfer part, it is possible to determine the heat losses in this zone of the furnace and evaluate correction coefficients when blast furnace conditions are varied, such as the composition of cast iron, blast temperature, humidity, removal or addition of various additives into the loaded charge, as well as changes in heat losses during blast furnace melting.

During the development of an information-modeling system for monitoring heat losses in the hearth of a blast furnace, the following steps are implemented:

-

functional modeling of the system and development of architecture, mathematical, and information support to the system;

-

selection of technology and software development and implementation of the design module;

-

implementation of the web application for the system;

-

debugging and testing of the software.

The methodology used in the design of the system is based on the principles of structural analysis and design of IDEFO [19]. The functional model developed using the Ramus software [20] contains 35 blocks at four levels of decomposition. This model defines the main functions and relationships between individual functional blocks in the system, control actions, and mechanisms for performing each function.

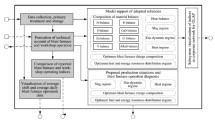

The algorithm for calculating heat losses in the lower part of the blast furnace is shown in Fig. 1.

The input components of the heat balance are as follows.

-

1.

Amount of heat released during the combustion of coke carbon fed to the tuyere zones.

-

2.

Amount of heat introduced into the furnace by heated blast.

-

3.

Amount of heat produced by the conversion of natural gas.

-

4.

Amount of heat generated during slag formation. The calculation of this component is carried out only for the case of loading “raw” limestone into the furnace.

-

5.

Amount of heat introduced into the lower zone of the furnace by heated charge materials. When calculating this component of heat input, the rates of charge materials, their heat capacity, and the temperature of the standby zone are taken into account.

The output components of the heat balance are as follows.

-

1.

Heat consumption for direct reduction of iron oxides.

-

2.

Heat consumption for direct reduction of cast iron impurities ([Si], [Mn], [P]) and desulfurization of cast iron.

-

3.

Heat consumption to compensate for the reduction of iron oxides with hydrogen.

-

4.

Heat removal by cast iron.

-

5.

Heat removal by slag.

-

6.

Heat removal by gas from the lower heat exchange part.

-

7.

Heat consumption for decomposition of blast moisture.

-

8.

External heat losses during melting determined as the difference between the input and output components of the zonal heat balance for the lower heat exchange part.

Calculation of correction coefficients for factor analysis

The calculation of the heat balance of the lower heat transfer part allows the savings in coke to be determined, which can be achieved by varying the heat consumption for any given process. To do this, the heat transfer from coke carbon is determined based on the established blast smelting parameters, while the variation in the coke rate is determined by the known heat consumption of any given process:

-

an increase in blast temperature by 10 °C;

-

reduction of silicon content in cast iron by 0.1%;

-

reduction of manganese content in cast iron by 0.1%;

-

reduction of the degree of direct reduction of iron by 1%;

-

removal of 10 kg/(t of cast iron) of limestone from the charge;

-

removal of 10 kg/(t of cast iron) of quartzite from the charge;

-

reduction of heat losses by 1%;

-

an increase in the CO2 content in the blast furnace gas by 1%.

The software for the information-modeling system to monitor heat losses in the lower part of the blast furnace is a cross-platform web application developed using the C# programming language. This application is built on the software platform .NET 6 with the help of Core MVC framework and Entity Framework [21]. The web application, having a three-level architecture, consists of a presentation level (client), a model level (application server), and a database level. SQL Server is used as a database management system (DBMS). The architecture of the developed software in C4 notation is shown in Fig. 2.

The software includes two containers: a console application and a web application. The console application, which runs on a schedule, is designed to gather data on various parameters of the technological process (such as blast characteristics, composition and properties of charge materials, and composition and properties of liquid melting products) from the database server of the control center of the factory automation control system (CC FACS). The obtained and calculated parameters averaged by days, weeks, and months are stored in the system database.

The web application includes the following main functions: selection of the period and visualization of the blast furnace operation parameters within the selected period; visualization of the calculation of the total heat balance and heat balance in the lower part of the furnace; calculation of the coefficients for factor analysis to assess variations in coke rate when certain process parameters are adjusted.

The visualization component for the blast furnace operation parameters during the reference period allows the variations in user-specified DCS parameters to be reviewed for the selected blast furnace and a specified period. The information is displayed in tabular form. A fragment of the web page of this feature is shown in Fig. 3.

The calculation of the total heat balance and heat balance in the lower part of the furnace, as well as the computation of correction coefficients for factor analysis, are carried out based on the operating parameters specified by the user for the selected period, which include blast characteristics, composition, and properties of charge materials, as well as the composition of liquid melting products.

A fragment of a web page visualizing the calculation of heat balance in the BF lower part is shown in Fig. 4. For user convenience, the calculation results can be printed directly from the browser.

Therefore, the developed software for the information-modeling system to monitor heat losses in the blast furnace offers:

-

calculation of heat losses in the lower part of the blast furnace, input and output components of the heat balance, as well as a set of intermediate indicators for any selected operation period of the blast furnace;

-

numerical and graphical display of calculation results;

-

storage (removal) of source datasets in a database;

-

printout of the results using browser functions.

Conclusion

-

1.

By using advanced methodology, computer technologies, and software, the software for the control system of heat losses in the hearth of a blast furnace was developed to estimate their value based on the current data on the furnace operation in terms of specific raw materials and mode parameters.

-

2.

The information-modeling system takes into account the basic physicochemical principles of the main processes occurring in the control object, as well as the principles of system analysis. In addition, it involves modern principles for developing and constructing mathematical models and software.

References

Tovarovsky IG (2009) Blast-furnace smelting. Porogi, Dnepropetrovsk

Bolshakov VI, Borodulin AV, Listopadov VS, Chaika AL, Sokhatskii AA, Shvachka AI (2014) Control of the total heat losses with cooling water on blast furnaces and their practical application. In: The creative heritage of V.E. Grum-Grzhimailo: History, Current state, Future. The collection of the International Scientific and Practical conference dedicated to the 150th anniversary of the great Russian scientist-metallurgist V.E. Grum-Grzhimailo. MiSIS, Moscow, pp 96–103

Ramm AN (1980) Advanced blast-furnace process. Metallurgiya, Moscow

Gotlib AD (1966) Blast-furnace process. Metallurgiya, Moscow

Borodulin AV, Gorbunov AD, Romanenko VI, Sushchev SP (2006) Blast furnace in energy dimension. DSTU, Dneprodzerzhinsk

Bolshakov VI, Borodulin AV, Gladkov NA et al (2004) Krivorozhstal Blast Furnace Production. Joint venture “Mir”, Krivoy Rog, Izd

Bolshakov VI (2007) Technology of high-performance energy-saving blast furnace smelting. Naukova Dumka, Kiev

Kurunov IF (2015) Current state of blast furnace production in China, Japan, South Korea, Western Europe, North, and South America. Metallurg 7:12–22 (https://elibrary.ru/item.asp?id = 23930117.)

Che Y, Wang L, Chen L (2021) Regression analysis of the heat balance thickness of a blast furnace hearth lining. J Physics: Conf Ser 1985(1)

Huang D, Andrade M, Pergi P, Caplick C, Everitt W, Storm L (2020) The effects of heat loss of blast furnace on its coke rate. Aistech—iron Steel Technol Conf Proc 1:329–339. https://doi.org/10.33313/380/038

Chaika AL, Lebed’ VV, Tsyupa KS, Shostak VY, KorniIov BV, Zherebetskii AA, Sokhatskii AA (2019) Heat losses in the cooling system and consumption of coke to compensate for them in blast furnaces of various volumes. Metallurgist 63(3/4):223–227. https://doi.org/10.1007/s11015-019-00815-w

Andreev VI, Pozdnyakov AV, Kurbatov Mishin Pikalov YLIVDS (2015) Investigation of heat losses in a blast furnace with oxy-coal injection. Metallurg 59(1):16–24. https://doi.org/10.1007/s11015-015-0056-y

Novikov VS, Babarykin NN, Marsuversky BA et al (1972) Use of highly basic agglomerate and non-fluxed pellets in blast furnace smelting. Chern Met 3:1–14

Kitaev BI, Yaroshenko YG, Sukhanov EL, Ovchinnikov YN, Shvydkiy VS (1978) Heat engineering of blast furnace process. Metallurgiya, Moscow

Filatov SV, Lozovich AV, Titov VN, Zagainov SA, Kurunov IF (2017) Performance analysis of blast furnaces at high melting intensity. Metallurg 10:18–21 (https://elibrary.ru/item.asp?id=30462975)

Honorin OP, Spirin NA, Terentyev VL et al (2005) Computer modeling for blast furnace process. In: Spirin NA (ed) USTU-UPI, Ekaterinburg

Spirin NA, Lavrov VV, Rybolovlev VY, Krasnobaev AV, Pavlov AV (2016) Use of contemporary information technology for analyzing the blast furnace process. Metallurgist 60:471–477. https://doi.org/10.1007/s11015-016-0317-4

Onorin OP, Polinov AA, Pavlov AV, Spirin NA, Gurin IA (2018) About a possibility of using blast furnace heat balance to control heat losses. Metallurgist 62(3/4):218–224

Cheremnykh SV, Semenov IO, Ruchkin VS (2003) Structural analysis of systems. IDEF technologies. Financy I Statistika, Moscow

Popov AI (2004) Tools for designing information systems. Publishing and Printing Complex “Izdatel’stvo standartov, Moscow

Freeman A (2017) Pro ASP.NET Core MVC. Williams, Moscow

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 2, pp. 71–75, February 2024. Russian DOI: https://doi.org/10.52351/00260827_2024_2_71

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Spirin, N.A., Gurin, I.A., Lavrov, V.V. et al. Information-modeling system for monitoring heat losses in the lower part of a blast furnace. Metallurgist 68, 224–230 (2024). https://doi.org/10.1007/s11015-024-01721-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-024-01721-6