Abstract

A new method for the determination of radiostrontium in large soil samples has been developed at the Savannah River Environmental Laboratory (Aiken, SC, USA) that allows rapid preconcentration and separation of strontium in large soil samples for the measurement of strontium isotopes by gas flow proportional counting. The need for rapid analyses in the event of a radiological dispersive device or improvised nuclear device event is well-known. In addition, the recent accident at Fukushima Nuclear Power Plant in March, 2011 reinforces the need to have rapid analyses for radionuclides in environmental samples in the event of a nuclear accident. The method employs a novel pre-concentration step that utilizes an iron hydroxide precipitation (enhanced with calcium phosphate) followed by a final calcium fluoride precipitation to remove silicates and other matrix components. The pre-concentration steps, in combination with a rapid Sr Resin separation using vacuum box technology, allow very large soil samples to be analyzed for 89,90Sr using gas flow proportional counting with a lower method detection limit. The calcium fluoride precipitation eliminates column flow problems typically associated with large amounts of silicates in large soil samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There is an increasing need to develop faster analytical methods for emergency response, including emergency environmental samples [1, 2]. There are a number of analytical methods reported that use ion exchange/extraction chromatography to determine radiostrontium in soil. Vajda and Kim [3] provide a very good overview of recent radiostrontium separation and analytical measurement techniques.

This review also included more classical methods using fuming nitric precipitation as reported by Bojanowski and Knapinska-Skiba [4]. Fuming nitric acid presents handling difficulties and can be very tedious and time-consuming. Wang et al. [5] reported a sequential method to determine actinides and strontium in soil samples. A large anion resin column (Dowex 1 × 8) was used to collect and separate Pu and Th. The rinse fractions from the anion resin were treated further and processed individually for Am, U and Sr. Several sequential precipitations were carried out. An oxalate precipitation was performed at pH 4.2 on the anion resin rinse solution followed by a Sr Resin separation. Strontium was counted using Čerenkov counting, while all actinide fractions were electrodeposited for counting by alpha spectrometry. The chemical recoveries using this method on National Institute of Standards and Technology (NIST) Radiochemistry Intercomparison Program (NRIP) soil for strontium were 63–77 %. A large number of sequential steps were required, but the accuracy of the results versus the NIST reference values was very good. Čerenkov counting, while it offers benefits regarding selectivity against low energy beta emitters and allows for rapid measurement of 89Sr, has a much higher detection limit than gas flow proportional counting.

Ageyev et al. [6] reported a sequential method for soil samples. After ashing the samples at 550 °C the samples were leached with 8 M nitric acid, followed by calcium oxalate precipitation, furnace heating of oxalates, redissolution in hydrochloric acid, iron hydroxide precipitation, and a lanthanum precipitation of plutonium, americium and curium. Carbonate, fuming nitric acid, chromate and iron hydroxide precipitations were performed to prepare strontium. Plutonium was separated using Dowex 1 anion resin loaded under reduced atmosphere. Am and Cm were precipitated as LaOH3, redissolved in dilute hydrochloric acid, separated on Dowex 50 cation resin loaded under reduced pressure. A gradient elution separation of Am and Cm with rare earths was performed using α-hydroxy-iso-butyric acid. Chemical yields for Sr were 50–70 %. The method is, however, relatively complex and would not be considered a rapid method.

Tavčar et al. [7] reported a method to determine actinides in soil. Soil and sediment samples up to 10 g were leached using strong nitric acid, filtration, evaporation, and the residue was redissolved in 1 M HNO3. The acid concentration was increased to 8 M HNO3 and the samples were loaded onto Dowex 1 × 8 resin. Sr was collected from the anion exchange eluent solution using calcium oxalate and the Sr was then separated using Sr Resin. Very large elution volumes were used in this method, including 100 ml of water to elute Sr from Sr Resin. The Sr was precipitated as an oxalate, redissolved and measured using liquid scintillation counting. The average chemical yield for Sr was 67 %.

Based on this survey of the literature, a more rapid method to determine radiostrontium in large soil samples is needed. The method would need simple, effective pre-concentration steps and good chemical yields.

Recently, the Savannah River Environmental Laboratory performed analyses on samples received from Japan in April, 2011 as part of a U.S. Department of Energy effort to provide assistance to the government of Japan. Of particular concern was whether it was safe to plant rice in certain areas (prefectures) near Fukushima. Two different analytical techniques were employed in the Savannah River Environmental Laboratory to determine 89,90Sr in Japanese soil samples very rapidly.

A rapid fusion technique using 1.5 g soil aliquots to enable a minimum detectable activity (MDA) of <1 pCi 89,90Sr/g of soil was employed. This sequential technique has been published recently by this laboratory for actinides and radiostrontium in soil and vegetation [8, 9]. It consists of a rapid sodium hydroxide fusion, pre-concentration steps using iron hydroxide and calcium fluoride precipitations, followed by Sr-Resin separation and gas flow proportional counting. To achieve a lower detection limit for analysis of certain soil samples, a 10 g aliquot of soil was taken, acid-leached and processed with similar preconcentration chemistry. The MDA using this approach was ~0.03 pCi/g (1.1 mBq/g)/, which is less than the 0.05–0.10 pCi/g 90Sr levels found in soil as a result of global fallout. The large amounts of iron in Japanese soil limited the size of soil sample aliquots that could be easily handled to ~10–15 g due to very large iron hydroxide precipitates. The chemical yields observed for the Japanese soil samples was typically 75–80 % and the laboratory control sample and matrix spike results looked very good for this work [10].

A newer version of this approach was developed for application to even larger sample aliquots (50 g) from soil samples taken at the Savannah River Site so that very low detection limits can be achieved. The method uses an acid leach, a rapid sample pre-concentration approach and vacuum-assisted column flow rates. The sample analyses required <16 h to complete, with a significant portion (4 h or more) of that time being the evaporation of the relatively large leachate solutions.

Experimental

Reagents

Sr Resin (4,4′,(5′)di-t-butylcyclohexane-18-crown-6), was obtained from Eichrom Technologies, Inc. (Lyle, Illinois, USA). Nitric, hydrochloric and hydrofluoric (HF) acids were prepared from reagent-grade acids (Fisher Scientific, Inc., Pittsburgh, PA, USA). All water was obtained from a Milli-Q2™ water purification system. All other materials were ACS reagent grade and were used as received. Radiochemical isotopes 90Sr were obtained from Eckert & Ziegler Analytics, Inc. (Atlanta, GA, USA) and diluted to the appropriate level.

Procedures

Column preparation

Sr Resin was obtained as cartridges containing 2 ml of each resin from Eichrom Technologies, Inc. Small particle size (50–100 μm) resin was employed, along with a vacuum extraction system (Eichrom Technologies).

Sample preparation

Soil samples obtained from a location near the Savannah River Site (Aiken, SC, USA) were dried at 110 °C and blended prior to taking sample aliquots. The soil was heated in a furnace at 550 °C to remove any organics present. Seven 50 g soil samples were aliquoted into 600 ml glass beakers. Sr carrier (6.09 mg Sr) was added to each sample to allow determination of chemical yield.

Known amounts of 90Sr were pipetted into each set of 50 g soil samples to demonstrate performance using this method. 90Sr was added to each set of soil samples to test at the following levels: 59.2, 11.84 and 5.92 mBq/g respectively. The uncertainty associated with the known value of 90Sr standard added was ~3 % at the 95 % confidence level. Unspiked soil aliquots was analyzed to determine the native amount of 90Sr present in the soil. The stable strontium in the soil was found to be very low relative to the amount of stable strontium added so no correction had to be made for the native stable Sr content.

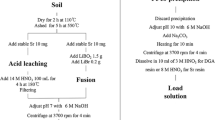

Figure 1 provides a flow chart of the soil sample preparation method. For 50 g soil samples, 50 ml concentrated nitric acid and 25 ml hydrochloric acid volumes were added. The samples were digested on medium heat to prevent splattering and taken to dryness on a hot plate. The solids were rinsed with 50 ml concentrated nitric acid, warmed on a hot plate and the leachate plus additional solids were transferred to a centrifuge tube. The centrifuge tubes were centrifuged at 3,500 rpm for 10 min. The leachate was transferred to a 600 ml beaker and heated on a hot plate to evaporate the leachate to dryness.

The residual solids were rinsed two more times. For each rinse, 25 ml of concentrated nitric acid were added to each beaker, and the leachate plus additional solids were transferred to the centrifuge tube. The centrifuge tubes were centrifuged at 3,500 rpm for 10 min. The leachate was transferred to a 600 ml beaker, heated on a hot plate to evaporate the leachate to dryness. The leachate solutions were evaporated to dryness on a hot plate on low to medium heat. If there were small solids still left in the leachate, the leachate was centrifuged again in a 50 ml tube to remove solids after the leachate volume reached ~40 ml, The residual solids were rinsed with ~10 ml concentrated nitric acid, centrifuged, and the rinse was added to the remaining leachate, which was taken to dryness.

To each evaporated leachate, 15–20 ml 1 M hydrochloric acid were added and warmed on a hot plate to easily dissolve the residue. This solution was transferred to 225 ml centrifuge tube and 1 ml 1.25 M calcium nitrate and 2 ml 3.2 M ammonium hydrogen phosphate were added to each tube. Twenty-five milliliters of concentrated ammonium hydroxide was added to each tube and the strongly alkaline solution was diluted to 180 ml with water.

The tubes were centrifuged at 3,500 rpm for 6 min and the supernatant was discarded. The remaining precipitate was dissolved in 40 ml 1.5 M HCl. This solution was diluted to ~170 ml with 0.01 M HCl and 25 ml 28 M HF were added to each sample. More of the undissolved precipitate resulting from the iron hydroxide/calcium phosphate precipitate will redissolve at this point and a new, much smaller calcium fluoride precipitate will form upon addition of HF. The samples were centrifuged for 10 min at 3,500 rpm. The CaF2 precipitate is small and can be dissolved easily in a small volume column load solution. For laboratories that have restrictions regarding the use of HF acid, the substitution of sodium fluoride may be possible.

The supernatant was removed and the residual solids containing the strontium were dissolved in 7 ml of concentrated nitric acid, 7 ml of 3 M HNO3–0.25 M boric acid, and 7 ml of 2 M aluminum nitrate. If any residual solids remained, these were rinsed with 5 ml 3 M HNO3, centrifuged to remove the solids and this rinse was added to the load solution. Additional 3 M HNO3 may be needed to redissolve the precipitate with very high Ca soils.

Column separation

Figure 2 provides a flow chart of the rapid column separation method using two 2 ml Sr cartridges (~1.4 g Sr Resin total). Sr Resin columns were conditioned with 10 ml 8 M HNO3. The sample solution was loaded onto the Sr Resin column at approximately ~1 drop per second. After the sample was loaded, a tube rinse of ~5 ml 8 M HNO3 was transferred to the Sr Resin column and allowed to pass through the resin at ~2 drops per second. The following column rinses were performed at ~2–3 drops per second: 15 ml 8 M HNO3, 10 ml 3 M HNO 3 –0.05 M oxalic acid, and 10 ml 8 M HNO3. Sr was eluted from the resin with 18 ml 0.05 M HNO3 at ~1 drop per second.

This solution was transferred to preweighed planchets and evaporated on a hot plate with medium heat to dryness. Two milliliters 0.05 M HNO3 were used to rinse each tube and then was transferred to each planchet, and evaporated to dryness on a hot plate. The dried planchets were allowed to cool and then were weighed to determine gravimetric carrier recovery. The planchets were counted by simultaneous gas flow proportional counting (Tennelec LB 4100) for 90 min. The detectors were calibrated using NIST Traceable 90Sr/90Y sources matching the sample geometry. Detector backgrounds are determined and subtracted from the sample counts. A mass attenuation correction factor was determined experimentally using prepared mounts containing 90Sr/90Y (>167 Bq) and a nominal amount of Sr carrier.

Apparatus

Polycarbonate vacuum boxes with 24 positions and a rack to hold 50 ml plastic tubes were used. Two boxes were connected to a single vacuum source by using a T-connector and individual valves on the tubing to each box.

Planchets were annealed for ~4 h in a furnace at 550 °C prior to use. This provides chemical resistance to the planchets so that iron oxide does not form during evaporation of the nitric acid, which would cause error in the gravimetric weights.

Results and discussion

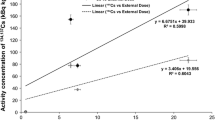

Table 1 shows the measured values for 90Sr in a set of seven 50 g soil samples spiked at the 59.2 mBq/g level. The average 90Sr result was 57.8 ± 1.7 mBq (1 standard deviation, SD) with an average bias of −2.36 %. The average stable Sr carrier recovery was 89.3 % (SD = 4.7 %), indicating very good chemical yield for the method even for 50 g sample aliquots. The measured values were corrected for native content in the soil of 1.35 mBq 90Sr/g.

Table 2 shows the measured values for 90Sr in a set of seven 50 g soil samples spiked at the 11.84 mBq/g level. The average 90Sr result was 11.5 ± 0.7 mBq/g (SD). The average stable Sr carrier recovery was 89.6 % (SD = 2.7 %) with an average bias of −2.51 %.

Table 3 shows the measured values for 90Sr in a set of seven 50 g soil samples spiked at the 5.92 mBq/g level (0.16 pCi/g), which is not much greater than global fallout levels. The average 90Sr result was 5.95 ± 0.22 mBq/g (SD), with an average bias of 0.43 %. The average stable Sr carrier recovery was 94.0 % (SD = 2.6 %), indicating very good chemical yield.

The tests indicate that for three different spiked levels that 90Sr can be measured very well. The sample pre-concentration steps to remove the soil matrix worked very well. Chemical yields were very good and no column flow issues were observed. The use of iron hydroxide precipitation enhanced with a slight amount of calcium phosphate was very effective, and the calcium fluoride removal of silicates ensured ease of column flow. It has been the experience in this laboratory that blending combinations of different co-precipitation steps can be a very effective way to maximize chemical yields from difficult sample matrices.

The MDA for the 90Sr using this method with gas flow proportional counting were calculated according to equations prescribed by Currie [11]:

where B is the total background counts = BKG (rate) × BKG count time, CT is the sample count time (min), R is the chemical recovery, V is the sample aliquot (g), Eff is the detector efficiency, and 0.060 is the conversion from dpm to mBq.

In low-level counting, where a zero background count is quite common, the constant 3 is used to prevent an excessively high false positive rate.

The MDA for the results can be adjusted as needed, depending on the sample aliquot and count time. For a 50 g sample aliquot, the method MDA for 90Sr with a 90 min count time is 0.41 mBq/g, typically below global fallout levels.

It should be noted that soil aliquots may have to be adjusted if very high levels of calcium are present in the soil. If very high levels of Ca are found, it may be necessary to reduce the soil sample aliquot or not add any additional Ca in the pre-concentration steps. A larger column load solution could also be tolerated with 4 ml Sr Resin. Combining purified solutions from smaller replicate aliquots may also be employed to maintain a low MDA even with a more difficult sample matrix.

The test data in Tables 1, 2, and 3 were obtained with nitric acid/hydrochloric acid leaching, without aggressively attacking the soil silicate matrix. It is also possible to add HF acid to the acid digestion step if smaller soil aliquots (25 g) and large Teflon beakers are used. The HF can be removed via evaporation in the presence of concentrated nitric acid and boric acid. The same sample preconcentration steps may be applied but the chemical yields are not as high. Table 4 shows results using the digestion of 25 g samples with HF acid. The average 90Sr result was 12.6 ± 1.2 mBq/g (SD), with an average bias of 6.1 %. The chemical yields for the stable strontium carrier were reduced to an average yield of 73 %. If acid digestion and leaching without HF provides sufficient ruggedness (often the case), a larger soil aliquot can be analyzed with a higher chemical yield. If individual 89Sr and 90Sr results are required, a second count measured after 7–10 days can be used to differentiate 89Sr and 90Sr. There are also Čerenkov counting techniques for more rapid determination of 89Sr and 90Sr, however the MDA levels will be significantly higher using this approach [12].

Conclusions

A new method to determine 90Sr has been developed that allows the rapid separation of radiostrontium in large soil samples with high chemical yields and effective removal of interferences. The simple matrix removal steps and rapid column separation steps resulted in reliable measurements of 90Sr at very low levels from 50 g soil aliquots. This approach allows large soil samples to be analyzed with a significant reduction in the detection limit.

References

Larivière D, Cumming T, Kiser S, Li C, Cornett R (2008) Automated flow injection system using extraction chromatography for the determination of plutonium in urine by inductively coupled plasma mass spectrometry. J Anal At Spectrom 23:352

Stricklin DL, Tjarnhage A, Nygren U (2002) Application of low energy gamma-spectrometry in rapid actinide analysis for emergency preparedness. J Radioanal Nucl Chem 251(1):69

Vajda N, Kim CK (2010) Determination of radiostrontium isotopes: a review of analytical methodology. Appl Radiat Isot 67:2306

Bojanowski R, Knapinska-Skiba D (1990) Determination of low-level 90Sr in environmental samples: a novel approach to the classical method. J Radioanal Nucl Chem 138(2):207

Wang J, Chen I, Chiu J (2004) Sequential isotopic determination of plutonium, thorium, americium, strontium and uranium in environmental and bioassay samples. Appl Radiat Isot 61:299

Ageyev VA, Odintsov OO, Sajeniouk AD (2005) Routine radiochemical method for the determination of 90Sr, 238Pu, 239+240Pu, 241Am and 244Cm in environmental samples. J Radioanal Nucl Chem 264(2):337

Tavčar P, Jakopič R, Benedik L (2005) Sequential determination of 241Am, 237Np, Pu radioisotopes and 90Sr in soil and sediment samples. Acta Chim Slov 52:60

Maxwell S, Culligan B, Noyes G (2010) Rapid method for actinides in emergency soil samples. Radiochim Acta 98(11):793

Maxwell S, Culligan B, Noyes G (2010) Rapid separation method for actinides and radiostrontium in vegetation samples. J Radioanal Nucl Chem 286(1):273

Rapid radiochemical methods in support of Fukushima presentation at radiobioassay and radiochemical measurements conference, Eichrom user’s group meeting, http://www.eichrom.com/radiochem/meetings/2011/rrmc/pdf/4-Maxwell-Eichromworkshop2011.pdf Accessed 2 Nov 2011

Currie LA (1968) Limits for qualitative and quantitative determination. Anal Chem 40:586

Martin JP, Odell KJ (1998) The development of emergency radioanalytical techniques for the determination of radiostrontium and transuranic radioisotopes in environmental materials. Radioact Radiochem 9(3):49–60

Acknowledgments

This work was performed under the auspices of the Department of Energy, DOE Contract No. DE-AC09-96SR18500.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maxwell, S.L., Culligan, B.K. & Shaw, P.J. Rapid determination of radiostrontium in large soil samples. J Radioanal Nucl Chem 295, 965–971 (2013). https://doi.org/10.1007/s10967-012-1863-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-012-1863-2