Abstract

Substitution of TbZn in the series of Ca0.5Ba0.5−x Tb x Zn y Fe12−y O19 (x = 0.00–0.10; Y = 0.00–1.00) hexaferrites prepared by sol–gel method and their effect on the structural, electrical and magnetic properties are investigated. Temperature-dependent magnetic behaviors of selected samples are observed up to the magnetic field of 8T taken over temperature ranges from 4.2 to 373 K. The coercivity of the samples decreases from 2740 to 1370 Oe with increasing temperatures in a linear fashion up to 373 K. The grain boundaries and the associated pinning fields seem to have an important role in the magnetic behavior of these hexaferrites. The resistivity of ferrite decreases from 24 × 108 to 15 × 108 Ω-m. The temperature dependence of resistivity and mobility exhibits the degenerate-type semiconductor-like behavior of these ferrites. The dielectric constant and dielectric loss decrease and show relaxation behavior at higher frequencies.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ferrites are considered to be the very useful magnetic materials discovered so far, and they possess wide range of technological applications. Among other types of ferrites, hexaferrites have unique electrical and magnetic properties and they are thought of very attractive type of magnetic materials having applications in different devices such as cores of transformer, magnetic memories, noise filters and isolators, magnetic recording media, magneto-optical devices and permanent magnets. Many studies on the magnetic properties of hexagonal ferrites have been reported, which shows enhanced magnetic, structural and microwave properties due to incorporation of rare earth elements [1–4]. Moreover, low cost, easy manufacturing and high power at low loss of these hexaferrite materials have greatly increased their production and effectiveness at commercial level. The studies on BaFe12O19 showed that nanosized hexagonal BaFe12O19 has a single magnetic domain and high anisotropy due to which it offers excellent magnetic properties which strongly depend on the mean grain size and morphology of the synthesized materials [5–9]. As communication and electronic systems are moving toward higher working frequencies, so the spinel ferrites seem to have less demand as compared to hexaferrites. Such type of technological progress has set off the potential of hexaferrites in order to replace spinel ferrites in applications having ferrite devices that operate in microwave frequencies for microwave absorbers. Research growth in the field of microwave-absorbing materials working at higher frequency range is driven by the ever increasing requirement of exploiting electromagnetic waves for wireless telecommunication systems and reduction in radar signatures, as in stealth technology. The intrinsic magnetic properties resulted from the specific site occupancy of the Fe ions and rare earth elements along with divalent cations enhance the electromagnetic properties of ferrites [10, 11]. These reasons make the manipulation of Fe and RE in the lattices, as a promising way to improve magnetic properties of hexagonal ferrites. Due to the fundamental and application point of view, the electrical properties are of great importance for hexaferrites. The electrical properties like activation energy and ac conductivity for conduction reveal very novel information regarding the usefulness of these materials for various applications [12]. In this work, the sol–gel method has been used to fabricate calcium barium hexaferrites. M-type hexaferrites as Ca/Ba base have not been studied extensively so far; however, some of the studies have been performed till now [13]. Calcium and barium are chosen as base due to their intrinsic properties, and also the combination of divalent and rare earth improves electrical and magnetic properties [14, 15]. The high electrical resistivity and low dielectric losses are thought to be useful in applications of microwave absorption, recording media, optical wave guides and permanent magnets [16]. The aim of the present study is to investigate the effect of TbZn substitution on electrical transport properties and temperature-dependent magnetization of Ca-based M-type hexaferrites.

2 Experiment details

2.1 Sample preparation

M-type hexaferrites with chemical composition of Ca0.5Ba0.5−x Tb x Zn y Fe12−y O19, x = 0.00–0.10 and y = 0.00–1.00 were prepared by sol–gel autocombustion method [21]. Ca0.5Ba0.5−x Tb x Zn y Fe12−y O19 samples were synthesized by utilizing analytical grade citric acid (used as chelating agent), iron chloride (FeCl3.6H2O), calcium chloride (CaCl2), barium nitrate Ba(No3)2, zinc nitrate Zn(NO3)2 and terbium oxide (Tb2O3) (99.99 % pure) by dissolving them one by one in 100 ml deionized water except Tb2O3 as it is insoluble in water. It was first dissolved in nitric acid at 80 °C and converted into nitrate and poured into the prepared solution. In order to maintain the pH value at 7, an aqueous solution of ammonia at 40:60 ratio was added drop-wise, meanwhile, stirring at 60 °C. The sols then prepared were allowed to gel at the temperature of 60 °C. After drying at 200 °C, powdered gel was formed. An agate mortar and pestle were used to ground the dried gel homogenously for 30 min. Finally, the homogenized powder was then sintered at 1100 °C for 8 h.

2.2 Characterization

X-ray diffraction analysis was performed using Shimadzu X-ray diffractometer equipped with CuKα radiation λ = 1.5406 Å. The crystallite sizes were found by Scherrer formula [17].

As ‘K’ is referred as the shape constant, λ indicates the wavelength, β is intensity of FWHM and the Bragg angle is denoted by θ. X-ray density values, bulk density, porosity and the volumes of unit cell were calculated in the research paper already published and include Fourier transform infrared spectroscopy, X-ray diffraction, vibrating sample magnetometry, scanning electron microscopy and electron microscopy titled, ‘Structural and magnetic properties of TbZn substituted Ca0.5Ba0.5Fe12O19 hexa-ferrite nanoparticles’ [18]. The sample pellets were made by using sintered powders. The sintered powders were compressed into the shape of pellets under the load of (30 kN) with the help of Paul-Otto Weber Hydraulic Press. Polyvinyl alcohol (3–5 wt%) was used as binder in the formation of the pellets. The binder was evaporated at 250 °C when pellets were resintered at 900 °C for 5 h. Moreover, the DC resistivity was measured using two-probe method by source meter model 2400 Keithley. The dielectric properties were measured using inductance, capacitance and resistance (LCR) meter model 8101 Gw INSTEK. The capacitance ‘C’ and dielectric loss are measured in the frequency range of 100 kHz. Dielectric constant ‘ε r’ was calculated using the following formula:

where d is the thickness of the sample, C is the measured capacitance, A is the area of cross section of the sample pellet and ε 0 is the dielectric permittivity of the free space. Ac conductivity was calculated from the values of ε r and dielectric loss using the relation

where f is the frequency of the applied voltage [19]

3 Results and discussions

3.1 Temperature-dependant M–H loop

The temperature dependence of M–H loops taken in the temperature ranges 4.2 and 373 K of a selected Ca0.5Ba0.5TbZnFe12O19 hexaferrite sample are shown in Fig. 1. The hysteresis loops were recorded at the temperatures of 4.2, 77, 273, 298 and 373 K, respectively. Between these temperatures, the increased thermal disorder decreases the coercivity in the samples and is shown in Fig. 2 and the coercivity of the sample decreased with increasing temperatures in a linear fashion up to 373 K. The decrease in coercivity is consistent with the reduction in grain size during heat treatment. The grain boundaries and the associated pinning fields seem to have an important role in the behavior of magnetic oxides. However, it has been inferred that large pinning fields exist at grain boundaries, their origin must be responsible for perturbations in the magnetic properties on a very fine scale and these changes in coercivity resulted due to domain wall pinning fields. Figure 3 shows the corresponding observed magnetic parameters of the TbZn-doped ferrites and reveals that the saturation magnetization M s and M r of the as-prepared ferrites decreased in response to the heat treatments. However, it has been reported earlier that for hexagonal ferrites, M s continuously decreases with increase in temperature and almost a linear behavior of saturation magnetization has been observed over a wide range of temperature [20, 21]. The effect of rare earth element Tb3+ and Zn substitution on the magnetic properties of the material is in general useful.

3.2 Electrical properties

3.2.1 Room temperature resistivity

Figure 4 shows room temperature resistivity as a function of TbZn content. The separation of the grains may lead to difficulty in the conduction of the free electrons from grain to grain. The room temperature resistivity decreases on average from 12.3 × 108 Ω-m to 6.7 × 108 Ω-m. As the number of Fe2+ at octahedral site is increasing with the increase in Tb3+ content, then as a result the hopping of electrons between Fe3+ and Fe2+ ions also takes place. Consequently, the resistivity starts to decrease with the increase in the Tb–Zn concentration. The decrease in resistivity may be due to the fact that due to increase in TbZn the separation of the grains decreases, which in turn decreases the resistivity [22].

3.2.2 Temperature-dependent resistivity

Figure 5 shows the Arrhenius plots of the present samples. In general, the electrical properties of the ferrite materials depend upon chemical composition, methods of preparation, sintering temperature, and grain size. Temperature-dependent DC electrical resistivity has been measured from 298 to 575 K. DC electrical resistivity as a function of temperature follows the Arrhenius equation [23]:

where ρ is the DC electrical resistivity at temperature T, ρ 0 is resistivity extrapolated to 1/T = 0, E a is the activation energy and k B is the Boltzmann’s constant. Figure 5 shows that by increasing temperature, the resistivity of ferrite decreases, indicating semiconductor behavior of these ferrites [24, 25]. The conduction in ferrite at room temperature is due to the impurities, whereas at high temperature it is thought of due to polaron hopping. The conductivity in ferrites may be explained by Verwey’s hopping mechanism. According to Verwey, the electronic conduction in ferrite is mainly due to hopping of electrons between ions of the same element present in more than one valence state distributed randomly over crystallographically different lattice sites [26, 27]. It has been reported that coupling of rare earth (RE) ions with transition metal ions as discussed above possibly introduces charge carriers from the hybridized orbital between RE 4f and O2−(2p x) [28]. However, four f 4 unpaired electrons in the 4f orbital of Tb atoms take part in the conduction process and decrease the resistivity. Figure 6 shows the activation energy versus concentrations. It is noted that the activation energies obtained from Arrhenius plots decrease with increasing concentration due to increase in grain size, which indicates that the conduction phenomenon is due to polaron hopping [29].

3.2.3 Drift mobility

Figure 7 shows the variation in drift mobility with temperature for Ca0.5Ba0.5−x Tb x Zn y Fe12−y O19 (x = 0.00–0.10; y = 0.00–1.00) ferrites. The drift mobility was calculated using the resistivity data and is calculated using Eqs. (5) and (6) given above [30].

where ‘ρ’ is electrical resistivity, ‘e’ is the charge on an electron and ‘n’ is the concentration of charge carriers and it is calculated by following relation;

where N A is Avogadro’s number, C Fe is the number of iron atoms in sample, ρ b is the bulk density and M is the molar mass of the samples. It is, however, observed that the drift mobility increases from 2.5 × 10−11 cm2 V−1 s−1 to 27.5 × 10−11 cm2 V−1 s−1 with the increase in temperature. This may be due to the fact that charge carriers start hopping from one site to another as the temperature increases [31]. The temperature dependence of resistivity and mobility shows that the samples are of degenerate-type semiconductors.

3.3 Dielectric properties

3.3.1 Dielectric constant

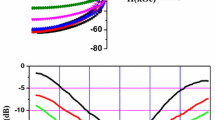

Figure 8 shows the dielectric constant versus frequency for Ca0.5Ba0.5−x Tb x Zn y Fe12−y O19 (x = 0.00–0.10; y = 0.00–1.00) at room temperature 30 °C. The dielectric constant decreases with increasing frequency. At high frequencies, the dielectric constant seems to be independent of frequency. This behavior of the samples is in accordance with the Maxwell–Wagner model [32]. According to the Maxwell–Wagner model [33], the dielectric materials with heterogeneous structure can be imagined as to be composed of good conducting grains separated by highly resistive thin grain boundaries. In this case, the applied voltage on the sample drops mainly across the grain boundaries and a space charge polarization is established at the grain boundaries. The space charge polarization is governed by the free available charges on the grain boundary and the conductivity of the sample. This is due to the fact that in ferrites, the space charge polarization directly depends upon Fe2+ ion concentration in a grain. It is, however, observed that Zn2+ ions have strong preference to occupy tetrahedral A-sites; therefore, concentration of Fe2+ ions on tetrahedral site decreases. Hence, due to decrease in electric polarization, the dielectric constant also decreased. This might also be due to the reason that the Tb3+ ions did not participate in the conduction process but impedes the motion of charge carriers [34]. Koops [35] proposed that the effect of grain boundaries is predominant at lower frequencies, i.e., higher dielectric constant for thinner grain boundaries. High dielectric constants decrease the penetration depth of the electromagnetic waves by increasing the skin effect. Hence, the much lower dielectric constants obtained for the ferrites warrant their application at high frequencies.

3.3.2 Dielectric loss

Figure 9 shows dielectric loss versus frequency for Ca0.5Ba0.5−x Tb x Zn y Fe12−y O19 (x = 0.00–0.10; y = 0.00–1.00) ferrites. Dielectric loss is an important part of the total core loss in magnetic materials. Hence, for low core loss, low dielectric losses are admirable. The dielectric loss decreased substantially with increasing frequency and reached constant value [36]. Dielectric loss represented the energy dissipation in the dielectric system. It is seen that for all the samples, it decreased continuously with increasing frequency. This might be due to the decrease in Fe2+ ion concentration, which is responsible for conduction losses, because of the increase in Tb3+ and Zn2+ contents as explained earlier [37]. In the low-frequency region corresponding to high resistivity due to grain boundaries, more energy is required for electron exchange between Fe3+ and Fe2+ ions, so that the energy loss is high. In the high-frequency range, corresponding to low resistivity, less energy is needed for electron transfer exchange between ferrous and ferric ions in the grains, and hence, the energy loss is minimized. Dielectric loss is an important part of the total core loss in magnetic materials [38]. Hence, for low core loss, low dielectric losses are desirable. The pattern of dielectric loss is similar to those of the real part of dielectric constant. The increase in hopping electrons resulted in a local displacement in the direction of the extent electric field, caused an increase in electric polarization and thus enhanced the dielectric loss. Hudson [39] has shown that the dielectric losses in ferrite are generally reflected in the conductivity measurements where the highly conductive materials exhibited high losses and vice versa.

3.4 AC conductivity

Figure 10 shows the results of AC conductivity (σ ac) as a function of frequency. The real AC conductivity σ′ consists of two terms [32]:

The first σ 1 is the DC conductivity, which is temperature dependent and has been discussed earlier as resistivity is discussed. It was observed that at high temperature the electrical conductivity is high and is frequency independent, as temperature is decreased to room temperature its conductivity decreased. Second term σ 2 is temperature and frequency dependent and is given by [28]:

where ω is the angular frequency, the parameter B has the units of the conductivity and the exponent n is non-dimensional. Equation (6) shows that (σ ac) is increased with increasing frequency. The results of AC conductivity could be explained on the basis of Maxwell–Wagner model and Koops phenomenological theory [40], which supposed that the ferrite samples consist of conducting grains separated by highly resistive thin-layered grain boundaries. According to this model, our results of AC conductivity at low frequencies describe the grain boundary behavior, while the dispersion at high frequency might be attributed to the conductivity of grains.

3.4.1 Conduction mechanism

Figure 11 shows the conduction mechanism for Ca0.5Ba0.5−x Tb x Zn y Fe12−y O19 (x = 0.00–0.10; y = 0.00–1.00) hexaferrites is hopping mechanism. The conduction in normal semiconductors is explained by the energy band mechanism or hopping mechanism of localized charge carriers. In the case of low-mobility semiconductors, such as ferrites, the localized ions come close enough due to the lattice thermal vibrations, and then, small polaron is induced. The intrinsic conduction in semiconductors resulted due to the transfer of electrons from filled valance band to empty conduction band. The intrinsic conduction mechanism in the samples under investigation is ruled out within the studied temperature range [41]. According to Verwey de Boer mechanism, the electron hopping between Fe2+ and Fe3+ ions at the equivalent octahedral B-sites are responsible for electric conduction in ferrite [42]. The value of n is calculated from the slope of the log of conductivity versus log of ω graphs. The AC conductivity in above figure showed little variations at low frequencies, and it follows the power law at relatively high frequencies by following expression of the formula: \(\sigma (\omega )\alpha \omega^{n}\), where ‘n’ is a fractional exponent (0 ≤ n ≤ 1), associated with the dynamic of ions hopping. However, the value of n progressively increases with increasing interactions among moving ions and vice versa at very low values, i.e., n = 0, completely independent of frequency. The values of exponent ‘n’ in the present ferrite samples varied from 0.80 to 0.93. The values of n between 0 and 1 suggest that the process of conduction in the ferrite samples examined follows the polaron hopping mechanism [43, 44].

4 Conclusions

The prepared samples have semiconductor-like behavior, indicating that resistivity decreases with increasing temperature. The drift mobility increases due to thermal activation of the charge carriers with increasing temperature. The dielectric constant and loss follow the normal dielectric dispersion behavior, which is in accordance with the Koops theory and Maxwell–Wagner bilayer model. It appears from the results that the binary mixture of TbZn ions can control the electrical behavior of the calcium–barium hexaferrite nanoparticles, while the conduction in Ca0.5Ba0.5−x Tb x Zn y Fe12−y O19 is explained by hopping conduction mechanism of localized charge carriers.

References

Albnese G, Dariu A, Licci F, Rinaldi S (1978) IEEE Trans Magn 14:710

Kown HJ, Shin JY, Oh JH (1994) J Appl Phys 75:6109

Naiden E, Maltsen V, Ryabtsen G (1990) Phys Stat Sol 120:209

Yoon K, Lee D, Jung H, Yoon S (1992) J Mater Sci 27:2941

Ding J, Maurice D, Miao WF, McCormick PG, Street R (1995) J Magn Magn Mater 150:417

Mendoza Suarez G, Matutes-Aquino JA, Escalante-Garcıa JI, Mancha-Molinar H, Rıos-Jara D, Johal KK (2001) J Magn Magn Mater 223:55

Abbas SM, Dixit AK, Chatterjee R, Goel TC (2007) J Magn Magn Mater 309:20

Kulikowski J (1984) J Magn Magn Mater 41:56

Ruan S, Xu B, Suo H, Wu F, Xiang S, Zhao M (2000) J Magn Magn Mater 212:175

Stergiou CharalamposA, Manolakis Ioannis, Yioultsis TraianosV, Litsardakis George (2010) J Magn Magn Mater 322:1532

Ramasamy DSR (1997) In: International conference electromagnetic interference and compatibility (INCEMIC-97), New Jersey 7B-7, p 459

El Hiti MA (1996) J Magn Magn Mater 192:305

Iqbal MJ, Ashiq MN, Gul IH (2010) J Magn Magn Mater 322(13):1720

Valanzuela R (2005) Magnetic ceramics. Cambridge University Press, Cambridge

Iqbal MJ, Ashiq MN (2008) Chem Eng J 136:383

Islam MU, Aen F, Niazi SB, Azhar Khan M, Ishaque M, Abbas T, Rana MU (2008) Mater Chem Phys 109:482–487

Khan HM, Islam MU, Xu Y, Ashiq MN, Ali I, Asif Iqbal M, Ishaque M (2014) Ceram Intl 40:6487

Khan HM, Islam MU, Xu Y, Iqbal MA, Ali I (2014) J Alloys Compd 589:258

Sindhu S, Anantharaman MR, Thampi BP, Malini KA, Kurian P (2002) Bull Mater Sci 25:599

Rezlescu N, Doroftei C, Rezlescu E, Popa PD (2006) Phys Status Solidi 15:3844

Lechevallier L, Le Breton JM, Wang JF, Harris IR (2004) J Magn Magn Mater 269:192

Che S, Wang J, Chen Q (2003) J Phys Condens Matter 15:L335

Wagner TR (1998) J Solid State Chem 136:120

Niasari MS, Davar F, Mahmoudi T (2009) Polyhedron 28:1455

Iqbal MJ, Khan RA (2009) J Alloys Compd 478:847

Che S, Wang J, Chen Q (2003) J Phys Condens Matter 15:L335

Chang Sun, Kangning Sun, Pengfei Chui (2012) J Magn Magn Mater 324:802

Kittle C (1996) An introduction to solid state physics, 5th edn. Wiley, New York

Abbas T, Islam MU, Chaudhry MA (1995) Mod Phys Lett B 9(22):1419

Smit J, Wijn HPJ (1959) Ferrites. Wiley, New York

Verwey EJW, De Boer JH (1936) Rec Trans Chem Des Pays Bas 55:531

Iqbal MJ, Farooq S (2009) Mater Chem Phys 118:308

Ahmed MA, Ateia E, El-Dek SI (2003) Mater Lett 57:4256

Rezlescu N, Rezlescu E, Pasnicu C, Craus ML (1994) J Phys Codens Matter 6:5707

Shobana MK, Sankara S, Rajendran V (2009) Mater Chem Phys 113:10

Murthy VRK, Shobanadri J (1976) Phys Status Solid A 36(2):133

Wagner KW (1913) Ann Phys 40:817

Sattar AA, Wafik AH, El-Sayed HM (2001) J Mater Sci 36:4703

Hudson AS (1968) Marconi Rev 37:43

Park JK, Kim DY (1996) J Amer Ceram Soc 79(5):1405

Zhu J, Tseng KJ (2000) C.F. IEEE Trans Magn 36:3408

Habasaki J, Ngai KL, Non-Cryst J (2006) Solids 352:5170

Guillén JAD, Guillén MRD, Padmasree KP, Fuentes AF, Santamaría J, León C (2008) Solid State Ion 179:2160

Asif Iqbal M, Islam M, Ali I, Khan HM, Mustafa G, Ali I (2013) Ceram Inter 39:1539

Acknowledgments

Authors are thankful to Higher Education Commission of Pakistan for providing financial support under 5000 indigenous fellowship program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, H.M., Islam, M.U., Xu, Y. et al. Electrical transport properties and temperature-dependent magnetization behavior of TbZn-substituted Ca0.5Ba0.5Fe12O19 hexaferrites. J Sol-Gel Sci Technol 78, 151–158 (2016). https://doi.org/10.1007/s10971-015-3907-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3907-x