Abstract

A new method for the determination of actinides and radiostrontium in limestone and marble samples has been developed that utilizes a rapid sodium hydroxide fusion to digest the sample. Following rapid pre-concentration steps to remove sample matrix interferences, the actinides and 89/90Sr are separated using extraction chromatographic resins and measured radiometrically. The advantages of sodium hydroxide fusion versus other fusion techniques will be discussed. This approach has a sample preparation time for limestone and marble samples of <4 h.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Limestone and marble have been used in many important buildings and monuments in the United States, including the Pentagon, the Lincoln Memorial, the Washington Monument, Washington National Cathedral in Washington, DC, and the Empire State Building in New York City. If a radiological dispersive device (RDD), improvised nuclear device (IND) or a nuclear accident such as the accident at the Fukushima Nuclear Power Plant in March, 2011 occurs that affects these monuments or buildings, there will be an urgent need for rapid analyses of limestone and marble materials to support dose mitigation and environmental clean-up. It has been the approach of the Savannah River Environmental Laboratory to combine rapid, rugged sample digestion and preconcentration techniques with rapid, innovative column purification methods to analyze building materials samples quickly. The use of vacuum-assisted flow rates and stacked cartridges containing highly selective extractant-coated chromatographic resins allows rapid sequential separations of multiple analytes in an emergency. This includes recently published methods for soil, concrete and brick, and asphalt. [1–3]

Limestone is sedimentary rock containing calcite and aragonite, which are different forms of calcium carbonate. Most limestone also contains skeletal fragments of marine organisms such as coral and mollusks. According to the US Geological Survey, “The main difference between limestone and marble is that limestone is a sedimentary rock, typically composed of calcium carbonate fossils, and marble is a metamorphic rock. Limestone forms when shells, sand, and mud are deposited at the bottom of oceans and lakes and over time solidify into rock. Marble forms when sedimentary limestone is heated and squeezed by natural rock-forming processes so that the grains recrystallize. If you look closely at a limestone, you can usually see fossil fragments (for example, bits of shell) held together by a calcite matrix. Limestone is more porous than marble, because there are small openings between the fossil fragments. Marble is usually light colored and is composed of crystals of calcite locked together like pieces of a jigsaw puzzle. Marble may contain colored streaks that are inclusions of non-calcite minerals.” [4] The sample composition of limestone and marble is very similar, with large amounts of calcium and carbonate present. Limestone or marble samples taken after a RDD or IND may be contaminated with refractory particles containing actinide isotopes, 89Sr and 90Sr. A rapid, rugged digestion is required to ensure total digestion of these refractory particles. Rapid, reliable measurement of these radionuclides is very important to maintain the public trust.

Vajda et al. [5] reported a method for actinides in soil in which 0.5 g soil samples were fused using lithium metaborate in platinum crucibles. After preconcentration of actinides using calcium fluoride precipitation, actinides were separated on TRU extraction chromatographic resin. The use of lithium metaborate fusion ensured that refractory particles were digested. The results agreed well with reference values, however, the method appears to be limited to 0.5 g soil aliquots and requires very expensive platinum crucibles. While lithium metaborate fusion can be very effective, it can also be somewhat difficult to remove from the crucible. In addition, when this fusion is not combined with calcium fluoride or lanthanum fluoride precipitation to remove silicates, the acidified fusion cake may need treatment with polyethylene glycol (PEG) to flocculate silica in the sample. If gel-like silicates are not removed, they can cause resin column clogging or loss or radionuclides on the residual solids.

Jia et al. [6] reported a fusion method for determination of thorium isotopes in soil by alpha-spectrometry. After fusion with Na2CO3 and Na2O2 at 600 °C, soil samples were leached with HNO3 and HCl. Thorium was coprecipitated together with iron(III) as hydroxides and/or carbonates at pH 9, separated from uranium and other alpha-emitters by a Microthene-TOPO (tri-octyl-phosphine oxide) chromatographic column, electrodeposited on a stainless steel disk, and measured by alpha-spectrometry. It was noted in this work that leaching of uranium and thorium from soil sample with only mineral acids (dilute or concentrated), such as HCl, HNO3, HClO4, HF, etc., may be incomplete. The method also addressed the common problem of resulting silicates, which interfere with subsequent method steps, by evaporation and precipitation of the silicate solids. This method provided total digestion of the soil aliquots by fusion, use of a furnace instead of a burner to allow multiple samples to be processed simultaneously, and a way to address silicates, at least for relatively small sample aliquots. The method also seems to be limited to 0.5 g soil and requires expensive platinum crucibles. The removal of silica required evaporation of a 150 mL leachate following the fusion, precipitation and washing of insoluble silicates, and filtration of remaining residue after final dissolution of an iron hydroxide precipitate.

The U.S EPA published a rapid carbonate fusion method for soil [7] that also requires an additional pre-digestion with hydrofluoric acid to remove silica, then fusion of one sample at a time over a burner using expensive platinum crucibles. The EPA soil fusion method, however, does direct that a rapid sodium hydroxide fusion, used in the EPA rapid method for concrete and brick, may also be used for soil. This fusion method can be performed in relatively inexpensive zirconium crucibles. [8] The ability to digest many samples at the same time in a furnace with inexpensive crucibles, instead of heating one at a time over a burner, would seem to be advantageous not only in an emergency, but also for routine laboratory processing.

Rugged soil dissolution methods are essential to accurately determine actinide isotopes in soil. The recent failure by ~80 % of participating labs in the U.S Department of Energy Mixed Analyte Performance Evaluation Program (MAPEP) Session 30 was traced to incomplete dissolution of refractory particles in the samples by acid digestion and points to the need for the implementation of robust sample digestion of soil samples and other solid matrices. Labs that did not utilize total dissolution methods typically reported 234U and 238U results that were ~60 % lower than the soil reference values, even when digesting this soil with hydrofluoric acid.

Jurečič et al. [9] studied several soil decomposition techniques and found that alkaline fusion digested uranium in the soils studied completely. Other techniques, such as conventional wet dissolution with mixtures of HNO3, HClO4 and HF acids, microwave dissolution using HNO3 and HF were less effective, with uranium losses of 35–60 %. Two reference materials, including NIST-4353a Rocky Flats Soil, and six soil samples from near a former uranium mine were investigated. It is interesting that the authors found more residual, undissolved uranium using microwave techniques than the conventional wet dissolution methods tested. Relatively long digestion and evaporation times (up to 2 days) were cited in this work. The rapid sodium hydroxide fusion can be completed in <30 min, with subsequent preconcentration steps typically taking <2 h. No evaporation steps are required, and uranium recoveries are nearly quantitative, even when refractory material is present.

Rapid sodium hydroxide fusion methods have been reported by this laboratory for many different sample matrices, including soil, concrete, brick and asphalt. The ruggedness of these methods has been validated by analyzing soil containing refractory Pu or U [10, 11]. Application of the sodium hydroxide fusion to limestone and marble, and optimization of the subsequent matrix removal and separation steps has led to a new method to determine actinides and radiostrontium in these building materials. The method, developed in the Savannah River Environmental Laboratory, effectively digests refractory actinide and strontium isotopes and allows a sample preparation for batches of 12 limestone or marble samples of <4 h. Several samples are fused simultaneously at 600 °C in zirconium crucibles in muffle furnaces.

Rapid sodium hydroxide fusion offers advantages over acid dissolution (which usually takes longer and may not be as rugged), as well as other fusion techniques. The preconcentration techniques effectively eliminate sample matrix interferences, and result in high chemical yields. Total dissolution is very important for the analysis of building materials such as limestone or marble, where refractory particles may be present following a radiological event. The sodium hydroxide fusion is rapid, rugged and can be performed using relatively inexpensive zirconium crucibles. The fusion can be performed at low temperature (600 °C), without a burner, and multiple samples can be processed simultaneously in furnaces. Unlike lithium metaborate fusion, the fusion cake comes out of crucible easily. This approach allows LaF3 and CaF2 preconcentration steps to remove iron, titanium and silicates, which can interfere with rapid column separations.

Once the sample is digested, there are many different stacked cartridge options, depending on which analytes are desired. Plutonium and neptunium are separated quickly and efficiently using TEVA Resin cartridges. Uranium can be collected and purified using TEVA plus TRU Resin cartridges, while Am/Cm can be separated using TEVA plus DGA Resin cartridges. A combination of TEVA + TRU + DGA Resin may also be used [2]. Rapid flow rates achieved using vacuum box technology, and stacked resin cartridges with highly selective extraction chromatographic resins significantly reduce separation times and waste volumes. Alpha spectrometry sources were prepared by cerium fluoride microprecipitation, however, electrodeposition can also be used with slight adjustments to some eluents. Other measurement techniques such as inductively-coupled plasma mass spectrometry (ICP-MS) can also be employed.

Experimental

Reagents

The extraction chromatography resins employed in this work are TEVA Resin® (Aliquat ™ 336), TRU-Resin® (tri-n-butylphosphate (TBP) and octyl (phenyl) N,N-diisobutylcarbamoylmethylphosphine oxide (CMPO)), DGA Resin (N,N,N′,N′-tetraoctyldiglycolamide), and Sr Resin (4, 4′, (5′) di-t-butylcyclohexane-18-crown-6), available from Eichrom Technologies, Inc., (Lisle, Illinois, USA) and Triskem International (Bruz, France). Nitric, hydrochloric and hydrofluoric acids were prepared from reagent-grade acids (Fisher Scientific, Inc.). All water was obtained from a Milli-Q2™ water purification system. All other materials were ACS (American Chemical Society) reagent grade. Radiochemical isotope tracers 236Pu, 242Pu, 243Am, and 232U were obtained from Eckert Zeigler Analytics, Inc. (Atlanta, GA, USA) and diluted to approximately 74 mBq mL−1 to enable yield corrections. 90Sr was obtained from Eckert Zeigler Analytics, Inc. (Atlanta, GA, USA) and diluted to approximately 2.96 Bq mL−1. 237Np and 244Cm were obtained from Eckert Zeigler Analytics, Inc. (Atlanta, GA, USA) and diluted to approximately 74 mBq mL−1. 232U tracer was prepared to be self-cleaning, removing its 228Th daughter using barium sulfate precipitation [12].

Procedures

Column preparation

TEVA, TRU, DGA and Sr Resins were obtained as 2 mL cartridges. Small particle size (50–100 μ) resin was employed, along with a vacuum extraction system (Eichrom Technologies). The small particle size coated support, with enhanced surface area, improves column separation efficiencies. Flow rates of ~1–2 mL min−1 were typically used for this work, slower on sample loading and final elution steps, faster for the rinses used to remove sample matrix interferences. It has been demonstrated that reduced separation times can be achieved using higher flow rates by increasing the applied vacuum without significant loss of analytes. [13, 14] To facilitate enhanced removal of interferences, column reservoirs and connector tips in the lid were changed after sample loading and prior to final elution of analytes.

Sample preparation

Figure 1 shows the sample preparation flowchart for actinides in limestone and marble samples. Limestone and marble samples were pulverized, homogenized and passed through a 20 mesh sieve prior to sampling so that representative samples could be taken. One gram aliquots of limestone and marble were analyzed for actinides, while 1.5 g aliquots were used for 90Sr measurements. For testing purposes, 90Sr was added but the method can also be tailored to measure 89Sr. MAPEP 30 soil aliquots (~0.25 g) were also placed into 250 mL low form zirconium crucibles along with the limestone or marble sample aliquots. The MAPEP soil samples were provided by Department of Energy (DOE)—Radiological and Environmental Sciences Laboratory (RESL), Idaho, USA. MAPEP 24 soil standard was chosen because the soil contains refractory 239Pu in the soil. Successful analysis would indicate analytical method ruggedness and applicability when refractory particles are present. Reference activities were calculated based on the activity added per mass of limestone or marble analyzed, excluding the mass of the MAPEP soil added.

Tracers were added to each crucible, and the crucibles were dried briefly on a hotplate. After removing crucibles from the hotplate, 15 g of NaOH pellets were added to each crucible. The crucibles were covered with a zirconium lid and placed into a furnace at 600 °C for ~15–20 min. The crucibles were removed from the furnace, cooled for about 10 min, and transferred to a hot plate. Water was added to dissolve the fusion cake on the hot plate and transfer the sample to 225 mL centrifuge tubes. Residual solids were removed from the crucibles by adding water and heating the crucibles on the hot plate as needed. A final rinse of 10 mL 3 M HNO3 was added to the crucibles, and heated until very hot on the hot plate to ensure complete removal of actinides and strontium from the crucible.

Sample preconcentration for actinides

The actinide preconcentration and matrix removal steps are described below. One hundred and twenty-five milligrams of Fe (added as Fe(NO3)3) and 5 mg of La (as lanthanum nitrate standard) were added to each 225 mL centrifuge tube prior to transferring the alkaline solution and solids from the crucibles into the tubes. The samples were diluted to 160 mL with water, 20 mL 12 M HCl was added, and the tubes were cooled in an ice bath to room temperature.

Due to the high calcium content in limestone and marble, no additional calcium was added to the limestone or marble aliquots. For processing of batches where reagent blank and laboratory control samples (LCS) are also included (no limestone or marble is added), 200 mg Ca may be added to simulate the high Ca matrix for the blank and LCS. Five milliliters of 3.2 M ammonium hydrogen phosphate were added to each tube, and each tube was capped and mixed well. The phosphate and 4 mL 20 % TiCl3 [added to each tube to reduce U(VI) to U(IV]), help improve uranium recovery during the precipitation steps. The samples were mixed and cooled in an ice bath for ~10 min. The tubes were centrifuged at 3500 rpm for ~5 min and the supernate was discarded. The precipitates were partially dissolved by adding 1.5 M HCl to a total volume of 80 mL in each tube and diluting to 170 mL with 0.01 M HCl, mixing well with each addition. After dilution, 1 mg of La (as lanthanum nitrate standard) was added to each sample. To ensure no actinides were in the hexavalent state and facilitate complete precipitation, 3 mL 20 % titanium chloride were added to each sample. Ten milliliters of 28 M HF were added to each tube. The samples were mixed well, dissolving any remaining Fe–Ti hydroxide solids and forming a La–Ca-fluoride precipitate. The tubes were cooled briefly in an ice bath for ~5 min, removed, allowed to stand for ~5 min and centrifuged for 5 min at 3500 rpm. The LaF3 removal step effectively removes almost all of the Fe and Ti, as well as silicates that can affect column flow.

The supernate was discarded, and the precipitate containing the actinides was dissolved in 7 mL of 3 M HNO3–0.25 M H3BO3, mixed, and transferred to 50 mL tubes. The 225 mL tubes were rinsed with 6 mL of 7 M HNO3, 7 mL of 2 M Al(NO3)3 and 3 mL 3 M HNO3, respectively, transferring the rinses to the 50 mL centrifuge tubes. The samples were mixed using a vortex stirrer and heated 2–5 min in a hot block heater at 105 °C. The 50 mL tubes were centrifuged to test for any traces of solid particulates, which were removed if needed. Typically, the sample load solutions are very clear. If gel-like solids are observed in the sample load solutions or flow problems are encountered for more difficult sample types, that particular sample may require slightly less titanium chloride added or a slightly larger load solution volume to facilitate total dissolution.

Sample preconcentration for 89,90Sr

Figure 2 shows the preconcentration steps for radiostrontium in limestone and marble samples. The method is very similar to the actinide method, however, no 12 M HCl was added, since the collection of alkaline earth elements such as Ca/Sr is desired. Additional phosphate was added to ensure effective precipitation of the strontium. Following the iron hydroxide and calcium fluoride precipitations, the supernate was discarded and the precipitate containing the strontium was dissolved in 7 mL of 3 M HNO3–0.25 M H3BO3 and 7 mL of 15.8 M HNO3, mixed, and transferred to 50 mL tubes. The 225 mL tubes were rinsed with 7 mL of 8 M HNO3 and 7 mL of 2 M Al(NO3)3, respectively, transferring the rinses to the 50 mL centrifuge tubes. The samples were mixed using a vortex stirrer and heated 2–5 min in a hot block heater at 105 °C. The 50 mL tubes containing the load solutions were centrifuged, and ant traces of solids were discarded.

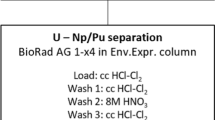

Column separation for actinides and 89,90Sr

Column separation techniques previously reported were used to separate and purify actinides. [1–3, 10, 11] Depending on the desired analytes, several separation schemes can be employed. Pu and Np isotopes were separated rapidly using a single TEVA Resin cartridge, while U isotopes are separated using a stacked TEVA + TRU Resin cartridge approach. Figure 3 shows how TEVA + TRU Resin as stacked cartridges can be used to rapidly separate Pu, Np and U using this method. Am and Cm are separated from interferences using TEVA + DGA Resin, while 90Sr is separated using Sr Resin (3 mL Sr Resin, using stacked 2 mL + 1 mL resin cartridges). The Sr Resin method used is similar to what was published for 90Sr in large soil samples, except that volumes were scaled back slightly for 3 mL Sr Resin instead of 4 mL Sr Resin. The sample load solutions were loaded onto 3 mL Sr Resin at approximately 1 drop per second. After the sample was loaded, a tube rinse of ~5 mL 8 M HNO3 was transferred to the Sr Resin column and allowed to pass through the resin at ~1–2 drops per second. The following column rinses were performed at ~2 drops per second: 15 mL 8 M HNO3, 5 mL 3 M HNO3–0.05 M oxalic acid, and 10 ml 8 M HNO3. Sr was eluted from the resin with 15 mL 0.05 M HNO3 at ~1 drop per second. [15]

Cerium fluoride microprecipitation was used to prepare the purified actinide samples for alpha spectrometry counting. After adding 50 µg Ce, 0.5 mL 30 wt% H2O2 and 1 mL 28 M HF to the Pu eluent solution and waiting 15 min, the solution was filtered using a 25 mm polypropylene filter (0.1 µm pore size disposable Resolve™ filter funnel). Each tube was rinsed with ~5 mL deionized water, followed by ethanol to facilitate drying. The filters were heated briefly under a heat lamp to ensure dryness. A similar approach was used for the Am/Cm and U eluents. For Am/Cm, 40 µg Ce, 0.2 mL 30 wt% H2O2 and 1 mL 28 M HF were added. To prepare the U eluents, 100 µg Ce, 0.5 mL 10 % TiCl3 and 1 mL 28 M HF were added. The additional Ce added for U eluents is needed to ensure effective precipitation of U even when higher levels of U are present in the samples. The filtering protocol as described above was followed after a 15 min wait time. Adding hydrogen peroxide to the Pu and Am/Cm precipitation steps provides additional decontamination from uranium by ensuring the U is U(VI), which does not carry on the CeF3 precipitate. TiCl3 is added during the uranium microprecipitation steps to reduce U(VI) to U(IV), which will carry with the CeF3.

Sr was eluted from 3 mL Sr Resin with 15 mL 0.05 M HNO3 at ~1 drop per second. This eluent solution was transferred to preweighed planchets and evaporated on a hot plate with medium heat to dryness. Two milliliters 0.05 M HNO3, used to rinse each tube, was transferred to each planchet, and evaporated to dryness on a hot plate. After dryness was reached, the planchets were heated ~10–15 min on the hot plate. The dried planchets were allowed to cool weighed to determine gravimetric carrier recovery. The planchets were counted by simultaneous gas flow proportional counting for 60 min. It is important that direct stable strontium carrier standardization on planchets (7–10 replicates) be heated on the hot plate at the same temperature for the same time as the samples to minimize gravimetric yield errors. Sr Resin also collects Pb isotopes while Bi daughter isotopes are eluted during the column rinse steps. During the short elution step, Bi daughters may grow in and be eluted with the 89Sr and 90Sr. This will typically be of little impact if relatively high levels of 89Sr and 90Sr are present in the samples, however, waiting 2–6 h to allow unsupported Bi isotopes to decay may be advisable.

It should be noted that samples with high levels of fresh fission products, present following a radiological event, may cause large uncertainties in the 90Sr measurement when using a “two count” approach to determine 89Sr and 90Sr after 90Y ingrowth. In that case, high levels of 89Sr may cause significant errors in the 90Sr measurements, which are based on a second count after ingrowth of 90Y to determine 89Sr and 90Sr. When the 89Sr is high, the 90Y ingrowth fraction is very small and hard to measure precisely. In cases such as these, purification of 89Sr and 90Sr, followed by collection and purification of 90Y, can offer a much more reliable assay of 90Sr. The 89Sr can then be calculated by difference by subtracting the appropriate amount of 90Sr (plus 90Y ingrowth) from the initial total 89Sr + 90Sr count. Figure 4 shows a DGA Resin separation method previously reported for seawater that may also be used for limestone, marble and other solid samples to purify 90Y. [16] This DGA Resin method has also been successfully used for high 89Sr, low 90Sr air filter samples from the MAPEP program. In this method, yttrium carrier is added to the planchet containing the purified 89Sr/90Sr after a 2–3 day (or longer) 90Y ingrowth period. The planchet solids are dissolved in 8 M HNO3 and transferred to a 50 mL tube. This 8 M HNO3 solution is loaded onto DGA Resin column to purify 90Y. 89Sr and 90Sr are effectively removed using this separation. After 90Y elution in 0.25 M HCl, a small volume of the final purified eluent was taken for ICP-MS assay to determine chemical yield.

Apparatus

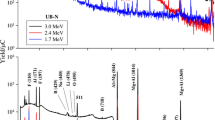

Plutonium, neptunium, uranium, americium and curium isotopic measurements were performed by alpha-particle pulse-height measurements using Passivated Implanted Planar Silicon (PIPS) detectors. The PIPS detectors have an active surface of 450 mm2. The nominal counting efficiency for these detectors is 28–30 %. The distance between the sample and detector surface is ~3 mm.

A Tennelec LB 4100 gas flow proportional counter was used to count the 90Sr spiked samples. The detectors were calibrated using NIST Traceable 90Sr/90Y sources matching the sample geometry. Detector backgrounds are determined and subtracted from the sample counts. A mass attenuation correction factor was determined experimentally using prepared mounts containing 90Sr/90Y (>167 Bq) and a nominal amount of Sr carrier. Planchets were annealed for ~1.5 h in a furnace at 450 °C prior to use. This provides chemical resistance to the planchets so that iron oxide does not form during evaporation of the nitric acid, which would cause error in the gravimetric weights.

Polycarbonate vacuum boxes with 24 positions and a rack to hold 50 mL plastic tubes were used. Two boxes were connected to a single vacuum source by using a T-connector and individual valves on the tubing to each box.

Results and discussion

Table 1 shows the individual results for the determination of 239/240Pu in six 1 g limestone samples spiked with a small amount of MAPEP 24 soil using this rapid separation method and alpha spectrometry. The results were corrected for 242Pu tracer yield. The average 239/240Pu result was 29.6 mBq g−1, with a 0.6 % bias and SD (standard deviation) of 2.2 mBq g−1. The average tracer recovery for 242Pu was 100 ± 4.9 % (SD). The high 242Pu tracer recoveries and excellent results for 239/240Pu versus known values indicate the ruggedness of the sample preparation and measurement steps, even for refractory Pu isotopes. The Full Width Half Maximum (FWHM) results for the 242Pu tracer peaks show acceptable alpha peak resolution. The uncertainties for the individual 239/240Pu results were typically ±7–8 % (1 SD), with a 16 h count time. Shorter count times may be used in a radiological emergency, with higher tracer activity levels added to minimize counting uncertainty for the tracer used.

Table 2 shows the individual results for the determination of 239/240Pu in six 1 g limestone samples spiked with MAPEP 30 soil samples. The results were corrected for 236Pu tracer yield. 236Pu tracer was added so that 237Np could also also be measured, since 242Pu interferes with the assay of 237Np, due to overlapping alpha particle energies. The average 239/240Pu result was 23.7 mBq g−1, with a 3.0 % bias and standard deviation (SD) of 1.3 mBq g−1. The average tracer recovery for 236Pu was 93.1 ± 6.1 % (SD). The full width half maximum (FWHM) results for the 236Pu tracer peaks show acceptable alpha peak resolution. The uncertainties for the individual 239/340Pu results were typically ±7–8 % (1 SD), with a 16 h count time.

Table 3 shows the individual results for the determination of 238Pu in six 1 g limestone sample spiked with 0.25 g MAPEP 30 soil sample. The average 238Pu result was 29.1 mBq g−1, with a 1.0 % bias and SD of 1.8 mBq g−1. Table 4 shows the results for 237Np in the same set of samples, also corrected for 236Pu tracer yield. The average 237Np result was 38.8 mBq g−1, with a 4.9 % bias and SD (standard deviation) of 2.7 mBq g−1. Without the second replicate sample which was biased high at 15 %, the overall bias for the set would have been only 2.9 %. The overall bias of <5 % was still acceptable, however.

Table 5 shows the individual results for the determination of 239/240Pu in four 1 g marble samples spiked with a small amount of MAPEP 24 soil. The results were corrected for 242Pu tracer yield. The average 239/240Pu result was 30.0 mBq g−1, with a 2.0 % bias and SD of 2.1 mBq g−1. The average tracer recovery for 242Pu was 96.0 ± 2.9 % (SD). The FWHM results for the 242Pu tracer peaks show acceptable alpha peak resolution. The uncertainties for the individual 239/340Pu results were typically ±7–8 % (1 SD), with a 16 h count time.

Table 6 shows the individual results for the determination of 241Am in four 1 g marble samples spiked with a small amount of MAPEP 32 soil. The results were corrected for 243Am tracer yield. The average 241Am result was 28.7 mBq g−1, with a −1.3 % bias and SD (standard deviation) of 1.1 mBq g−1. The average tracer recovery for 243Am was 88.8 ± 3.7 % (SD). The FWHM results for the 243Am tracer peaks show acceptable alpha peak resolution. The uncertainties for the individual 241Am results were typically ±7–8 % (1 SD), with a 16 h count time. 244Cm was also determined from the Am alpha spectrum, using 243Am tracer to correct the 244Cm results. Table 7 shows that the average 244Cm result was 34.5 mBq g−1, with a 0.7 % bias and SD of 2.5 mBq g−1.

Table 8 shows the individual results for the determination of 238U in eight 1 g limestone samples spiked with a small amount of MAPEP 32 soil. The results were corrected for 232U tracer yield. The average 238U result was 48.4 mBq g−1, after correction for a native 238U content of 8.5 mBq/g. with a −3.6 % bias and SD (standard deviation) of 1.5 mBq g−1. The average tracer recovery for 232U was 92.8 ± 6.0 % (SD). The FWHM results for the 232U tracer peaks show acceptable alpha peak resolution. The uncertainties for the individual 238U results were typically ±7–8 % (1 SD), with a 16 h count time.

Table 9 shows the individual results for the determination of 90Sr in seven 1 g limestone samples spiked with 1.415 Bq g−1 90Sr. The 90Sr results were corrected for chemical yield using a stable strontium gravimetric method, with an average value of 73.8 %. The average 90Sr result was 1.40 Bq g−1, with an average bias of −0.79 %, and SD of 0.04 Bq g−1. Adjustments were made in the phosphate level added in the initial preconcentration step to see if phosphate was a limiting reagent and the chemical yield would increase. This was tested because of the high level of calcium in the samples. Table 10 shows that the increased phosphate (8.5 mL 3.2 M ammonium phosphate added instead of 7 mL .2 M ammonium phosphate) did not increase the chemical yield. Though the chemical yield did not increase significantly, the 90Sr results were still excellent, with an average bias of only −0.12 %. Table 11 shows the results when the fluoride level across the final CaF2 precipitation step was increased. The volume of 28 M HF added was increased from 10 mL to 15 mL and the average chemical yield increased to 84.6 %, a significant increase in yield. This test showed that the fluoride ion level was limiting the calcium and strontium precipitation efficiency and that a higher level was needed to enhance chemical yields. The average bias for the 90Sr measurements was only −0.85 %. The MDA (Minimum Detectable Activity) for actinide isotopes using this method with measurement by alpha spectrometry was calculated according to equations prescribed by Currie: [17]

where B is the total background counts,=BKG (rate) × sample count time; CT is the sample count time (min), R is the chemical recovery; V is the sample aliquot (g); EFF is the detector efficiency; A is the isotopic abundance (in most cases this will be ~1); 0.060 = conversion from dpm to mBq.

The minimum detectable activity MDA for the alpha spectrometry results can be adjusted as needed, depending on the sample aliquot and count time. For a 1 g limestone or marble aliquot, the method MDA for the actinide isotopes with a 16 h count time is ~500 μBq g−1, assuming a detector efficiency of ~28 %, 1 count background per 16 h and a chemical recovery of 90 %. Samples counted for only 4 h are estimated to have an MDA of ~1.4 mBq g−1.

For 89Sr or 90Sr in limestone and marble samples, the MDA is ~18 mBq g−1 for a 1.5 g sample aliquot, 60 min count time, 90 % chemical recovery, 54 % detector efficiency and 1.5 count per minute background using gas flow proportional counting. The count time may be increased to lower the MDA if desired.

Conclusions

A new rapid fusion method to determine actinide isotopes, 89Sr and 90Sr in 1 g −1.5 g limestone and marble samples has been developed that allows the separation of these isotopes with high chemical yields and effective removal of interferences. It has been validated by adding MAPEP 24 soil standards containing refractory 239Pu isotope to the limestone and marble samples. The sodium hydroxide fusion technique is fast and rugged. The stacked cartridge approach offers many options, depending on the analytes required. The new method is rapid, effective and has been optimized for chemical yields and removal of interferences.

References

Maxwell S, Culligan B, Noyes G (2010) Rapid separation method for actinides in emergency soil samples. Radiochim Acta 98:1–8

Maxwell S, Culligan B, Wall AG (2011) Rapid radiochemical method for determination of actinides in emergency concrete and brick samples. Anal Chim Acta 701:112–118

Maxwell S, Culligan B, Hutchison J (2014) Rapid determination of actinides in asphalt samples. J Radioanal Nucl Chem 299(3):1891–1901

How do you recognize limestone and marble? http://pubs.usgs.gov/gip/acidrain/4.html. Accessed 12 Jan 2015

Vajda N, Törvényi A, Kis-Benedek G, Kim CK, Bene B, Mácsik Z (2009) Rapid method for the determination of actinides in soil and sediment samples by alpha spectrometry. Radiochim Acta 97:395–401

Jia G, Torri G, Ocone R, Di Lullo A, Boshcetto R (2008) Determination of thorium isotopes in mineral and environmental water and samples by a-spectrometry and the fate of thorium in water. Appl Radiat Isot 66:1478–1487

Rapid method for fusion of soil and soil-related matrices prior to Americium, Plutonium, and Uranium analyses for environmental remediation following radiological incidents. http://www2.epa.gov/sites/production/files/2015-06/documents/soil_dissolution_by_fusion_for_am_pu_u_09-17-12_epa-600-r-12-636637638.pdf

Rapid method for sodium hydroxide fusion of concrete and brick matrices prior to Americium, Plutonium, Strontium, Radium and Uranium Analyses for Environmental Remediation Following Radiological Incidents. http://www2.epa.gov/sites/production/files/2015-06/documents/concrete_and_brick_dissolution_by_fusion_rev_0_402r14004.pdf

Jurečič S, Benedik L, Planinšek P, Nečemer M, Kump P, Pihlar B (2014) Analysis of uranium in the insoluble residues after decomposition of soil samples by various techniques. Appl Radiat Isot 87:61–65

Maxwell S, Hutchison J, McAlister D (2015) Rapid fusion method for the determination of refractory thorium and uranium isotopes in soil samples. J Radioanal Nucl Chem 305:631–641

Maxwell S, Culligan B, Hutchison J, McAlister D (2015) Rapid fusion method for the determination of Pu, Np, and Am in large soil samples. J Radioanal Nucl Chem 305:599–608

Sill C (2004) Purification of radioactive tracers for use in high sensitivity alpha spectrometry. Anal Chem 46(11):1426–1431

Gostic J (2009) Evaluation of extraction chromatography resins for rapid actinide analysis, Doctoral Thesis at University of Nevada Las Vegas. http://digitalscholarship.unlv.edu/cgi/viewcontent.cgi?article=1103&context=thesesdissertations

Maxwell S, Culligan B, Noyes G (2010) Rapid separation method for actinides in emergency air filter samples. Appl Radiat Isot 2010:2125–2131

Maxwell S, Culligan B (2013) Rapid determination of radiostrontium in large soil samples. J Radioanal Nucl Chem 295:965–971

Maxwell S, Culligan B, Utsey R (2013) Rapid determination of radiostrontium in seawater samples. J Radioanal Nucl Chem 298:867–875

Currie LA (1968) Limits for qualitative and quantitative determination. Anal Chem 40:586–593

Acknowledgments

This work was performed under the auspices of the Department of Energy, DOE Contract No. DE-AC09-96SR18500. The authors wish to acknowledge Becky Chavous, Jeff Filmon and Sharon Fulton for their assistance with this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maxwell, S.L., Culligan, B., Hutchison, J.B. et al. Rapid method to determine actinides and 89/90Sr in limestone and marble samples. J Radioanal Nucl Chem 310, 377–388 (2016). https://doi.org/10.1007/s10967-016-4783-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-016-4783-8