Abstract

A new rapid method for the determination of actinides in asphalt samples has been developed that can be used in emergency response situations or for routine analysis. If a radiological dispersive device, improvised nuclear device or a nuclear accident such as the accident at the Fukushima Nuclear Power Plant in March, 2011 occurs, there will be an urgent need for rapid analyses of many different environmental matrices, including asphalt materials, to support dose mitigation and environmental clean-up. The new method for the determination of actinides in asphalt utilizes a rapid furnace step to destroy bitumen and organics present in the asphalt and sodium hydroxide fusion to digest the remaining sample. Sample preconcentration steps are used to collect the actinides and a new stacked TRU Resin + DGA Resin column method is employed to separate the actinide isotopes in the asphalt samples. The TRU Resin plus DGA Resin separation approach, which allows sequential separation of plutonium, uranium, americium and curium isotopes in asphalt samples, can be applied to soil samples as well.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There are a number of analytical methods reported that use ion exchange/extraction chromatography plus alpha spectrometry to determine actinides in environmental samples. Wang et al. [1] reported a sequential method to determine actinides and strontium in soil samples. The chemical recoveries using this method on environmental samples were as follows: plutonium (61–85 %), americium (42–65 %), and uranium (56–73 %). A large number of sequential steps were required, but the accuracy of the results versus reference values was very good. The sequential approach saves time, but many of the steps are still quite time-consuming. In an emergency, a rapid straight-forward approach is needed.

Weinreich et al. [2] reported a method for concrete which utilized acid digestion of concrete powder, followed by plutonium and uranium separation and measurement. Plutonium was separated using a classical anion resin separation followed by evaporation of effluents and loading to UTEVA Resin for separation of uranium isotopes. While the chemical yields for uranium were greater than 90 %, plutonium yields were less consistent, perhaps resulting from less consistent valence adjustment with hydrogen peroxide in 8M nitric acid. UTEVA Resin separation can also retain 210Po, which could be present at high levels depending on the nature of an emergency sample.

There does not seem to be reported analytical methods for actinides in asphalt samples in the scientific literature. A rapid soil method was reported by this laboratory to separate and determine actinides in emergency soil samples using sodium hydroxide fusion [3]. A similar analytical approach was taken for concrete and brick samples [4]. The importance of having a rugged digestion method for refractory particles on environmental samples is well-known [5].

A new method to determine Pu, Am, Cm and U isotopes in asphalt samples has been developed in the Savannah River National Laboratory (Aiken, SC, USA). This approach has a sample preparation time for asphalt samples of <8 h. This method can be used in emergency response situations or for routine analysis. The samples were analyzed using a rapid sodium hydroxide fusion, followed by precipitation steps including a lanthanum fluoride matrix removal step, followed by a stacked TRU Resin + DGA Resin. An iron hydroxide precipitation enhanced with Ti+3 reductant is used to remove the excess alkaline matrix and a lanthanum fluoride precipitation is used to remove the Fe, Ti, as well as other sample matrix components which can interfere, such as silicates which can adversely affect column flow.

Previously, a stacked cartridge method using TEVA Resin + TRU Resin + DGA Resin has been used in this laboratory to separate multiple actinides using the rapid fusion methodology. This method works very well, but for this work a TRU Resin + DGA Resin cartridge method was employed as an option to reduce the number of resin cartridges needed and lower costs. Lanthanum, which follows Am on DGA Resin, was removed using a dilute nitric acid rinse. Vacuum box technology was used to allow rapid flow rates and a stacked resin cartridge approach to reduce separation times. Alpha sources are prepared using cerium fluoride microprecipitation for counting by alpha spectrometry. This new method showed high chemical recoveries and effective removal of interferences. The fusion, unlike fusions that are performed one at a time over a burner, can be performed quickly and simultaneously in a furnace or furnaces at only 600 °C. One advantage of sodium hydroxide fusion is that, unlike lithium metaborate, for example, it is relatively easy to remove the fused sample from the crucible after the fusion step. Reusable zirconium crucibles, which are much less expensive than platinum crucibles, were employed.

Experimental

Reagents

The resins employed in this work are TRU-Resin® (tri-n-butylphosphate (TBP) and octyl (phenyl) N,N-diisobutylcarbamoylmethylphosphine oxide (CMPO)) and DGA Resin (N,N,N′,N′-tetraoctyldiglycolamide), available from Eichrom Technologies, Inc., (Lyle, Illinois, USA) [6, 7]. Nitric and hydrofluoric acids were prepared from reagent-grade acids (Fisher Scientific, Inc.). All water was obtained from a Milli-Q2™ water purification system. All other materials were ACS reagent grade. Radiochemical isotope tracers 242Pu, 243Am, and 232U that were obtained from Analytics, Inc. (Atlanta, GA, USA) and diluted to approximately 74 mBq ml−1 were employed to enable yield corrections. 244Cm was obtained from Analytics, Inc. (Atlanta, GA, USA) and diluted to approximately 74 mBq ml−1. 232U tracer was prepared to be self-cleaning, removing its 228Th daughter using barium sulfate precipitation [8].

Procedures

Column preparation

TRU and DGA Resin columns were obtained as cartridges containing 2 ml of each resin from Eichrom Technologies, Inc.. Small particle size (50–100 micron) resin was employed, along with a vacuum extraction system (Eichrom Technologies). Flow rates of ~1–2 ml min−1 were typically used for this work, slower on sample loading and final elution steps, faster for the rinses used to remove sample matrix interferences.

Sample preparation

It is very important to obtain a representative sample for the analysis of asphalt. Asphalt samples were crushed, ground to a fine powder to homogenize the sample as well as possible. A small amount of MAPEP 24 (Mixed Analyte Performance Evaluation Program) soil sample was added to the asphalt samples to test for ruggedness regarding refractory isotopes. The MAPEP samples were provided by Department of Energy (DOE)—Radiological and Environmental Sciences Laboratory (RESL), Idaho, USA. Eight replicate 1 g aliquots of asphalt sample were added to 250 ml zirconium crucibles. To spike the samples with actinides, 400 mg of MAPEP 24 soil standard and 244Cm standard (35.5 mBq) were added to the eight spiked replicate samples. MAPEP 24 soil standard was chosen because the 239Pu present in this soil is refractory. Successful analysis would indicate analytical method ruggedness and applicability when refractory particles are present. For the separate soil analysis to test the TRU Resin + DGA Resin approach, 1 g aliquots of MAPEP 24 soil standard were added to 250 ml zirconium crucibles.

Figure 1 shows the rapid furnace heating, fusion and precipitation steps used to digest the samples and preconcentrate the actinides from the alkaline fusion matrix. Tracers were added to each crucible and the crucibles were dried on a hotplate. After removing crucibles from the hotplate, 15 g of NaOH were added to each crucible. The crucibles were covered with a zirconium lid and placed into a furnace at 600 °C for ~15 min.

After removing the crucibles from the furnace, they were cooled for about 10 min, transferred to a hot plate and water was added to transfer the solids to 225 ml centrifuge tubes. The residual solids were removed from the crucibles by adding water and heating the crucibles on the hot plate as needed. One hundred and twenty-five milligrams of Fe (added as Fe (NO3)3) and five milligrams of La (as La (NO3)3) were added to each 225 ml centrifuge tube prior to transferring the alkaline solution and solids from the crucibles into the tubes. The samples were diluted to 180 ml with water and cooled in an ice bath to room temperature.

Two milliliters of 1.25 M Ca(NO3)2 and five milliliters of 3.2M (NH4)2HPO4 were added to each tube and each was capped and mixed well. The Ca and PO4 ions were added to enhance uranium recoveries. Ten milliliters of 10 % TiCl3 were added to each tube and mixed well. Increasing the 10 % TiCl3 used from a 5 ml volume to a 10 ml volume also enhances uranium yields. The samples were cooled in an ice bath to room temperature. The tubes were centrifuged at 3,500 rpm for 6 min and the supernatant was discarded. The remaining solids were dissolved in a total volume of ~60–80 ml of 1.5M HCl. This solution was diluted to ~170 ml with 0.01M HCl. After dilution, 1 mg of La (as La(NO3)3) was added to each sample. To ensure no actinides were in the hexavalent state and facilitate complete precipitation, 5 ml of 10 % titanium chloride were added to each sample. Twenty-five milliliters of 28M HF were added to each sample. The samples were mixed well and allowed to stand for ~10 min and centrifuged for 6 min at 3,500 rpm.

The supernatant was removed and the residual solids containing the actinides were dissolved in 5 ml of 3M HNO3-0.25M H3BO3, 6 ml of 7M HNO3 and 7 ml of 2M Al(NO3)3. The LaF3 removal step effectively removes almost all of the Fe and Ti, as well as silicates that can affect column flow. The aluminum nitrate was previously scrubbed to remove trace uranium by passing approximately 250 ml of 2M aluminum nitrate through a large column (Environmental Express, Mount Pleasant, SC, USA) containing 7 ml of UTEVA Resin (Eichrom Technologies) at ~10–15 ml/min. These columns were prepared from a water slurry of the UTEVA Resin.

A valence adjustment was performed on the load solution by adding 0.2 ml 1.5M sulfamic acid and 1.25 ml 1.5M ascorbic acid with a 3 min wait step to reduce plutonium to Pu3+. Following the reduction step, 1 ml 3.5M NaNO2 was added to oxidize plutonium to Pu4+. After this oxidation step, 4 ml 15.8M HNO3 was added to each sample to increase the nitrate concentration. This enhances Pu and U retention on TRU Resin and lowers Ca retention on DGA Resin. The overall total nitrate in the load solution is ~7.5M nitrate.

Column separation

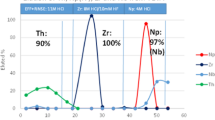

Figure 2 shows the column separation method used. TRU Resin cartridges and DGA Resin cartridges were stacked and placed on the vacuum box (TRU Resin on top) and 50 ml centrifuge tubes were used to collect rinse or final purified fractions.

After the valence adjustment as described above, the sample solution was loaded onto the TRU Resin + DGA Resin stacked column at approximately 1 drops per second. After the sample was loaded, a tube rinse of ~5 ml 8M HNO3 was transferred to the TRU Resin + DGA Resin column and allowed to pass through the resin at ~1–2 drops per second. A rinse of 10 ml 10M HNO3 was added to each column to ensure Po+4 was eluted from TRU Resin at ~1 drop per second. Then 15 ml 4M HCl was added directly to the TRU + DGA column at ~1–2 drops per second to elute Am from TRU Resin onto DGA Resin. The TRU Resin and DGA Resin cartridges were split and processed separately from that point on two separate vacuum boxes for efficiency.

After placing a new column reservoir on the TRU Resin cartridge, Pu was eluted from TRU Resin using 15 ml 3M HCl-0.02M TiCl3 slowly at ~1 drop per second. The Pu is reduced to Pu+3 and eluted from the column. TRU Resin was then rinsed with 5 ml 8M HNO3-0.03 % H2O2 at ~1 drop per second to ensure all the uranium is in the U+6 valence state. To remove thorium and neptunium, 10 ml 4M HCl-0.2M HF were added to rinse TRU Resin at 1–2 drops per second, followed by a rinse of 7.5 ml 4M HCl-0.2 M HF-0.002M TiCl3 to ensure full removal of all Po+4. By ensuring uranium is in the U+6 valence state, losses during the thorium/neptunium removal step are minimized. For asphalt or soil samples containing larger amounts of Th, the rinse volume with 4M HCl-0.2M HF can be increased as needed. Uranium was eluted using 15 ml 0.1M ammonium bioxalate at ~1 drop per second. If ICP-MS measurement of uranium isotopes is desired, 0.01M ammonium bioxalate may be used. Column connector tips were changed to eliminate any possibility of cross-contamination from the Th rinse solution that passes through prior to U elution.

To prepare the purified Pu samples for alpha spectrometry counting, 10 ml of water was added to reduce the acid strength and 0.5 ml 30 wt% H2O2 was added to oxidize any uranium ions that might be present to prevent uranium co-precipitation. After adding 50 μg Ce and 2 ml 28M HF to the Pu eluent solution and waiting 15 min, the solution was filtered using a 25 mm polypropylene filter (disposable Resolve™ filter funnel). Each tube was rinsed with ~5 ml deionized water, followed by ethanol to facilitate drying. The filters were heated briefly under a heat lamp to ensure dryness. For the uranium eluent solutions, 100 μg Ce, 0.5 ml 10 % TiCl3 (to reduce U+6–U+4) and 1 ml 28M HF were added and the tubes mixed well. The higher Ce level (100 μg) was added to ensure complete precipitation of uranium even when higher levels of uranium are present. After 15 min, the solutions were filtered as described above.

The DGA Resin separation for Am is described below. Twelve milliliters of 3M HCl were added to each DGA Resin cartridge at ~2 drops per second to ensure complete Ca removal. Three milliliters of 1M HNO3 were added to each column to remove chloride ions. To remove La present, 20 ml 0.05M HNO3 was added to each DGA resin cartridge at ~1–2 drops per second. To remove any thorium present, 12 ml 3 M HNO3-0.25 M HF was added at ~1–2 drops per second. Next, 5 ml 3M HCl was added to remove any residual fluoride ions. Am and Cm isotopes were eluted with 12 ml 0.25 M HCl at ~1 drops per second.

To prepare the Am/Cm eluent solutions for microprecipitation, 40 μg Ce and 200 ul of 30 wt% H2O2 were added to each tube, followed by 1 ml 28M HF. The slightly lower Ce level (40 μg) is used to ensure good alpha peak resolution since a very small amount of La could still be present. The 30 wt% H2O2 is added to ensure any residual uranium ions, if present, are oxidized to U+6 and do not precipitate. After 15 min, the solutions were filtered as described above.

Apparatus

Plutonium, americium, curium and uranium isotopic measurements were performed by alpha-particle pulse-height measurements using Passivated Implanted Planar Silicon (PIPS) detectors. The PIPS detectors have an active surface of 450 mm2. The nominal counting efficiency for these detectors is 0.30. The distance between the sample and detector surface is ~3 mm.

Polycarbonate vacuum boxes with 24 positions and a rack to hold 50 ml plastic tubes were used. Two boxes were connected to a single vacuum source by using a T-connector and individual valves on the tubing to each box.

Results and discussion

Table 1 shows the individual results for the determination of 239Pu in eight 1 g asphalt samples spiked with MAPEP 24 soil using this rapid separation method and alpha spectrometry. The results were corrected for 242Pu tracer yield. The average 239Pu result was 39.9 mBq g−1 sample, with a 1.7 % bias and SD (standard deviation) of 1.8 mBq g−1. The average tracer recovery for 242Pu was 91.3 ± 6.2 % (SD). The high 242Pu tracer recoveries and excellent results for the analyte versus known values indicate the sample preparation and measurement steps were effective.

Tables 2 and 3 shows the results for the determination of 241Am and 244Cm in spiked asphalt samples using alpha spectrometry. The average 241Am result was 23.3 mBq g−1, with a –4.6 % bias and SD of 3.1 mBq g−1. The average 244Cm result was 36.5 mBq g−1, with a 2.8 % bias and SD of 4.6 mBq g−1. The average tracer recovery for 243Am was 84.1 ± 12.6 % (SD). The 243Am tracer corrections were applied to the 241Am and 244Cm sample results. This illustrates that under these conditions that 243Am works very well as a yield monitor for 244Cm as well. The results illustrate that DGA Resin continues to be an excellent resin for Am/Cm separation from difficult sample matrices.

Tables 4 and 5 shows the results for the determination of 234U and 238U isotopes for the eight spiked asphalt samples. The U isotope results by alpha spectrometry were corrected for 232U tracer yield. The average 238U result was 72.0 mBq g−1 (SD of 8.4 mBq g−1). The average 238U result was corrected for the 238U content found in the unspiked concrete sample, 39.8 mBq g−1, to give an average result of 72.0 mBq g−1. This resulted in an average bias of −2.1 % for 238U in the asphalt samples. The individual bias measurements show some variation, likely related to the relatively large native content of uranium and the possibility of sample to sample variation depending on homogeneity. The average 234U result was 71.5 mBq g−1 (SD of 8.8 mBq g−1). The average 234U result was corrected for the 234U content found in the unspiked concrete sample, 39.8 mBq g−1, to give an average result of 71.5 mBq g−1. This resulted in an average bias of −2.8 % for 234U in the asphalt samples. The average 232U tracer yield was 86.3 ± 7.0 % (SD). The excellent U isotope results indicate very good removal of 210Po, which interferes with the 232U tracer measurement.

Table 6 shows the 239Pu results when this method was applied to 1 g MAPEP 24 soil aliquots. The furnace step used to remove organics in the asphalt samples was not used for the MAPEP 24 soil samples. The results were corrected for 242Pu tracer yield. The average 239Pu result was 94.7 mBq g−1, with a −3.3 % bias and SD of 3.2 mBq g−1. The average tracer recovery for 242Pu was 96.9 ± 9.4 % (SD).

Table 7 shows the results for the determination of 241Am in MAPEP 24 soil samples using alpha spectrometry. The average 241Am result was 58.8 mBq g−1, with a 4.1 % bias and SD of 4.1 mBq g−1. The average tracer recovery for 243Am was 96.2 ± 7.0 % (SD). The 243Am tracer corrections were applied to the 241Am results.

Table 8 shows the results for the determination of 238U in MAPEP 24 soil samples. The U isotope results were corrected for 232U tracer yield. The average 238U result was 183.3 mBq g−1 (SD of 5.5 mBq g−1). The average 232U tracer yield was 91.2 ± 43.9 % (SD).

The removal of 210Po is very important for the reliable measurement of U isotopes in samples by alpha spectrometry since 210Po and 232U tracer have overlapping alpha energies. 210Po has very little retention on TRU Resin in the high nitric acid load and rinse solutions (k′ < 4 in 10 M HNO3), [9] but has a k′ of ~1,000 on TRU Resin in 4 M HCl. Po+4 also resists formation of fluoride anionic complexes, and therefore any residual Po+4 not removed with the nitric acid rinsing would likely be retained on TRU Resin during the Th rinse step with 4M HCl-0.2M HF. The addition of a small rinse volume of 4M HCl-0.2M HF-0.002 M TiCl3 reduces Po+4–Po+2, which is unretained on TRU Resin, and provides additional assurance of the removal of 210Po. The minimal bias versus reference values for spiked asphalt and reference soil samples in Tables 4, 5 and 8 indicate this approach was effective. Po+4 is retained on DGA Resin after passing through TRU Resin, but remains on DGA Resin during the elution of Am and Cm using 0.25 M HCl [9].

The MDA (minimum detectable activity) for the actinide isotopes by alpha spectrometry were calculated according to equations prescribed by Currie [10]:

where B is a total background counts, BKG (rate) * sample count time, CT is a sample count time (min), R is a chemical recovery, W is a sample aliquot (g), EFF is a detector efficiency, 0.060 is a conversion from dpm to mBq.

In low-level counting, where a zero background count is quite common, the constant 3 is used to prevent an excessively high false positive rate.

The MDA (minimum detectable activity) for the alpha spectrometry results can be adjusted as needed, depending on the sample aliquot and count time. For a 1 g sample aliquot, the method MDA for the actinide isotopes with a 16 h count time is ~0.74 mBq g−1. Depending on the MDA required, the sample aliquot and count time may be adjusted accordingly. Higher level tracers (370 mBq) may be used in conjunction with shorter count times, such as 1–4 h., for more rapid analysis [3]. Samples counted for 4 h had a MDA of ~1.8 mBq g−1 .

Figure 3 shows an example of the spectra of Pu isotopes in an asphalt sample. The 242Pu tracer recovery was 97.3 % and the Full Width Half Maximum (FWHM) was 44.1 keV, showing acceptable alpha peak resolution and good tracer recovery. The 239Pu peak labeled on the spectra represents 239Pu plus 240Pu, since these isotopes have overlapping alpha energies. Figure 4 shows an example of the spectra of Am and Cm in an asphalt sample. The 243Am tracer recovery was 103.1 % and the Full Width Half Maximum (FWHM) was 63.5 keV, showing acceptable alpha peak resolution and good tracer recovery. Figure 5 shows an example of the spectra of U isotopes an asphalt sample. The 232U tracer recovery was 103.4 % and the Full Width Half Maximum (FWHM) was 41.1 keV, showing acceptable alpha peak resolution and good tracer recovery.

The furnace heating and rapid fusion method plus precipitation steps takes about 3 h for a batch of 10 samples, followed by actinide separation steps that take about 2.5–3 h to complete (depending on flow rates used). Samples may be counted by alpha spectrometry for 1–16 h in an emergency or for routine analyses using appropriate level tracers for the desired count time to minimize counting uncertainty. If an RDD, IND or even a nuclear accident were to occur in an area where asphalt materials must be tested for radioactivity levels, this rapid method can be applied to samples even containing refractory particle with high throughput and reliability.

The TRU Resin + DGA Resin column method was effective after furnace heating and rapid fusion of the asphalt sample. The use of TRU Resin instead of TEVA Resin may offer a couple of slight disadvantages, however, depending on the measurement technique used. One advantage of using TEVA Resin instead of TRU Resin for Pu separation is the option to collect and purify Pu and Np together. There is also an option to use a stacked TEVA Resin + DGA Resin approach, when U is not needed. If Pu isotopic assay by inductively-coupled plasma mass spectrometry (ICP-MS) is desired using direct elution of Pu from TEVA Resin, a Pu eluent solution of 0.05M HCl-0.025M HF-0.02M hydroxlyamine hydrochloride (HH) may be used instead of 0.1M HCl-0.05M-0.01M TiCl3 eluent solution used for alpha spectrometry. Even though the kinetics of this reduction of Pu+4–Pu+3 are not as rapid as when using Ti+3, the rate of reduction is sufficient during the 15 min elution time to facilitate effective Pu removal from TEVA Resin [11].

For soil or asphalt samples, which can contain large amounts of 238U, the measurement of 239Pu by ICP-MS can be hampered significantly due to 238UH+ hydride formation and 238U peak tailing. The importance of removing 238U to prevent interference on the measurement of 239Pu in soil and other environmental samples is well-known [12–14]. Kim et al. [15] noted that the 238U level in the purified solutions should be less than 100 pg/ml to minimize spectral interference on the measurement of 239Pu by ICP-MS.

There are options reported by this laboratory to allow very high decontamination of uranium from the Pu to allow ICP-MS assay without interference from 238U hydride. Pu can be eluted from TEVA Resin as Pu+3 through a 1 ml UTEVA cartridge onto DGA Resin to achieve very high uranium decontamination factors and then Pu is eluted from DGA with a small volume of 0.02M HCl-0.005M HF-0.01 M hydroxylamine hydrochloride [16].

Initial tests using 3M HCl-0.02M hydroxlyamine hydrochloride to attempt to elute Pu from TRU Resin showed low Pu yields, but perhaps with a slower flow rate (or wait step after initial contact) to accommodate the slower kinetics of hydroxlyamine hydrochloride this could be achieved. Of interest may also be the transfer of Pu isotopes onto a separate DGA Resin for additional uranium removal using 3 M HCl-0.02 M TiCl3, similar to what is done with TEVA Resin to achieve high U decontamination prior to ICP-MS assay.

The TRU Resin + DGA Resin approach also allows stacking of a Sr Resin cartridge below the TRU and DGA cartridges for simultaneous collection and purification of 89Sr and 90Sr. The TRU+DGA Resin option is simply another effective tool for sequential actinide separations and the particular application may determine which approach is preferred.

Conclusions

A new rapid method to determine Pu, U, Am and Cm isotopes in asphalt samples has been developed that allows the separation of these isotopes with high chemical yields and effective removal of interferences. The fusion technique is fast and rugged, demonstrating very good recoveries of MAPEP standards which contain refractory 239Pu. The TRU Resin + DGA Resin stacked approach was shown to be a viable separation option, and can be applied successfully to soil samples as well.

References

Wang J, Chen I, Chiu J (2004) Sequential isotopic determination of plutonium, thorium, americium, strontium and uranium in environmental and bioassay samples. Appl Radiat Isot 61:299–305

Weinreich R, Bajo S, Eikenberg J, Atchison F (2004) Determination of uranium and plutonium in shielding concrete. J Radioanal Nucl Chem 261(2):319–325

Maxwell S, Culligan B, Noyes G (2010) Rapid separation method for actinides in emergency soil samples. Radiochim Acta 98:793–800

Maxwell S, Culligan B, Wall AG (2011) Rapid radiochemical method for determination of actinides in emergency concrete and brick samples. Anal Chim Acta 701:112–118

Sill C, Sill D (1995) From the lab: sample dissolution. Radioact. Radiochem. 6(1):8–14

Horwitz P, Dietz M, Nelson D, LaRosa J, Fairman W (1990) Concentration and separation of actinides from urine using a supported bifunctional organophosphorus extractant. Anal Chim Acta 238:263–271

Horwitz P, McAlister D, Bond A, Barrans AB Jr (2005) Novel extraction chromatographic resins based on tetraalkyldiglycolamides: characterization and potential applications. Solv Extr Ion Exch 23(3):319–344

Sill C (1974) Purification of radioactive tracers for use in high sensitivity alpha spectrometry. Anal Chem 46(11):1426–1431

Maxwell S, Culligan B, Hutchison J, Utsey R, McAlister D (2013) Rapid determination of 210Po in water samples. J Radioanal Nucl Chem 298(3):1977–1989

Currie LA (1968) Limits for qualitative and quantitative determination. Anal Chem 40:586–593

Maxwell S, Culligan B, Hutchison J (2013) Rapid fusion method for determination of plutonium isotopes in large rice samples. J Radioanal Nucl Chem 298:1367–1374

Varga Z, Surányi G, Vajda N, Stefánka Z (2007) Rapid sequential determination of americium and plutonium in sediment and soil samples by ICP-SFMS and alpha-spectrometry. Radiochim Acta 95(2):81–87

Ayranov M, Krahenbuhl U, Sahli H, Rollin S, Burger M (2005) Radiochemical separation of actinides from environmental samples for determination with DF-ICP-MS and alpha spectrometry. Radiochim Acta 93(5):249–258

Maxwell S, Culligan B, Noyes G, Jones V, Nichols S, Noyes G, Bernard M (2010) (2010), Rapid determination of 237Np and Pu isotopes in large soil samples by inductively-coupled plasma mass spectrometry. Anal Chim Acta 682:130–136

Kim CS, Vajda N (2007) Determination of Pu isotope concentrations and isotope ratio by inductively coupled plasma mass spectrometry: a review of analytical methodology. J Anal At Spectrom 22:827–841

Maxwell S, Culligan B, Noyes G, Jones V, Nichols ST, Bernard M (2011) Rapid determination of 237Np and Pu isotopes in urine by inductively-coupled plasma mass spectrometry and alpha spectrometry. Health Physics Journal 101(2):180–186

Acknowledgments

This work was performed under the auspices of the Department of Energy, DOE Contract No. DE-AC09-96SR18500. The authors wish to acknowledge Staci Britt, Jack Herrington and Becky Chavous for their assistance with this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maxwell, S.L., Culligan, B.K. & Hutchison, J.B. Rapid determination of actinides in asphalt samples. J Radioanal Nucl Chem 299, 1891–1901 (2014). https://doi.org/10.1007/s10967-013-2885-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-013-2885-0