Abstract

This work presents the results from stability studies for several electrolytic conductivity (EC) reference materials submitted to repeated use conditions, as required by the last version of the ISO 17034 standard. Eight batches of reference materials, composed of water or water/n-propanol and HCl or KCl (at different concentrations), were studied, with nominal EC values ranging from 5 to 12,825 µS·cm−1. The materials were submitted to a simulation of repeated use, with the manipulation of bottles once a week and their storage under refrigeration with air gaps inside them. They were then analyzed once a month by the EC primary measurement method. The measurement results were evaluated to check for deviations from conventional long-term stability monitoring and for variation trends using normalized error and linear regression statistical tests. The results indicated that the repeated use simulation caused deviations in the EC for the 100 and 500 µS·cm−1 reference materials and variation trends in the EC for the 5000 and 12,825 µS·cm−1 reference materials. From the results, the uncertainty related to stability monitoring under repeated use conditions was calculated for each reference material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Electrolytic conductivity (EC) is related to the total concentration of all ionized substances in a liquid sample. Its routine measurement is simple, fast, inexpensive, robust, and sensitive, making it the most used parameter for assessing water purity. Pure water is of great importance in many fields, such as in pharmaceutical, chemical, metallurgical, biotechnology, and semiconductor industries; environmental and food safety; oceanographic and hydrological studies; power generation; and clinical laboratories, where it can be used as a solvent, reagent, cleaning material, and/or sterile medium [1,2,3,4,5,6,7,8,9].

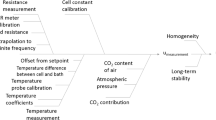

The so-called EC primary measurement method (ECPM), which has been established and accepted worldwide and has mainly been carried out at national metrology institutes, is based on resistance measurements between two circular platinum electrodes, usually at different alternating current (AC) frequencies and at 25 °C. The electrodes are within a cylindrical electrochemical cell (with an accurately determined diameter), and two distances between the electrodes are employed (with an accurately determined distance variation) so that the cell constant can be determined [10,11,12].

Routine EC measurements by essay laboratories are usually carried out using a commercial meter and cell. In this case, traceability can be established by the use of Certified Reference Materials (CRM) for determining the cell constant so that the results obtained can be linked to those from the ECPM. The certification process of a reference material involves several studies to assess homogeneity and stability. Short-term and long-term stability studies, for instance, are usually carried out to evaluate the stability of the material under transportation and storage conditions, respectively. Since 2016, with the publication of the ISO 17034 standard, a new stability study is required to assess the stability of reference materials under repeated use conditions, where the subsampling of one unit of the material is allowed. As result, and when applicable, the uncertainty related to some observed instability must be estimated and incorporated to the final uncertainty of the CRM and/or some instruction of use must be given in the certificate of the material to avoid possible instability effects regarded to its repeated use [11, 13, 14]. Up to the present date, no published paper has reported results on the stability studies of EC reference materials under repeated use conditions.

Therefore, this work presents the results from the stability studies of several EC reference materials (ranging from 5 to 12,825 µS·cm‒1), under repeated use conditions, using the ECPM at the National Institute of Metrology, Quality and Technology (INMETRO), in Brazil. The results were statistically evaluated to check for some instability and the corresponding uncertainties were estimated.

2 Experimental Section

2.1 Samples

Eight batches of EC reference materials were studied. The materials were packed into 250 mL borosilicate glass bottles, since the use of glass bottles did not affect significantly the long term stability of electrolytic conductivity reference materials, as was shown in a previous work [11]. Descriptions of the chemical composition of the materials are given in Table 1. As can be seen, most of the reference materials studied were composed of water and KCl, as suggested by IUPAC [15]. However, for the materials with low EC values (below 100 µS·cm‒1), two other chemical compositions were chosen to be evaluated, based on previous publications [10, 11, 16]: water and HCl was selected for the 25 and 50 µS·cm‒1 reference materials, whereas water:1-propanol 70:30 (w:w) and KCl was selected for the 5·µS·cm‒1 reference material. In each case, the presence of HCl or 1-propanol was chosen to minimize carbon dioxide interference in the EC (by minimizing carbonic acid formation and ionization). Ultrapure water (provided by an Elga Purelab Option-Q water purifier), reagent grade 1-propanol (≥ 99.5%, Sigma-Aldrich), low impurity HCl solution (30%, Merck Suprapur®), and reagent grade KCl (≥ 99.0%, Sigma-Aldrich) were used in the preparation of the reference materials.

2.2 Instrumentation

The ECPM was carried out using the EC primary measurement system (ECPS) from INMETRO. This system uses a cylindrical electrochemical cell (about 5 cm diameter) made of a ceramic material. The cell contains two platinum electrodes, one at each side of the cylinder. The cell is placed vertically at a metallic holder inside a polystyrene closed box with three heat exchangers (Bürklin) at its bottom, through which water from a thermostatic bath (Fluke/Hart Scientific 7011) flows. The platinum electrode at the upper side of the cell can be electronically moved along the cylindrical body (a movable electrode). In addition, the system also contains the following equipment: a thermometric bridge (Fluke/Hart Scientific 1590) connected to a Pt-100 sensor; an inductance, capacitance, and resistance (LCR) meter (Agilent 4284A); a direct current (DC) servo motor (Physik Instrumente M-227.25) connected to an electronic controller (Physik Instrumente C-863); a linear displacement measurement system (Heidenhain CT250); and a microcomputer with an USB/GPIB interface (Agilent 82357B), running homemade software (written in Visual Basic Community 2018) for equipment control, data acquisition, and calculations. More detailed descriptions of the ECPS can be found in previous works [10, 11]. The thermometric bridge with sensor, the LCR meter, the linear displacement measurement system, and the cell diameter, all of which can affect the EC determination, were previously calibrated at INMETRO.

2.3 Repeated Use Simulation

For each EC reference material, six closed bottles were opened, and half of their contents were transferred to six empty bottles. Then, the six pairs of bottles (with about 125 mL of liquid on each) were closed and placed into a refrigerator at 4 °C (as recommended in the certificates of these reference materials after opening a bottle). This was done to simulate the storage of opened bottles by the user of the reference material, with a given air gap inside them. Once a week, each pair of bottles was removed from the refrigerator and opened, and all of their content was sequentially transferred from one bottle to the other for about one minute. They were then closed again (keeping about 125 mL of liquid in each) and placed back in the refrigerator. This was done to simulate the use of one subsample of the material once a week by the user of the reference material. Once a month, one pair of bottles was removed from the refrigerator and opened, and all of the content was placed into only one of the bottles, which was then analyzed by the ECPM. At the end of six months, six measurements were carried out by the ECPM, and no bottle remained in the refrigerator (classical stability study design). The measurement results were compared to those from conventional long-term stability monitoring (from closed bottles) of the same reference materials.

2.4 EC Determination

For each determination by the ECPM, the electrochemical cell was first filled with about 150 mL of the sample solution and the sample temperature was monitored until it stabilized (between 24.98 and 25.02 °C). Then, measurements of temperature and resistance were acquired, using 10 different AC frequency values and two positions of the movable Pt electrode (with a displacement of 0.02 m), resulting in one measurement cycle. The AC frequency values employed were dependent on the reference material analyzed (frequencies where the reactance values are closer to zero), ranging from 60 to 8,000 Hz to 100–20,000 Hz. For each position of the movable Pt electrode, the resistance of the sample was calculated by the linear extrapolation of the resistance for the inverse of the AC frequency equal to zero. Then, one EC value (κ) was calculated according to Eq. 1.

where Δl is the displacement of the movable Pt electrode, RU is the resistance of the sample at the upper electrode position, RL is the resistance of the sample at the lower electrode position, D is the cell diameter, TM is the temperature measured, TR is the reference temperature (25 °C in this case), and α is a coefficient related to EC variation as a function of the temperature, which depends on the TR and the chemical composition of the reference material. At least 12 measurement cycles were carried out for each EC determination. More details on the ECPM can be found in previous works [1, 10,11,12].

2.5 Data Evaluation

The results from stability monitoring under repeated use conditions (SMRU) were evaluated in two different ways, for each reference material: (1) a direct comparison of each data point from SMRU to all the data from conventional long-term stability monitoring (LTSM), using the normalized error statistical test [17, 18], and (2) a linear regression statistical test [13, 19] for the data from SMRU to check for variation trends.

3 Results and Discussion

3.1 EC Determination

The data from a series of measurement cycles for one EC determination are given in Fig. 1 for the 50 and 5000 µS·cm‒1 reference materials. As can be observed, the EC results along the measurement cycles (and along time) were quite stable for the 5000 µS·cm‒1 reference material; however, similar data for the 50 µS·cm‒1 reference material showed a continuous decrease along the measurement cycles. The chemical composition of the 50 µS·cm‒1 reference material suggests an explanation. As this material was composed of water and HCl, the H+ ions bind to the ceramic material on the internal surface of the electrochemical cell, causing a decrease in the EC along the measurements cycles for every EC determination. The same occurred for the 25 µS·cm‒1 reference material, which was also composed of an HCl solution. Therefore, for the reference materials with KCl (see Table 1), the final EC result was calculated using the average of the EC values from all cycles. For the reference materials with HCl, the final EC result was calculated using a linear extrapolation of the EC values for the time when the electrochemical cell was filled.

3.2 Stability Monitoring Under Repeated Use Conditions

The EC results from SMRU for all reference materials studied are shown in Fig. 2, together with those from LTSM for the same batch of each reference material. The zero time in this figure represents the day when the bottles from the repeated use conditions were opened (see Sect. 2.3). As the time period from LTSM embraces all the time from SMRU, some data from LTSM (taken before SMRU) had negative time values in the figure. The results from the linear regression statistical tests (applied only to the data from SMRU) are given in Table 2.

EC results from stability monitoring under repeated use conditions (in red) compared to those from long-term stability monitoring (in black), with expanded uncertainties (k = 2), for the reference materials of a 5 µS·cm‒1, b 25 µS·cm‒1, c 50 µS·cm‒1, d 100 µS·cm‒1, e 500 µS·cm‒1, f 1408 µS·cm‒1, g 5000 µS·cm‒1, and h 12,825 µS·cm‒1 (Color figure online)

The data from SMRU for each reference material show that all the six data points from the 100 µS·cm‒1 reference material and the last three data points from the 500·µS cm‒1 reference material were significantly higher than those from LTSM of these materials. This was confirmed by the results from the normalized error statistical tests, which were all higher than 1 for the comparisons among each of these nine data points and all the data from LTSM of the same reference material. That is, for these reference materials, the repeated use simulation, which involved opening and manipulating the bottles, caused a deviation in the EC results in relation to the closed bottles. These EC increases, in this case, are probably related to some carbon dioxide input and dissolution after opening the bottles (considering the carbon dioxide was not fully equilibrated between the air and the materials when they were prepared and bottled). For the other reference materials, all the data points from SMRU were statistically similar to at least one data point from LTSM of the same reference material (normalized errors lower than 1). That is, for these reference materials, every single result from SMRU, when analyzed apart from the other results, could be from a closed bottle. This behavior is related to the solvent or solute (for the 5, 25, and 50 µS·cm‒1 reference materials), where the carbonic acid formation and ionization is minimized, or to the higher KCl concentrations (for the 1408, 5000, and 12,825 µS·cm‒1 reference materials), where the effect of carbon dioxide dissolution on the EC would be relatively lower.

When evaluating all the data from SMRU together for each reference material using linear regression statistical tests (Table 2), a significant increasing trend in the data can be observed for the 500, 5000, and 12,825 µS·cm‒1 reference materials, since |b| was higher than \(\left(u_{{\text{b}}} \times t_{{{\text{tab}}}}\right)\). This was already expected for the 500 µS·cm‒1 reference material, since the previous evaluation indicated that the first half of the data were similar to those from LTSM, whereas the last half were higher than those. For the 5000 and 12,825 µS·cm‒1 reference materials, the results indicated that they were also affected by opening and manipulating the bottles, but at a relatively slower rate than the 100 and 500 µS·cm‒1 reference materials. The explanation here is probably the same as above; that is, some carbon dioxide input and dissolution must be occurring after opening of the bottles.

When the results from SMRU for all electrolytic conductivity reference materials composed of KCl aqueous solutions are analyzed, from the lowest (100 µS·cm‒1) to the highest concentration (12,825 µS·cm‒1), a transition can be observed from a deviation in the results (compared to those from LTSM) to a trend in the results along time (indicated by the linear regression statistical tests). However, and surprisingly, the results from the 1408 µS·cm‒1 reference material showed no deviation or trend and thus there was no additional information or data to support any possible explanation of that.

From the results discussed above, it was possible to calculate an uncertainty value related to SMRU for each reference material studied. The results are shown in Table 3. For the 100 and 500 µS·cm‒1 reference materials, where a significant deviation was found between at least some results from SMRU and those from LTSM, the uncertainty value was calculated as the difference between the average of the deviating results and the average of the LTSM results, divided by the square root of three. For the 5000 and 12,825 µS·cm‒1 reference materials, where a significantly increasing trend was found in the results from SMRU, the uncertainty value was calculated using the slope from the linear regression of these results, multiplied by 90 and divided by the square root of three. The 90, in this case, is related to the number of days each bottle will last considering its use once a week by the user (which was simulated in the repeated use conditions) and a consumption of about 20 mL with each use. Alternatively, an uncertainty value of zero could also be attributed in this case, with a limitation in the expiration time of the materials after their opening, according to the slope from SMRU and the final uncertainty of the materials. And finally, for the 5, 25, 50 and 1408 µS·cm‒1 reference materials, where no deviation and no trend was found in the results from SMRU, the uncertainty value was calculated using the slope uncertainty multiplied by 180. The 180, in this case, is related to the time interval between measurements used in LTSM. Alternatively, an uncertainty value of zero could also be attributed in this case, but informing users of any significant deviation (from the certified values) found in the future results from LTSM.

4 Conclusions

Stability studies were successfully carried out for eight batches of EC reference materials (with values from 5 to 12,825 µS·cm‒1), submitted to repeated use conditions, using the primary measurement method. The manipulation of bottles once a week and their storage under refrigeration with air gaps inside them were shown to be effective in simulating the repeated use conditions by a common user of the reference materials. The use of the primary measurement method was chosen to allow the detection of possible small trends in the measurement data over time, which could not be sensed with analytical methods having less precision.

The results from the studies showed that, except for the 1408 µS·cm‒1 reference material, all the materials composed of only water and KCl were affected by the repeated use simulation, resulting in deviations (compared to the closed bottles) or increasing trends in the EC results, which were probably related to some carbon dioxide input and dissolution. On the other hand, all materials containing HCl or 1-propanol have not been affected by the repeated use simulation, since these reagents minimized the carbon dioxide interference in the EC. The deviations or trends observed could be quantified and used to calculate the values of a new uncertainty source, related to stability monitoring under repeated use conditions. This new uncertainty source will be used in the uncertainty calculation for new batches of these reference materials, increasing the reliability of their certified values.

References

Máriássy, M., Pratt, K.W., Spitzer, P.: Major applications of electrochemical techniques at national metrology institutes. Metrologia 46, 199–213 (2009). https://doi.org/10.1088/0026-1394/46/3/007

Seitz, S., Manzin, A., Jensen, H.D., Jakobsen, P.T., Spitzer, P.: Traceability of electrolytic conductivity measurements to the international system of units in the sub mS m– 1 region and review of models of electrolytic conductivity cells. Electrochim. Acta 55, 6323–6331 (2010). https://doi.org/10.1016/J.ELECTACTA.2010.06.008

Orrù, E., Durbiano, F., Ortolano, M.: Reference measurement system for low electrolytic conductivity values with a flowing solution. Meas. Sci. Technol. 24, 035903 (2013). https://doi.org/10.1088/0957-0233/24/3/035903

Callegaro, L., Durbiano, F., Orru, E., Trinchera, B.: An impedance spectrometer for the metrology of electrolytic conductivity. IEEE Trans. Instrum. Meas. 62, 1766–1770 (2013). https://doi.org/10.1109/TIM.2012.2230731

Zhang, B., Lin, Z., Zhang, X., Yu, X., Wang, X.: Absolute measurement system for low electrolytic conductivity of aqueous solutions based on van der Pauw’s theory using a flow-through cell. Accredit. Qual. Assur. 19, 433–438 (2014). https://doi.org/10.1007/s00769-014-1081-4

Orrù, E., Durbiano, F., Ortolano, M.: Development of an in-line calibration system for flow-through cells for low electrolytic conductivity values. Accredit. Qual. Assur. 19, 11–16 (2014). https://doi.org/10.1007/s00769-013-1023-6

Zhang, B., Lin, Z., Zhang, X., Yu, X., Wei, J., Wang, X.: System for absolute measurement of electrolytic conductivity in aqueous solutions based on van der Pauw’s theory. Meas. Sci. Technol. 25, 055005 (2014). https://doi.org/10.1088/0957-0233/25/5/055005

Thirstrup, C., Snedden, A., Deleebeeck, L.C.: Addressing the challenges of traceable electrolytic conductivity measurements in water. Meas. Sci. Technol. 28, 124001 (2017). https://doi.org/10.1088/1361-6501/aa875d

Thirstrup, C., Snedden, A., Jensen, H.D.: Bridging the gap between ultrapure water and reference materials in electrolytic conductivity measurements. IEEE Trans. Instrum. Meas. 66, 2745–2754 (2017). https://doi.org/10.1109/TIM.2017.2708398

Fraga, I.C.S., Lopes, J.C., Sobral, S.P., Ribeiro, C.M.: Certification of a low value electrolytic conductivity solution using traceable measurements. Accredit. Qual. Assur. 18, 99–104 (2013). https://doi.org/10.1007/s00769-013-0964-0

Fraga, I.C.S., Lopes, J.C., Cordeiro, L.R., da Silva, L.F., Borges, P.P.: Evaluation of the stability of solutions of low electrolytic conductivity by primary measurements. J. Solution Chem. 44, 1920–1936 (2015). https://doi.org/10.1007/s10953-015-0384-3

Asakai,T., Maksimov, I., Onuma, S., Suzuki, T., Miura, T., Hioki, A.: New Japanese certified reference materials for electrolytic conductivity measurements. Accredit. Qual. Assur. 22, 73–81 (2017). https://doi.org/10.1007/s00769-017-1253-0

Gonzaga, F.B., Dias, J.C.: Long-term stability monitoring of pH reference materials using primary pH method. Anal. Bioanal. Chem. 407, 3249–3252 (2015). https://doi.org/10.1007/s00216-014-8263-0

ISO 17034: 2016 General Requirements for the Competence of Reference Material Producers. International Organization for Standardization, Geneva (2016)

Pratt, K.W., Koch, W.F., Wu, Y.C., Berezansky, P.A.: Molality-based primary standards of electrolytic conductivity. Pure Appl. Chem. 73, 1783–1793 (2001). https://doi.org/10.1351/pac200173111783

Wu, Y.C., Berezansky, P.A.: Low electrolytic conductivity standards. J. Res. Natl. Inst. Stand. Technol. 100, 521–527 (1995). https://doi.org/10.6028/jres.100.039

ISO 13528: 2015 Statistical Methods for Use in Proficiency Testing by Interlaboratory Comparison. International Organization for Standardization, Geneva (2015)

Gonzaga, F.B., Dias, J.C., Jehnert, D., Werner, B., Schräpler, K., Vyskočil, L.: Evaluation of a compact differential cell for secondary pH measurements by a bilateral interlaboratory comparison. Electroanalysis (2013). https://doi.org/10.1002/elan.201300135

ISO Guide 35: 2017 Reference Materials—Guidance for Characterization and Assessment of Homogeneity and Stability. International Organization for Standardization, Geneva (2017)

Acknowledgements

This work was supported by the National Council of Technological and Scientific Development (CNPq) (Grant Nos. 573894/2008-6 and 307771/2015-6) and the São Paulo Research Foundation (FAPESP) (Grant Nos. 2008/57808-1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cunha, K., Pardellas, L. & Gonzaga, F.B. Stability Monitoring of Electrolytic Conductivity Reference Materials Under Repeated Use Conditions by the Primary Measurement Method. J Solution Chem 49, 306–315 (2020). https://doi.org/10.1007/s10953-020-00961-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10953-020-00961-9