Abstract

Three bio-based isosorbide bis(acid ester)s were synthesized by condensation of isosorbide with three symmetrical cyclic anhydrides (namely, succinic, diglycolic and phthalic anhydrides). The isosorbide-based diacids were obtained in high yields (79–97%) and converted to their diacid dichloride derivatives, which were then utilized to design series of bio-based polyester and poly(ester amide)s with wide range of thermal properties. The polyesters were synthesized in o-dichlorobenzene, utilizing either cis/trans-1,4-cyclohexanediol or 1,6-hexanediol, the polyesters were obtained in high yields (78–91%), showed good thermal stabilities, excellent solubility in organic solvents and glass transition temperatures in the range of -13.7 to 102.8 °C. Additionally, a series of novel aliphatic poly(ester amide)s was synthesized interfacially by polyamidation of the isosorbide bis(diglycolic acid) or isosorbide bis(succinic acid) derivatives with either trans-1,4-diaminocyclohexane or 1,6-hexanediamine. The aliphatic poly(ester amide)s obtained showed good thermal stabilities, good solubility in organic solvents and glass transition temperatures up to 129 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Stimulated by concerns related to petroleum depletion and environmental sustainability, good share of scientific attention has been oriented toward the development of materials by inclusion of bio-derived monomers extracted from feedstock's [1, 2]. Biomass feedstock's provides a considerably rich variety of renewable monomers that can replace their existing counterparts from fossil sources.

The majority of agro-industrial biomass composed of lignin, hemicelluloses and cellulose carbohydrates, all together called lignocelluloses biomass [3]. However, hemicelluloses and cellulose carbohydrates are among the most important classes of agro-industrial biomass residues; they can be depolymerized to offer pentose and hexose sugars, which can be catalytically converted to renewable sugar-based monomers [1, 3].

1,4:3,6-Dianhydrohexitols (also known as isohexides) are heterocyclic carbohydrate-derived diols that exist as the stereoisomers isosorbide, isomannide and isoidide, which are derived from D-glucose, D-mannose and L-iditol, respectively [4]. Isohexides consist of two cis-fused tetrahydrofuran rings with V-shaped molecular structures and two secondary hydroxyl groups positioned at carbons 2 and 5 with exo- or endo- orientations; isosorbide isomer has both exo- and endo- hydroxyl groups in its molecular structure situated at carbons 2 and 5, respectively. On the other hand, the isomannide isomer has two endo- whereas isoidide isomer has two exo- hydroxyls. In view of this difference in the hydroxyl groups orientation, 1,4:3,6-dianhydrohexitols exhibit different physical properties (e.g., melting point). Additionally, the reactivity of the hydroxyl groups depends on both their orientation and their involvement in an intramolecular hydrogen bonding, although the involvement of the endo- hydroxyl groups in intramolecular hydrogen bonding leads to higher nucleophilicity, the relatively reduced steric hindrance of the exo- hydroxyl group makes it more chemically reactive [5]. Industrially, the large-scale availability of glucose gave the isosorbide isomer an exceeding value over the isoidide isomer, while synthetically, the higher reactivity of isosorbide made it more applicable as monomer in material synthesis than isomannide isomer [5, 6].

Isosorbide has been employed to produce a large variety of polyesters (PEs) [7,8,9,10,11,12,13,14,15,16,17,18,19,20] and poly(ester amide)s (PEAs) [21,22,23,24]. The presence of isosorbide unit in the polymer backbones was found to impart many desirable features such as stiffness, improved thermal stabilities and enhanced glass transition temperatures (Tg) [4]. However, the low reactivity of isosorbide led to difficulties in obtaining high-molecular weight polymer [25, 26].

Several series were reported on direct polyesterfication of isosorbide with a variety of cycloaliphatic [7, 8] and aliphatic dicarboxylic acid derivatives containing methylene units of different chain lengths [9, 10]. The aliphatic copolyesters were synthesized under different reaction conditions and were studied as plasticizers for poly(vinyl chloride) [11], as biocompatible polymers [12] and as coating materials [13]. Due to its nontoxicity, isosorbide was also utilized as a building block in the synthesis of biocompatible PEs for bone tissue engineering. For instance, isosorbide-based oligo-L-lactide was prepared as an intermediate to produce porous scaffolds [14]. While in a later work, isosorbide-based oligo-D,L-lactide was employed as a chain extender to improve the mechanical properties of biodegradable polyurethanes for bone tissue regeneration [15]. Moreover, isosorbide was utilized as a diol in the synthesis of semi-aromatic terephthalate PEs [16] and as a comonomer in the synthesis of co- and terpolyesters including, but not limited to, poly(ethylene terephthalate-co-isosorbide terephthalate) [17], poly(1,4-cyclohexanedimethylene-co-isosorbide terephthalate) [18] and poly(decamethylene-co-isosorbide 2,5-furandicarboxylate) [19].

Owing to its chirality, rigidity and nontoxicity, isosorbide was employed as a commoner in the synthesis of biodegradable and optically active PEAs. Conversely to PEs, limited share of scientific work has been however published on the use of isosorbide as a building block in PEAs. In the field of optically active PEAs, Philip and Sreekumar polycondensed isosorbide with diacid dichlorides of bismale amic acid and bis-azoaromatic chromophores to synthesize PEAs for non-linear optical applications. The results showed that the chirality of isosorbide improved the PEAs optical properties, whereas its rigidity granted an increase in the PEAs glass transition temperatures [21]. Regarding to their use as biodegradable PEAs, several studies reported on the esterification of isosorbide with two equivalents of α-amino acids and p-toluenesulfonic acid monohydrate to produce O,O’-bis-(α-aminoacyl)-isosorbide [22,23,24]. In a second step, the amino groups were deprotonated and polymerized with either active diesters of dicarboxylic acids [22, 23] or diacid dichlorides [24]. The series obtained were designed to have degradation products with low cytotoxicity and tunable degradation rates [23, 24].

Since the presence of two different hydroxyl groups with different chemical reactivities in isosorbide (exo and endo hydroxyl groups) makes it a monomer of low reactivity [27], good share of work has been directed toward the development of difunctional derivatives of isosorbide [28,29,30,31]. One interesting approach to overcome the reactivity limitation is to condense isosorbide with bio-based anhydrides to obtain difunctional derivatives with enhanced reactivity [29]. Zenner et al. reported the synthesis of dicarboxylic acid monomer by double esterification reaction of isosorbide with succinic anhydride [29]. The monomer was investigated as non-toxic tackifier [32], and was converted to its diisocyanate derivative, which was employed to produce bio-renewable polyurethane [29]. In a following work, Wilbon et al. reported the synthesis isosorbide bis(succinic acid) using microwave heating, the monomer was obtained in significantly reduced synthesis time and was polymerized with glycerol to produce bio-based, cross-linked polyester [20].

In this publication, we report the synthesis, characterization, and thermal properties of two series of novel isosorbide-based PEs and PEAs. Since our interest lies in the development of isosorbide-based building blocks and polymers, we report here facile routes for the double esterification of isosorbide with symmetrical cyclic anhydrides (succinic, diglycolic and phthalic), the conversion of these bis(acid ester)s to their diacid dichloride derivatives and their use in polyesters and poly(ester amide)s synthesis. Additionally, this paper discusses the effect of various building blocks on polymer properties such as solubility, thermal stability and glass transition temperature.

Materials

All chemicals used were of analytical grades and used as received unless otherwise stated. Isosorbide was purchased from Sigma-Aldrich. Oxalyl chloride, succinic anhydride, diglycolic anhydride, trans-1,4-diaminocyclohexane, potassium hydrogen carbonate, 1,4-dioxane, tetrahydrofuran and HCl solution 35% (w/w) were purchased from Acros, anhydrous chloroform, toluene, 2-propanol and ethyl acetate from VWR. Cis/trans-1,4-cyclohexanediol was purchased from Alfa Aesar, phthalic anhydride and 1,6-hexanediol were purchased from Merck-Schuchar, N,N-dimethylacetamide (DMAc) and N,N-dimethylformamide (DMF) from Daejung, o-dichlorobenzene (o-DCB) and acetone from Pharmacos. Pyridine was purchased from Riedel–de Haen, and 1,6-hexanediamine from Aldrich. Succinic anhydride and phthalic anhydride were purified by sublimation under vacuum. Trans-1,4-diaminocyclohexane and 1,6-hexanediamine were purified by recrystallization from cyclohexane under argon atmosphere.

Measurements

The inherent viscosity of the dilute polymers solutions were measured with a dilution Ubbelohde glass capillary viscometer (Rheotek, Poulten Selfe & Lee Ltd., Essex, England) in a thermostated water bath at 25.0 ± 0.1 or 35.0 ± 0.1 °C. Dilute polymers solutions were temperature equilibrated for approximately 15 min then the viscosity measurements were repeatedly recorded until reproducible values were obtained. Intrinsic viscosities [η] were calculated by the single point method described by Solomon and Ciuta [33, 34]. The viscosities average molecular weights (Mv) were calculated for the PEs series by Mark-Houwink-Sakurada equation, using the coefficients (K = 1.28 × 10–4 and α = 0.78) determined for polyesters with a close molecular structure (Eq. 1) [35]. However, no such parameters were available in the literature for PEAs with similar chemical structures.

The infrared (IR) spectra (from 550–4000 cm−1) were recorded using a Thermo Nicolet Nexus 670 FTIR spectrophotometer equipped with attenuated total reflection (ATR). 1H Nuclear Magnetic Resonance (NMR), 13C NMR and 1H-13C HMQC-DEPT 135 (HMQC: Heteronuclear Single Quantum Coherence; DEPT: Distortionless Enhancement by Polarization Transfer) spectra were recorded in DMSO-d6 or CDCl3 on a 500 MHz (1H NMR) and 125 MHz (13C NMR) spectrophotometer (Bruker Avance III). Chemical shifts (δ) were expressed in ppm using tetramethylsilane (TMS) as an internal standard.

The glass transition temperatures (Tg) were studied using Netzsch DSC 204 F1 differential scanning calorimeter (Selb Bavaria, Germany). Tg measurements were performed under dry nitrogen gas using 8 ± 3 mg samples. To eliminate any previous thermal history, the samples were firstly heated from ambient temperature to the 150 °C, maintained at this temperature for 4 min, and rapidly cooled with liquid nitrogen to an appropriate starting temperature. The thermal behavior was then obtained from the second scan by heating the samples at a rate of 10 °C/min, and the Tg values were taken as the inflection of the step transition. Thermal stabilities of the samples were studied by thermogravimetric analysis (TGA) using a Netzsch STA 409 PG/PC thermal analyzer (Selb Bavaria, Germany). The measurements were conducted at the heating rates 10 or 20 °C/min under dry nitrogen gas purging at a flow of 50 mL/min.

Experimental

Synthesis of isosorbide bis(succinic acid) (1)

Monomer 1 was synthesized according to a previously described method [29] with slight modification. A mixture of isosorbide (3.65 g, 25 mmol) and succinic anhydride (6.25 g, 62.5 mmol, 2.5 eqv.) was fitted in 50 mL round-bottomed flask, the flask was flushed with argon gas for 5 min then quickly sealed with a stopper. The entire reaction vessel was then immersed in an oil bath and heated at 120 °C for 24 h. Upon reaction completion, the excess succinic anhydride was removed by sublimation under reduced pressure. The crude product was then dissolved in 40 mL ethyl acetate, stirred with charcoal, filtered then extracted with distilled water (20 mL × 3), the organic layer was dried over Na2SO4, filtered and the solvent evaporated under reduced pressure. The formed oily product was dried in vacuoat 75 °C for 8 h to give the final pure product as a viscous yellowish oil (8.4 g, 97% yield).

Synthesis of isosorbide bis(diglycolic acid) (2)

Similarly to 1, monomer 2 was synthesized in the melt as described below. However, optimization of the reaction conditions and purification approach was carried out to improve the yield. A mixture of isosorbide (3.65 g, 25 mmol) and diglycolic anhydride (7.25 g, 62.6 mmol, 2.5 eqv.) was fitted in 50 mL round-bottomed flask, the flask was flushed with argon gas for 5 min then quickly sealed with a stopper. The entire reaction vessel was then immersed in an oil bath and heated at 150 °C for 48 h. The excess diglycolic anhydride was removed by sublimation under reduced pressure and the crude product was purified by recrystallization 5 times from ethyl acetate/ petroleum ether (3/1, v/v) followed by drying in vacuo at 75 °C for 12 h. The pure product was obtained as a viscous yellowish oil (7.44 g, 78.7%).

Synthesis of isosorbide bis(phthalic acid) (3)

Monomer 3 was synthesized using pyridine as both solvent and catalyst. A solution of isosorbide (3.65 g, 25 mmol) and phthalic anhydride (9.26 g, 62.6 mmol, 2.5 eqv.) in 35 mL of dry pyridine was refluxed for 6 h. The reaction mixture was cooled in ice bath then dropped over 100 mL of ice-cold 2 M HCl solution. The precipitated solid was then filtered, dried and recrystallized twice from 2-propanol /toluene mixture to give the pure product as a white solid (Tm: 99–101 °C, 10.1 g, 91%).

Isosorbide bis(acid chloride ester) monomers

The diacid dichloride monomers of 1, 2 and 3 were synthesized according to a previously described method [36] with slight modification. Oxalyl chloride (100 mmol, 12.7 g, 4 eqv.) was added dropwise to a solution of isosorbide bis(acid ester) derivatives 1,2 or 3 (25 mmol), 4 drops dry DMF in an ice-cold anhydrous chloroform (40 mL). Upon dropping completion, the solution was stirred at room temperature for 5 h to reach the reaction completion and the excess oxalyl chloride was stripped in vacuo using several portions of chloroform. The isosorbide bis(acid chloride ester) monomers were obtained as a yellow oils and were used without further purification.

Polyesters synthesis (PE1-6)

PE1-6 were synthesized using a modification of a previously reported method [37]. Under argon gas flow, a solution of isosorbide diacid dichloride derivative (5 mmol) in o-dichlorobenzene (7 mL) was added dropwise to a stirred, preheated (80 °C) solution of dihydroxy compound (5 mmol) in o-dichlorobenzene (7 mL). Upon the addition completion, the reaction temperature was gradually increased to 130 °C over a period of 1 h, and kept at this temperature for an additional hour. The mixture was then allowed to cool to room temperature, and then diluted with n-hexane (70 mL) to precipitate the polymer. The solvent mixture was then decanted and the obtained polyester was dissolved in chloroform and precipitated in tenfold of methanol (v/v). The purified polymer was dried in vacuo at 70 °C for 12 h.

Poly(ester amide)s synthesis (PEA1-4)

PEA1-4 were synthesized similarly to the procedure described in [38]. A solution of isosorbide bis(acid chloride ester) (5 mmol, 1eqv.) in anhydrous chloroform (20 mL) was added dropwise to a vigorously stirred, ice-cold solution (0–5 °C) of diamine (5 mmol, 1 eqv.) and potassium hydrogen carbonate (10 mmol, 2 eqv.) in water (15 mL). The reaction mixture was stirred at a high speed in the ice bath for 30 min and at room temperature for one hour. The formed polymers were isolated by filtration, rinsed extensively with water and chloroform, and dried in vacuo at 60 °C to constant weights. The crude polymers were further purified by precipitation from DMF to tenfold of ethyl acetate (v/v).

Results and discussion

Monomers and polymers synthesis and spectral characterization

The reactivity difference between the two secondary hydroxyl groups of isosorbide restricted the direct use of this eco-friendly diol in the synthesis of bio-based polymers. One method to overcome this drawback is to improve isosorbide reactivity via chemical derivatization, for this purpose, we report here on the synthesis of three highly reactive isosorbide derivatives and the employment of these difunctionalized derivatives in the synthesis of novel PEs and PEAs.

At first, isosorbide was alcoholysized with three symmetrical cyclic anhydrides to obtain three isosorbide bis(acid ester)s (Scheme 1a), these derivatives were synthesized in the melt or in solution and were obtained in high purity and high yields (78.7–97%). It was noticed that monomer 2 has the lowest yield (78.7%) with respect to monomers 1 and 3, which may originate from the reduced ring strain within the six-membered anhydride ring (diglycolic anhydride) that results in lower reactivity.

In a second step, isosorbide bis(acid ester)s were converted to their diacid dichloride derivatives using oxalyl chloride (Scheme 1b), the highly reactive products obtained from this step were directly used as monomers for copolymers synthesis. It is worth noting that this reaction was performed under mild conditions to avoid ester group hydrolysis. According to the synthetic approaches described in the experimental part and presented in Scheme 2, six novel polyesters (PE1-6) were prepared in o-dichlorobenzene by polycondensation reaction of isosorbide bis(acid chloride ester)s monomers with linear or cyclic diols.

Additionally, the monomers were employed in the synthesis of a series of PEAs (PEA1-4) as shown in Scheme 3. The PEAs were synthesized interfacially by the polycondensation reaction of isosorbide bis(acid chloride ester)s monomers with linear or cyclic diamines in the presence of an inorganic base to neutralize the acid produced from the amine-acid chloride reaction. The monomers and polymers chemical compositions were ascertained by FTIR, 1H and 13C NMR spectroscopy. Whereas other characteristics of the polycondensates were evaluated by inherent viscosity, solubility, TGA and DSC measurements.

Our attempts to produce PEAs from isosorbide bis(phthalic acid) result in the majority of cases, in the production of phthalimide oligomers instead of the long chain polymers. This may have been due to the occurrence of the preferred intramolecular cyclization reaction, which limits the step-growth polycondensation reaction and results in formation of oligomers in low yields [39].

Spectral characterization of isosorbide bis(acid ester)s

Chemical characterizations of isosorbide bis(acid ester)s structures were performed by FTIR, 1H and 13C NMR spectroscopy. Figure 1 illustrates the FTIR spectra of the three isosorbide bis(acid ester)s, the broad bands observed in the range from 2526 to 3436 cm−1 were assigned to the carboxylic acid stretching vibration. The stretching vibration of the ester group appeared as a strong band in the range from 1723 to 1734 cm−1.

The 13C NMR spectra confirmed the presence of two types of carbonyl carbons in the derivatives structures. However, due to the non-symmetrical structure of isosorbide, the signals corresponding to the ester and carboxylic acid carbonyl carbons appeared as two pairs of peaks in the chemical shift range from 167 to 174 ppm. Additionally, the carboxylic acid protons (-COOH) appeared in the 1H NMR spectra as broad peaks in the chemical shift range from 12.17 to 13.35 ppm.

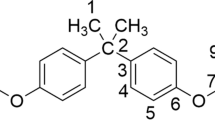

Figure 2 displays the 1H and 13C NMR spectra of isosorbide bis(phthalic acid) (3) as an example, for this derivative, the peaks of isosorbide protons appeared in the range from 3.81 to 5.30 ppm, while their corresponding carbons signals appeared in 13C NMR spectrum as six peaks in the range from 70.4 to 85.5 ppm.

The signals for the aromatic phthalate ring protons appeared in range from 7.63 to 7.82 ppm, whereas the signals attributed to its aromatic carbons were observed at the range from 128 to 133 ppm.

Total assignments of NMR chemical shifts of isosorbide bis(acid ester)s are given in Table S1 (Electronic Supplementary Information, Table S11H and 13C NMR data of the monomers obtained in DMSO-d6). The signals of the succinate protons moiety (-CH2-CH2-) in isosorbide bis(succinic acid) (1) appeared at the range of 2.43 to 2.55 ppm, and their associated carbons were observed at 29 ppm. As for isosorbide bis(diglycolic acid) (2) signals, the protons peaks of the diglycolic moiety (-CH2-O-CH2-) appeared in the range from 4.04 to 4.38 ppm while their corresponding carbons signals were detected at 67 and 68 ppm.

Spectral characterization of PEs

Spectral characterization of the PEs structures were achieved by means of NMR and FTIR. The main characteristic absorption bands of the synthesized PEs are summarized in Table S2 (Electronic Supplementary Information, Table S2 Main IR bands of the synthesized PEs and PEAs), whereas Fig. 1 displays the FTIR of PE1 as representative PE and Table 2 lists the yields of the synthesized PEs.

In the PEs FTIR spectra, no obvious absorption was observed in the carboxylic acid stretching region, indicating low contents of the carboxylic acid end group in the polymeric products. Besides, the FTIR spectra of the PEs showed the characteristic absorption bands of the carboxylate group around 1730, 1265 and 1150 cm−1 and the methylene units stretching vibration bands in the range from 3000 to 2850 cm−1.

The structures of the PEs were also corroborated by 1H and 13C NMR. The spectra obtained for the PEs contained sets of signals belonging to isosorbide and ester carbonyl groups, which agrees with the data obtained from the FTIR. An assignment of the main 1H and 13C chemical shifts of the PEs are given in Table S3 (Electronic Supplementary Information, Table S3 Main spectroscopic data of PEs and PEAs synthesized in this work 1H and 13C NMR data) while Figs. 3 and 4 shows the 1H and 13C NMR spectra of PE1 (as a representative example), respectively.

In the 1H NMR spectra obtained for PE1, PE3 and PE5, new signals corresponding to the cis/trans-cyclohexylene CH protons were observed in the range from 3.78 to 5.11 ppm, while the methylene protons of the same unit appeared in the range from 1.25 to 2.36 ppm. In 13C NMR spectra, the signals of the cis/trans-cyclohexylene CH carbons appeared in the range from 70.8 to 72.3 ppm, whereas the signals observed in the range from 27.2 to 27.8 ppm were assigned to the methylene carbons of the cis/trans-cyclohexylene unit. Likewise, the NMR spectra of PE2, PE4 and PE6 were in consistency with their expected structures. As reported in Table S3, the 1H NMR spectra showed the methylene protons signals of the 1,6-hexylene unit in the range from 1.26 to 4.32 ppm. On the other hand, the 13C NMR showed three peaks corresponding to 1,6-hexylene methylene carbons in the range from 25.3 to 65.4 ppm.

Spectral characterization of PEAs

The FTIR spectra of PEAs showed the characteristic absorption band of amide A at 3299–3258 cm−1, amide B at 3079–3060 cm−1, amide I at 1651–1629 cm−1 and amide II at 1536–1520 cm−1. Moreover, the ester group (-COO-) absorption band was observed in the range 1749–1723 cm−1. Figure 1 displays the FTIR of PEA1 as representative PEA, whereas Tables 2 and S2 summarizes the yields and main IR bands of the PEAs synthesized, respectively.

In order to confirm their chemical structures, the synthesized PEAs were also characterized by 1H, 13C and 2D-NMR spectroscopy. The spectra were found to be in agreement with FTIR data and with the postulated polymer structures. As summarized in Table S3, the formation of the amide group and the appearance of new signals correlated to the diamine units indicated a successful synthesis of the PEAs. The 1H NMR spectra of PEA1-4 showed singlet in the range from 7.74 to 7.84 ppm for the amide proton (-CONH-). Additionally, sets of signals belonging to isosorbide, succinate (in PEA1-2) and diglycolate (in PEA3-4) moieties were found in their expected range. The NMR signals correlated to the methylene protons in the 1,6-hexylene unit (in PEA2 and PEA4) were centered at 3.02 (-NH(CH2CH2CH2-)2NH-), 1.37 (-NH(CH2CH2CH2-)2NH-) and 1.19–1.24 ppm (-NH(CH2CH2CH2-)2NH-), while their corresponding methylene carbons resonated around 37, 29 and 26 ppm, respectively.

Figures 3, 4 and 5 show 1H, 13C NMR and 1H-13C HMQC-DEPT 135 spectra of PEA1, respectively. The NMR spectra obtained for PEA1 (and similarly PEA3) showed two separated protons peaks in the range from 1.18 to 1.95 ppm, these signals showed HMQC correlation to cyclohexyl methylene carbons signals near 31.5 ppm (Fig. 5), and therefore they were assigned to the axial and equatorial methylene protons of this unit. On the other hand, the 1H NMR signal near 3.5 ppm were found to be HMQC correlated to the cyclohexyl tertiary carbons near 48 ppm, and therefore assigned to the tertiary protons of trans-1,4-cyclohexylene unit.

Polymers solubility

The polymer solubility was tested in several commonly used organic solvents at room temperature using concentrations in the range of 3 to 5% (w/v). The PEAs were found to be soluble in polar aprotic solvents such as DMSO, DMF and DMAc and insoluble in diethyl ether, chloroform and ethyl acetate. Clearly, the presence of the intermolecular hydrogen bonding in PEAs results in poor solubility in weakly polar or non-polar solvents. However, high polarity aprotic solvents interrupt this strong intermolecular interaction, and results in higher solubility.

On the other hand, the synthesized PEs showed good solubility in a variety of organic solvents (Table 1), this feature emerges from the lack of strong intermolecular interaction between polymers chains. The results also demonstrated that the solubility depends on the polymer chemical composition. For instance, polyesters containing diglycolate (PE3 and PE4) and phthalate (PE5 and PE6) units showed good solubility in ethyl acetate. Apparently, the presence of the flexible diglycolate and the spacing phthalate segments results in reduced polymer chains packing and enhanced solubility. Additionally, polymer containing cis–trans cyclohexane unit (PE3 and PE5) showed good solubility in acetone. This may be attributed to the lower symmetry of the cis isomer than the corresponding trans isomer, which results in reduced polymer stereoregularity, reduced intermolecular packing and hence higher solubility [40].

Solution viscosity measurements

The inherent viscosities were measured using Ubbelohde capillary viscometer for diluted polymers solutions of the PEs and PEAs in CHCl3 at 25.0 ± 0.1 °C and in DMSO at 35.0 ± 0.1 °C, respectively. The PEs had inherent viscosities (ƞinh) in the range from 0.40 to 0.58 dL/g and Mv in the range from 52,000 to 32,000 g/mol (Table 2), which reflect moderate molecular weights of the PEs synthesized. It is noticeable that the PEs derived from monomer 3 had the lowest inherent viscosity and Mv values when compared with PEs derived from the monomers 1 and 2. This result is plausible since the polycondensation reaction takes place at the sterically hindered ortho position of the aromatic ring in monomer 3. Moreover, the inherent viscosities and Mv values of the polymers derived from the primary linear diol (1,6-hexanediol) were slightly higher than those derived from the secondary cycloaliphatic diol (cis/trans-1,4-cyclohexanediol) due to the relatively low reactivity of the secondary alcoholic groups. On the other hand, the inherent viscosities and of the PEAs were in the range from 0.23 to 0.25 dL/g suggesting low to moderate molecular weights (Table 2).

Thermal properties

Thermal stability: TGA

TGA was evaluated under non-oxidative conditions in the interval from room temperature to 600 °C. The TGA thermograms of the polymers synthesized presenting sample mass loss versus temperature are shown in Fig. 6 and the results are summarized in Table 2. The PEs showed no thermal decomposition below 114 °C (Fig. 6a) and 1% mass loss (T1%) in the temperatures range of 114–223 °C (Table 2), this temperature range associates usually with the loss of adsorbed solvent molecules (e.g., o-DCB) or traces of impurities. However, the PEs synthesized showed in general good thermal stabilities with 5% mass loss (T5%) in the temperature range of 162 to 332 °C. The TGA thermograms of 1,6-hexylene-containing PEs (PE2, PE4 and PE6) showed one-stage decomposition with higher T50% values when compared with their analogous cis/trans-1,4-cyclohexylene-containing PEs (PE1, PE3 and PE5).

Considering that polyesters thermal decomposition goes mainly through β-hydrogen bond scission [41], cis/trans-1,4-cyclohexylene-containing PEs would probably exhibit higher vulnerability to thermal decomposition due to the higher number of β-hydrogens available for elimination. On the other hand, PEs with cis/trans-1,4-cyclohexylene unit in the backbones showed a two-stage thermal decomposition (see Fig. 6a), this may be attributed to the difference between the cis and trans isomers decomposition behavior in the cycloaliphatic unit [42]. Additionally, PEs with cis/trans-1,4-cyclohexylene unit showed higher residual mass at 500 °C indicating the formation of less volatile decomposition products. Moreover, the incorporation of the heterocyclic, stiffening isosorbide unit in the PEs structure improved the thermal resistance of the PEs. For instance, poly(hexelene succinate) was reported to have 5% mass loss (T5%) at 321 °C, this value was, however, improved in this work upon the introduction of isosorbide in the polymer backbone to 332.5 [43].

On the other hand, the PEAs showed good thermal stabilities with T5% ranging from 166 to 284 °C (Table 2, Fig. 6b). The polymers containing 1,4-cyclohexylene unit (PEA1 and PEA3) in their structure showed a rather higher heat resistance when compared with their 1,6-hexylene-containing PEAs (PEA2 and PEA4). The rigidity of the 1,4-cyclohexylene ring was reflected in the increase in both T5% and the residual mass values at 500 °C, indicating their higher thermal stability and lower decomposition products volatility [44], respectively.

Thermal transitions: DSC

The glass transition temperature (Tg) is a thermal property of fundamental importance for polymers possible applications. Herein, thermal transition properties of the synthesized PEs and PEAs were investigated by DSC. The DSC data of the synthesized materials are given Table 2 and their thermograms are given in Fig. S1 (Electronic Supplementary Information, Fig. S1 DSC thermograms of a) PEs and b) PEAs). Cis/trans-1,4-cyclohexylene moiety containing PEs exhibited higher Tg values compared with their open chain analogues, 1,6-hexylene-containing PEs, this result is highly expected due to the presence of the stiffening cyclohexylene ring in the polymers backbone [45]. Moreover, the presence of the diglycolate unit in the PEs backbone decreased the Tg values compared with the PEs containing succinate or phthalate units in their backbone (Fig. S1a). This decrease is most attributed to the presence of the diglycolate-ether linkage in the polymer chain, which effectively increases the polymer chain flexibility, escalates the molecular mobility and impedes an efficient macrochains packing [46, 47]. Furthermore, the introduction of the stiffening isosorbide unit in the PEs structure improved the Tg values compared with poly(butylene succinate) (Tg = −15.1 °C) and Poly(hexylene succinate) (Tg = −52.7 °C) [48].

On the other hand, PEAs are generally characterized by exhibiting high Tg values; this predominant observation was confirmed by the DSC study in this work. The PEAs synthesized in this series displayed high Tg values compared with their PEs analogues, this rise in Tg values is caused by the presence of hydrogen bonding among polymers chains [49]. Furthermore, the incorporation of the trans-1,4-cyclohexylene unit in the PEAs (PEA1 and PEA3) structures resulted in a dramatic increase in the Tg values, this result is expected since the presence of this symmetrical rigid segment in the PEAs structure leads to more efficient chains packing and stronger hydrogen bonding interaction [50]. The DSC thermograms of the PEAs synthesized are presented in Fig. S1, and the Tg values are reported in Table 2.

Conclusion

Two series of novel linear bio-based polymeric condensates, belonging to the classes polyesters and poly(ester amide)s based on isosorbide were synthesized and characterized. Isosorbide was first esterified with two equivalents of cyclic anhydrides to give isosorbide bis(acid ester) monomers, which were successfully transformed to their diacid dichlorides. The reaction of isosorbide with cyclic anhydrides let us overcome the difference in reactivity between the two hydroxyl groups of isosorbide. These monomers were then polycondensed in solution with diols to give polyesters, the polyesters were obtained in high yields (78–91%), showed good thermal stabilities and Tg values in the range from -13.5 to 102.8 ºC. Additionally, a series of novel poly(ester amide)s were synthesized from isosorbide bis(diglycolic acid) or isosorbide bis(succinic acid) and various diamines. The poly(ester amide)s were synthesized interfacially and were obtained in good yields (58–70%). They had good thermal stabilities with 5% mass loss temperature (T5%) in the range from 166 to 240 °C, and Tg temperatures in the range from 39.3 to 129.5 ºC. Thermal properties analysis showed that the polymers synthesized exhibit wide range of thermal properties that can cover broad range of applications.

References

Zhu Y, Romain C, Williams CK (2016) Sustainable polymers from renewable resources. Nature 540:354–362. https://doi.org/10.1038/nature21001

Nakajima H, Dijkstra P, Loos K (2017) The recent developments in biobased polymers toward general and engineering applications: Polymers that are upgraded from biodegradable polymers, analogous to petroleum-derived polymers, and newly developed. Polymers (Basel) 9

Isikgor FH, Becer CR (2015) Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers. Polym Chem 6:4497–4559. https://doi.org/10.1039/C5PY00263J

Fenouillot F, Rousseau A, Colomines G, Saint-Loup R, Pascault JP (2010) Polymers from renewable 1,4:3,6-dianhydrohexitols (isosorbide, isomannide and isoidide): A review. Prog Polym Sci 35:578–622. https://doi.org/10.1016/j.progpolymsci.2009.10.001

Rose M, Palkovits R (2012) Isosorbide as a renewable platform chemical for versatile applications-quo vadis? Chemsuschem 5:167–176. https://doi.org/10.1002/cssc.201100580

Feng X, East AJ, Hammond WB, Zhang Y, Jaffe M (2011) Overview of advances in sugar-based polymers. Polym Adv Technol 22:139–150. https://doi.org/10.1002/pat.1859

Garaleh M, Yashiro T, Kricheldorf HR, Simon P, Chatti S (2010) (Co-)Polyesters Derived from Isosorbide and 1,4-Cyclohexane Dicarboxylic Acid and Succinic Acid. Macromol Chem Phys 211:1206–1214. https://doi.org/10.1002/macp.200900656

Yoon WJ, Oh KS, Koo JM, Kim JR, Lee KJ, Im SS (2013) Advanced polymerization and properties of biobased high Tg polyester of isosorbide and 1,4-cyclohexanedicarboxylic acid through in situ acetylation. Macromolecules 46:2930–2940. https://doi.org/10.1021/ma4001435

Juais D, Naves AF, Li C, Gross RA, Catalani LH (2010) Isosorbide Polyesters from Enzymatic Catalysis. Macromolecules 43:10315–10319. https://doi.org/10.1021/ma1013176

Liu X, Desilles N, Lebrun L (2020) Polyesters from renewable 1,4:3,6-dianhydrohexitols for food packaging: Synthesis, thermal, mechanical and barrier properties. Eur Polym J 134:109846. https://doi.org/10.1016/j.eurpolymj.2020.109846

Yin B, Hakkarainen M (2011) Oligomeric isosorbide esters as alternative renewable resource plasticizers for PVC. J Appl Polym Sci 119:2400–2407. https://doi.org/10.1002/app.32913

Park HS, Gong MS, Knowles JC (2012) Synthesis and biocompatibility properties of polyester containing various diacid based on isosorbide. J Biomater Appl 27:99–109. https://doi.org/10.1177/0885328212447245

Caretto A, Passoni V, Brenna N, Sitta M, Ogliosi L, Catel G, Turri S, Griffini G (2018) Fully Biobased Polyesters Based on an Isosorbide Monomer for Coil Coating Applications. ACS Sustain Chem Eng 6:14125–14134. https://doi.org/10.1021/acssuschemeng.8b02659

Vogt S, Larcher Y, Beer B, Wilke I, Schnabelrauch M (2016) Fabrication of highly porous scaffold materials based on functionalized oligolactides and preliminary results on their use in bone tissue engineering. Eur Cells Mater 4:30–38. https://doi.org/10.22203/ecm.v004a03

Ma Y, Liu J, Luo M, Xing J, Wu J, Pan H, Ruan C, Luo Y (2017) Incorporating isosorbide as the chain extender improves mechanical properties of linear biodegradable polyurethanes as potential bone regeneration materials. RSC Adv 7:13886–13895. https://doi.org/10.1039/c6ra28826j

Feng L, Zhu W, Zhou W, Li C, Zhang D, Xiao Y, Zheng L (2015) A designed synthetic strategy toward poly(isosorbide terephthalate) copolymers: A combination of temporary modification, transesterification, cyclization and polycondensation. Polym Chem 6:7470–7479. https://doi.org/10.1039/c5py01167a

Stanley N, Chenal T, Jacquel N, Saint-Loup R, Prates Ramalho JP, Zinck P (2019) Organocatalysts for the Synthesis of Poly(ethylene terephthalate- co -isosorbide terephthalate): A Combined Experimental and DFT Study. Macromol Mater Eng 304:1900298. https://doi.org/10.1002/mame.201900298

Koo JM, Hwang SY, Yoon WJ, Lee YG, Kim SH, Im SS (2015) Structural and thermal properties of poly(1,4-cyclohexane dimethylene terephthalate) containing isosorbide. Polym Chem 6:6973–6986. https://doi.org/10.1039/c5py01152c

Chebbi Y, Kasmi N, Majdoub M, Cerruti P, Scarinzi G, Malinconico M, Dal Poggetto G, Papageorgiou GZ, Bikiaris DN (2019) Synthesis, characterization, and biodegradability of novel fully biobased poly(decamethylene- co-isosorbide 2,5-furandicarboxylate) copolyesters with enhanced mechanical properties. ACS Sustain Chem Eng 7:5501–5514. https://doi.org/10.1021/acssuschemeng.8b06796

Wilbon PA, Swartz JL, Meltzer NR, Brutman JP, Hillmyer MA, Wissinger JE (2017) Degradable thermosets derived from an isosorbide/succinic anhydride monomer and glycerol. ACS Sustain Chem Eng 5:9185–9190. https://doi.org/10.1021/acssuschemeng.7b02096

Philip B, Sreekumar K (2001) Optically active poly(ester-amide)s: synthesis and characterization. Polym Int 50:1318–1323. https://doi.org/10.1002/pi.777

Okada M, Yamada M, Yokoe M, Aoi K (2001) Biodegradable polymers based on renewable resources. V. Synthesis and biodegradation behavior of poly(ester amide)s composed of 1,4:3,6-dianhydro-D-glucitol, α-amino acid, and aliphatic dicarboxylic acid units. J Appl Polym Sci 81:2721–2734. https://doi.org/10.1002/app.1718

Gomurashvili Z, Kricheldorf HR, Katsarava R (2000) amino acid based bioanalogous polymers. Synthesis and study of new poly(ester amide)s composed of hydrophobic a-amino acids and dianhydrohexitoles. J Macromol Sci A 37:215–227. https://doi.org/10.1081/MA-100101089

Al-Tayyem BH, Sweileh BA (2020) Synthesis, characterization and hydrolytic degradation of novel biodegradable poly(ester amide)s derived from Isosorbide and α-amino acids. J Polym Res 27:1–14. https://doi.org/10.1007/s10965-020-2021-0

Park S-A, Jeon H, Kim H, Shin S-H, Choy S, Hwang DS, Koo JM, Jegal J, Hwang SY, Park J, Oh DX (2019) Sustainable and recyclable super engineering thermoplastic from biorenewable monomer. Nat Commun 10:2601. https://doi.org/10.1038/s41467-019-10582-6

Saxon DJ, Luke AM, Sajjad H, Tolman WB, Reineke TM (2020) Next-generation polymers: Isosorbide as a renewable alternative. Prog Polym Sci 101

Zhang M, Tu Y, Zhou Z, Wu G (2020) Balancing the transesterification reactivity of isosorbide with diphenyl carbonate: Preferential activation of: Exo -OH. Polym Chem 11:5512–5525. https://doi.org/10.1039/d0py00764a

Feng L, Zhu W, Li C, Guan G, Zhang D, Xiao Y, Zheng L (2015) A high-molecular-weight and high-Tg poly(ester carbonate) partially based on isosorbide: synthesis and structure–property relationships. Polym Chem 6:633–642. https://doi.org/10.1039/C4PY00976B

Zenner MD, Xia Y, Chen JS, Kessler MR (2013) Polyurethanes from isosorbide-based diisocyanates. Chemsuschem 6:1182–1185. https://doi.org/10.1002/cssc.201300126

Belgacem C, Medimagh R, Fildier A, Bulete A, Kricheldorf H, Ben RH, Chatti S (2015) Synthesis and characterization of isosorbide-based α, ω-dihydroxyethersulfone oligomers. Des Monomers Polym 18:64–72. https://doi.org/10.1080/15685551.2014.947554

Besse V, Auvergne R, Carlotti S, Boutevin G, Otazaghine B, Caillol S, Pascault JP, Boutevin B (2013) Synthesis of isosorbide based polyurethanes: An isocyanate free method. React Funct Polym 73:588–594. https://doi.org/10.1016/j.reactfunctpolym.2013.01.002

Zenner MD, Madbouly SA, Chen JS, Kessler MR (2015) Unexpected tackifiers from isosorbide. Chemsuschem 8:448–451. https://doi.org/10.1002/cssc.201402667

Mao L, Pan L, Ma B, He Y (2022) Synthesis and characterization of bio-based amorphous polyamide from dimethyl furan-2,5-dicarboxylate. J Polym Environ 30:1072–1079. https://doi.org/10.1007/s10924-021-02265-5

He T, Liu T, Huang J, Wang X, He Y, Ma B (2021) Synthesis of alternating semi-aromatic poly(ester amide)s and the amide transesterification. J Polym Res. https://doi.org/10.1007/s10965-021-02661-4

Papaspyrides CD, Vouyiouka S, Georgousopoulou IN, Marinkovic S, Estrine B, Joly C, Dole P (2016) Feasibility of solid-State postpolymerization on fossil- and bio-based poly(butylene succinate) including polymer upcycling routes. Ind Eng Chem Res 55:5832–5842. https://doi.org/10.1021/acs.iecr.6b00588

Shao Y, Ding M, Xu Y, Zhao F, Dai H, Miao XR, Yang S, Li H (2017) Synthesis and self-assembly of shape amphiphiles based on POSS-dendron conjugates. Molecules 22:622. https://doi.org/10.3390/molecules22040622

Pion F, Ducrot P-H, Allais F (2014) Renewable alternating aliphatic–aromatic copolyesters derived from biobased ferulic acid, diols, and diacids: sustainable polymers with tunable thermal properties. Macromol Chem Phys 215:431–439. https://doi.org/10.1002/macp.201300702

Wroblewska A, Zych A, Thiyagarajan S, Dudenko D, Van Es D, Hansen MR, Koning C, Duchateau R, Jasinska-Walc L (2015) Towards sugar-derived polyamides as environmentally friendly materials. Polym Chem 6:4133–4143. https://doi.org/10.1039/c5py00521c

Koyama E, Sanda F, Endo T (1997) Polycondensations of hydroxycarboxylic acids derived from optically active aminoalcohols and acid anhydrides - syntheses of functional poly(ester-amide)s. J Polym Sci A Polym Chem 35:345–352. https://doi.org/10.1002/(SICI)1099-0518(19970130)35:2%3c345::AID-POLA17%3e3.0.CO;2-P

Zhuang Y, Seong JG, Lee YM (2019) Polyimides containing aliphatic/alicyclic segments in the main chains. Prog Polym Sci 92:35–88

Thiyagarajan S, Meijlink MA, Bourdet A, Vogelzang W, Knoop RJI, Esposito A, Dargent E, Van Es DS, Van Haveren J (2019) Synthesis and thermal properties of bio-based copolyesters from the mixtures of 2,5- a nd 2,4-furandicarboxylic acid with different diols. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.9b04463

Wang J, Liu X, Zhu J (2018) Manipulating the properties of Poly(1,4-Cyclohexylenedimethylene Terephthalate) (PCT) just by tuning steric configuration of 1.4-Cyclohexanedimethanol (CHDM). Macromol Chem Phys 219:1800172. https://doi.org/10.1002/macp.201800172

Li M, Jing J, Su T (2022) Synthesis of poly(hexamethylene succinate-co-ethylene succinate) copolymers with different physical properties and enzymatic hydrolyzability by regulating the ratio of monomer. Front Bioeng Biotechnol 10:600. https://doi.org/10.3389/fbioe.2022.894046

Feng Y-C, Zhao H, Hao T-H, Hu G-H, Jiang T, Zhang Q-C (2017) Effects of Poly(cyclohexanedimethylene terephthalate) on Microstructures, Crystallization Behavior and Properties of the Poly(ester ether) Elastomers. Materials (Basel) 10:694. https://doi.org/10.3390/ma10070694

Colonna M, Berti C, Binassi E, Celli A, Fiorini M, Marchese P, Messori M, Brunelle DJ (2011) Poly(1,4-cyclohexylenedimethylene-1, 4-cyclohexanedicarboxylate): analysis of parameters affecting polymerization and cis-trans isomerization. Polym Int 60:1607–1613. https://doi.org/10.1002/pi.3128

Matos M, Sousa AF, Silva NHCS, Freire CSR, Andrade M, Mendes A, Silvestre AJD (2018) Furanoate-based nanocomposites: a case study using poly(butylene 2,5-furanoate) and poly(butylene 2,5-furanoate)-co-(butylene diglycolate) and bacterial cellulose. Polymers (Basel) 10(810):810. https://doi.org/10.3390/polym10080810

Soccio M, Costa M, Lotti N, Gazzano M, Siracusa V, Salatelli E, Manaresi P, Munari A (2016) Novel fully biobased poly(butylene 2,5-furanoate/diglycolate) copolymers containing ether linkages: Structure-property relationships. Eur Polym J 81:397–412. https://doi.org/10.1016/j.eurpolymj.2016.06.022

Bikiaris RD, Ainali NM, Christodoulou E, Nikolaidis N, Lambropoulou DA, Papageorgiou GZ (2022) Thermal Stability and Decomposition Mechanism of Poly(alkylene succinate)s. Macromol 2:58–77. https://doi.org/10.3390/macromol2010004

Liu Q, Wang C, Guo Y, Peng C, Narayanan A, Kaur S, Xu Y, Weiss RA, Joy A (2018) Opposing effects of side-chain flexibility and hydrogen bonding on the thermal, mechanical, and rheological properties of supramolecularly cross-linked polyesters. Macromolecules 51:9294–9305. https://doi.org/10.1021/acs.macromol.8b01781

Hussain F, Park S, Jeong J, Kang S, Kim J (2020) Structure–property relationship of poly(cyclohexane 1,4-dimethylene terephthalate) modified with high trans-1,4-cyclohexanedimethanol and 2,6-naphthalene dicarboxylicacid. J Appl Polym Sci 137:48950. https://doi.org/10.1002/app.48950

Acknowledgements

The authors thank The Deanship of Scientific Research of The University of Jordan for the financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-Tayyem, B.H., Sweileh, B.A. Synthesis and characterization of novel bio-based polyesters and poly(ester amide)s based on isosorbide and symmetrical cyclic anhydrides. J Polym Res 30, 18 (2023). https://doi.org/10.1007/s10965-022-03356-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03356-0