Abstract

To separate Y(III) from a Sr(II)–Y(II) mixture, two silica-based adsorbents, CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P were prepared by impregnating octyl(phenyl)-N,N-diisobutylcarbamoyl methylphosphine oxide (CMPO) extractant and a molecule modifier (1-Dodecanol) into macroporous silica/polymer composite support (SiO2-P). The Adsorbents showed high adsorption affinity to Y(III) and weak adsorption affinity to Sr(II) in HNO3 solution. The amount of adsorbed Y(III) increased with the HNO3 in the solution. The amount of adsorbed Y(III) increased with contact time and reached equilibrium within 30 min. The results showed that a pseudo-second-order kinetic model with a high correlation coefficient described the adsorption process better than other kinetic models. Successful Y(III) separation from Sr(II)–Y(III) mixture in HNO3 solution was achieved.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The heat-generated nuclides, 90Sr, with a half-life of approximately 28 years, exhibits high radioactivity and heat generation, and large quantities of Sr and Y isotopes (~ 1.1 kg/1 tHU, 45 GWd/t) are present in high-level liquid waste (HLLW) generated by the spent nuclear fuel reprocessing [1, 2]. Thus, selective 90Sr separation from HLLW is an important environmental issue in nuclear waste management. In our previous research, Sr(II), one of the heat-generating elements in HLLW, was separated from simulated HLLW by extraction chromatography using distilled water as eluent [1, 2].

Moreover, 90Y, a daughter nuclide of 90Sr, is a useful isotope in radiopharmaceuticals for various therapeutic applications in nuclear medicine, and it must be separated from a 90Sr–90Y mixture for use in this field [3, 4]. In the 90Sr decay system, the majority of 90Y is generated from beta decay of 90Sr, and it has a short half-life (T1/2 = 64.1 h) to form stable daughter nuclide 90Zr, mainly at 2.28 MeV [5]. This is represented by the following reaction;

As separation and purification of 90Y from 90Sr–90Y mixtures before use for radiotherapy are essential, numerous chemical methods for separating 90Y, including precipitation [6], solvent extraction [7, 8], ion exchange [9], and extraction chromatography [10, 11], have been studied.

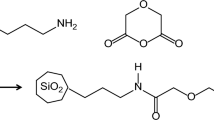

An impregnation method for extraction chromatography was recently proposed, involving immobilization of organic extractants in a macroporous silica/polymer composite support (SiO2-P). SiO2-P is an inorganic/organic hybrid material prepared by impregnating a macroporous SiO2 substrate with a copolymer. Advantages of SiO2-P include strong acidity, radiation resistance, and mechanical strength, and it is easily separated from solids and liquids.

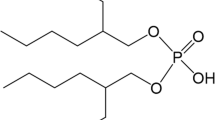

However, 90Y exists as a trivalent cation in solution; thus, it can be separated from a 90Sr–90Y mixture using impregnated octyl(phenyl)-N,N-diisobutylcarbamoyl methylphosphine oxide (CMPO), a known extractant for trivalent cations.

To understand the adsorption and separation behavior of Y(III), we investigated the effects of acid concentration, contact time, and temperature for two adsorbents, silica-based CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P. Moreover, it was verified that 90Y could be separated continuously from a 90Sr–90Y mixture using a column. The adsorbents were prepared by impregnating CMPO extractant and a molecular modifier (1-dodecanol) into a macroporous silica/polymer composite support (SiO2-P), exploiting its high immobilizing capacity to separate Y(III) from a Sr(II)–Y(III) mixture. This article describes the preparation of a CMPO-impregnated adsorbent; kinetic modeling and adsorption thermodynamics for Y(III) adsorption by adsorbents were studied by batch and column experiments, respectively.

Experimental

Materials

Sr(NO3)2 (98%) and SrCl2 (95%) for experiments were obtained from Wako Pure Chemical Industries, Ltd. Y(NO3)3·6H2O (99.99%) and YCl3·6H2O (99.99%) were obtained from Kanto Chemical Co.

Preparation of adsorbent

In this study, two silica-based adsorbents, CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P were prepared. CMPO/SiO2-P was prepared by impregnating CMPO extractant into SiO2-P, and (CMPO + Dodec)/SiO2-P was prepared by impregnating CMPO extractant and 1-Dodecanol as a molecule modifier into SiO2-P.

The SiO2-P particles were washed thrice with about 300 cm3 methanol and dried in a vacuum for approximately 1 day. CMPO (18 g) extractant was dissolved in 200 cm3 dichloromethane, which was used as a diluent, with and without 1-Dodecanol (6 g) as a molecule modifier. The washed SiO2-P [36 g (with 1-dodecanol) or 42 g (without)] and dichloromethane were mixed, and the diluent was removed with rotary evaporator. The residue was dried under vacuum overnight at 313 K, and 60 g of the two adsorbents, CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P were obtained [12].

Batch method

In the batch method, the adsorption behaviors of Sr(II) and Y(III) ions onto CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P were examined. Dry adsorbent (0.2 g) was mixed with 4 cm3 liquid phase solution in a 13.5 cm3 glass vial under several contact times in a thermostatic shaking bath at 160 rpm. This solution contained 10 mM (M = mol dm−3) of Sr(II) and Y(III) ions with different concentrations of HNO3 or HCl. Following phase separation of the mixture by filtration, the metal ions concentrations in the liquid phase were determined by inductively coupled plasma-atomic emission spectrometer (ICP-AES, Shimadzu ICPE-9000). The distribution coefficients (Kd, cm3 g−1) and uptake ratios (R, %) of Sr(II) and Y(III) ions were calculated as follows:

where C0, Ct and Ce are the metal ion concentrations before adsorption, after adsorption at time t, and after reaching equilibrium in the liquid phase in ppm, respectively. m is the weight of dry adsorbent in g and V is the volume of the liquid phase in cm3.

Column method

The columns ware prepared by packing approximately 4 g CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P adsorbents into glass column (8 mm inner diameter × 120 mm length). Several elutions were passed through the column for the adsorption experiment. HNO3 solution (2 M) containing 5 mM Sr(II) and Y(III) was fed into the column. HNO3 solution (2 M) without metal ions was fed into the column continuously as washing solution. H2O was also fed into the column continuously. The solutions were fed into the column at a flow rate of 0.3 cm3/min with a metering pump, and the column was maintained at 298 K with a thermostatic water jacket. Simultaneously, outflowing solution from the column was collected with a fraction collector in 2.5 ml per a tube. The concentration of metal ions in the fractions were determined by ICP-AES. Additionally, a pH meter (HORIBA pH meter D-52) was used to measure the pH of the fractions.

Results and discussion

Effect of acid concentration

The effect of the acid concentration was determined by a batch method. The result with CMPO/SiO2-P is shown in Fig. 1 and that with (CMPO + Dodec)/SiO2-P is shown in Fig. 2. Y(III) showed a high adsorption affinity for CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P, and this increased with the HNO3 concentration. However, Y(III) showed weak adsorption on both adsorbents in HCl solution. Sr(II) showed weak adsorption on CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P in HNO3 and HCl solutions.

CMPO has good selectively for the adsorption of trivalent Rare Earth (RE) and MA(III) [13]. It is believed that Y(III), which is trivalent RE, forms a complex with NO3− and impregnated CMPO. The proposed complex formation is as follows:

According to Eqs. (4)–(6), as the NO3− concentration increase, the chemical equilibrium shift to the right and Y(NO3)3 increases. In conjunction with this, Y(NO3)3(CMPO/SiO2-P) and Y(NO3)3((CMPO + Dodec)/SiO2-P) increase. Consequentry, Y(III) showed strong adsorption in high HNO3 concentration.

From another viewpoint, Kd for (CMPO + Dodec)/SiO2-P is lower than for CMPO/SiO2-P. It was considered that (CMPO + Dodec)/SiO2-P contains 1-dodecanol and CMPO in the same microporous structure. Therefore, it is thought that 1-dodecanol inhibits the chelate complex formation between Y(III) and CMPO due to its geometrical arrangement and/or its hydrophobicity.

As it was verified that Y(III) exhibited weak adsorption on both adsorbents in HCl, the remaining batch experiments were performed in HNO3.

Effect of contact time

The effect of contact time in HNO3 solution was assessed by a batch method. Figure 3, shows plots of time versus Qt fitted to the pseudo-second-order kinetic model, described later. The Y(III) uptake on CMPO/SiO2-P increased with the contact time and reached equilibrium within 30 min. However, the Y(III) uptake on (CMPO + Dodec)/SiO2-P reaches equilibrium almost immediately. Additionally, the uptake ratios on CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P at equilibrium were approximately 56% and 69% respectively, at 298 K.

According to a report by Ho and Mckay [14], a pseudo-second-order kinetic model for this adsorption system was developed. This assumes that the adsorption rate is controlled by chemical adsorption and that the adsorption capacity is proportional to the number of active sites on the adsorbent. To investigate the kinetic data of the adsorption, the rate constants for of Y(III) adsorption on CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P were determined by the pseudo-second-order equation:

where Qt and Qe are the amounts of Y(III) adsorbed at time t and at equilibrium (mg g−1), respectively, and k is the rate constant of the pseudo-second-order adsorption (g mg−1 h−1).

Plots of t/Qt versus t, shown in Fig. 4, show straight lines with high correlation coefficients (R2) of nearly 1. This indicated that the results fitted well with the pseudo-second-order model. Thus, chemisorption governs the rate-controlling step of this adsorption. The values of Qe and k are determined as 13 mg g−1 and 4.9 g mg−1 h−1 for CMPO/SiO2-P and 11 mg g−1 and 37 g mg−1 h−1 for (CMPO + Dodec)/SiO2-P from the slopes of the straight lines. These results for Qe were similar to the experimental values of 13 mg g−1 (CMPO/SiO2-P, 5 h) and 11 mg g−1 ((CMPO + Dodec)/SiO2-P, 5 h) at 298 K.

Effects of temperature

The effect of temperature in HNO3 solution was evaluated by batch method. To investigate the thermodynamic nature of the adsorption on CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P, several thermodynamic parameters were calculated using the Van’t Hoff equation, as shown below:

where ΔG0 is the change in Gibbs free energy (kJ mol−1), which is the fundamental criterion of spontaneity; ΔH0 is the change in standard enthalpy (kJ mol−1). ΔS0 is the change in standard entropy (J K−1 mol−1). R is the gas constant (8.314 J mol−1 K−1), T is the temperature (K); and Kd is the distribution coefficient at an equilibrium defined in Eq. (2).

Plots of ln(Kd) versus 1/T, shown in Fig. 5, show straight lines with correlation coefficients (R2) of 1. The values of ΔH0 and ΔS0 were determined from the slope and intercept of the linear variation, and ΔG0 was calculated for each temperature. Table 1 summarizes these values. As ΔH0 and ΔS0 were negative for both adsorbents, the adsorption processes were exothermic, and the reaction progresses at a lower temperature with both adsorbent. Furthermore, since the ΔG0 values were negative under all conditions, Y(III) adsorption on CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P was spontaneous under the experimental condition.

Column separation

Figures 6 and 7 show the results for separating Y(III) from Sr(II)–Y(III) by extraction chromatography using CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P. Sr(II) flowed out from the adsorbent-packed column immediately without adsorbing while feeding HNO3 solution. However, Y(III) hardly flowed out while feeding HNO3 solution. Subsequently, when H2O began to feed into the column, the adsorbed Y(III) on the adsorbent eluted from the column. No elution tailing was observed in the elution curves, and the elution band was narrow, indicating that the elution kinetics of CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P with Y(III) were rapid. Concerning the material balance, the chemical yield of Y(III) was calculated as about 100 wt%. Satisfactory separation and recovery of Y(III) from a Sr(II)–Y(II) mixture with CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P were achieved.

Conclusions

In this study, to separate Y(III) from a Sr(II)–Y(III) mixture, the silica-based CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P adsorbents were prepared by impregnating CMPO extractant and a molecule modifier into the macroporous SiO2-P support. The adsorption behavior of Sr(II) and Y(III) on both adsorbents was investigated by a batch method under various conditions involving different concentrations of acids (HNO3 or HCl), contact times, and temperatures.

Regaring the effect of the acid concentration, the adsorbents showed a high adsorption affinity with Y(III) and weak adsorption affinity with Sr(II) in HNO3 solution. Additionally, as the HNO3 concentration increases, Y(III) showed strong adsorption on CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P. Kd reached approximately 100 when using CMPO/SiO2-P in 5 M HNO3. However, Y(III) showed weak adsorption on both adsorbents in HCl. Sr(II) showed weak adsorption under all conditions. Concerning the effect of contact time, the Y(III) uptake on CMPO/SiO2-P reached equilibrium within 30 min and that on (CMPO + Dodec)/SiO2-P reached equilibrium immediately. Additionally, the uptake ratios on CMPO/SiO2-P and (CMPO + Dodec)/SiO2-P at an equilibrium were approximately 56% and 69%, respectively, at 298 K. This indicated that Y(III) adsorption on CMPO adsorbents fitted well with the pseudo-second-order model with a high correlation coefficient. The calculated Qe values were similar to the experimental values of 13 mg g−1 (CMPO/SiO2-P) and 11 mg g−1 ((CMPO + Dodec)/SiO2-P). Regarding the effect of temperatue, ΔH0 was − 8.6 for CMPO/SiO2-P and − 6.6 for (CMPO + Dodec)/SiO2-P. Therefor, Y(III) adsorption on CMPO adsorbents was spontaneous. Using the column method, successful separation of Y(III) from a Sr(II)–Y(III) mixture was achieved using both adsorbents in 2 M HNO3 and H2O with a satisfactory recovery rate (almost 100%).

The above results show that both adsorbents have sufficient capacity to separate Y(III) from a Sr(II)–Y(III) mixture. However, it is considered that CMPO/SiO2-P is better from the viewpoint of Kd and the saturated adsorption amount because it works with a higher 90Y concentration.

References

Zhamg A, Kuraoka E, Kumagai M (2007) Development of the chromatographic partitioning of cesium and strontium utilizing two macroporous silica-based calix[4]arene-crown and amide impregnated polymeric composites: PREC partitioning process. J Chromatogr A 1157(1):85–95

Wu Y, Kim SY, Tozawa D, Ito T, Tada T, Hitomi K, Kuraoka E, Yamazaki H, Ishii K (2012) Equilibrium and kinetic studies of selective adsorption and separation for strontium using DtBuCH18C6 loaded resin. J Nucl Sci Technol 49(3):320–327

Chakravarty R, Pandey U, Manolkar RB, Dash A, Venkatesh M, Pillai MRA (2008) Development of an electrochemical 90Sr–90Y generator for separation of 90Y suitable for targeted therapy. Nucl Med Biol 35(2):245–253

Lee JS, Park UJ, Son KJ, Han HS (2009) One column operation for 90Sr/90Y separation by using a functionalized-silica. Appl Radiat Isot 67(7):1332–1335

Vanura P, Makrlik E (2002) Separation of microamounts of yttrium from strontium by using nitrobenzenesolution of sodium dicarbollylcobaltate in the presence of 18-crown-6. J Radioanal Nucl Chem 251(3):499–501

Schulz LA, Bray LA (1987) Solvent extraction recovery of byproduct 137Cs and 90Sr from HNO3 solutions-A technology review and assessment. Sep Sci Technol 22(2-3):191–214

Horwitz EP, Dietz ML, Fisher DE (1991) SREX: a newprocess for the extraction and recovery of strontium from acidic nuclear waste streams. Solv Extr Ion Exch 9(1):1–25

Pais J, Selucky P, Kyrs M (1976) Extraction of alkali metals into nitrobenzene in the presence of univalent polyhedral borate anions. J Inorg Nucl Chem 38(7):1376–1378

Wheelwright EJ (1970) A generic ion-exchange process for the recovery and purification of valuable elements from the nuclear industry. In: Conference proceedings of ion exchange in the process industries, 16–18 July 1969, London, United Kingdom Society of Chemical Industry, pp 202–208

Horwitz EP, Dietz ML, Fisher DE (1991) Separation and preconcentration of strontium from biological, environmental, and nuclear waste samples by extraction chromatography using a crown ether. Anal Chem 63(5):522–525

Lumetta GJ, Wester DW, Morrey JR, Wagner MJ (1993) Preliminary evaluation of chromatographic techniques for the separation of radionuclides from high-level radioactive waste. Solv Extr Ion Exch 11(4):663–682

Xu Y, Kim S-Y, Ito T, Nakazawa K, Funaki Y, Tada T, Hitomi K, Ishii K (2012) Adsorption and separation behavior of yttrium and strontium in nitric acid solution by extraction chromatography using a macroporous silica-based adsorbent. J Chromatogr A 1263:28–33

Turanov AN, Karandashev VK, Yarkevich AN, Safronova ZV, Kharitonov AV, Radygina NI, Fedoseev AM (2004) Extraction of U(VI), Th(IV), Pu(IV), Am(III), and rare-earth elements from nitric acid solutions with diphenyl-(dialkylcarbamoylmethyl)phosphine oxides substituted in the methylene bridge. Radiochemistry 46:461–467

Ho YS, Mckay G (1999) Pseudo-second order model for sorption process. Process Biochem 34(5):451–465

Acknowledgements

This work was supported by JSPS KAKENHI Grant Number 16H02444.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kawamura, T., Ito, T. & Kim, SY. Adsorption and separation behavior of strontium and yttrium using a silica-based CMPO adsorbent. J Radioanal Nucl Chem 320, 9–14 (2019). https://doi.org/10.1007/s10967-019-06446-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-019-06446-4