Abstract

A chemical treatment process for removal of radionuclides associated with concrete from the decommissioning of nuclear power plants was adopted using a simple and effective precipitation method. Major radionuclides Co-60 and Eu-152 present in the concrete were confirmed to be selectively removed from the dissolved-concrete liquor as precipitates by pH-adjustment to pH 9. It was evaluated that HFO and HAO played important roles in the co-precipitation of Eu and Co, respectively. Nuclide decontamination factors were at least 6666 for Co-60 and 10,000 for Eu-152, respectively, and high enough to meet the requirement for release of decontaminated radioactive wastewaters in Korea.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

When nuclear facilities, including nuclear power plants, are operated, or decommissioned, a variety of radioactive wastes are generated. Management options for the wastes and the treatment methods to be used are determined depending on not only the physical and chemical characteristics of the raw waste but also the circumstances within each country, e.g. disposal cost, available disposal sites, and the acceptance criteria required by the disposal site to which the wastes will be consigned, etc. [1,2,3,4,5]. The Kori 1 nuclear reactor, a pressurized water reactor (PWR) which was the first nuclear power plant in Korea, was permanently shut down in 2017 and is to be decommissioned by mid-2030. Other units in Korea will face the same fate in series when they reach the end of their operating lifetime; with the recent closure of Wolsong 1, a pressurized heavy water reactor (PHWR), in late 2019. A further five reactors are scheduled for closure between 2023 and 2026, bringing the total to seven. Such a rate of closures within a relatively short space of time will significantly increase the demand for treatment and management solutions for wastes arising during decommissioning activities over the coming years.

Concrete accounts for approximately 30% of the total volume of construction materials used for a nuclear power plant (NPP) [6]. Some of this concrete is contaminated over the course of its operational lifetime. Two kinds of radioactive concrete wastes can occur, either by activation or contamination. The former is generated around bioshield structures due to neutron absorption by stable isotopes in the structure, while the latter occurs when pre-existing radionuclides come into contact and remain associated with the surface or subsurface of the concrete in the nuclear facilities, such as around fuel storage ponds, waste handling operations, and other supporting facilities [7,8,9].

The quantities of radioactive concrete waste greatly change depending on the type and operational history of the nuclear power plant, contamination level, applied dismantling and decontamination technologies, and the disposal-related regulation to be applied within each country etc.. The IAEA reported that the estimated amounts of radioactive concrete waste are 750 ton and 900 ton from decommissioning of GCR (250 MWe) and PWR (900 to 1300 W), respectively [9,10,11]. However, actual amounts generated in the cases of decommissioning of Tokai-1 (GCR, 166 MWe) in Japan, and Maine Yankee (PWR, 860 MWe) in United States are known to be 10,000 ton and 63,485 ton, respectively [12, 13]. Furthermore, the worldwide trend of tightening regulation on radioactive waste management can greatly affect the generated amount of radioactive concrete waste and the disposal cost [2, 14]. The disposal cost for radioactive waste in Korea is very expensive at approximately US$ 13,000 per drum of 200 L as of 2020. Taking into consideration the possibility of generating large amounts of radioactive concrete waste from the decommissioning of nuclear power plants, the effort to reduce the amount is essential for successful decommissioning under planned budgetary constraints. It is therefore important to propose and develop new ways in which to handle and treat this waste such that the overall volume of waste designated for disposal can be reduced.

Process suggested for decontamination of radioactive concrete waste using physical and chemical treatments

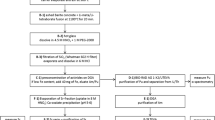

As a part the effort to reduce waste volumes, KAERI is developing a process for the high volume reduction of the concrete waste to be disposed through decontamination of the radioactive concrete, as proposed in Fig. 1 [15, 16]. At its core, the proposed process involves separating the aggregate and cement components.

Concrete consists of aggregates (gravel (coarse aggregate, > 2.5 mm), sand (fine aggregate, < 2.5 mm), etc.) and cement; the latter acting as a binder for the aggregates [12]. It is known that the aggregate accounts for around 70–75% of concrete volume, while the radionuclides are mainly associated with the cement phase rather than the aggregate [17,18,19,20]. Therefore, if the cement phase is separated from the concrete, thus leaving the aggregate ‘contaminant free’, then the volume of the radioactive concrete waste to be disposed of can be greatly reduced.

The process in Fig. 1 consists of two main categories, i.e. physical and chemical treatments. The former is for separation of cement and aggregates of the concrete and is achieved by thermal treatment of the concrete followed by physical grinding and sieving. This represents conventional methods utilized for the recycling of ordinary concrete wastes [14, 15, 17,18,19]. The latter, chemical treatment, is for the dissolution of (1) cement remaining on the separated aggregate (Fig. 1 Chem. treatment 1), and (2) separated cement (Fig. 1 Chem. treatment 2) producing a dissolved-concrete liquor; and is the focus of this work.

Studies to reduce the volume of contaminated concrete waste to be disposed have been performed by separating cement from aggregate of concrete waste by physical grinding and sieving after heating the concrete to temperatures between 500 and 800 °C [12, 14, 15, 17,18,19,20,21]. However, physical treatment alone is found to be insufficient to meet regulatory requirements in Korea for the release of the separated aggregate as clearance [21, 22], because some contaminated cement phase still remains on the gravel surface even after the treatment [17, 23]. Therefore, as shown in Fig. 1, a step of gravel washing with HCl (Chem. treatment 1 in Fig. 1) is suggested to be added after the separation of cement from gravel by the physical treatment. To further reduce the volume of radioactive concrete waste to be disposed, the process involves the chemical treatment of the separated cement which consists of: dissolving the cement with HCl; selective separation of the radionuclides; and physical separation of the precipitate and supernatant (Chem. treatment 2 in Fig. 1). The effluent generated during the gravel washing step (Chem. treatment 1) is combined with the dissolved cement liquor (Chem. treatment 2).

If the separated gravel and fine aggregates like sand are decontaminated sufficiently to meet clearance requirements, then they can be recycled, reused or released to the environment as landfill [24, 25]. Further, provided that the radionuclides in the dissolved-concrete liquor are separated from the solution as a precipitate and filtered sufficiently, then the filtrate can be released to the environment as well, with the separated solids stabilized and immobilized for disposal.

Estimation of radionuclides in contaminated concrete waste generated from decommissioning NPPs

It is important to know the radionuclides present within radioactive concrete wastes because the means to separate the nuclides from the cement phase can be tailored according to their chemical characteristics. Specific radionuclides formed in activated concrete depend heavily on the elemental composition of the concrete. In other words, they are typically formed through activation of impurities in the cement phase of the bioshield concrete by neutron capture during reactor operation [26]. Furthermore, nuclide ratios depend heavily on reactor operational parameters such as neutron flux and operational lifetimes. On the other hand, contaminated concrete occurs by spills of radioactive materials or radioactive water on the concrete surface and their infiltration into the concrete interior. Accordingly, the generation of activated concrete is inevitable, but that of contaminated concrete is site specific and varies, depending on the history of the NPP and maintenance regimes. The major radionuclides formed via activation are known to be Co-60 and Eu-152 [7, 26, 27]. The Co and Eu components in the bioshield concrete exist as impurities of cement. The radionuclides were also reported to be dominant in the bioshield concrete of a demolished research reactor in Korea [28]. The most abundant radionuclides in surface contaminated concrete were known to be Cs-137, Co-60, and others [17, 26, 27]. Based on these evaluations, the representative radionuclides existing in the radioactive concrete waste generated from the decommissioning of a NPP can be said to be Cs-137, Co-60 and Eu-152 [26, 29].

Cesium is known to be removed from solution by unique adsorbents such as zeolite, metal ferrocyanide, silicotitanate, etc. rather than precipitation technology [30,31,32]. Cs was confirmed to be easily removed from the dissolved-concrete liquor by K4Fe(CN)6 in our preliminary experiment [33]. Accordingly, this work studied selective removal of Co and Eu using coprecipitation induced by the formation of hydrous ferric oxide (HFO) and hydrous aluminium oxide (HAO) formed in the dissolved-concrete liquor with simple pH control; where Fe and Al ions already exist together in the dissolved-concrete liquor (Refer to Table 1). Coprecipitation by HFO and HAO can produce extremely low soluble metal species in solution, which are highly pH dependent [34,35,36]. Coagulation–flocculation of hydrolysis species of Fe and Al ions form a host phase to which target nuclides can associate, leading to their removal by coprecipitation through either inclusion, occlusion or by adsorption via inner-sphere/outer-sphere binding mechanisms [37].

In this work, the thermodynamic chemical behaviour of chemical species existing in the dissolved-concrete liquor were first evaluated as a function of pH change, and then the coagulation–flocculation system for the removal of Co and Eu from solution was investigated in single, binary (M–Fe or M–Al, M = Co or Eu), ternary (M–Fe–Al, M = Co or Eu), and multi-components systems. The coprecipitation mechanism and optimal conditions for selective separation of the target radionuclides were also evaluated. Results show that the proposed chemical processes (Fig. 1) can greatly reduce the volume of concrete waste generated from the decommissioning of nuclear power plants, thus reducing the final volume destined for disposal.

Experimental

Concrete handling and dissolved concrete liquor generation

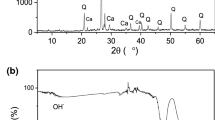

The goal of the chemical treatment process (Fig. 1) is to separate the target radionuclides (Co-60, Eu-152) from the combined effluents. In this work, hydrochloric acid was selected to dissolve the separated cement and to wash the aggregate based on our preliminary experiments and literature [21, 33, 38, 39]. The concrete block specimen used in this work was an ordinary Portland cement concrete obtained from a company in Korea (Chungcheong Environment Ltd Co.). The concrete blocks were first milled to a size of approximately 40 mm. Then the crushed concrete was heated at 550 °C for 1 h and was pulverized with a ball-mill to sequester the cement phase from the course aggregate. The milled particles were sieved to separate them with less than 1 mm diameter. The cement powder (mixture of cement and fine aggregate such as sand) and the separated course aggregate (on which the cement phase was still left) were dissolved and washed with 2 M HCl at room temperature for 2 h, respectively. In both cases, a ratio of 10 ml of the acid and 1 g of the solid phase was used. When the cement powder was dissolved, 29.7% of its initial weight was measured to decrease leaving the undissolved fine aggregate component. The dissolution yield was very similar to the ratio of cement to aggregate in the cement phase of concrete as reported in the literature [6, 13, 17]. It means almost complete dissolution of cement phase consisting of mostly 3CaO·SiO2(C3S), 2CaO·SiO2(C2S), 3CaO·Al2O3(C3A), 4CaO·Aln·Fe2-nO3(C4AF) and others in the acid solution [18]. The effluents from both of the dissolution and washing step were mixed.

Table 1 shows the concentrations of major elements in the solution where all the effluents from three batches of the dissolution and the washing were put together. Then inactive Co (CoCl2) and Eu (EuCl3) were added into the solution (where the Co and Eu did not exist in the Portland cement concrete sample used this work) such that the concentrations of Co and Eu were 10 ppm and 1 ppm, respectively, to obtain a simulated dissolved-concrete solution; the target solution in this work. The concentrations of added Co and Eu were determined based on a literature where the average composition of 36 bioshield concrete samples from the 12 nuclear power plant sites in United State were evaluated [26].

Dissolved concrete liquor treatment

To evaluate the coprecipitation of Co and Eu by formation of HFO and HAO from Fe and Al existing in the target solution, the dissolved-concrete solution (100 mL) was placed into a 250 mL beaker and stirred with a magnetic stirrer bar at either 60 rpm (slow mixing) or 300 rpm (rapid mixing). The pH of the solution was then adjusted in a range between 1 and 13, while stirring, via the addition of NaOH solutions (5, 1, 0.1 M). The pH of the solution was recorded throughout using a pH meter (Orion Star A215) and an electrode (ROSS Ultra® pH/ATC Triode Electrode 8157BNUMD, Thermo scientific). Solution samples of 0.2 mL were taken throughout the pH adjustment phase and filtered through a 0.22 μm syringe filter before being appropriately diluted and analysed. To further understand the effect of elements existing in the dissolved-concrete solution on the removal of Co and Eu, the chemical behaviours of each element in Table 1 or their binary and ternary systems were measured with a change of pH. The volume of final precipitate was measured using a measuring cylinder into which the solution containing the flocs generated after the precipitation experiment was poured. Active dissolved-concrete liquor simulant was prepared which was dosed with radioisotope solutions of Co-60, and Eu-152 to have 200 Bq mL−1 of Co-60 and 100 Bq mL−1 of Eu-152. For the experiment using active concrete solution, once the required pH was reached, the liquor was separated via centrifuge (3000 rpm, 10 min). The separated supernatant was then filtered through a 0.22 μm syringe filter before being analysed.

All the elemental concentrations in inactive solutions and radionuclides in active solutions were measured by an Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES) (Analytikjena PQ9000 Elite), and a MCA (Multi-channel γ-analyser with a HP-Ge detector, Camberra, GC2018), respectively. All the experiments were carried out at room temperature. All the chemicals used in this work were reagent grade and used as received.

Results and discussion

Removal of radionuclides in dissolved concrete liquor

The coprecipitation method is usually used when direct precipitation of the target metal ions to levels permissible for release is difficult, typically due to their low initial concentrations in solution. Accordingly it is widely used in the treatment of radioactive wastewater where the concentrations of target radioactive ions are very low compared with other species in solution [34,35,36, 40,41,42,43,44]. The coprecipitation of target metal ions in the carrier phase (host phase) occurs by their adsorption on to or incorporation in to a freshly precipitated solid phase of the different metal ion as a carrier phase [37]. The carrier phase is usually hydrous metal oxides (HMO: M = Fe, Al) with an amorphous structure, which are formed through the hydrolysis of the carrier phase ions due to their low solubilities near neutral pH range [34,35,36,37,38]. Hydrolysis accompanied by coagulation-flocculation of ionic species of the carrier phase in solution was initiated by the solution pH adjustment. When iron or aluminium amorphous metallic hydroxides (HFO or HAO, respectively) form in solution, their surface charge changes depending on the condition of the solution [45, 46]. Surface charge affects the coprecipitation phenomena because the HMO solid can adsorb contaminants due to electrostatic interactions with metal ions of opposite charge [37, 46]. The coprecipitation mechanism can be explained as follows. Fe and Al ions in solution form several interchangeable mononuclear species through hydrolysis according to the corresponding pH like Eq. (1) [47,48,49]. The Al and Fe ion species such as MOH2+, M(OH)2+ (M = Fe, Al) are known to form polynuclear clusters with hydroxyl bridges forming, which is called coagulation, before their precipitation as the amorphous phases Al(OH)3(am) and Fe(OH)3(am) takes places. The hydrous oxide cluster exhibits amphoteric behaviour via surface ionization e.g. Eq. (2) and Eq. (3) [50]. The clusters play the role of carrier material facilitating the coprecipitation of other metal ions. Sorption reactions of target metal ions occurs on the surface of the clusters, which is generally explained with the surface complexation reaction model between the sorbing metal ion and surface functional groups of the hydrous oxide of the cluster according to Eq. (4). The surface complex model is known to be extended further with the surface precipitation model like Eqs. (5) and (6) to explain new surface continuum phase between adsorption and bulk solution precipitation of the target metal ion [50,51,52,53].

where M is Fe or Al, and \(\equiv {\text{MOH}}_{2}^{ + }\), \(\equiv {\text{MOH}}^{0}\), and \(\equiv {\text{MOH}}^{ - } ~\) represent positively charged, neutral, and negatively charged surface hydroxyl groups, respectively.

where X represents target metal ion.

where ≡ and = denote bonds at the surface: ≡M(OH)0 represents [M(OH)3]n and = M(OH)0 represents [M(OH)2]n.

As seen in Table 1, the dissolved-concrete liquor contains Fe and Al ions in high enough concentrations for coagulation-flocculation to occur together with the target elements of Co and Eu [54]. Coprecipitation of Co and Eu induced through the formation of HFO and HAO was tried as a way to remove them from the dissolved-concrete liquor, because coprecipitation is simple and effective to treat the concrete waste solution. To evaluate the chemical behaviour of such a coprecipitation phenomenon between Fe, Al, and the target elements, it is necessary to understand the speciation of all the relevant elements in the solution. For that, actual thermodynamic equilibrium data of the elements measured in the media are required, but it is very hard to obtain them at this stage. Therefore, thermodynamic analysis was carried out in this work by using the equilibrium data of major species of the relevant elements existing in the solution based on literature [55]. Knowing the exact pH value that causes the most formation of HFO and HAO in solution is important with respects to effective usage of Fe and Al, and optimal dosing of chemicals for pH adjustment of the concrete wastewater. The selection of optimal pH results in minimal generation of secondary waste after the wastewater treatment by the coagulation-flocculation.

Solubilities of the major elements in the dissolved-concrete liquor and chemical speciation of Fe and Al ions as a function of pH were evaluated by using the chemical equilibrium modelling code of MINEQL 4.5 with thermodynamic data [55]. Figure 2 shows the calculated solubilities of the elements reported in Table 1 in water as a function of pH by using the modelling code. For the calculation, it was assumed that Fe, Al, Co, Eu, Si, Mg, and Ca were saturated with α-FeO(OH), α-Al(OH)3, Co(OH)2, Eu(OH)3, Si(OH)4, and Ca(OH)2, respectively. The total concentrations of each element in the system used for the evaluation were setup as 1000 ppm for Al and Fe, 10,000 ppm for Ca, 500 ppm for Mg, 2000 ppm for Si, 10 ppm for Co, and 1 ppm for Eu, respectively, taking into consideration Table 1. Figure 3 shows the species distributions of carrier elements Fe and Al used for the coprecipitation of the target elements. Al3+ and Fe3+ ions begin to hydrolyze from the acidic condition with the formation of various hydrolyzed-cationic species. They show to have their lowest solubilities around pH 6.8 and 8, respectively, where Al(OH)3 and Fe(OH)3 solid phases are the most dominant. On the other hand, the hydrolysis of the target elements Co and Eu begins to occur beyond pH 7, and have the lowest solubilities in the pH range between 10 and 11. The hydrolysis of Ca begins over pH 11 (Fig. 2). For the selective removal of Co and Eu from the dissolved-concrete solution, Ca, which is the most abundant in the solution, should remain in solution as free hydrated ions, while the target elements are sequestered as precipitates from the solution. Otherwise, the volume of secondary waste to be disposed of will increase, which would result in inefficiencies of the proposed process. The concentrations of Co and Eu at the pH corresponding to the lowest solubilities are in order of 10–5 to 10–8 M. However, the release requirements to environment of Co-60 and Eu-152 in radioactive wastewater according to act of nuclear safety and security commission in Korea are 0.3 Bq mL−1, and 0.5 Bq mL−1 [49], which are equivalent to approximately 8.2 × 10–14 M and 4.9 × 10–13 M, respectively. Therefore, the direct precipitation of Co and Eu by hydrolysis cannot meet the release requirements required for the final effluent out of the process of Fig. 1. In addition, such direct hydrolyses of Co and Eu at high pH range over 10 can cause simultaneous precipitation of other metal ions of Mg and Ca, etc. as well as Fe and Al, which results in increase in final volume of precipitate to be disposed of. Accordingly, the target elements with very low concentrations in the dissolved-concrete liquor should be removed by coprecipitation around pH where hydrolyses of Fe and Al ions occur.

To evaluate the behaviours of major elements found in the dissolved-concrete liquor (shown in Table 1) and to compare with the calculated results presented in Fig. 2, the concentration of each element in solution was measured at different pHs. The results are shown in Fig. 4a. For that experiment, all the initial solutions containing single elements were first prepared in 0.1 M HCl and then their pHs were adjusted in the alkaline direction up to pH 13 with NaOH at an interval of 1 h between each pH adjustment, because the dissolved-concrete liquor was generated using HCl, as explained in Fig. 1. The concentration behaviours of all the elements except Si with a change of pH are generally in agreement with those in Fig. 2 that were calculated with thermodynamic data available in the literature. The flat line for each element shown at the lowest value of each curve was because of the detection limit of each element by the ICP-OES used in this work. For example, the detection limit concentration of Fe and Al was 20 ppb (~ 10–7 M). Accordingly, actual concentrations in the range can be lower than the detection limit value (It will be discussed in detail later using active dissolved-concrete liquor). In the case of Si, the concentration remained constant until pH 4 at the same level as the initial concentration at pH 1, and then decreased in the pH range between 4 and 8, beyond pH 8 Si re-dissolved reaching the initial concentration. However, Si solubility is generally known to be approximately 100 ppm between pH 1 and 8 while exponentially increasing in alkaline conditions [56, 57]. The discrepancy is considered to be ascribed to precipitation kinetics of silica ion of monosilicic acid existing in the prepared solution using HCl in Fig. 4. It is reported that re-precipitation of silica from acid solutions takes time and aging for polymerization of the dissolved silica ion to form primary particles and then flocculate [58]. Therefore, the high concentration of Si in solution in acidic media (Fig. 4) is considered to eventually drop to the same level as thermodynamic solubility value shown in Fig. 2 [59]. Figure 4b shows the concentration changes of the major elements in concrete with a change of pH in the real dissolved-concrete liquor where inactive Co and Eu were spiked. The behaviours of all the elements except Co and Eu are similar to those in single element system of Fig. 4a in water. The pH at which Co and Eu concentrations reached the lowest values was shifted slightly, precipitating earlier than expected within the acidic region. The pH in the case of Eu moved to 6 (10 in single element system), and that of Co did too to 9 (11 in single element system). The reason is considered to be because Co and Eu ions in solution were removed from the solution by the coprecipitation due to the adsorption of them onto the HFO and HAO formed through Eqs. (1)–(6). These results mean that the Co and Eu ions existing in the dissolved-concrete liquor can be effectively removed from the dissolved concrete solution (where Ca is dominant (see Table 1)) by the action of HFO and HAO formed through Fe and Al ions existing together with them in the solution, with Ca remaining in the solution. The effluent including Ca after the treatment is to be released to environment.

Evaluation of co-precipitation mechanisms

To further understand the behaviour and mechanism of coagulation–flocculation accompanying the coprecipitation of the target elements with HFO and HAO, the concentrations of the elements were measured with a change of pH in the systems of single-element solution of Co and Eu, binary-elements solution together with Fe ions or Al ions, and ternary-element solution together with both of Fe and Al ions. The results are shown in Fig. 5. In the case of Eu (Fig. 5a), the concentration in Eu in the single system decreased from pH 5 and reached the lowest value of 2.2 × 10–7 M at pH 10. In the case of the binary system of Eu-Al, the concentration began to decrease at a lower pH and reached the lowest value of 2.9 × 10–8 M (detection limit of Eu by ICP-OES used in this work) at pH 9. The systems of Eu-Fe and of Eu-Fe-Al showed almost the same behaviours with respect to Eu concentration and showed earlier concentration drop of Eu at lower pH than in the Eu-Al system, and reached the detection limit of Eu by pH 7. These results mean that the formation of HFO by ferric ions play a more important role in the coprecipitation of Eu from the solution rather than aluminium ions.

In the case of Co (Fig. 5b), the concentration of Co as a single component system decreased from pH 8 and reached the lowest value of 2.7 × 10–6 M around pH 11. In the case of the binary system of Co–Fe, the concentration of Co began to decrease at lower pH than in the single system, but its slope became sluggish above pH 9 and reached the lowest value of 3.54 × 10–8 M (detection limit of Co by the ICP-OES used) at pH 11. However, in the cases of binary system of Co-Al, and ternary system of Co–Al–Fe, the Co concentration decreased at an earlier pH than in the binary system of Co-Fe, and reached the detection limit at pH 9. These results mean that HAO plays more important role in coprecipitation of Co than Fe in the Co-Al- Fe system.

Radioactive simulant tests

Based on the results of Figs. 4 and 5, the pH to simultaneously and effectively remove Eu and Co from the dissolved-concrete liquor by pH adjustment of the solution can be determined to be 9. However, the results obtained by ICP-OES cannot confirm that their final concentrations in the supernatant after precipitation by the pH adjustment meet the requirements for environment release of Co-60 (0.3 Bq mL−1) and Eu-152 (0.5 Bq mL−1) because of the detection limit of used ICP-OES, as mentioned above. To confirm this, an active dissolved-concrete solution was prepared by dosing Co-60 and Eu-152 radioisotopes in the solution used in Fig. 4b.

The initial activities of Co-60 and Eu-152 in the solution were approximately 200 Bq mL−1, and 100 Bq mL−1, respectively. The prepared solution was pH-adjusted first to pH 3, then pH 9 to confirm the selective removal of Eu and Co without precipitation of Ca. The formed solids were then separated by centrifuge before the supernatant was filtered through a 0.22 µm syringe filter. Finally, the remaining supernatant was adjusted to pH 11 for precipitation of Ca. The supernatants after each pH-adjustment were taken for analysis, and their activities were counted for 1 h by the HP-Ge detector. The results are shown in Fig. 6. The activities of Co-60 and Eu-152 in the solution at pH 3 were 85.0 Bq mL−1, and 37.4 Bq mL−1, respectively. The activities decreased a little even at pH 3, which was thought to be ascribed to the adsorption by HFO. Ferric ion is known to begin to precipitate with forming HFO over pH 2 [59], which is observed in Fig. 4 as well. The activities of Co-60 and Eu-152 were not detected in the supernatant after the precipitation of HFO and HAO occurred at pH 9. The detection limits of the nuclide measured for one hour by the HP-Ge detector used in this work were approximately 0.03 Bq mL−1 for Co-60 and 0.01 Bq mL−1 for Eu-152, respectively, which are much lower than the release limits of 0.3 Bq mL−1 for Co-60 and 0.5 Bq mL−1 for Eu-152 in Korea.

Taking into consideration of their initial activities in solution and the detection limits of the nuclides by MCA, the decontamination factors for each nuclides in solution was evaluated to be at least 6666 for Co-60 and 10,000 for Eu-152, respectively. These results are sufficiently high to meet the requirement for release of treated dissolved-concrete liquor. Analysis of the final solution after pH adjustment to pH 11, and analysis of the formed calcium precipitates revealed that both were free from Co-60 and Eu-152 radioisotopes. These results of Figs. 5 and 6 mean that the radionuclides Co-60 and Eu-152 existing in radioactive concrete waste can be effectively removed by way of co-precipitation of the nuclides induced with pH-adjustment of the concrete-dissolved liquor. Taking into consideration all of the results obtained in this work, it can be concluded that the precipitation method studied in this work to remove the radionuclide in radioactive concrete waste can be adopted into the process suggested in this work (in Fig. 1) for treatment of the radioactive concrete waste to be generated from the decommissioning of nuclear power plants.

Conclusions

The behaviour of ion species of elements present in radioactive concrete waste were evaluated in solutions with different pHs. The major radionuclides of Co-60 and Eu-152 in the concrete waste were confirmed to be selectively and effectively removed from the dissolved-concrete solution as precipitates by pH-adjustment to pH 9. The removal mechanism was ascribed to the coprecipitation by HFO and HAO formed by ferric and aluminium ions that were present together in the dissolved-concrete liquor. The decontamination factors of the nuclides were high enough to meet the requirement for release of radioactive wastewater in Korea, evaluated to be at least 6666 for Co-60 and 10,000 for Eu-152, respectively. The experimental results showed that the chemical treatment process of concrete waste generated from the decommissioning of nuclear power plant, which was suggested in Fig. 1, is possible for significant volume reductions of the concrete waste to be disposed.

References

Song J-S, Kim Y-K, Lee S-H (2015) A pre-study on the estimation of NPP decommissioning radioactive waste and disposal costs for applying new classification criteria. J Nuclear Fuel Cycle Waste Technol 3(1):45–53

NEA/OECD Report (1999) Low-level radioactive waste repositories: an analysis of costs

US NRC report (2010) Waste burial charges. NUREG-137 Rev, 16

Ojovan MI, Batyukhnova OG (2007) Glass for nuclear waste immobilization. Waste Management 2007 Conference, Tucson, AZ

Ojovan MI, Lee WE (2005) An introduction to nuclear waste immobilization, 2nd edn. Elsevier, Amsterdam

Peterson P. F. et al., (2005) Metal and concrete inputs for several nuclear power plants. UCBTH-05–001.

Hohmann B. P. et al.( , 2012) Irradiated concrete in nuclear power plants: bridging the gap in operational experience. International Atomic Energy Agency. IAEA-CN-194-095

IAEA Report (1998) Radiological characterization of shut down nuclear reactors for decommissioning purposes. International Atomic Energy Agency. IAEA-TRS-389

Lee K-Y, Oh M, Kim J, Lee E-H, Kim I-S, Kim K-W, Chung D-Y, Seo B-K (2018) Trends in technology development for the treatment of radioactive concrete waste. J Nucl Fuel Cycle Waste Technol 16(1):93–105

IAEA (2001) Methods for the minimization of radioactive waste from decontamination and decommissioning of nuclear facilities. Technical Reports Series No. 401, Vienna

U.S. Nuclear Regulatory Commission (2001) Inventory of materials with very low levels of radioactivity potentially clearable from various types of facilities. USNRC Inventory Report, Virginia

Deju R, Dragusin D, Robu I, Mazilu C, Tuca C (2013) Review on radioactive concrete recycling methods. Rom Rep Phys 65:1485–1504

EPRI (2005) Maine Yankee decommissioning experience report, Detailed experiences 1997–2004. EPRI Report, Illinois

US NRC report (2010) Waste burial charges. NUREG-137 Rev 16

Korea Patent (2020) Treatment method for volume reduction of radioactive concrete fine powder. KR 10-2020-0016752

Foster RI, Oh M, Kim K-W, Lee K-Y (2019) Co60 & Eu152 removal from dissolved concrete liquor: initial precipitation studies. In: Proceeding of the Korean radioactive waste society conference, Autumn, Jeju, pp 339–340

Corelissen HAW, van Hulst LPDM (1990) Volume reduction of contaminated concrete I. Separation by heating. Kema Sci Tech Rep 8(6):345–358

Kaplan MF (1989) Concrete radiation shielding: nuclear physics, concrete properties, design and construction. Wiley, New York

IAEA (1998) New methods and techniques for decontamination in maintenance or decommissioning operations. IAEA-TECDOC-1022, Vienna

Min B-Y, Choi W-K, Lee K-W (2010) Volume reduction of dismantled concrete waste generated from KRR-2 and UCP. Nucl Eng Technol 42(2):175–182

Oh MK, Lee KY, Foster RI, Lee CH (2021) Feasibility study on the volume reduction of radioactive concrete wastes using thermomechanical and chemical sequential process. J Environ Chem Eng. To be printed

Korea Nuclear Safety & Security Commission Notification (2014) Radioactive waste classification and clearance criteria guide. Notification No.2014-3

Korea Patent (2011) Volume reduction method and the method of preparation for clean aggregates from radioactive concrete waste. KR 1061480B1

Ishikura T, Ueki H, Ohnishi K, Oguri D (2004) Utilization of crushed radioactive concrete for mortar to fill waste container void space. J Nucl Sci Technol 41(7):741–750

NEA/OECD Report (2017) Recycling and reuse of materials arising from the decommissioning of nuclear facilities

DOE Report (1995) Contaminated concrete: occurrence and emerging technologies for DOE decontamination, DOE/ORO/2034

US NRC Report (1984) Long-lived activation products in reactor materials. NUREG/CR-3474

Park S-K, Chung U-S, Jung K-J, Park J-H (2003) Korea research reactor–1 & 2 decommissioning project in Korea. Waste Management 2003, Tucson, AZ

SKI Report (1992) Waste from decommissioning of nuclear power plants. SKI-TR-92-17

Lee K-Y, Kim K-W, Park M, Kim J, Oh M, Lee E-H, Chung D-Y, Moon J-K (2016) Novel application of nanozeolite for radioactive cesium removal from high-salt wastewater. Water Res 95:134–141

Lee K-Y, Kim J, Oh M, Lee E-H, Kim K-W, Chung D-Y, Moon J-K (2017) Effect on Cs removal of solid-phase metal oxidation in metal ferrocyanides. Radiochim Acta 105(12):1043–1048

Lee H-Y, Kim H-S, Jeong H-K, Park M, Chung D-Y, Lee K-Y, Lee E-H, Lim W-T (2017) Selective removal of radioactive cesium from nuclear waste by zeolites: on the origin of cesium selectivity revealed by systematic crystallographic studies. J Phys Chem C 121:10594–10608

KAERI Report (2019) Development of advanced decommissioning, decontamination, and remediation technology for nuclear facilities. KAERI/RR-4522/2019

Kim K-W, Baek Y-J, Lee K-Y, Chung D-Y, Moon J-K (2016) Treatment of radioactive waste seawater by coagulation–flocculation method using ferric hydroxide and poly acrylamide. J Nucl Sci Technol 53(3):439–450

Karthikeyan KG, Elliott HA, Cannon FS (1997) Adsorption and coprecipitation of copper with the hydrous oxides of iron and aluminium. Environ Sci Technol 31:2721–2725

Karthikeyan KG, Elliott HA, Chorover J (1999) Role of surface precipitation in copper sorption by the hydrous oxides of iron and aluminium. J Colloid Interface Sci 209:72–78

Foster RI, Oh MK, Yang D, Shon WJ, Kim KW, Lee KY (2019) Antimony(III/V) removal from industrial wastewaters: treatment of spent catalysts formally used in the SOHIO acrylonitrile process. Water Sci Technol 80(3):529–540

Chandra S (1983) Hydrochloric acid attack on cement mortar-analytical study. Cem Concrete Res 18:193–203

Nazari A, Sanjayan JG (2017) Handbook of low carbon concrete. Elsevier, New York

Pang F, Teng P, Teng T, Mohd OAK (2009) Heavy metal removal by hydroxide precipitation and coagulation-flocculation methods from aqueous solutions. Water Qual Res J Can 44(2):174–182

Potts M, Churchwell D (1994) Removal of radionuclides in wastewater utilizing potassium ferrate (VI). Water Environ Res 66(2):107–109

Hobbs D (1999) Precipitation of uranium and plutonium from alkaline salt solutions. Nucl Technol 128:103–112

Baeza A, Fernandez M, Herranz M, Legarda F, Miro C, Salas A (2004) Elimination of man-made radionuclides from natural wasters by applying a standard coagulation-flocculation process. J Radioanal Nucl Chem 260(2):321–326

Matsuzuru H, Koyama K, Wadachi Y (1972) Treatment of plutonium liquid wastes by flocculation. J. Atomic Energy Soc Jpn 14(6):8–22

Yukselen Y, Kaya A (2003) Zeta potential of kaolinite in the presence of alkali, alkaline earth and hydrolysable metal ions. Water Air Soil Pollut 145:55–168

Saka E, Guler C (2006) The effects of electrolyte concentration, ion species and pH on the zeta potential and electrokinetic charge density of montmorillonite. Clay Miner 41(4):853–861

Bratby J (2008) Coagulation and flocculation in water and wastewater treatment, 2nd edn. IWA publishing, London

Korea Nuclear Safety & Security Commission (2014) Guide for radiation protection, Notification No. 2014-34

Tang H, Xiao F, Wang D (2015) Speciation, stability, and coagulation mechanisms of hydroxyl aluminum clusters formed by PACl and alum: a critical review. Adv Colloidal Interface Sci 226:78–85

Scheck J, Lemke T, Gebauer D (2015) The role of chloride ions during the formation of akaganéite revisited. Mineral 5:778–787

Dzombak DA, Morel FMM (1990) Surface complexation modelling. Wiley, New York

Meima JA, Comans RNJ (1998) Application of surface complexation/precipitation modelling to contaminant leaching from weathered municipal solid waste incinerator bottom ash. Environ Sci Technol 32:688–693

Lutzenkirchen J, Behra P (1996) On the surface precipitation model for cation sorption at the (Hydr)oxide water interface. Aquat Geochem 1:375–397

Kim K-W, Shon W-J, Oh M-K, Yang D, Foster RI (2019) Evaluation of dynamic behavior of coagulation-flocculation using hydrous ferric oxide for removal of radioactive nuclides in wastewater. Nucl Eng Technol 51:738–745

Baes C, Mesmer Jr R (1986) The hydrolysis of cation. Rorbert E. Krieger Pub. Co., Malabar, Florida

Alexxander GB, Heston WM, Iler RK (1954) The solubility of amorphous silica in water. J Phys Chem 58:453–455

Hamrouni B, Dhahbi M (2001) Analytical aspects of silica in saline waters-application to desalination of brackish waters. Desalination 136:225–232

Gorrepati EA, Wongthahan P, Raha S, Fogler HS (2010) Silical precipitation in acidic solutions: mechanism, pH effect and salt effect. Langmuir 26(13):10467–10474

Weatherill JS, Morris KM, Bots P, Stawski TM, Janssen A, Abrahamsen L, Blackham R, Shaw S (2016) Ferrihydrite formation: the role of Fe 13 Keggin clusters. Environ Sci Technol 50:9333–9342

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (NRF-2017M2A8A5015147).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shon, WJ., Foster, R.I., Oh, M. et al. Targeted separation of radionuclides from contaminated concrete waste generated from decommissioning of nuclear power plants. J Radioanal Nucl Chem 329, 1417–1426 (2021). https://doi.org/10.1007/s10967-021-07868-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-021-07868-9