The paper presents a description of the information modeling system for the distribution of hot blast and natural gas through the tuyeres of a blast furnace. The developed system is distinguished by considering the main physical and chemical laws and ongoing processes in the control object. The system is based on the method of determining the blast flow through the air tuyeres using the thermal power of the flow passing through the tuyere and the value of the heat removal taken from this tuyere. Based on the calculation results, the system determines the main parameters of the blast mode of the blast furnace and the parameters of individual tuyere hearths, including the theoretical combustion temperature, the blast velocity from the tuyere, the kinetic energy of the blast, the length of the oxygen and carbon dioxide combustion zones of the tuyere hearth, and others. The required natural gas consumption through the blast furnace tuyeres is calculated, which ensures the maintenance of the theoretical combustion temperature in the blast furnace tuyeres at a given level in the design mode. The architecture of the software is described, the characteristics of the modules are presented, and its operation is illustrated. The developed software can be used by the technological personnel of the blast-furnace process to improve the efficiency of blast-furnace smelting.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

When operating a blast furnace (BF), the actual distribution of blast over tuyeres is not uniform; differences are observed in the blast consumption over individual tuyeres, which range from 5% to 50% [1,2,3,4,5,6]. The uneven distribution of the blast over the tuyeres leads to varying lengths of the tuyere hearths, which leads to differences in the burden descent in individual sectors of the furnace, while a deformed gas flow is formed over the cross- section. A distortion of the charge level on the furnace top is possible, as is a circumferential unevenness of the thermal and reduction work of the gas, as well as a difference in the gas temperature in certain peripheral sectors of the furnace [1,2,3,4,5,6,7,8]. The flow rate of natural gas is set for each tuyere, with an uncontrolled distribution of blast over tuyeres. Thus, the gas temperature in the tuyere chambers will be different, and maintaining the theoretical combustion temperature within optimal limits becomes impossible.

In Refs. [7, 8], the thermal engineering mode of operation of the cooled nozzle of a tuyere tool was analyzed. Results demonstrated that the nozzle head can be regarded as a type of calorimeter, and the amount of heat lost on this element determines the flow rate of the heated blast passing through the tuyere. The authors proposed an automated system for controlling the distribution of hot blast over tuyeres. They also issued recommendations for changing the flow rate of natural gas through air tuyeres, which ensures the minimum deviation of the theoretical combustion temperature in tuyere chambers from the specified one [8].

This paper uses a method for determining the blast flow rate for tuyeres based on the utilization of heat power of the flow passing through the tuyere and the value of its heat removal. In this case, the water consumption for tuyere cooling is recorded, logging the temperature of the water at the inlet and outlet of the tuyeres. When the blast passes through the tuyere, part of the heat flux is assumed to transfer to the water cooling for the tuyere; a high degree of heat flux indicates a high level of heat passage. The rationale for this method is presented in [9]. Moreover, this paper assumes that the designs of all air tuyeres installed on the furnace are the same, the wall thickness of all tuyeres is equal, and the heat transfer coefficients from the blast to the tuyere and from the tuyere to the cooling water are also constant. Thus, the coefficient of thermal conductivity of the walls of the tuyeres is also assumed to be constant.

In the implemented calculation algorithm, the tuyere diameter determines the blast outflow rate from the tuyere using its known blast flow rate and the established blast characteristics (temperature, pressure, humidity, oxygen content in the blast, and natural gas consumption at individual tuyeres). Therefore, the values of the blast kinetic energy and the length of the oxygen and carbon dioxide combustion zones of the tuyere hearth are also determined [10,11,12]. Calculating the theoretical combustion temperature in each tuyere hearth is possible using the known values of the blast characteristics. The proposed and implemented method based on calculations for each of the tuyeres helps determine the required consumption of injected fuel (natural gas) to maintain the theoretical combustion temperature at a given level and calculate a set of parameters for the tuyere hearth for the prognosis period.

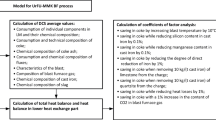

The methodology for system design is based on the ideas and notations of IDEF0 structural analysis and design methods [13]. An information-simulating system for controlling the distribution of hot blast and natural gas over the BF tuyeres has been developed using the capabilities of this methodology. The model developed using the Ramus software [14] contains more than 30 blocks at four levels of decomposition, defines the main functions and relationships between the individual functional blocks of the system, and controls actions and mechanisms for performing each function.

Figure 1 presents the level 1 decomposition of the functional model, which includes the following four blocks: preparation of the initial data, preliminary calculations, calculation of the distribution of hot blast and natural gas over the BF tuyeres, and analysis results.

The architecture of the developed information modeling system for the distribution of hot blast and natural gas through the BF tuyeres is presented in Fig. 2. The system has a modular architecture and includes the modules of data processing, calculation, and output and analysis of results. This approach facilitates the process of software testing and allows the development of modules of different types independently of each other.

The data processing module is designed to read information regarding the BF structural dimensions and the values of the controlled parameters required for calculations from the blast-furnace shop automated control system database for a user-specified period of time. The authorized user has the possibility to correct the groups of data for each of the tuyeres, namely, the state of the tuyeres (open or closed), consumption and temperature difference of water during the passage of the tuyere, and consumption of natural gas. The same module provides for the possibility of adjusting the set values of theoretical combustion temperatures in each tuyere hearth.

The calculation module comprises the following four blocks: determination of hot blast flow rates at individual tuyeres; calculation of the required flow rates of natural gas on these tuyeres to maintain the theoretical combustion temperature at a given level; calculation of the parameters of tuyere centers; calculation of the relative area of tuyere hearths to the area of the hearth. The modeling is based on the balance model of the UrFU- MMK BF [10,11,12].

The analysis module includes the diagnostics of the obtained solution and the issuance of recommendations for adjusting the consumption of natural gas at individual BF tuyeres.

The results output module is designed to prepare data from the calculation and analysis modules, which are displayed on the user interface.

The software represents a web application developed in the C# programming language based on the ASP.NET Core MVC framework using the .NET 6 software platform [15]. The SQL Server database management system was chosen as the database for the developed system.

A set of parameters is determined for two periods, namely base and design, using the developed software based on the calculation result. For the base period, a set of parameters for the tuyere chamber is calculated in accordance with the averaged actual indicators of the BF operation. Meanwhile, in the design period, a set of the same parameters is calculated for a given distribution of the theoretical combustion temperature (including uniform) over the BF tuyeres.

A set of basic parameters is determined on the basis of the calculation results obtained using the developed software:

-

blast flow rate through the tuyere, m 3/min;

-

theoretical combustion temperature on each tuyere, °C;

-

required consumption of natural gas to maintain the theoretical combustion temperature at a given level in the design period, m 3/h;

-

blowdown rate on each tuyere, m/sec;

-

kinetic energy of blowdown at each tuyere, kgm/sec;

-

length of the circulation and oxidizing zones on each tuyere, m;

-

amount of heat for heating water at each tuyere, kW;

-

area of tuyere hearths, m2 ;

-

relative area of tuyere hearths to the hearth area, %.

Figure 3 shows a fragment of the “Base period” tab with the modeling results in the base period. The figure includes the main blast, technological, and average design parameters of the BF operation in the base period.

Figure 4 presents a fragment of a web page with simulation results for the base period, which includes the main parameters of the operation of each of the BF tuyeres.

The “Design period” tab presents the average design parameters of the blast mode, as well as those for individual tuyeres and tuyere hearths with changes in natural gas consumption by tuyeres. Therefore, the theoretical combustion temperature at the tuyeres corresponds to the specified one (Fig. 5).

The analysis of the simulation results for the initial data version presented indicates that the average theoretical combustion temperature on the tuyeres in the base period was 2027°C. The natural gas flow rate adjustment for all tuyeres is 1160 m 3/h, with a total change in natural gas flow from 16,370 m 3/h to 15,803 m 3/h, to maintain the theoretical combustion temperature at all operating tuyeres at a given level of 2050°C.

A web page with a histogram of the actual consumption of natural gas (base period) by tuyeres of the required flow rate to maintain the theoretical combustion temperature at a given level (design period) is presented in Fig. 6.

Conclusions

An information-simulating system for monitoring the distribution of hot blast and calculating the parameters of tuyere zones has been developed using modern technologies.

The system provides for the calculation of the required consumption of natural gas through the blast furnace tuyeres, which will ensure the maintenance of the theoretical combustion temperature at the BF tuyeres at a given level as well as the parameters of their operation in the design mode.

The developed information-simulating system can be used by the technological personnel of the blast- furnace process to increase the efficiency of blast-furnace smelting. The system aimed to improve burden descent, increase the degree of use of thermal and chemical energy in gases, raise the productivity of furnaces, and reduce coke consumption.

Introducing an appropriate automatic control system is necessary to implement the proposed distribution of natural gas by BF tuyeres.

References

V. P. Lyaluk, I. G. Tovarovskii, and D. A. Kassim, “Uniformity of blast-furnace parameters over the perimeter,” Steel Transl., 48, 179–184 (2018); https://doi.org/10.3103/S0967091218030087.

M. Yu. Shirshov, V. G. Druzhkov, A. V. Pavlov, and I. E. Prokhorov, “The results of assessing the uniformity of blast distribution over blast furnace tuyeres,” Teoriya Tekhnol. Metallurgich. Proizvod., No. 2, 27–30 (2014); https://elibrary.ru/item.asp?id=23177364.

S. K. Sibagatullin, A. S. Kharchenko, A. A. Polinov, A. V. Pavlov, M. A. Semenyuk, and V. A. Beginyuk, “Stabilization of the ratio of natural gas and blast consumptions in blast furnace tuyeres,” Teoriya Tekhnol. Metallurgich. Proizvod., No. 1 (14), 23–25 (2014); https://elibrary.ru/item.asp?id=23177758.

V. P. Lyaluk, A. K. Tarakanov, D. A. Kassim et al., “Improving the uniformity of blast distribution around the circumference of the hearth of a blast furnace,” Metallurg, No. 2, 30–34 (2018); https://elibrary.ru/item.asp?id=32497626.

V. N. Andronov and Yu. A. Belov, “Evaluation of the efficiency of distribution of blast and natural gas by tuyeres,” Stal’, No. 9, 15–17 (2002).

Y. S. Semenov, V. V. Horupakha, E. I. Shumelchik, and M. A. Alter, “Blast furnace operation improvement by forming uniform circular distribution of Raceway’s thermal mode,” Iron Steel Technol Conf. Expos. (2021); https://doi.org/10.33313/382/118-50413-37.5.

N. M. Mozharenko, A. A. Paranosenkov, and V. I. Negoda, Development of Systems for Monitoring and Regulating the Hot Blast Flow through Air Tuyeres of a Blast Furnace [in Ukrainian], Fundamental and Applied Problems of Ferrous Metallurgy, Collection of Research Papers, Dnipropetrovsk, IChM NAS Ukraine, No. 10, 71–78 (2005).

N. M. Mozharenko, V. V. Kanaev, A. A. Paranosenkov, G. V. Panchokha, G. I. Orel, V. S. Listopadov, and K. A. Dmitrenko, Automated Control System for Blast Flow in Blast Furnace Air Tuyeres [in Ukrainian], Fundamental and Applied Problems of Ferrous Metallurgy, Collection of Research Papers, Dnipropetrovsk, IChM NAS Ukraine, No. 11, 34–42 (2005).

A. A. Polinov, A. V. Pavlov, O. P. Onorin, N. A. Spirin, and I. A. Gurin, “Distribution of blast over air tuyeres of a blast furnace,” Metallurg, No. 5, 23–27 (2018).

N. A. Spirin, V. V. Lavrov, V. Yu. Rybolovlev, L. Yu. Gileva, A. V. Krasnobaev, V. S. Shvydkiy, O. P. Onorin, K. A. Shchipanov, and A. A. Burykin, Mathematical Modeling of Metallurgical Processes in Automated Process Control Systems [in Russian], UrFU, Yekaterinburg (2014).

N. A. Spirin, V. V. Lavrov, V. Yu. Rybolovlev, A. V. Krasnobaev, O. P. Onorin, and I. E. Kosachenko, Model Decision Support Systems in Automated Process Control Systems for Blast-Furnace Smelting [in Russian], UrFU, Yekaterinburg (2011).

A. V. Pavlov, A. A. Polinov, N. A. Spirin, O. P. Onorin, and V. V. Lavrov, “The use of model systems for solving new technological problems in blast-furnace production,” Metallurg, No. 6, 35–40 (2017).

S. V. Cheremnykh, I. O. Semenov, and B. C. Ruchkin, Structural Analysis of Systems. IDEF Technologies [in Russian], Finansy i statistika, Moscow (2003).

A. I. Popov, Free Tools for Designing Information Systems [in Russian], IPK Izdatelstvo standartov, Moscow (2014).

A. Freeman, ASP.NET CoreMVC with C# Examples for Professionals [in Russian], Williams, Moscow (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 7, pp. 91–96, July, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Spirin, N.A., Gurin, I.A., Lavrov, V.V. et al. Information-Simulating System for Distribution of Hot Blast and Natural Gas Through the Blast Furnace Tuyeres. Metallurgist 67, 1006–1013 (2023). https://doi.org/10.1007/s11015-023-01590-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01590-5