Abstract

WO3 thin films were grown onto the glass and fluorine-doped tin oxide-coated glass substrates using chemical spray pyrolysis technique. X-ray diffraction analyses reveal that all the films possess orthorhombic phase of WO3. Morphologies of the films have been found to vary with Mo-doping concentrations. Three-dimensional atomic force micrographs reveal that the 5 at% Mo-doped film has the maximum image surface area and is optimal for improved electrochromic performance. Cyclic voltammetry studies show that the cathodic and anodic peak current densities have the highest values for the 5 at% Mo-doped WO3 film. Relative to the undoped film, the change from coloured to bleached state is faster for the 5 at% Mo-doped WO3 film. Considering the reversibility and the switching response from chronoamperometry and the coloration efficiency from cyclic voltammetry, it has been concluded that the 5 at% Mo-doped WO3 film has an optimal electrochromic response.

By analysing the results of cyclic voltammetry and chronoamperometry measurements, it has been found that the 5 at% Mo-doped WO3 film has optimal electrochromic performance.

Highlights

-

As-deposited films possess orthorhombic phase of WO3.

-

5 at% Mo-doped WO3 films have the maximum image surface area.

-

WO3 film doped with 5 at% Mo exhibits fastest switching response.

-

5 at% Mo-doped film exhibits optimal electrochromic performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Electrochromism is the phenomenon exhibited by certain materials, where the materials reversibly change their colours when they are subjected to an electric field. Reversible change in colour arises when the material undergoes different electronic states during electrochemical redox reactions. The most important feature of electrochromism is that an electric field is required only during the change (colour or bleach process), which can be controlled at any intermediate stage. Owing to persistence and reversible nature of colour change, such materials, called electrochromic materials, are used in smart windows, which control the amount of light and heat passing through them. In addition, electrochromic materials are used to automatically dimming rear-view mirrors in various ambient light conditions, and more recently, in electrochromic displays.

Electrochromic materials belong to both inorganic and organic chemical systems. Inorganic systems include transition metal oxides, phthalocyanine compounds, Prussian blue, etc., whereas organic systems are bipyridilium systems, conducting polymers, etc. [1,2,3,4,5,6]. Among transition metal oxides, tungsten oxide (WO3) is the most promising one for electrochromic device applications, and therefore has been widely studied. Kostis et al. [7] have reported the improved electrochromic behaviour of highly porous WO3 films deposited by the hot wire method combined with rapid injection of oxygen pulses. Bhosale et al. [8] have studied the electrochromic properties of hydrothermally synthesised WO3 nanoflowers on etched ITO substrates. Li et al. [9] have investigated the electrochromic performance of amorphous tungsten oxide films deposited by DC sputtering. Karuppasamy and Subrahmanyam [10] have studied electrochromic behaviour of sputter-deposited vanadium doped WO3 thin films.

Various techniques such as pulsed laser deposition [11], spin coating [12], sol–gel [13], electrodeposition [14], sputtering [15], etc. have been employed to prepare WO3 thin films. In the present work, chemical spray pyrolysis technique being simple in operation and involving low-cost equipment, has been used to grow WO3 thin films. It is a well established fact that electrochromic performance of the films is closely linked to the microstructural features of the films, which are greatly influenced by the deposition technique, the precursor and the solvent used. Another effective way to alter the microstructural features of the film is the inlay of appropriate dopants in the host lattice network. Although addition of dopants such as V, Ti, Zn, Nb, Ni, Ru, etc. in WO3 lattice network has been studied for improving the electrochromic behaviour of the films [10, 16,17,18,19], but exploration of new dopants as well as less-investigated dopants such as Mo, Gd, etc. in WO3 lattice network to improve electrochromic performance of the films always remains the subject of great interest to the materials scientists, which is behind the motivation and the driving force for this investigation. Yin et al. [15] have studied the influence of Gd doping on electrochromic behaviour of sputter-deposited WO3 films and found high coloration efficiency and fast switching response for the Gd-doped film. Karuppasamy and Subrahmanyam [10] have reported that the addition of vanadium to WO3 thin films decreases coloration efficiency of the films. Paipitak et al. [16] have investigated the influence of Ti and Zn doping on the structural and electrochromic performance of sol–gel-derived WO3 thin films and found that small doping concentration of Ti improves the electrochromic performance of the films. Influence of Nb doping on the electrochromic properties of spray-deposited WO3 thin films have been studied by Bathe and Patil [17]. They have reported that the coloration efficiency is decreased upon Nb doping, but the charge storage capacity, reversibility and cycle stability improve for the doped films. Green et al. [18] have studied electrochromism in sputter-deposited NixW1−x oxide films and reported that Coloration efficiency improves for films with 0.10 < x < 0.15. Cazzanelli et al. [19] have examined the influence of Ru doping on the optical and electrochromic properties of sputter-deposited WO3 thin films, and found that the presence of Ru ions affects these properties of the films. To the best of our knowledge, there are only a very few investigations on the effect of Mo doping on the electrochromic behaviour of tungsten oxide thin films [20, 21]. León et al. [20] have reported the improved electrochromic behaviour of sprayed WO3 thin films by Mo doping. Madhavi et al. [21] have found that 1.3 at% Mo doping to sputter-deposited WO3 thin films improves optical modulation and coloration efficiency of the films. In this paper, we have reported the results on the electrochromic performance of spray-pyrolysed WO3 thin films upon Mo doping. The novelty of this study is that the host and dopant precursors used here are quite different from those used by earlier researchers [20], resulting in modification in the microstructural and electrochromic properties of the films.

2 Experimental details

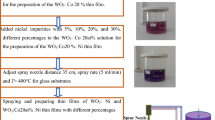

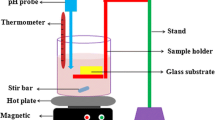

Undoped and Mo-doped WO3 thin films were grown onto the glass and fluorine doped tin oxide (FTO)-coated glass substrates, employing the chemical spray pyrolysis technique. Spray pyrolysis involves the pyrolytic decomposition of a precursor solution when sprayed onto the hot substrate, resulting in the formation of thin films. The host precursor solution used here was ammonium tungstate ((NH4)2WO4) dissolved in warm water (60–70 °C). Ammonium tungstate as the host precursor was chosen in the present investigation because first, the decomposition reaction was thermodynamically favourable and no residue of the reactant was left behind in the deposited films; second, the precursor salt was completely dissolved in the warm water without any further chemical treatment; and third, the precursor salt was commercially available and cost-effective. The dopant salt used was molybdenum (V) chloride (MoCl5). All the chemicals were of high purity obtained from Alfa Aesar (U.K.). Prior to deposition, the glass and FTO-coated glass substrates were cleaned thoroughly. The schematic representation of home-made spray pyrolysis set-up has been described elsewhere [22]. The deposition parameters were optimised to grow good quality thin films by controlling the process parameters after several depositions. It has been found that substrate temperature is the most crucial parameter in spray pyrolysis, which was kept at ~390 ± 10 °C. The concentration of host precursor solution was 0.1 m. The electrode area of as-deposited film in each case was 2.5 cm2. The amounts of tungsten oxide deposited on the substrates were determined with the help of an electronic precision balance (Citizen make; Model CX165). The reproducibility of the films was confirmed by analysing the experimental results of several samples under identical conditions. The formation of WO3 film can be described by the following chemical reaction [23]:

The as-deposited films were subjected to further characterisations of different physical properties. The crystallographic phases of the as-deposited films were determined by X-ray diffraction (XRD) analyses using a Rigaku X-ray diffractometer with CuKα1 (λ = 1.5406 Å) radiation. The surface morphologies of the films were evaluated using a field-emission scanning electron microscope and an atomic force microscope (AFM). Compositional analyses of the films were carried out by the energy-dispersive X-ray (EDX). The optical transmittance spectra of the films were recorded by employing a Shimadzu UV–Vis–NIR spectrometer (Model: UV 3600 Plus) in the wavelength range of 300–800 nm. The electrochromic behaviour of the films deposited on FTO-coated glass substrates were studied using a three-electrode electrochemical cell configuration with the film as a working electrode, platinum wire as a counter electrode, and Ag/AgCl as a reference electrode. All measurements were taken by means of an Electrochemical Analyser (Model: Autolab PGSTAT101) in the electrolyte of 0.01 m H2SO4.

3 Results and discussion

3.1 Structural and morphological studies

3.1.1 XRD analyses

The XRD profiles of the as-deposited films onto FTO-coated glass substrates are shown in Fig. 1. All the films are polycrystalline in nature and possess orthorhombic phase of WO3 (JCPDS Card No. 71-0131). No phase corresponding to molybdenum or other molybdenum compound is observed in the pattern, indicating that molybdenum gets incorporated into the tungsten oxide lattice. Orthorhombic phase of WO3 has also been reported by Madhavi et al. [20] in the sputtered tungsten oxide films. Rajagopal et al. [24] have observed orthorhombic phase of WO3 in hydrothermally synthesised WO3 nanostructures. León et al. [21] have reported the monoclinic phase of WO3 in spray-pyrolysed tungsten oxide films, where the spray solution used was tungsten chloride (WCl6) dissolved in dimethylformamide (HCON(CH3)2). It has been established that WO3 shows the polymorphism behaviour, i.e., it crystallises in a variety of crystal lattice systems. The basic structure of tungsten oxide consists of WO6 octahedra shared among several arrangements (edges, corners, and planes) and connected with one another by W–O–W bonds. The structural transformation occurs due to the shifts in the position of W atom in the octahedra, and the changes in the W–O bond lengths [2, 25]. In fact, the polymorphism of WO3 is influenced considerably by the growth technique as well as process parameters including precursors and solvents used in the technique.

It has been observed that the preferential growth of the film along different lattice planes is closely related to the varying Mo-dopant concentration. The low intensity peaks (132) and (420) observed in the XRD pattern of undoped WO3 disappear with the addition of 1 at% Mo doping, whereas additional peaks in the XRD pattern are observed upon higher Mo doping. The diffraction peaks corresponding to FTO glass substrate are not seen in the XRD profile of 5 at% Mo-doped WO3 film. It is inferred that nucleation and growth kinetics of the films are dependent upon Mo doping concentration. The d-spacings corresponding to three most intense peaks observed in the XRD profiles of the films, and the average crystallite size estimated from these peaks using the Scherrer Eq. 2 given below [22] are listed in Table 1. The unit cell parameters (a, b, and c) and the lattice strain (ε) have been determined using the Eq. 3 and the tangent formula (4) given below [22, 26], respectively, and are listed in Table 1.

where λ, β′ and θ represent the X-ray wavelength, the full width at half maximum (FWHM) of the diffraction peak, and the Bragg’s diffraction angle, respectively. Variation observed in the crystallite sizes of different films is attributed to the density of nucleation sites during the film growth, which, in turn, is influenced by the Mo doping concentration. The unit cell parameters listed in Table 1 are found to be in close agreement with those described in JCPDS Card No. 71-0131 (a = 7.341 Ǻ, b = 7.570 Ǻ, and c = 7.754 Ǻ). A little variation observed in the unit cell parameters upon Mo doping is attributed to incorporation of molybdenum into WO3 lattice network as the ionic radii of W6+ and Mo6+ are different.

3.1.2 SEM analyses

Figure 2a–d presents the SEM micrographs and the corresponding EDX profiles of the WO3 films. The undoped WO3 film exhibits island-like morphology comprising of tiny grains. With the addition of molybdenum in WO3, the morphology of film is changed. Upon 1 at% Mo doping, the film presents interweaved nest-like morphology. With the increase of doping to 2 at%, the morphology changes to root-like architecture. On further enhancement to 5 at% Mo doping, the film presents densely interweaved nest-like morphology. The enhanced interweaved-channels in 5 at% Mo-doped film provide sufficient pathways for easy diffusion of ions into the film network and faster kinetics which improve the electrochromic performance of the films. The EDX profiles confirm the presence of elements W and O in the undoped film, and W, Mo, and O in the doped films.

3.1.3 AFM analyses

Two- and three-dimensional AFM images, depicted in Fig. 3a–d, of the WO3 films have been analysed using the Nanoscope Analysis software. The topographical parameters, viz., image surface area, image projected surface area, root mean square roughness (Rq) and average roughness (Ra) of the films thus obtained are listed in Table 2. As evident from the Table 2, among all the films, the image surface area is maximum for the 5 at% Mo-doped film, implying that the topography of the film is optimal for improved electrochromic performance. Further, the values of Rq and Ra are maximum for the 1 at% Mo-doped film followed by those of 5 at% Mo-doped film. This may arise due to more number of nucleation sites available during the time of film growth in the case of 5 at% Mo-doped film relative to that available in the 1 at % doped film; which is in agreement with the topographies of these films [Fig. 3(b, d)].

3.2 UV–visible spectroscopy studies

Optical transmission spectra of the WO3 films deposited onto glass substrates are shown in Fig. 4. It has been found that all the films exhibit high transmittance varying between 65% and 75% in the visible range. Because of different film morphologies (surface roughness), there is a variation in transmittance arising out of the scattering of light [27]. Shifting of the absorption edge towards longer wavelength upon Mo doping implies decrease in the band gap energy. The optical band gap energies have been determined using the well-known Tauc’s equation [28]:

where K is a constant, Eg is the band gap energy of the semiconductor, α is the absorbance coefficient, and the values of exponent p depend upon the nature of band transition (p = ½ for direct transition, and p= 2 for indirect transition).

Having the reports of both direct and indirect transitions occurred in WO3 [22, 29], the band gap energy value has been determined for both types of transitions. The direct band gap energy has been determined by extrapolating the linear portion of the (Ahν)2 versus hν plots to the energy-axis, shown in Fig. 5. Inset of Fig. 5 presents the plot of (Ahν)2 versus hν of 1 at% Mo-doped film in the extended ordinate. The direct band gap energies thus obtained are in the range of 3.50–3.56 eV. The direct band gap energy values of WO3 films depend upon the crystallinity of the films, and can be found in the range of 3.27–3.65 eV [30]. The indirect band gap energy has been estimated from the linear extrapolations of the plots of (Ahν)1/2 versus hν to the energy-axis, shown in Fig. 6. Variation in the indirect band gap energies arises owing to the formation of allowed energy states in the band gap region of WO3. In general, semiconducting materials may have direct or indirect band gap depending upon their crystal structures which are influenced by the preparative conditions. But in some cases, a material may have the both if it has a partial crystalline nature or is under the application of strain. Sharon et al. [31] have also reported both direct and indirect band gap energies for orthorhombic WO3 film prepared by the vacuum evaporation technique.

3.3 Electrochromic studies

The basic mechanism involved in electrochromism is the phenomenon of charge transport in the crystal lattice. WO3 thin film with tungsten sites as oxidation state W+6 is colourless in nature. Owing to insertion of charges during electrochemical reaction, W+6 are reduced to W+5 states, giving blue coloration to the film. On electrochemical oxidation, W+6 sites are generated, changing blue coloration in the film to colourless. It has been widely accepted that insertion and extraction of electrons and metal ions (H+, Li+, etc.) in the crystal lattice play an important role in electrochromism. The electrochemical redox reaction involving coloration and bleaching phenomena in WO3 thin films can be written as [32]:

where M+ = H+, Li+, etc. MxWO3 is, in general, called as tungsten bronze. The subscript x in the formula MxWO3 represents the fractional number of sites, called the insertion coefficient, which are filled in the WO3 lattice. At low x, intervalence charge transfer between W+5 and W+6 adjacent states results in blue coloration to the film. At higher x, the inserted ions expand the lattice of WO3, whereas the compensating electrons enter the extended states of conduction band and thus alter its electronic structure which, in turn, affects its optical properties [1]. The electrochromic behaviour of the WO3 films has been investigated by analysing the results of cyclic voltammetry (CV), Chronoamperometry, and impedance spectroscopy measurements.

3.3.1 Cyclic voltammetry

To investigate the cathodic/anodic behaviour of the WO3 films, CV measurements were performed in the potential region of + 0.7 V to − 0.7 V at four different scan rates viz. 10, 20, 50, and 100 mV/s in the electrolyte of 0.1 m H2SO4. The cyclic voltammograms of the films thus measured are depicted in Fig. 7. Usually, when the WO3 film electrodes are cathodically polarised, they have a progressive increase in the blue coloration with increasing cathodic potential. When the blue film electrodes are anodically polarised, they are bleached and almost colourless. During cathodic scan, as the potential is decreased, the current density goes on decreasing and attains a maximum negative value at the potential of − 0.7 V, corresponding to deep blue coloration to the film. This process is associated with the insertion of electrons and H+ ions into the WO3 films, resulting in the reduction of W+6 to W+5 states. During anodic scan, with the increase of potential, the current density goes from negative value to a maximum positive value and then decreases, corresponding to bleaching of the films. This is associated with the extraction of intercalated charges from the film structure, leading to the oxidation of W+5 → W+6. As evident from the cyclic voltammograms, all the films show a well-defined broad anodic peak during anodic scan, whereas a spike instead of a peak is observed at the potential of − 0.7 V during cathodic scan. Non-appearance of a well-defined peak in cathodic region is attributed to the back electromotive force formed within the tungsten bronze during ion insertion [33]. As shown in Fig. 7, the cathodic and anodic peak current densities are found to have the highest values for the WO3 film doped with Mo concentration of 5 at%.

It has been found that for each film the anodic peak current density increases with the increasing scan rate and also shifts towards the higher potential. Shifting of anode peak position towards higher potential indicates that the change from coloured to bleached state is slower at higher scan rates [21]. This may be attributed to slower electron exchange kinetics at higher scan rates. The cathodic peak (spike) current density also rises with the increase of scan rate. The increase in cathodic and anodic peak current densities at higher scan rates is due to enhanced extent of H+ ions insertion and extraction in the WO3 film structure [34, 35]. Furthermore, the increased area of cyclovoltammetric curve with the increasing scan rate indicates larger amount of charge exchange during redox reaction at higher scan rates.

Figure 8 presents the cyclic voltammograms of all the films recorded at a particular scan rate of 10 mV/s. Except for the case of 2 at% Mo doping, the cathodic and anodic peak current density increases for the WO3 films doped with 1 at and 5 at% Mo. This indicates high capability of charge insertion and extraction for the film structure [36]. Also the anodic peak potential shifts towards the lower potential relative to that observed in the undoped WO3 film. This indicates that the change from coloured to bleached state is faster for the WO3 films doped with Mo. This is closely related to the microstructural features of the films. Among all the films, the area of cyclovoltammetric curve of the 5 at% Mo-doped WO3 film has been found to be maximum [Fig. 8], signifying the greatest amount of charge exchange taking place in the film during electrochemical redox reaction. This reveals that insertion and extraction of H+ ions are enhanced in WO3 film doped with 5 at% Mo.

The extent of insertion and extraction of H+ ions into the WO3 host lattice can be studied by calculating the diffusion coefficient using Randles–Sevcik equation [37, 38]:

where Jp is the peak current density in A/cm2, n is the number of electrons involved in the redox process (it is assumed to be 1), D is the diffusion coefficient in cm2/s, C is the concentration of active ions in the electrolyte solution in mol/cm3, and ν is the scan rate in V/s. The diffusion coefficients thus obtained are listed in Table 3. It has been found that there is a variation in the diffusion constant values upon Mo doping, which could be due to variation in the mobility of the diffusing ionic species (H+) in the redox reaction. The mobility of the H+ ions in the film is influenced greatly by the microstructural features of the film.

To calculate the coloration efficiency of the WO3 films, the optical transmittance spectra of the coloured (with the application of cathodic potential of − 0.7 V) and bleached (with the potential of + 0.7 V) states of the films were recorded, and are shown in Fig. 9. The change in optical density (∆ OD) has been determined from the optical transmittances of coloured (Tcoloured) and bleached (Tbleached) films using the relation:

Coloration efficiency (η) defined as the ratio of the change in optical density to the amount of charge intercalated, has been determined by the relation [39]:

where A is the electrode area of the film and Q is the amount of charge intercalated which is derived from the CV measurements [9, 38]. Figure 10 presents the plot of change in optical density, ΔOD, versus wavelength, λ, of the WO3 films, whereas plot of the amount of charge intercalated per unit area, Q/A, versus Mo-dopant concentration is depicted in Fig. 11. It has been found that the coloration efficiency of the WO3 film improves upon Mo doping, having the highest value 43.3 for the doping of 5 at% Mo. This evinces that the structure of 5 at% Mo-doped WO3 film provides an easy way to diffusion and charge transfer process of ions.

The electrochemical stability of the WO3 films has been examined by repeating reduction–oxidation cycles between the sweep potential range from + 0.7 V to − 0.7 V several times at the scan rate of 50 mV/s [Fig. 12]. In all the films, the nature of the cyclovoltammetric curves remains almost unchanged even after 100 reduction–oxidation cycles, thus establishing good electrochemical stability of the films.

3.3.2 Chronoamperometry

Chronoamperometry measurements were carried out for 10 cycles with the potential being stepped between − 0.7 V and + 0.7 V vs. Ag/AgCl for 25 s, and are shown in Fig. 13. Here, we only present the first three cycles to avoid clustering of data in the figure. In the time interval 0–25 s, the film was in coloured state while in the next time interval 25–50 s the film was in bleached state. As evident from the Fig. 11, in 5 at% Mo-doped film, on applying the potential of − 0.7 V, the current density remains constant for a considerable time and then begins to decrease. This leads to infer that in the beginning for a considerable time, there is no potential barrier formed at the WO3-electrolyte interface; as a result the current density arising due to insertion of H+ ions into the film remains almost constant. Later on, a progressive potential barrier at the WO3-electrolyte interface is formed, resulting in a decrease in current. Further, during oxidation cycle, on applying the potential of + 0.7 V, the current density remains constant for some time and thereafter begins to fall. Therefore, it is inferred that during bleaching, in the beginning for some time, the extraction of H+ ions from the bulk of the film is not governed by the space-charge. The WO3 film doped with 5 at% Mo exhibits fastest switching response. In general, the coloration process is slower than the bleaching in WO3 films owing to faster bleaching kinetics [17].

The reversibility of the films, defined as the ratio of the charge extracted to the charge intercalated in the film, is listed in Table 3. The values of charge intercalated and charge extracted are obtained from the integration of the cathodic and anodic current densities. It has been found that the reversibility is optimal for the film with 5 at% Mo doping. Considering the reversibility and the switching response from chronoamperometry and the coloration efficiency from cyclic voltammetry it has been concluded that the 5 at% Mo-doped WO3 film has an optimal electrochromic response.

3.3.3 Electrical impedance spectroscopy

Figure 14 presents the Nyquist plots in the frequency range of 10 kHz–1 Hz, comprising of the real versus the imaginary component of the electrical impedance of the WO3 films. The Bode plots comprising of the logarithm of the measured impedance (Z) and the phase angle, versus the logarithm of the frequency are depicted in Fig. 15. The Bode plots provide a good comparison of total impedance values for WO3 films. The Nyquist impedance plots have been analysed using Nova software, taking into consideration the equivalent circuit shown in the inset of Fig. 12, and the fitted parameters are listed in Table 4. In the equivalent circuit, Rs corresponds to the electrolyte resistance; Rfilm and Cfilm are the resistance and capacitance of the WO3 film, respectively; Rct is the charge transfer resistance at the electrolyte/electrode interface, signifying how beneficial is the film morphology for proton transfer; W is the Warburg diffusion impedance (ionic diffusion in the film electrode), and Cdl is the capacitance of WO3/electrolyte interface [40]. Mathematically, Warburg impedance is expressed as: W = 1/[Yo (jω)0.5], where Yo is the admittance (1/ |Z|) at ω = 1 rad/s. Among all the circuit elements, the charge transfer resistance is the most important element of the circuit, closely linked to the electrochromic behaviour of the films. The charge transfer resistance is the resistance offered to the process of electrons from the film electrode to the H+ ions in the liquid phase, and therefore it should have low value for films showing good electrochromic properties [41, 42]. Goodness of fit, χ2, in impedance spectroscopy is also included in Table 4. The lower values of chi-square support the best fit of Nyquist plots. As evident from Table 4, the charge transfer resistance is least for the 5 at% Mo-doped WO3 film. That is why during chronoamperometry measurements [Fig. 13], on applying the cathodic potential, the current density remains constant for a considerable time in the case of 5 at% Mo-doped film.

A comparison of this work with those for other dopants in WO3-based films/devices reported earlier in literature is presented in Table 5.

4 Conclusions

All the as-prepared films possess orthorhombic phase of WO3. With varying Mo-doping concentrations, the morphologies of films change. Three-dimensional AFM image analyses show that the 5 at% Mo-doped film has the maximum image surface area. The optical direct band gap energies of WO3 films have been found to be in the range of 3.50–3.56 eV. Among all the films, WO3 doped with 5 at% Mo exhibits fastest switching response and highest colouration efficiency. It has been concluded that the spray-pyrolysed 5 at% Mo-doped WO3 films have an optimal electrochromic performance, and therefore have the potential to be used as an effective electrochromic material for smart window applications.

Nyquist impedance plots of the WO3 films. Solid and dashed lines represent the experimental and fitted data, respectively. Inset of Fig. 12 represents the equivalent circuit fitting

References

Somani PR, Radhakrishnan S (2002) Mater Chem Phys 77:117

Granqvist CG (1995) Handbook of Inorganic Electrochromic Materials, Elsevier, Amsterdam

Kahl JL, Faulkner LR, Dwarakanath K, Tachikawa H (1986) J Am Chem Soc 108:5434

Honda K, Ochiai J, Hayashi H (1986) J Chem Soc Chem Commun 1:168

Bruinink J (1976) Electrochromic display devices. In: Kmetz AR, VonWilli FK (Eds.) Non-emissive Electro-optic Displays. Plenum Press, New York

Bernard MC, Goff AH-L, Zeng W (1998) Electrochem Acta 44:781

Kostis I, Vasilopoulou M, Soultati A, Argitis P, Konofaos N, Douvas AM, Vourdas N, Papadimitropoulos G, Davazoglou D (2013) Microelectron Eng 111:149

Bhosale NY, Mali SS, Hong CK, Kadam AV (2017) Electrochim Acta 246:1112

Li C, Hsieh JH, Hung M-T, Huang BQ (2015) Thin Solid Films 587:75

Karuppasamy KM, Subrahmanyam A (2008) J Phys D: Appl Phys 41:035302. 6pp

Rougier A, Portemer F, Quede A, Marssi ME (1999) Appl Surf Sci 153:1

Wang Z, Hu X (2001) Electrochim Acta 46:1951

Ozer N, Lampert CM (1999) Thin Solid Films 349:205

Hepel M, Redmond H, Dela I (2007) Electrochim Acta 52:3541

Yin Y, Lan C, Hu S, Li C (2018) J Alloy Compd 739:623

Paipitak K, Techitdheera W, Porntheeraphat S, Pecharapa W (2013) Energy Procedia 34:689

Bathe SR, Patil PS (2007) J Phys D: Appl Phys 40:7423

Green SV, Pehlivan E, Granqvist CG, Niklasson GA (2012) Sol Energy Mater Sol Cells 99:339

Cazzanelli E, Castriota M, Kalendarev R, Kuzmin A, Purans J (2003) Ionics 9:95

O-Rueda de León JM, Acosta DR, Pal U, Casta˜neda L (2011) Electrochim Acta 56:2599

Madhavi V, Kumar PJ, Kondaiah P, Hussain OM, Uthanna S (2014) Ionics 20:1737

Mukherjee R, Kushwaha A, Sahay PP (2014) Electron Mater Lett 10:401

Mukherjee R, Prajapati CS, Sahay PP (2014) J Therm Spray Technol 23:1445

Rajagopal S, Nataraj D, Mangalaraj D, Djaoued Y, Robichaud J, Khyzhun OY (2009) Nanoscale Res Lett 4:1335

Muller U (1993) Inorganic Structural Chemistry. Wiley, Chichester

Wahab MA (2010) Solid State Physics. Narosa Publishing House, New Delhi

Beena D, Lethy KJ, Vinodkumar R, Pillai VPM, Ganesan V, Phase DM, Sudheer SK (2009) Appl Surf Sci 255:8334

Goswami A (2005) Thin Film Fundamentals, New Age International (P) Ltd., New Delhi

Asghari Z, Eshghi H (2017) J Electron Mater 46:1439

Deb SK (1973) Philos Mag 27:801

Sharon M, Sharan MK, Jawalekar SR (1984) Sol Energy Mater 10:329

Patil PS, Patil PR, Kamble SS, Pawar SH (2000) Sol Energy Mater Sol Cells 60:143

Patil PR, Pawar SH, Patil PS (2000) Solid State Ion 136–137:505

Sivakumar R, A. Raj ME, Subramanian B, Jayachandran M, Trivedi DC, Sanjeeviraja C (2004) Mater Res Bull 39:1479

Meenakshi M, Gowthami V, Perumal P, Sivakumar R, Sanjeeviraja C (2015) Electrochim Acta 174:302

Kalagi SS, Mali SS, Dalavi DS, Inamdar AI, Im H, Patil PS (2012) Electrochim Acta 85:501

Nicholson RS, Shain I (1964) Anal Chem 36:706

Mukherjee R, Sahay PP (2016) J Alloy Compd 660:336

Lu Y, Liu L, Mandler D, Lee PS (2013) J Mater Chem C 1:7380

Lee SH, Cheong HM, Tracy CE, Mascarenhas A, Pitts JR, Jorgensen G, Deb SK (2000) Appl Phys Lett 76:3908

Alsawafta M, Golestani YM, Phonemac T, Badilescu S, Stancovski V, Truong V-V (2014) J Electrochem Soc 161:H276

Mishra RK, Prajapati CS, Sahay PP (2018) J Alloy Compd 749:172

Acknowledgements

We express our gratitude to Centre for Interdisciplinary Research, MNNIT Allahabad, India for providing XRD and UV–Vis measurements, and Sophisticated Analytical Instrument Facility, Indian Institute of Technology Bombay, India for SEM and AFM characterisation facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, A., Prajapati, C.S. & Sahay, P.P. Modification in the microstructural and electrochromic properties of spray-pyrolysed WO3 thin films upon Mo doping. J Sol-Gel Sci Technol 90, 281–295 (2019). https://doi.org/10.1007/s10971-019-04960-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-04960-1