Abstract

The limited applications of α-cyclodextrin (αCD) require elaboration of effective preparation procedures for inclusion compounds of this native macrocyclic host. The solid-phase guest exchange in anhydrous inclusion compounds with organic guests was used in the present work to activate the inclusion properties of αCD without the presence of water. The initial inclusion compounds and the products of this exchange process were characterized using thermogravimetry combined with mass spectrometry of evolved vapors (TG/MS) and powder X-ray diffraction. Solid-phase guest exchange in inclusion compounds of αCD enables encapsulation of organic guests in the higher amounts than can be achieved with a saturated hydrate of α-cyclodextrin under the same conditions. The developed guest exchange procedure does not demand optimization of components ratio and preparation conditions. The solid-phase guest exchange in one of the studied ternary systems produces an amorphous inclusion compound, which heating gives a true amorphous αCD without any traces of its crystalline phase. This is a first evidence of α-cyclodextrin amorphization without its complete dissolution, that can be used in practical applications where an amorphous state of this host is needed having a higher inclusion capacity than its crystalline forms.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Inclusion compounds of cyclodextrins (CDs) are widely used in pharmaceutics and in food, textile and cosmetic industries [1,2,3,4,5]. For preparation of such solid inclusion compounds, the most used methods are the grinding [6] or “CD + guest” mixing in pastes and slurries [2, 7], which does not require a large amount of solvent and complete dissolution of the CD. However, the efficiency of these methods is not the same for different CDs. For example, complexation with alpha-cyclodextrin (αCD) can be not effective in the presence of hydration water [8]. Typically, water is used as the third component to activate the guest inclusion [9, 10], but, in the case of αCD, water acts more like a competing agent [8]. This is a result of the much higher affinity of αCD for water, compared with that of beta-cyclodextrin (βCD) [11]. This fact restricts significantly the applicability of conventional preparation methods for αCD inclusion compounds (clathrates), thus reducing the practical application of αCD.

Due to the fact that water is a worse activating guest for αCD than for βCD, a method of solid-phase guest exchange may be more preferable for preparation of αCD inclusion compounds. This method was developed for the preparation of βCD inclusion compounds with guests, which are not included by dry βCD or its saturated hydrate [10, 12]. In this work, we propose the usage of organic compounds to activate a guest inclusion in αCD in the absence of water in accordance with the scheme shown in Fig. 1. Volatile organic compounds—ethanol, 2-propanol and acetonitrile—were chosen as “leaving guests” as they are well included (more than 1 mol per mol αCD) into anhydrous αCD (Fig. 1b) and have a relatively small affinity for αCD according to the Gibbs inclusion energy, estimated on the basis of their vapor sorption isotherms [11]. In addition, a hydrophobic dichloromethane was also taken as a leaving guest, which is not included by dry αCD [11] but can be encapsulated by αCD hydrate in the presence of a desiccant [8]. Thus, all selected departing guests have a significantly lower affinity for αCD than water, and their exchange should be thermodynamically more favorable.

The objective of this study was to develop a method for preparing the αCD inclusion compounds by solid-phase guest exchange and to compare inclusion capacity in the proposed method (Fig. 1c) with a conventional procedure where water is replaced with a target guest (Fig. 1a). In the present work, a comparison was also made for various leaving guests to find the one that is most effectively exchanged in αCD by other organic compounds. The effect of the initial crystal packing and the structural changes caused by guest exchange on the resulting inclusion capacity was also studied.

The effect of the used guest exchange procedure on the crystallinity of the resulting product was also studied. The most interesting in this relation is the preparation of αCD in amorphous state, which increases its inclusion capacity for small molecules that are important for food industry [13, 14].

Experimental

Materials

α-Cyclodextrin, Sigma-Aldrich, Cat. No. 28705, was dried at 140 °C for 8 h in vacuum of 100 Pa before the experiments. Such dried αCD has a hydration level less than 1% by mass with the absence of volatile organic guests checked by thermogravimetry with mass spectrometry of evolved vapors. Organic guests were purified as described in Ref. [15]. Additionally, all guests were dried using 3Å molecular sieves. The purity of guests checked by GC was at least 99.5%.

Sample preparation

Initial αCD clathrates with ethanol, 2-propanol and acetonitrile were prepared by saturation of dried αCD in binary ‘solid host + guest vapor’ systems as described earlier [11]. The clathrate with dichloromethane αCD·0.6CH2Cl2 was prepared in two steps: (1) saturation of hexahydrate αCD·6H2O with dichloromethane vapor in the presence of 3Å molecular sieves to prepare clathrate αCD·1.0CH2Cl2·2H2O as described elsewhere [8]; (2) dehydration by the heating of αCD·1.0CH2Cl2·2H2O at 140 °C for 20 min in air in oven. For solid-phase guest exchange, the samples of initial binary αCD clathrates (50-60 mg) were equilibrated with Guest 2 vapors in sealed 15-mL vials for 72 h. In these vials, an excess of liquid sorbate (100 μL) was placed in a separate glass micro-insert and had not any direct liquid–solid phase contact with a host powder. Molecular sieves 3Å (60-70 mg) were added as a desiccant to the vials.

To prepare the guest-free amorphous αCD, its amorphous inclusion compound was heated at 140 °C for 20 min in oven in air and then cooled to room temperature (RT). The amorphous αCD was crystallized by saturation with water vapors for 2 h at RT.

Simultaneous thermogravimetry with mass spectrometry

Simultaneous thermogravimetry with mass spectrometry of evolved vapors (TG/MS) was used to determine the composition of αCD clathrates. This experiment was performed using Netzsch STA 449 C Jupiter with quadrupole mass spectrometer QMS 403 C Aeolos as described elsewhere [16]. The temperature was scanned with a rate of 10 K min−1 up to 280 °C in argon atmosphere. For ternary clathrates with strongly overlapping MS peaks, an additional MS-calibration was used. For this calibration, an equimolar liquid mixture of guests was sampled directly to TG/MS device in the isothermal mode at 120 °C. A ratio of guest peaks on ion curves was used for the calculation of mass spectrometer sensitivity to the studied guests. The contents of organic guest in inclusion compounds were estimated with an error of 0.1 mol per 1 mol of αCD.

X-ray powder diffraction

X-ray powder diffractograms were obtained using Rigaku MiniFlex 600 diffractometer with a D/teX Ultra detector. Cu Kα radiation (30 kV, 10 mA) was used, Kβ radiation was attenuated with Ni filter. The experiments were made at room temperature in the reflection mode, at speed of 5° min−1, without sample rotation. Samples were placed into a glass holder. The most diffractograms were determined also with addition of standard silicon powder SRM 640d, and corresponding corrections were applied to the patterns obtained.

Results and Discussion

To study the solid-phase guest exchange according to the scheme in Fig. 1b and c, binary inclusion compounds αCD·2.2EtOH, αCD·1.2i-PrOH and αCD·2.1MeCN prepared as described in [11] were used as the initial state. Also, the anhydrous clathrate αCD·0.6CH2Cl2 was used for this purpose being prepared by dehydration of αCD·1.0CH2Cl2·2H2O, which is formed as described in [8]. The compositions of these binary clathrates were determined by the TG/MS method. For αCD·2.2EtOH, αCD·1.2i-PrOH, αCD·2.1MeCN and αCD·1.0CH2Cl2·2H2O, the obtained TG/MS curves coincide with those previously published [8, 11]. The TG/MS curves for αCD·0.6CH2Cl2 are given in Electronic supplementary material (ESM).

For guest exchange, the initial binary clathrates were equilibrated with the saturated vapors of Guest 2 compounds: propionitrile, acetone, 1-propanol, nitromethane, dichloromethane and benzene. These substances were studied as Guest 2 because they are poorly included by αCD hydrate and the hydration effect on the inclusion of these guests by αCD was previously studied [8]. The products of the solid-phase guest exchange were studied by TG/MS method. Corresponding TG/MS curves are shown in Fig. 2 and ESM. From these curves, compositions of the resulting inclusion compounds, total mass loss corresponding to the guest release Δm and points of guest release peaks Tmax on MS curves were determined. These parameters are given in Table 1 for all studied Guests 2 except benzene, which is not included in any experiment more than 0.1 mol per mol αCD, ESM.

In most cases (Table 1), the products of guest exchange are ternary clathrates containing both leaving guest and Guest 2. Only n-propanol is not able to replace ethanol and isopropanol. Also, very small amounts of dichloromethane (0.1 mol per mol αCD) are included in the exchange of propionitrile and isopropanol in their binary clathrates with αCD. In this relation, αCD differs from βCD, which clathrates lose some leaving guests completely under the same guest exchange conditions [10, 17]. Ethanol shows the lowest degree of exchange, retaining at least 1.6 mol per mol αCD from the initial 1:2.2 (host/guest) contents. At least half of dichloromethane remains in the products of its solid-phase exchange (Table 1). Isopropanol and acetonitrile show a much higher degree of release in this process: their average residual content is 33% and 18% of their initial values, respectively.

The used procedure of guest exchange affects the observed thermal stability of the resulting products. The peak points of Guest 2 release in MS curves (Tmax) (Table 1) are lower on 30–100 °C than these values for ternary clathrates prepared under the optimized hydration conditions [8]. For products of guest exchange, the values Tmax of Guest 2 and leaving guest are quite close in all cases (Table 1), making it impossible to remove one included guest without removing another. Such behavior can be explained by encapsulation of both Guest 2 and leaving guest inside the αCD cavity, which thus does not discriminate these guests.

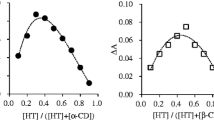

A comparison of the studied leaving guests by the exchange capacity of their binary clathrates for Guest 2 is shown in Fig. 3. Besides, the compositions of the saturation products with the same Guest 2 vapors are shown in Fig. 3 for hexahydrate αCD·6H2O without optimization of the hydration history [8] because the saturation process for this initial state can be recognized as the solid-phase exchange of water for organic guest. Unlike the studied binary clathrates with organic guests, the hexahydrate αCD·6H2O does not include Guests 2 studied in this work in significant amounts [8]. Thus, the solid-phase guest exchange of organic guests in absence of water may give better inclusion results than the conventional preparation procedure in the presence of hydration water.

Contents of Guest 2 in αCD clathrates prepared by solid-phase exchange of various leaving guests at 25 °C. * Additional sorption of dichloromethane by the initial αCD·0.6CH2Cl2 clathrate. The data for water as a leaving guest are for the saturated hydrate αCD·6H2O from Ref. [8]

Comparison of the exchange results for the studied leaving guests shows that acetonitrile is the best for activation of inclusion for such Guests 2 as propionitrile, dichloromethane and n-propanol, as shown in Fig. 3. Isopropanol is the best leaving guest in exchange with nitromethane and acetone. For all Guests 2 studied, the exchange of isopropanol gives the same or higher inclusion capacity for Guest 2 as the exchange of ethanol. This difference between these two alcohols may be caused by a lower affinity (inclusion Gibbs energy) of isopropanol for dry αCD compared with that of ethanol [11]. Exchange of acetonitrile shows the highest average Guest 2 contents also being the least selective for all Guests 2 studied.

To reveal the effect of the structural changes upon guest exchange, all products of solid-phase guest exchange were studied by X-ray powder diffraction method. The obtained diffraction patterns are shown in Fig. 4 and ESM. The patterns of the initial clathrates αCD·2.1MeCN (Fig. 4a) and αCD·1.2i-PrOH were identified elsewhere [8] as being of columnar and Form IIIa types, respectively. Form IIIa is the crystal packing type of anhydrous αCD [8] (Fig. 4b). The diffraction pattern of αCD·0.6CH2Cl2, ESM, belongs to the type of Form III.

Analysis of the diffractograms obtained (Fig. 4, ESM) shows that the products of guest exchange have more or less pure crystal packing of dried αCD (Form IIIa) (Fig. 3b) with characteristic peaks at 2θ angles of 4.9°, 13.7°, 16.0° [8]. In the products of acetonitrile exchange for all studied Guests 2 (Fig. 4f and g, ESM), the admixture of the initial columnar packing (Fig. 4a) with the characteristic peaks at 7.4°, 12.0° and 19.8° [8, 18] is observed. Also, the traces of columnar packing are observed for the product of ethanol exchange for acetone and propionitrile (Fig. 4e, ESM). For comparison, columnar packing was observed for the product of acetone inclusion in αCD hydrate with the optimized hydration history and level [8].

The columnar packing of αCD·2.1MeCN is more loose and has much more space for guests than that of Form IIIa [8]. So, the observed partial presence of the columnar packing in diffraction patterns of exchange products with the leaving acetonitrile may be a cause of the better exchange capacity of this initial clathrate in the most studied cases (Table 1, Fig. 3). The exclusions are the exchange products with acetone and nitromethane in the initial αCD·1.2i-PrOH, which have Form IIIa packing (Fig. 4c, ESM), both in the initial and final states, but perform a higher inclusion capacity than that of the initial αCD·2.1MeCN. The cause may be the lowest affinity of i-PrOH for dry αCD [11].

An unusual structural effect was found for the product of ethanol exchange for nitromethane. The resulting inclusion compound αCD·0.6MeNO2·1.9EtOH has an amorphous structure (Fig. 4h). The diffraction pattern of this product has two wide halos with maxima at 2θ angles of 14° and 20°. Such pattern with a randomly dispersed structure was previously observed for the amorphous αCD prepared by spray drying [19], while, for example, the product of αCD ball milling is only partially disordered [19, 20]. The amorphous αCD·0.6MeNO2·1.9EtOH was heated up to 140 °C in air, which gives a complete removal of both guests according to the TG/MS data for this clathrate, ESM. The prepared guest-free αCD still has the same diffraction pattern of an amorphous material, ESM, as the inclusion compound αCD·0.6MeNO2·1.9EtOH.

The resulting dry amorphous αCD crystallizes upon its saturation with water vapors, as well as the amorphous αCD obtained by spray drying [21]. The prepared αCD hydrate does not contain an amorphous phase and has a typical crystal packing of Form III [22] according to its powder diffraction pattern, ESM. The observed crystallization to the ordinary hydrate means that the amorphization of αCD is not caused by chemical reactions of αCD with ethanol and nitromethane during the saturation and heating. Thus, for the first time, an amorphous anhydrous αCD was obtained by the dry method without preparing its dilute solution. The amorphization of αCD upon exchange of ethanol for nitromethane may be caused by partial dissolution of the initial αCD·2.2EtOH in the saturated nitromethane vapors with the formation of solid amorphous product when a small fraction of the volatile organic components is evaporated.

Conclusions

Solid-phase guest exchange in anhydrous α-cyclodextrin clathrates allows encapsulation of organic guests in the higher amounts than conventional preparation methods for inclusion compounds of this host using its saturated hydrate. An activation of inclusion properties of dry α-cyclodextrin by organic “leaving guest” instead of water helps to overcome the high affinity of this native cyclodextrin for water, which significantly restricts the applications of α-cyclodextrin. The solid-phase exchange of organic guest does not require the optimization of preparation conditions. The exchange of acetonitrile and 2-propanol enables the highest inclusion for target guests, with acetonitrile showing the lowest exchange selectivity.

The amorphization of α-cyclodextrin by the solid-phase exchange of the initially included ethanol for nitromethane and further guest release is the first evidence of preparation of true amorphous α-cyclodextrin without formation of its dilute solution. This technologically friendly procedure can be used to prepare dry amorphous α-cyclodextrin, which is of great interest for practical applications.

References

Crini G. Review: A history of cyclodextrins. Chem Rev. 2014;114:10940–75.

Hedges AR. Industrial applications of cyclodextrins. Chem Rev. 1998;98:2035–44.

Hădărugă NG, Bandur GN, David I, Hădărugă DI. A review on thermal analyses of cyclodextrins and cyclodextrin complexes. Environ Chem Lett. 2019;17:349–73.

Radu C-D, Parteni O, Ochiuz L. Applications of cyclodextrins in medical textiles—review. J Control Release. 2016;224:146–57.

Kfoury M, Auezova L, Greige-Gerges H, Fourmentin S. Promising applications of cyclodextrins in food: improvement of essential oils retention, controlled release and antiradical activity. Carbohydr Polym. 2015;131:264–72.

Brusnikina M, Silyukov O, Chislov M, Volkova T, Proshin A, Mazur A, et al. Effect of cyclodextrin complexation on solubility of novel anti-Alzheimer 1,2,4-thiadiazole derivative. J Therm Anal Calorim. 2017;130:443–50.

Sbârcea L, Ledeţi A, Udrescu L, Văruţ R-M, Barvinschi P, Vlase G, et al. Betulonic acid—cyclodextrins inclusion complexes. J Therm Anal Calorim. 2019;138:2787–97.

Gatiatulin AK, Osel’skaya VY, Ziganshin MA, Gorbatchuk VV. Smart control of guest inclusion by α-cyclodextrin using its hydration history. RSC Adv. 2019;9:37778–87.

Yoshii H, Furuta T, Yasunishi A, Hirano H. Minimum number of water molecules required for inclusion of d-limonene in the cyclodextrin cavity1. J Biochem. 1994;115:1035–7.

Gorbatchuk VV, Gatiatulin AK, Ziganshin MA, Gubaidullin AT, Yakimova LS. Unusually high efficiency of β-cyclodextrin clathrate preparation by water-free solid-phase guest exchange. J Phys Chem B. 2013;117:14544–56.

Gatiatulin AK, Osel’Skaya VY, Ziganshin MA, Gorbatchuk VV. Size exclusion effect in binary inclusion compounds of α-cyclodextrin. Phys Chem Chem Phys. 2018;20:26105–16.

Gatiatulin AK, Ziganshin MA, Gorbatchuk VV. Selective preparation of beta-cyclodextrin clathrates by solid-phase exchange of included tetrahydrofurane for volatile guests in absence of water. J Therm Anal Calorim. 2014;118:987–92.

Ho TM, Howes T, Bhandari BR. Encapsulation of CO2 into amorphous alpha-cyclodextrin powder at different moisture contents—Part 1: encapsulation capacity and stability of inclusion complexes. Food Chem. 2016;203:348–55.

Ho BT, Bhandari BR. Novel solid encapsulation of ethylene gas using amorphous α-cyclodextrin and the release characteristics. J Agric Food Chem. 2016;64:3318–23.

Armarego WLF, Chai CLL. Purification of laboratory chemicals. Boston: Butterworth-Heinemann; 2009.

Yakimova LS, Ziganshin MA, Sidorov VA, Kovalev VV, Shokova EA, Tafeenko VA, et al. Molecular recognition of organic vapors by Adamantylcalix[4]arene in QCM sensor using partial binding reversibility. J Phys Chem B. 2008;112:15569–75.

Gatiatulin AK, Ziganshin MA, Yumaeva GF, Gubaidullin AT, Suwińska K, Gorbatchuk VV. Using water-mimic organic compounds to activate guest inclusion by initially dry beta-cyclodextrin. RSC Adv. 2016;6:61984–95.

Topchieva IN, Tonelli AE, Panova IG, Matuchina EV, Kalashnikov FA, Gerasimov VI, et al. Two-phase channel structures based on α-Cyclodextrin–polyethylene glycol inclusion complexes. Langmuir. 2004;20:9036–43.

Ho TM, Howes T, Bhandari BR. Characterization of crystalline and spray-dried amorphous α-cyclodextrin powders. Powder Technol. 2015;284:585–94.

Kaminski K, Adrjanowicz K, Kaminska E, Grzybowska K, Hawelek L, Paluch M, et al. Impact of water on molecular dynamics of amorphous α-, β-, and γ-cyclodextrins studied by dielectric spectroscopy K. Phys Rev E. 2012;86:031506.

Frieler L, Ho TM, Anthony A, Hidefumi Y, Yago AJE, Bhandari BR. Crystallisation properties of amorphous cyclodextrin powders and their complexation with fish oil. J Food Sci Technol. 2019;56:1519–29.

Chacko KK, Saenger W. Topography of cyclodextrin inclusion complexes. 15. Crystal and molecular structure of the cyclohexaamylose-7.57 water complex, form III. Four- and six-membered circular hydrogen bonds. J Am Chem Soc. 1981;103:1708–15.

Acknowledgements

The work was supported by Russian Government Program of Competitive Growth of Kazan Federal University and by the subsidy allocated to Kazan Federal University for the state assignment in the sphere of scientific activities from the Ministry of Science and Higher Education of the Russian Federation (MSHE RF), No. 0671-2020-0061.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gatiatulin, A.K., Osel’skaya, V.Y., Ziganshin, M.A. et al. Guest exchange in anhydrous inclusion compounds of α-cyclodextrin and its amorphization. J Therm Anal Calorim 146, 2417–2422 (2021). https://doi.org/10.1007/s10973-020-10428-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10428-0