Abstract

The thermal behaviours and kinetics of biodiesels produced from beef tallow and corn oils were examined by using thermal analysis techniques (TG-DTG/DSC) at different heating rates in this study. The biodiesels were analysed with 1H-NMR and GC–MS techniques. It was seen that the biodiesel samples are composed of both saturated (Myristic acid C14:0, palmitic acid C16:0, stearic acid C18:0,) and unsaturated (Palmitoleic acid C16:1, oleic acid C18:1, linoleic acid C18:2) FAMEs from GC–MS analysis. Kinetic parameters for the combustion process of biodiesels were determined by using the iso-conversional model-free methods, KAS and FWO methods. The activation energy of beef-tallow biodiesel from KAS method is 86.11 kJ mol−1, and from FWO method is 83.52 kJ mol−1. The activation energy of corn-oil biodiesel from KAS method is 79.12 kJ mol−1, and from FWO method is 90.07 kJ mol−1. It was figured out that the activation energies of the biodiesel samples have values close to each other, and controlling reaction mechanism for both biodiesel samples by using master-plot method are power law (P4). It was obtained CP (cloud point) and CFPP (cold filter plugging point) values from DSC analysis. CP values of biodiesel from beef tallow and corn oil are 16.1 °C and − 5.5 °C, respectively. CFPP values of biodiesel from beef tallow and corn oil are − 11.2 °C and − 6.7 °C, respectively. It was obtained from TG-DSC analysis that the origins of biodiesel samples on thermal behaviours are dominant at low temperatures (< 0 °C), yet the origins are not important at high temperature, and the combustion properties are the same as each other.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The rapid increase in the world population and urbanization, the interest and demand for energy resources is increasing day by day. Most of the energy we need is generally provided by petroleum-derived fossil fuels such as natural gas, coal, and gasoline. The resources are in abundance around the world. However, they have caused the high level of harmful gaseous emission, the global warming, and the waste accumulation. The increase in their costs has urged people to research alternative fuels [1, 2].

Biodiesel, not resemble to diesel, shows itself as an alternative, attractive fuel, and environmentally friend (almost zero sulphur and low CO2 contribution). Since its ignition temperature is higher than diesel, it is safer to store and transport, it can be used in diesel engines without any change and it extends the life of the engine because of its high lubricity. It can also be mixed efficiently with oils/fats and diesel fuels in certain proportions or used pure [3]. Contrary to all these advantages, the major disadvantage of biodiesel is its high cost [4]. It is obtained from vegetable oil and animal fat. However, when crude vegetable oils, which are already used in the food industry, are used as biodiesel crude materials, the production cost increases even more. For this reason, the use of waste oils in biodiesel production is more preferred such as non-edible oils as potential feedstocks [5,6,7]. Since beef tallow is a waste oil that is not preferred in the food sector, it is a good alternative as a biodiesel crude material [8].

The combustion behaviour, combustion mechanism, ignition temperature and delay, etc., are very important parameters for a fuel [9]. In order to use biodiesel as a motor fuel, its thermal stability or oxidation behaviour with the temperature increase must be known in advance. If biodiesel has poor thermal stability at high-temperature engine operations, it will lead to undesirable situations such as gum creation and it causes the storage problem [10]. Therefore, biodiesel produced from different oil/fat should be measured the properties such as thermal decomposition, activation energy, temperature and enthalpy of crystallization, thermooxidative behaviour and thermal stability, and specific heat using thermal analysis techniques [11,12,13].

The thermal analysis (TG-DTG/DSC) emerges as an auxiliary technique to determine and compare the combustion characteristics and the thermal stabilities of biodiesel obtained from different resources. The use of TGA analysis for the oxidation of pure biodiesel or diesel/biodiesel blends has many advantages such as being able to work with a small amount of sample, being sensitive, fast and precise [14], and this technique can be used in esters’ boiling point determination and in monitoring the transesterification reaction [15]. In addition, TG analysis can find the differentials between both biodiesel and pollutants. Although biodiesel is a mixture of mono-alkyl esters, it generally decomposes within a certain temperature range. This feature provides both information on the purity of biodiesel and distinguishing between itself and its pollutants. Differential scanning calorimetry (DSC), which is sensitive, fast and repeatable, can be used as the thermo-analytical method to examine and determine the melting/crystallization properties of fuels [16], fats [17] and oils [18].

Thermal behaviour and combustion properties of fuels have been the subject of many researches [14, 19]. The TG-DTG analysis of synthesized biodiesels is generally encountered in the literature, but there are fewer studies about the kinetics analysis and DSC cycle analysis. In this study, it is aimed to characterize, determine and compare the thermal properties and kinetics parameters of combustion process of biodiesels derived from corn oil (vegetable oils) and beef tallow (animal fats) by using thermogravimetric analysis methods. In addition, it was investigated in the study both high temperature and low temperature behaviours of biodiesel samples with the aid of thermal analysis.

Experimental

Materials

The beef tallow and corn oil used in the study were obtained from a local slaughterhouse and a local market in Erzurum, Turkey, respectively. The properties of the beef tallow and corn oil are given in Table 1. Methyl alcohol (Merck reagent of 99.9% purity) and potassium hydroxide catalyst (Flake reagent of 99.9% purity) were used during the biodiesel production.

Biodiesel production from beef tallow and corn oil

700 g of corn oil/beef tallow was put into a 1000-mL jacketed glass reactor and heated to 60 °C. A mechanical stirrer to mix the reactor contents, a condenser to prevent methanol loss and a constant temperature circulator to stabilize the temperature were connected to the rector. Potassium hydroxide catalyst dissolved in methanol (KOH = 1% w/w of oil, methanol-to-oil molar ratio = 6:1) was added to the stirring reactor at 600 rpm and the transesterification reaction was started. At the end of the 2 h reaction time, the content of the reactor was transferred to a separator funnel and the glycerin phase was separated from the bottom. The methyl ester phase (biodiesel) in the separator funnel was washed three times with deionized water for its purification (Fig. 1). It was placed in a rotary evaporator and kept there under vacuum at 80 °C in order to remove residual methanol. Elemental analysis of biodiesel samples produced from beef tallow and corn oil is shown in Table 2.

Analysis

Physicochemical properties

Saponification and iodine numbers of crude corn oil and beef tallow were determined by EN ISO 3657 and EN ISO 3961, respectively. The physicochemical properties of crude corn oil, beef tallow and biodiesel samples produced from them were determined according to relevant standards (EN/ASTM). Density was measured by an automatic density meter (Rudolph Research Analytical. DDM 2909). Cloud point and pour point were analysed by using Seta Cloud and Pour Point Bath (11010-2). Kinematic viscosity was determined by using Koehler kV4000 series viscometer. The acid number was determined through the titration method using a KOH-ethanol solution.

Determination of fatty acid composition

Fatty acid compositions of crude corn oil, beef tallow and the biodiesel samples obtained by transesterification were analysed by a gas chromatograph (GC) system equipped with an auto-injector (SHIMADZU. QP 2010) and the RESTEK Rtx-Wax capillary column (60 m × 0.25 mm id.. 0.25). The initial oven temperature was 140 °C for 5 min and was increased to 240 °C at a rate of 3 °C min−1, then maintained for 17 min.

Thermal analysis

Thermogravimetric analyser (Perkin Elmer Pyris) for TG-DTG/DSC analysis was used to better understand and characterize the combustion profiles and the thermal stability of biodiesel samples. TG-DTG/DSC profiles were performed in 25–600 °C at different heating rates (5, 10, 15 and 20 °C min−1) and in air atmosphere of 100 mL min−1. The samples of approximately 30 mg were put in alumina pan. TG-DTG data were utilized to determine the kinetics parameters of biodiesel combustion process.

DSC cycle analysis

Approximately 10 mg of each oil sample was taken (with a precision of 0.01 mg) into the sample container made of Al2O3. DSC analysis was performed on DSC 8500 PerkinElmer instrument. Firstly, samples were heated at a heating rate of 10 °C min−1 from − 60 to 30 °C, then cooled from 30 to − 60 °C at the same heating rate.

Results and discussion

Physicochemical properties of biodiesel samples

Some fuel properties of biodiesel samples produced from beef tallow and corn oil were determined by means of some of the EN 14214 and ASTM D 6751 standard specifications. The obtained results are given in Table 3. As shown in Table 3, biodiesel samples produced from both beef tallow and corn oil meet these standard specifications.

Determination of fatty acid composition of biodiesel samples

Fatty acid methyl ester (FAME) compositions of biodiesel samples produced from beef tallow and corn oil were also determined by GC. The FAME yields of beef-tallow and corn-oil biodiesels were 99.8% and 99.9%, respectively. Table 4 shows the list of major compounds in the biodiesel samples produced from beef tallow and corn oil. Accordingly, the biodiesel samples are composed of both saturated (Myristic acid C14:0, palmitic acid C16:0 and stearic acid C18:0) and unsaturated (Palmitoleic acid C16:1, oleic acid C18:1 and linoleic acid C18:2) FAMEs. As shown in Table 4, beef-tallow biodiesel mostly contains saturated FAMEs (about 60%), while corn-oil biodiesel mostly contains unsaturated FAMEs (about 85%). This is an expected situation because vegetable oils contain more unsaturated fatty acids while animal fats contain more saturated fatty acids. The fatty acid profile of biodiesel is determined by the type of oil/fat from which it is produced. The amount of saturated and unsaturated fatty acids in the biodiesel may affect its general fuel properties [20]. The fact that corn-oil biodiesel contains largely unsaturated fatty acid methyl esters positively affects its cold flow properties such as viscosity, pour point and cloud point, which are important fuel properties [21].

1H-NMR analysis

It is seen H-NMR spectra of biodiesel samples from beef tallow and corn oil in Figs. 2 and 3, respectively. The peak of 5.3 ppm indicates the alkene containing hydrogen (CH2 = CH). This peak of biodiesel from corn oil is more prominent than the peak of biodiesel from the beef tallow. There are two distinct peaks demonstrating the presence of methyl esters in the biodiesels. The peak of alkoxy group in the methyl ester (CO2CH3) is at 3.6 ppm, and the peak of ester α methylene group (CH2CO2CH3) is at 2.3 ppm. The peak at 2.7 ppm is seen only in H-NMR spectra of biodiesel from corn oil and shows the presence of the two double bonds of the α-methylene group (C=CH–CH2–CH=C). In H-NMR spectra, the peak at 2.02 ppm is related to one double bond of the α-methylene group (=CH–CH2–), and the peak at 1.61 ppm indicates to the ester β-methylene group (CH2–C–COOCH3). The sharp peak at 1.25 ppm shows the backbone of methylene (–CH2)n–) and the peak at 0.90 ppm is the terminal methyl protons (C–CH3) [22].

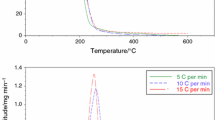

TG-DTG analysis

TGA/DTG curves of biodiesel samples from beef tallow and corn oil are shown in Figs. 4 and 5, respectively. DSC graphs of biodiesel samples are in Figs. 6 and 7. TGA profiles were performed at heating rates of 5, 10, 15 and 20 °C min−1 in air atmosphere. Examined TG results, it is seen that the curves shift to the right as the heating rate increases. The temperature difference between the biodiesel sample and the furnace causes the situation. Therefore, higher heating rates will rise that the ignition, peak-max and offset (burn-out) temperatures [23].

The ignition, peak-max and the offset temperatures being key features in determining the combustion behaviour of any fuel (coal, biomass and diesel/biodiesel) can easily be obtained from DTG graphs (Tables 5, 6). The temperatures inform in detail about the combustibility and thermal stability of biodiesels. The determination of peak-max temperature (maximum mass loss rate) is very important. The samples with lower peak temperature can be easily ignited and burned [24] and when this temperature is high, the fuel is less reactive. The peak-max temperature increases as the heating rate increases. As stated before, the offset temperature of the biodiesels varies with increasing heating rate. As a fuel parameter, the offset temperature indicates the residence time and the completion of oxidation [25, 26].

At Figs. 4 and 5, it is understood that the oxidation processes of samples have only one decomposition step under non-isothermal conditions. Although it looks like a single step in the TG curve of biodiesel from corn oil, its DTG curve shows actually two consecutive events. They are the consecutive reactions that indicate of the decomposition of the fatty acid methyl ester (FAME) compositions (especially linoelaidic acid 53.23%, oleic acid 31.11%). In the literature, it is expressed that the boiling point of linoelaidic acid is 229–230 °C, oleic acid is 360 °C, and the flash point of linoelaidic acid is 112 °C, oleic acid is 189 °C. In addition, it is exhibited that linoelaidic acid decomposes at 280.7 °C [27]. The flash point stearic acid and palmitic acid, which are mainly components of beef-tallow biodiesel, are 113 °C and 206 °C, respectively. DSC graphs (Figs. 6, 7) illustrate already the exothermic situation not the endothermic in the temperature range. Therefore, it should be mentioned the combustion/oxidation process in the temperature range.

At Tables 5 and 6, when it is examined the temperatures at 10 °C min−1 heating rate of both biodiesel samples, it is seen that the ignition temperature of biodiesel from corn oil is 205 °C, and biodiesel from beef tallow is 200 °C. The offset temperature of biodiesel from corn oil and beef tallow is 288 °C. According these values, the biodiesel from corn oil compared to the beef tallow. It can be explained that are almost same the thermal stabilities and the ignition and peak-max temperatures. The offset temperature of biodiesel from corn oil is slightly higher than beef tallow. It means that the oxidation time will take a little longer. In the literature, it is found that the ignition temperature of the biodiesel from Pongamia oil for 10 °C min−1 is 190 °C and the offset temperature is 340 °C [10].

Biodiesel is a mixture of mono-alkyl esters and generally decomposes within a certain temperature range. In TG analysis, the feature can be used to obtain the information on the purity of any biodiesel. For example, at heating rate of 5 °C min−1 the combustion of the biodiesel from beef tallow occurs in the temperature range of 195–272 °C. In the literature, the European Standard UN 142146 states that the minimum purity of a fresh biodiesel is approximately 96.5% [28]. For both biodiesels, the mass losses having only one step are approximately 99%. As will be understood from TG-DTG graphs, it can be said that the biodiesel samples are relatively pure, since they decompose with a mass loss of 99% in narrow temperature range. As a result of GC, the mass loss corresponds to the combustion of oleic acid, linoelaidic acid being the most abundant component in the corn-oil biodiesel, and the palmitic acid, stearic acid, and oleic acid in the beef-tallow biodiesel. According to all the heating rates, the biodiesel samples ignite and oxidize completely at in narrow and low temperature range. Therefore, it would not cause any difficulty for the utilization of synthesized biodiesels as an alternative fuel at the compression–ignition engine conditions.

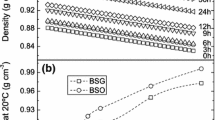

DSC cycle analysis

For DSC cycle analysis, biodiesel samples were heated in the air condition from − 60 to 30 °C at a heating rate of 10 °C min−1 and then cooled from 30 to − 60 °C at the same heating rate. DSC melting/crystallization cycles obtained for biodiesel samples are shown in Figs. 8 and 9, respectively.

Firstly, it is seen that according to the heating curves, both biodiesels have two endothermic peaks. The peak temperatures of biodiesel from beef tallow can be referred as the melting process of unsaturated compounds at − 32.3 °C (linoleic acid) and saturated compounds at 18.8 °C (oleic acid) in Fig. 8 [29, 30]. In addition, the peaks of biodiesel from corn oil can be referred as the melting of unsaturated (− 46.5 °C) and saturated (1.0 °C) compounds. Secondly, in the cooling curves, it is obtained the state transitions having two exothermic peaks. The crystallization of saturated compounds is represented itself by two exothermic peaks at − 11.2 and − 15.3 °C, and the crystallization of unsaturated compounds is at − 51.5 °C for the biodiesel from beef tallow. The crystallization peaks of biodiesel from corn oil are seen as the saturated compounds at − 6.7 °C and − 10.2 °C and unsaturated at − 58.6 °C.

The crystallization temperature is an important factor to prepare diesel/biodiesel mixes and to evaluate the behaviour of biodiesel in colder climate regions. The crystallization temperature of biodiesel from corn oil is higher than the biodiesel from beef tallow. The large peak of the biodiesel from beef tallow in heating curve is a signal of the content significantly higher of saturated fatty acids. Unlike, the large peak of the biodiesel from corn oil in cooling curve is a signal of the content significantly higher of unsaturated fatty acids [31]. In the literature, it is stated that cloud point (CP) and cold filter plugging point (CFPP) can be determined by DSC analysis [32]. CP value is the onset of crystallization peak, and CFPP value is the maximum value of the exothermic peak. Then, these values can be get on the cooling curve. CP values of biodiesel from beef tallow and corn oil are 16.1 °C and − 5.5 °C, respectively. CFPP values of biodiesel from beef tallow and corn oil are − 11.2 °C and − 6.7 °C, respectively. The important temperature values are required to characterize and classify different origin biodiesels.

Kinetics analysis

Model-free methods

Kinetics analysis for the decomposition processes of biodiesel samples was performed from the TG-DTG results at different heating rates. The conversion values (α) for each temperature were obtained from TG data. The activation energies (Ea) of samples were calculated by model-free methods, KAS and FWO methods [33, 34]. Ea was obtained from the graph of ln (β/T2) versus 1000/T at KAS method [35, 36] and the graph of ln β versus 1000/T at FWO method [37, 38]. The calculated activation energies (Ea) are shown in Table 7. At Figs. 10 and 11, it is seen that the linear fit plots are nearly parallel, which indicates that by using the KAS and FWO methods.

Ea (average) for the decomposition of biodiesels from corn oil and beef tallow is found as 79.12 kJ mol−1 and 86.11 kJ mol−1 from the KAS method, respectively. Ea is found as 83.52 kJ mol−1 and 90.07 kJ mol−1 from the FWO method, respectively. In the literature, the activation energies corresponding to the combustion process of the biodiesel from canola oil were found as 117 kJ mol−1 by KAS method, and 123 kJ mol−1 by FWO method [19].

Mechanism of reaction

It was performed the master-plots method being a graphical analysis for identifying the reaction mechanism of the biodiesel samples at decomposition region. The method uses 0.5 conversion value as a reference point.

It is plotted theoretical values [g(α)/(g(0.5)] versus each conversion value and also experimental values [p(u)/p(0.5)] versus each conversion value. At the choice of the mechanism best suited to experimental data, it should pay attention to be equal to between theoretical values and experimental values [39, 40].

In the literature, it is stated that the kinetics study for a homogenous reaction (gas or solution phase) intends generally to supply the rate constants and reaction mechanisms that define the advance of all reactions. The reaction mechanisms display in detail the conversion of any reactant to product [40, 41].

It is seen that the calculated experimental data for biodiesel samples were appropriate to the theoretical data of power law (P4) kinetic mechanism at Figs. 12 and 13. P4 kinetic mechanism takes into account the constant nuclei growth without thought to growth restrictions and is generally used at the analysis of the acceleratory period of a curve [41].

Conclusions

In the study, it was obtained biodiesel samples from two different origins and renewable resources. The biodiesel from beef tallow that is waste oil was compared to the biodiesel from corn oil that is continuously investigated by researchers, based on the thermal and combustion behaviours. Structural properties of the obtained biodiesels were tried to be determined by GC–MS and H-NMR analyses. Combustion behaviours were monitored by TG-DTG-DSC analyses. At high temperature, although the biodiesel from beef tallow generally composes of saturated compounds and the biodiesel from corn oil composes to unsaturated compounds, both display the same combustion properties (activation energy, combustion mechanism, ignition/offset temperature, etc.) On the contrary, the origins of biodiesel samples show their effects particularly at low temperatures (> 0 °C). The temperatures such as cloud point (CP) and cold filter plugging point of biodiesel samples are quite different from each other. All these evaluations were made with the help of thermal analysis (TG-DTG/DSC).

The average activation energy for the combustion of biodiesels from corn oil and beef tallow is found as 79.12 kJ mol−1 and 86.11 kJ mol−1 from the KAS method, respectively. It is 83.52 kJ mol−1 and 90.07 kJ mol−1 from the FWO method, respectively. The controlling reaction mechanism is power law P4 model. In short, it was observed that the combustion behaviours of biodiesel samples in the study were independent of the origin of the oil. Future research has been aimed that it can be realized under various engine operating conditions such as engine performance, exhaust emission and combustion behaviour, injection pressure, compression ratio, and injection time of internal combustion engines using biodiesel from beef tallow.

Abbreviations

- A :

-

Frequency factor or preexponential factor (s−1)

- E :

-

Activation energy or apparent activation energy (kJ mol−1)

- R :

-

Gas constant (8.314 J mol−1 K−1)

- T :

-

Absolute temperature (K)

- β :

-

Heating rate (°C min−1)

- α :

-

Conversion rate

References

Jeyakumar N, Narayanasamy B. Effect of basil antioxidant additive on the performance, combustion and emission characteristics of used cooking oil biodiesel in CI engine. J Therm Anal Calorim. 2020;140(1):457–73.

Yesilyurt MK, Yilbasi Z, Aydin M. The performance, emissions, and combustion characteristics of an unmodifed diesel engine running on the ternary blends of pentanol/safflower oil biodiesel/diesel fuel. J Therm Anal Calorim. 2020;140:2903–42.

Ma Q, Zhang Q, Zheng Z. An experimental assessment on low temperature combustion using diesel/biodiesel/C2. C5 alcohol blends in a diesel engine. Fuel. 2021;288:119832.

Moraes PS, Engelmann JI, Igansi AV, Cadaval TRSA Jr, de Almeida Pinto LA. Nile tilapia industrialization waste: evaluation of the yield, quality and cost of the biodiesel production process. J Clean Prod. 2020;287:125041.

Yesilyurt MK, Cesur C. Biodiesel synthesis from Styrax officinalis L. seed oil as a novel and potential non-edible feedstock: a parametric optimization study through the Taguchi technique. Fuel. 2020;265:1125.

Yesilyurt MK, Cesur C, Aslan V, Yilbasi Z. The production of biodiesel from safflower (Carthamus tinctorius L.) oil as a potential feedstock and its usage in compression ignition engine: a comprehensive review. Renew Sustain Energy Rev. 2020;119:109574.

Eryilmaz T, Yesilyurt MK. Influence of blending ratio on the physicochemical properties of safflower oil methyl ester-safflower oil, safflower oil methyl ester-diesel and safflower oil-diesel. Renew Energy. 2016;95:233–47.

Doğan TH, Temur H. Effect of fractional winterization of beef tallow biodiesel on the cold flow properties and viscosity. Fuel. 2013;108:793–6.

Chouhan AS, Singh N, Sarma A. A comparative analysis of kinetic parameters from TGDTA of Jatropha curcas oil, biodiesel, petroleum diesel and B50 using different methods. Fuel. 2013;109:217–24.

Dwivedi G, Sharma MP. Experimental investigation on thermal stability of pongamia biodiesel by thermogravimetric analysis. Egypt J Pet. 2016;25(1):33–8.

Raslavičius L, Striūgas N, Felneris M, Skvorčinskienė R, Miknius L. Thermal characterization of P. moriformis oil and biodiesel. Fuel. 2018;220:140–50.

Wang S, Uzoejinwa BB, Abomohra AEF, Wang Q, He Z, Feng Y, et al. Characterization and pyrolysis behavior of the green microalga Micractinium conductrix grown in lab-scale tubular photobioreactor using Py-GC/MS and TGA/MS. J Anal Appl Pyrol. 2018;135:340–9.

Karin P, Borhanipour M, Songsaengchan Y, Laosuwan S, Charoenphonphanich C, Chollacoop N, et al. Oxidation kinetics of small CI engine’s biodiesel particulate matter. Int J Autom Technol. 2015;16(2):211–9.

Jain S, Sharma M. Thermal stability of biodiesel and its blends: a review. Renew Sustain Energy Rev. 2011;15(1):438–48.

Chand P, Reddy CV, Verkade JG, Wang T, Grewell D. Thermogravimetric quantification of biodiesel produced via alkali catalyzed transesterification of soybean oil. Energy Fuels. 2009;23(2):989–92.

Jesus J, Ferreira A, Szilágyi I, Cavalheiro E. Thermal behavior and polymorphism of the antioxidants: BHA, BHT and TBHQ. Fuel. 2020;278:118298.

Fabiani C, Pisello AL, Barbanera M, Cabeza LF, Cotana F. Assessing the potentiality of animal fat based-bio phase change materials (PCM) for building applications: an innovative multipurpose thermal investigation. Energies. 2019;12(6):1111.

Alarcon RT, Gaglieri C, Lamb KJ, North M, Bannach G. Spectroscopic characterization and thermal behavior of baru nut and macaw palm vegetable oils and their epoxidized derivatives. Ind Crops Products. 2020;154:112585.

Kok MV, Topa E. Thermal characterization and model-free kinetics of biodiesel sample. J Therm Anal Calorim. 2015;122(2):955–61.

Mumtaz MW, Adnan A, Anwar F, Mukhtar H, Raza MA, Ahmad F, et al. Response surface methodology: an emphatic tool for optimized biodiesel production using rice bran and sunflower oils. Energies. 2012;5(9):3307–28.

Hoekman SK, Broch A, Robbins C, Ceniceros E, Natarajan M. Review of biodiesel composition, properties, and specifications. Renew Sustain Energy Rev. 2012;16:143–69.

Ullah Z, Bustam MA, Man Z, Khan AS, Muhammad N, Sarwono A. Preparation and kinetics study of biodiesel production from waste cooking oil using new functionalized ionic liquids as catalysts. Renew Energy. 2017;114:755–65.

Li S, Whitely N, Xu W, Pan W-P. Characterization of coal by thermal analysis methods. 2005.

Marinov S, Gonsalvesh L, Stefanova M, Yperman J, Carleer R, Reggers G, et al. Combustion behaviour of some biodesulphurized coals assessed by TGA/DTA. Therm Chim Acta. 2010;497(1–2):46–51.

Varol M, Atimtay A, Bay B, Olgun H. Investigation of co-combustion characteristics of low quality lignite coals and biomass with thermogravimetric analysis. Therm Chim Acta. 2010;510(1–2):195–201.

Liu Z, Quek A, Hoekman SK, Srinivasan M, Balasubramanian R. Thermogravimetric investigation of hydrochar-lignite co-combustion. Bioresour Technol. 2012;123:646–52.

Harry-O’Kuru R, Mohamed A, Xu J, Sharma B. Synthesis and characterization of corn oil polyhydroxy fatty acids designed as additive agent for many applications. J Am Oil Chemists’ Soc. 2011;88(8):1211–21.

Díaz-Ballote L, Gómez-Hernández K, Vega-Lizama ET, Ruiz-Gómez MA, Maldonado L, Hernández E. Thermogravimetric approach for assessing the oxidation level of a biodiesel sample. Quim Nova. 2018;41(5):492–6.

Nicolau CL, Klein AN, Silva CA, Fiorucci AR, Stropa JM, Santos EO, et al. Thermal properties of the blends of methyl and ethyl esters prepared from babassu and soybean oils. J Braz Chem Soc. 2018;29(8):1672–9.

Misutsu MY, Cavalheiro LF, Ricci TG, Viana LH, de Oliveira SC, Junior AM, et al. Thermoanalytical methods in verifying the quality of biodiesel. Biofuels—status and perspective. Croatia: InTech; 2015. p. 251–69.

Alexandre ECF, Silveira EV, de Souza Castro CF, Sales JF, de Oliveira LCS, Viana LH, et al. Synthesis, characterization and study of the thermal behavior of methylic and ethylic biodiesel produced from tucumã (Astrocaryum huaimi Mart.) seed oil. Fuel. 2015;161:233–8.

Ramalho E, Carvalho Filho J, Albuquerque A, De Oliveira S, Cavalcanti E, Stragevitch L, et al. Low temperature behavior of poultry fat biodiesel: diesel blends. Fuel. 2012;93:601–5.

Vyazovkin S, Wight CA. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Therm Chim Acta. 1999;340:53–68.

Vyazovkin S, Chrissafis K, Di Lorenzo ML, Koga N, Pijolat M, Roduit B, et al. ICTAC Kinetics Committee recommendations for collecting experimental thermal analysis data for kinetic computations. Therm Chim Acta. 2014;590:1–23.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Nation Bureau Stand. 1956;57(4):217–21.

Trans AT. Joint convention of four electrical institutes. Res Rep Chiba Inst Technol. 1971;16:22–31.

Flynn JH, Wall LA. A quick, direct method for the determination of activation energy from thermogravimetric data. J Polym Sci Part B Polym Lett. 1966;4(5):323–8.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Japan. 1965;38(11):1881–6.

Wanjun T, Yuwen L, Xi Y, Cunxin W. Kinetic studies of the calcination of ammonium metavanadate by thermal methods. Ind Eng Chem Res. 2004;43(9):2054–9.

Doğan F, Kaya İ, Bilici A. Azomethine-based phenol polymer: synthesis, characterization and thermal study. Synth Metals. 2011;161(12):79–86.

Khawam A, Flanagan DR. Solid-state kinetic models: basics and mathematical fundamentals. J Phys Chem B. 2006;110(35):17315–28.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Doğan, T.H., Naktiyok, J. Thermal behaviours at low and high temperature of biodiesels produced from beef tallow and corn oil. J Therm Anal Calorim 147, 9025–9035 (2022). https://doi.org/10.1007/s10973-021-11160-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11160-z