Abstract

In the pursuit of better solvents for use in the extractive desulfurization (EDS) of liquid fuel, the pyrollidinium and phosphonium based ionic liquids (ILs) have been improved by combining them with selected molecular compound modifiers. The modifiers, which are imidazole, poly(ethylene) glycol (PEG 200) and sulfolane were selected to induce previously nonexistent mechanisms in the presence of refractory sulfur compounds. The addition of PEG 200 and sulfolane were observed to have a more positive impact on the performance of the ILs than the addition of imidazole under the same conditions. This provides further support for the idea that π–π interaction may not be the predominant interactions for the ILs that are the highly effective in EDS. Using the sulfolane modified tetrabutylphosphonium methanesulfonate [P4444][MeSO3], up to 81% dibenzothiophene (DBT) removal was recorded at a temperature of 30 °C and solvent-to-mass ratio of 1:1 and after a 30 min mixing time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In most countries, the current sulfur content in diesel and fuel oils produced from refineries is still in a range above the set environmental limit [1]. Extractive desulfurization (EDS) is one of the most promising desulfurization methods. This technique requires milder operating conditions and can easily be integrated into existing refinery infrastructure. One of the critical aspects of EDS is finding a suitable solvent. This solvent should preferably possess high sulfur affinity and capacity and be environmentally friendly. The probability that at least one IL among more than 106 possibilities can fit this description is high. It is impractical to experiment on all the possible ILs and therefore, by categorizing ILs, a systematic approach can be used. Because these categories are a reflection of the properties of the ILs, different categories show varying desulfurization capabilities [2, 3]. Most of the work available in the literature involved EDS experiments using ILs containing an aromatic cation such as the imidazolium and pyridinium based ILs [4,5,6,7,8]. For this reason and because understanding the interaction between the sulfur compound and the IL is a huge step towards identifying the most suitable IL, the predominant desulfurization mechanism was thought to be π–π interaction. Other possible mechanisms were acknowledged, including, among others, CH(IL)–π bonding, π–cation interactions, hydrogen bonding and insertion of sulfur compounds into the dynamic structure of the IL.

The work carried out by Wilfred et al. [9] using quaternary ammonium-based ILs hinted at the possibility that the π–π interaction may not be the predominant interaction involved and showed the role of specific volume or bulkiness of the IL on the desulfurization efficiency. The results of this work are interesting as they open up the possibility of obtaining a suitable EDS solvent that does not contain an aromatic ring in its cation. Although this finding widens the research area once more, studying the desulfurization efficiency of ILs that do not contain aromatic ring will also shed more light on the role of the aromatic ring in desulfurization. In fact, other interactions can also be studied in the same manner through the addition of compounds that may induce specific interactions. In this regard, two types of ILs were selected; phosphonium-based ILs containing no rings and pyrrolidinium-based ILs containing non-aromatic rings.

Four types of interactions between the IL and sulfur compounds were identified as being responsible for the high percentage sulfur removal (%SR) for some ILs. It was assumed that modifying the ILs to facilitate these interactions would result in better performance. The identified interactions include: (a) π–π interactions between the aromatic ring of the IL and the aromatic ring of the sulfur compound, (b) cation–π interactions between the cation of a metal halide added to the IL and the aromatic ring of the sulfur compound, (c) dibenzothiophene and benzothiophene inclusion as a result of bulkiness/high molar volume of the IL and (d) taking advantage of the principle of like dissolves like. The π–π interaction also known as π-stacking is a non-covalent attractive forces that occurs when the positive electrostatic potential from one aromatic compound aligns with the negative electrostatic potential on the aromatic ring of another. This is thought to be the main mechanism behind extraction of sulfur compounds from simulated fuel using imidazolium and pyridinium-based ILs [3]. It was therefore assumed that addition of an aromatic ring to the IL would allow this interaction. Another form of the π-interaction is the cation–π interaction, which may occur between the face of the electron rich π system of an aromatic sulfur compound and an adjacent cation. In EDS, this is known as π-complexation where, for instance, the Fe3+ ion in a FeCl3 based IL having an electronic configuration of 1s22s22p63s23p63d54 s0 can form a sigma bond (σ) with the π electron density (empty s-orbital). Furthermore, the d-orbitals of the cation can back-donate electron density to the anti-bonding π-orbitals of the sulfur rings [10]. ILs can be modified to possess these features by adding FeCl3 at certain mole ratios. In fact, work has been carried out in this area and improvements in the performance of the ILs have been recorded [10,11,12]. It has also been shown that the increase in the alkyl group chain length, which is related to the molar volume and to a lesser extent the specific density of the IL, resulted in improving the %SR [13, 14]. Therefore, modifying the IL to possess a higher molar volume or at least higher specific density is expected to improve the %SR of the IL. Finally, the principle of like dissolves like was also used to improve the desulfurization efficiency of the IL. It was reported that some aromatic nitrogen compounds, such as indole and pyridine, possess much higher affinity to the imidazolium-based ILs than aromatic sulfur compounds. It was also reported that the imidazolium cation has better selectivity towards thiophene removal than pyridinium or quinolinum cations all due to similarity in structure [3]. The similarity in structure between the solvent and the sulfur compound is expected to result in favorable arrangements or alignments in the form of polar–non-polar or electron rich–electron deficient regions of the IL and the sulfur compounds.

To this end, imidazole, FeCl3, PEG (polyethylene glycol with a molar mass of 200) and 2,3,4,5-tetrahydrothiophene-1,1-dioxide (sulfolane) were added as modifiers, at a ratio of 1:1, to each IL in order to study the possible improvement in the efficiencies of the previously studied ILs [15] resulting from each of the aforementioned mechanisms. The ILs are expected to interact with the modifiers via H-bonding. The investigation into the effect of the modifiers on the properties and performance of the ILs is presented in this work.

2 Experimental

2.1 Chemicals

Dibenzothiophene (98%) was supplied by Aldrich. Thiophene (99%) and 1-benzothiophene for synthesis was supplied by Merck. Acetonitrile (99.9%, HPLC grade) was also supplied by Merck. Hexadecane (99%) was supplied by BDH. Iso-dodecane (80%, mixture of isomers tech) and toluene (ACS) were supplied by Alfa Aesar and Honeywell, respectively. The ionic liquids tetrabutylphosphonium methanesulfonate [P4444][MeSO3] (98%) and triisobutyl(methyl)phosphonium p-toluenesulfonate [Pi444,1][Tos] (98%) were supplied by Cytec and Sigma Aldrich respectively while 1-butyl-1-methylpyrrolidinium bis(trifluoromethylsulfonyl)imide [BMPyrr][TFSI] (99%) and 1-hexyl-1-methylpyrrolidinium bis(trifluoromethylsulfonyl)imide [HMPyrr][TFSI] (99%) were supplied by Iolitec. Imidazole and poly(ethylene glycol) 200 (PEG 200) were supplied by Merck. 2,3,4,5-Tetrahydrothiophene-1,1-dioxide (sulfolane) was supplied Acros Organics while ferric chloride was supplied by Alfa Aesar.

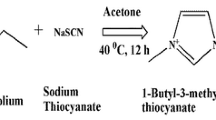

The structures of the cation and anion of the ILs are presented in Scheme 1 and the structures of the sulfur compounds and the modifiers are presented in Scheme 2. All chemicals were used as supplied without further purification (Scheme 3).

Furthermore, the [P4444][MeSO3] and [Pi444,1][Tos] are hydrophilic in nature while [BMPyrr][TFSI] and [HMPyrr][TFSI] are hydrophobic in nature.

2.2 Experimental Procedure

IL-modifier and mixtures were prepared by mixing an IL and a modifier at a molar ratio of 1:1 using a thermomixer. The mixing was carried out at 600 rpm and 80 °C for 2 h or until a homogenous transparent liquid was formed.

A mixture of iso-dodecane (51%), hexadecane (39%) and toluene (10%) was prepared to represent the sulfur-free simulated fuel. Appropriate amounts of thiophene (T), benzothiophene (BT) and dibenzothiophene (DBT) were dissolved in the mixture to obtain a mixture with 500 ppm each of thiophene (T), benzothiophene (BT) and dibenzothiophene (DBT).

20 mL screw-capped chromacol vials were used for the extractive desulfurization (EDS) experiments. Time (30–90 min) and temperature (30–70 °C) were identified as factors affecting the EDS process. All preliminary experiments were carried out under atmospheric pressure in a thermomixer using a fuel-to-solvent ratio of 1:1 (w/w). At the end of each EDS experiment, the mixture was allowed to settle, after which a sample of fuel was withdrawn for chemical analysis. HPLC was used to determine the sulfur content of the simulated fuel before and after the EDS experiment. The relationship shown as Eq. 1 was used to determine the percentage sulfur removal.

where %SR is the % sulfur removal, Co the initial sulfur concentration (ppm), and C t the sulfur concentration after (t) min.

2.3 Experimental Design

A response surface methodology using D-optimal design was employed for the optimization of the performance of the modified ILs. Design Expert 7.0 was used for the design, optimization and analysis of the experiment. The four independent factors studied were mixing time, temperature, IL-modifier mass fraction and the type of solvent. The following quadratic equation was used for fitting the experimental data.

where Y is the response (%SR), X i are factors and β0, β i , β ii and β ij are the coefficients of the intercept, linear, square and interaction effects, respectively.

2.4 Chemical and Thermal Analysis

For the thermal phase change analysis, a differential scanning calorimeter (DSC), DSC TA Q20 (version 2, V24.10 build 122) made by TA instruments, was used. In a typical measurement, a Tzero aluminum hermetic pan and lid were used. A 99.9992% nitrogen gas at 50.0 mL·min−1 was passed through the system. A modulated mode was used with the method set to equilibrate at − 80 °C and to modulate at ± 0.523 °C every 100 s. The machine was set to ramp at 2.00 °C·min−1 to 80 or 120 °C.

An Anton Paar DMA4500 M equipped with Techne-Tempette TE-8A external water-circulator for temperature control, was used for the measurement of density.

Viscosity measurements were carried out using a Malvern Bohlin Germini rheometer. During the viscosity measurement, the shear rate was varied from 1 to 100 s−1 while the temperature was varied from 30 to 80 °C. Average uncertainties in the melting point, density and viscosity measurements are 0.01 °C, 0.0001 g·cm−3 and 5% respectively.

A PerkinElmer Fourier transform infrared spectroscopy (FTIR) instrument was used for determination of the state of the modifiers in the IL. A Frontier model of the FTIR was used (serial number of LR 64912C); this was equipped with class 1 Laser product, BS EN & IEC 60825-1: 2007. Scans were made at a resolution of 32 cm−1 and accumulation set at 64. Prior to the FTIR analysis, a drop of the modified IL is added to an appropriate amount of KBr and ground to powder. The resultant powder was pelletized and inserted into the instrument’s pellet holder.

An Agilent high performance liquid chromatography (HPLC) model 1260 Infinity, equipped with a reverse column and variable wavelength detector was used. The column specifications are 150 × 4.6 mm, 5 μm, 100A (Ecosil C18-extend). The temperature of the column was set at 25 °C. The mobile phase consisted of a mixture of 70 vol% acetonitrile and 30 vol% water. The flow rate was kept at 1 mL·min−1 and the injection volume was set to 1 μL. Detection of thiophene and dibenzothiophene was made at 234 nm while that of benzothiophene was made at 290 nm. Finally, the method’s R2 was determined to be 0.99994 and 0.99972 for dibenzothiophene and benzothiophene, respectively.

3 Result and Discussion

All ILs were observed to form homogenous solutions with all the modifiers at 80 °C with the exception of the FeCl3. For this reason, further work could not be carried out on the FeCl3 modified ILs.

3.1 Properties

To further understand the physical characteristics of the modified ILs, their basic physical properties (including melting point, density and viscosity) were determined.

3.1.1 Melting Point

The melting points of the ILs and their modified counterparts were measured (Table 1). The melting points of imidazole, sulfolane and PEG were obtained from their MSDS as 89–91 °C, 20–26 and − 65.00 °C, respectively. Two endotherms were observed upon mixing [HMPyrr][TFSI] with imidazole. Physical observation at room temperature revealed two distinct phases (a solid and liquid phase). The two endotherms could then be a case of freezing point depression of a material due to addition of a solute. The first endotherm (− 12.56 °C) relates to the depressed freezing point of [HMPyrr][TFSI] due to the presence of dissolved imidazole as an impurity. Note that the imidazole is already in its solid state at this temperature. The second endotherm represents the depressed freezing point of imidazole due to presence of dissolved/adsorbed [HMPyrr][TFSI] IL from the melting point of imidazole to a little above 30 °C. The melting point of the [HMPyrr][TFSI]: sulfolane mixture was measured as − 31.71 °C. This represents a freezing point depression with respect to both the IL and sulfolane. With respect to [HMPyrr][TFSI]: PEG, only a glass transition temperature of − 23.24 °C was observed.

In the case of the [P4444][MeSO3] modified systems, a freezing point depression was observed for both [P4444][MeSO3]:imidazole and the [P4444][MeSO3]:sulfolane. No endotherm was observed for the [P4444][MeSO3]:PEG system. The mixtures involving the [BMPyrr][TFSI] IL, which include [BMPyrr][TFSI]:imidazole, [BMPyrr][TFSI]:sulfolane and [BMPyrr][TFSI]:PEG showed similar behavior to the mixtures involving the [HMPyrr][TFSI] IL. No endotherm was detected in all the mixtures consisting of [Pi444,1][Tos]: [Pi444,1][Tos]:imidazole, [Pi444,1][Tos]:sulfolane and [Pi444,1][Tos]:PEG.

3.1.2 Density

Figure 1 shows the densities of the modified pyrrolidinium-based ILs as functions of temperature. For the mixture involving [BMPyrr][TFSI], the density decreased in the order [BMPyrr][TFSI] > [BMPyrr][TFSI]:sulfolane > [BMPyrr][TFSI]:imidazole > [BMPyrr][TFSI]:PEG > sulfolane > PEG for all measured temperature. For the mixture involving [HMPyrr][TFSI], the order in the decrease in density was determined as [HMPyrr][TFSI] > [HMPyrr][TFSI]:sulfolane > [HMPyrr][TFSI]:imidazole > sulfolane > [HMPyrr][TFSI]: PEG > PEG. Figure 2 shows plots of the densities of the hydrophilic phosphonium-based ILs against temperature. The densities of the mixtures involving [Pi444,1][Tos] decreased in the order sulfolane > PEG > [Pi444,1][Tos]: sulfolane > [Pi444,1][Tos]: PEG > [Pi444,1][Tos]:imidazole > [Pi444,1][Tos]. A similar trend was observed for the mixtures involving [P4444][MeSO3]. The [P4444][MeSO3] based mixtures had the lowest densities. The densities of sulfolane and PEG as functions of temperature can be found in the Supporting Information (Fig. S1). Furthermore, the density of imidazole is not included in the sequence as imidazole is solid at room temperature with a density of 1.030 g·cm−3 (MSDS).

3.1.3 Viscosity

The viscosities of the modified pyrrolidinium and hydrophilic phosphonium-based ILs are presented in Figs. 3 and 4, respectively. In each case, the addition of the modifiers decreased the viscosity of the IL. For the pyrrolidinium-based ILs, the viscosities of the ILs have decreased upon addition of PEG, a greater decrease was observed with the addition of imidazole. Addition of sulfolane resulted in the lowest viscosity values for both ILs at all temperatures. On the other hand, the viscosities of the hydrophilic phosphonium-based ILs decreased with the addition of imidazole, a larger decrease was observed with PEG while the addition of sulfolane resulted in the lowest viscosities.

A geometric reduction as a function of temperature was also observed for most the solvents measured. For the [BMPyrr][TFSI]-based mixture, the reduction in viscosity was 77% for the pure IL and [BMPyrr][TFSI]:PEG within the temperature range of 30–80 °C. The corresponding reduction in viscosity for the [BMPyrr][TFSI]: sulfolane mixture was 74% while the decrease in viscosity of the [BMPyrr][TFSI]: imidazole mixture within the temperature of 50–80 °C was 58%. For the [HMPyrr][TFSI] based mixtures, the reductions in viscosity within the temperature range of 30–80 °C were 80, 76 and 78% for the pure IL, [HMPyrr][TFSI]:sulfolane and [HMPyrr][TFSI]:PEG, respectively. [HMPyrr][TFSI]:imidazole experienced a 67% reduction in viscosity between 50 and 80 °C. The highest viscosity reductions were recorded for the [Pi444,1][Tos] system, which were 95, 92, 91 and 88% for the pure IL, [Pi444,1][Tos]:imidazole, [Pi444,1][Tos]: sulfolane and [Pi444,1][Tos]:PEG, respectively, in the temperature range of 30–80 °C. The corresponding viscosity reductions for the [P4444][MeSO3] based mixtures were 88, 86 and 84% for [P4444][MeSO3]:imidazole, [P4444][MeSO3]:sulfolane and [P4444][MeSO3]:PEG, respectively.

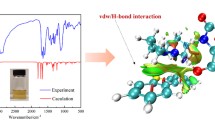

3.1.4 Fourier Transforms Infrared Spectroscopy (FTIR)

After mixing the ILs with the modifiers, FTIR analyses were carried out on all the mixtures. The essence of this study was to ensure that the key properties of the modifiers remain intact. For instance, the aromatic ring of the imidazole should remain intact for any π–π interactions to take place. This way, any improvement in EDS efficiency or otherwise can be attributed to the presence of the property of the modifier under investigation. Therefore, the bands indicating the important properties of the modifiers were searched for in the FTIR spectra. Figure 5 shows the FTIR spectra of [BMPyrr][TFSI] and its modifications. All the spectra resemble the spectra of the pure IL with the presence of new peaks indicating the presence of new species. For [BMPyrr][TFSI]:imidazole, new peaks were observed at 1530 and 830 cm−1. These peaks were attributed to C=C stretching (1650–1430 cm−1) and out-of-plane C–H bending (900–690 cm−1), respectively [16]. Both bands are indicative of an aromatic ring. In the case of [BMPyrr][TFSI]:sulfolane, peaks at 1417, 1300 and 1277 cm−1 represents –CH2 deformation, wagging and twisting vibrations. The peaks at 1258, 1111 and 442 cm−1 represent SO2 antisymmetric switching, symmetric switching and wagging, respectively. The peak at 908 cm−1 can be assigned to ring deformation. All of these are characteristic peaks of sulfolane [17]. The peaks at 2918 and 1408 cm−1 for [BMPyrr][TFSI]:PEG indicate –CH2 stretching and bending vibrations, respectively. The peak at 1382 cm−1 can be attributed to C–CH3 bending vibrations between one of the alkyl groups of the cation and the PEG or H–C–O in-plane bending of the PEG. The peak at 460 cm−1 was attributed to C–F stretching vibrations between PEG and the anion. Strangely, two peaks at 855 and 705 cm−1 appeared to be due to either the nitrate N–O stretching and NO2 bending or N–H wagging [16].

Figure S2 (Supporting Information) presents the FTIR measurement results for the [HMPyrr][TFSI], [Pi444,1][Tos] and [P4444][MeSO3] ILs. Similar to the case of the [BMPyrr][TFSI], bands at 1531 and 828 cm−1 were identified and attributed to the presence of the aromatic ring in IH. Peaks such as 1417, 1303, 1277, 1258, 1110, 908 and 442 cm−1, which are characteristic bonds of sulfolane, were identified. Only two peaks, at 1384 and 465 cm−1, were identified in [HMPyrr][TFSI]:PEG. Although the new peaks obtained from the [Pi444,1][Tos]:imidazole and [Pi444,1][Tos]:PEG solvents could not demonstrate the presence of the modifiers, peaks obtained for [Pi444,1][Tos]:sulfolane indicated the presence of sulfolane. Finally, peaks obtained for the [P4444][MeSO3] modifications were similar to those obtained for the [BMPyrr][TFSI] and [HMPyrr][TFSI] modifications, which indicated the presence of the properties of the modifiers. Very few FTIR studies of this kind of mixture are available in the literature.

3.2 Extractive Desulfurization

Preliminary experiments were carried out to study the response of the modified ILs with mixing time and temperature and determine whether any improvements in sulfur removal can be achieved. The results of such experiments are discussed below.

3.2.1 Effect of Mixing Time

Mixing time as a factor affecting performance of the IL and its modification was studied and ther results are presented as Fig. S3 (Supporting Information) for the [BMPyrr][TFSI] based mixtures. It can be seen that the %SR increased to a maximum for all the mixtures after 90 min of mixing. Furthermore, all the mixtures achieved better %SR removal than the pure IL. For BT, the %SR obtained at 90 min were 54, 49, 57 and 56% using [BMPyrr][TFSI], [BMPyrr][TFSI]:imidazole, [BMPyrr][TFSI]:sulfolane and [BMPyrr][TFSI]:PEG, respectively. Except for [BMPyrr][TFSI]:imidazole, in which EDS was carried out at 50 °C, addition of these modifiers caused a greater positive impact on the performance of the IL at 30 min. The decrease in SR(BT) with addition of the imidazole at 60–90 min can be attributed to the negative effect of the increase in temperature (50 °C). The slightly improved performance at 30 °C can therefore be linked to the existence of new interaction between the IL mixture and the sulfur compounds as discussed above. Similar explanation can be given for the performances of the [BMPyrr][TFSI] based mixtures on DBT removal. Owing to its higher electron density, DBT removal was slightly higher than the BT removal. %SR (DBT) values were 52, 59 and 59% for the [BMPyrr][TFSI], [BMPyrr][TFSI]:sulfolane and [BMPyrr][TFSI]:PEG mixtures, respectively, at 30 °C and 90 min. In general, the improvements obtained by addition of modifiers to the pure IL are not so pronounced after 60 min for the removal of BT and DBT. A similar trend was also observed for thiophene, where the increase was from 36% for the pure IL after 30 min to around 52% for all the modified mixtures.

Figure S4 (Supporting Information) shows the results obtained after carrying out extraction with the [HMPyrr][TFSI] based mixtures. An increase in %SR(T) from 43% for pure IL to 54% using [HMPyrr][TFSI]:sulfolane after 30 min was recorded. Although the %SR was not very sensitive to increases in time for all the mixtures, the results after 90 min of extraction were still superior. The %SR (BT) obtained at 90 min were 56, 54, 60 and 61% for the [HMPyrr][TFSI], [HMPyrr][TFSI]: midazole, [HMPyrr][TFSI]:sulfolane and [HMPyrr][TFSI]:PEG mixtures, respectively. Similar to the case of the [BMPyrr][TFSI] based mixtures, the [HMPyrr][TFSI]:sulfolane and [HMPyrr][TFSI]:PEG mixtures have higher, and identical, efficiencies. The %SR (DBT) were 59, 56, 64 and 64%, respectively. Note that EDS using [HMPyrr][TFSI]:imidazole was carried out at 50 °C. There was generally only a slight improvement in the performance of the IL especially after 60 min. At 30 min, the improvement is more significant, which serves as an advantage.

Figure S5 (Supporting Information) shows the results obtained for EDS experiments carried out on the [Pi444,1][Tos] based mixtures. After 30 min, %SR(T) was found to increase from 31% using the pure IL to 49, 57, and 51% using the [Pi444,1][Tos]:imidazole, [Pi444,1][Tos]:sulfolane and [Pi444,1][Tos]:PEG mixtures, respectively. For BT, a sharp improvement was also recorded after 30 min from 39% using the pure IL to 57, 66 and 61% for the [Pi444,1][Tos]: midazole, [Pi444,1][Tos]:sulfolane and [Pi444,1][Tos]:PEG mixtures, respectively. Clear improvement can be seen and may be attributed to the increased interactions due to the presence of a ring, sulfolane’s similarity to the sulfur compound and the introduction of a chain-like structure with a consequent wrapping effect. The %SR remained constant after 30 min while the SR of the pure IL increased to 54% after 90 min. Improvement of DBT removal was observed. At 30 min, the %SR(DBT) increased from 41% (pure IL) to 66% ([Pi444,1][Tos]:imidazole), 70% ([Pi444,1][Tos]:sulfolane) and 67% ([Pi444,1][Tos]:PEG). The %SR of the ([Pi444,1][Tos]:sulfolane and [Pi444,1][Tos]:PEG mixtures remained at this level up to 90 min while the %SR for the pure IL and the [Pi444,1][Tos]:imidazole mixture rose to 58% and 66%, respectively. It can be seen that the %SR(BT, DBT) increases in the order [Pi444,1][Tos]:sulfolane > [Pi444,1][Tos]:PEG > [Pi444,1][Tos]:imidazole > [Pi444,1][Tos]. This indicates the superiority of sulfolane as a modifier for improvement of EDS using this IL.

Figure 6 shows the results of the investigation into the effect of time on %SR of the [P4444][MeSO3] based mixtures. After 30 min, %SR (T, BT, DBT) of (39%, 50%, 54%), (59%, 68%, 75%), (64%, 73%, 81%) and (58%, 67%, 74%) were obtained using the pure IL, [P4444][MeSO3]:imidazole, [P4444][MeSO3]:sulfolane and [P4444][MeSO3]:PEG, respectively. In contrast %SR(T, BT, DBT) of [P4444][MeSO3]:imidazole, [P4444][MeSO3]:sulfolane and [P4444][MeSO3]:PEG remained roughly the same up to 90 min, the %SR(T), %SR(BT) and %SR(DBT) for the pure IL increased to 61, 67 and 70%, respectively. It should be noted that the experiments involving the pure IL were carried out at 60 °C due to its melting point (58 °C) while the experiments involving the mixtures were carried out at 30 °C. Therefore, a better comparison could be made at the same temperature.

3.2.2 Effect of Temperature

Figure S6 (Supporting Information) shows the plots of %SR(T), %SR(BT) and %SR(DBT) against temperature. It was observed that %SR(T, BT) for the [BMPyrr][TFSI]:sulfolane and [BMPyrr][TFSI]:PEG mixtures remained relatively the same with the increase in temperature. This indicates that the likely increase in the affinity of the mixtures toward BT with increase in temperature is cancelled out by the increase in the affinity of the simulated fuel towards BT. However, a slight decrease in %SR(BT) was observed using the [BMPyrr][TFSI]:imidazole mixture, which indicates a relative increase in the affinity of the simulated fuel towards BT. This also raises the possibility that weakening the interactions between the modifier and the IL inhibits the BT affinity of the mixture. The plot of %SR(DBT) against temperature indicates that all the [BMPyrr][TFSI] based mixtures were irresponsive to the change in temperature (30–70 °C). In contrast, the %SR(BT, DBT) obtained using [HMPyrr][TFSI]:sulfolane and [HMPyrr][TFSI]:PEG decreased with the increase in temperature, while those obtained using [HMPyrr][TFSI]:imidazole slightly increased when the temperature was increased. As can be seen in Fig. S7 (supplementary information), the %SR(DBT) using [HMPyrr][TFSI]:PEG is more responsive to the increase in temperature than the [HMPyrr][TFSI]:sulfolane mixture. In the case of thiophene (T), the %SR increased when the temperature was increased for [HMPyrr][TFSI]:imidazole and [HMPyrr][TFSI]:sulfolane while it remained constant for [HMPyrr][TFSI]:PEG. Furthermore, the performances of all the mixtures were superior to that of the pure IL.

Figure S8 (Supporting Information) shows a decrease for the [Pi444,1][Tos] based mixtures SR(BT, DBT) when the temperature was increased. Since this trend is the reverse to that obtained using the pure IL, the SR(BT, DBT) observed at 70 °C using the pure IL is greater that than that for the [Pi444,1][Tos]:imidazole and [Pi444,1][Tos]:PEG mixtures. However, an increase in %SR(T) was observed with the ncrease in temperature for all the mixtures. A decrease in %SR(BT, DBT) with increasing temperature was also observed in experiments involving [P4444][MeSO3] based mixtures (Fig. 7). Furthermore, at 70 °C, %SR(BT, DBT) achieved using pure IL was found to be less than those obtained using the mixtures. This indicates the superiority of the mixture solvents as compared to the pure IL. The %SR remained roughly the same for thiophene removal.

The observed decrease in %SR(BT, DBT) with the increase in temperature using the mixtures discussed above is due to the relative decrease in the affinity of the mixtures toward the sulfur compounds. A number of works in the literature have reported similar trends [9, 18, 19]. Also, work with mixtures as solvents, such as the deep eutectic solvents, have shown similar behavior [20, 21]. If the increase in temperature is assumed to affect the interactions of a possible stable structure formed between the IL and the modifier, then distortion of this structure is partly responsible for the observed decrease. It can then be assumed that this distortion, coupled with the fact that the increase in temperature is accompanied by an increase in the affinity of the fuel towards the sulfur compound, resulted in the observed decrease in %SR with temperature.

Based on previous studies, it can be seen that, firstly, DBT is relatively easier to remove than BT. Secondly, sulfolane and PEG as modifiers are almost always better than imidazole as a modifier despite its aromatic ring, which was supposed to induce π–π interactions. It should be noted that π–π interactions were assumed to be induced because the imidazole modified mixtures performed better in some cases. However, the strength of the interaction can be assumed to be less than those induced by the presence of sulfolane and PEG. Thirdly, the performances of the hydrophilic phosphonium based ILs were improved more than those of the pyrrolidinium-based ILs. The %SR(DBT) increased by 39, 50 and 37% using [P4444][MeSO3]:imidazole, [P4444][MeSO3]:sulfolane and [P4444][MeSO3]:PEG (30 min, 30 °C), respectively. The %SR(DBT) also increased by 49, 71 and 63% using [Pi444,1][Tos]: midazole, [Pi444,1][Tos]:sulfolane and [Pi444,1][Tos]:PEG, respectively. Even though a higher increase in %SR was recorded using the [Pi444,1][Tos] based mixtures, the highest %SR(DBT) was recorded using the [P4444][MeSO3] based system. The partition coefficient obtained in the case of [P4444][MeSO3]:sulfolane is about 4.18, which is quite high and comparable to those in pyridinium based ILs [22].

3.3 Optimization of Operating Conditions using the D-Optimal Design Methodology

A D-optimal design method was used to determine the optimal operating condition. Two categorical factors were introduced namely [P4444][MeSO3]:sulfolane and [P4444][MeSO3]:PEG. This means that in the process of optimization, the performance of the two modifiers must be compared. [P4444][MeSO3]:imidazole was not selected because of its higher viscosity.

As was already observed, the %SR does not change with increasing mixing time beyond 30 min. Furthermore, %SR was observed to decrease with increase in temperature. The reason behind considering these factors, despite the fact that the %SR is either unresponsive or is negatively affected by them, is to determine the probable interaction between any of these factors and the other factor (mass fraction) which may result in a high %SR. Furthermore, it is expected that increasing the fuel-to-solvent ratio will result in a decrease in %SR. It is interesting to see whether this decrease can be offset by the interaction between any two factors. Table S1 (Supporting Information) shows the levels and range of the independent variables. Experiments were carried and the results were analyzed and fitted to the quadratic model presented as Eq. S1 (Supporting Information).

The response surfaces of DBT, BT and T, presented as Figs. S10, S11 and S12 respectively, were optimized and the predicted results were validated (Table 2). It should be noted that up to > 99% SR can be achieved but only at low fuel-to-solvent ratio (1:4 w/w), which is not attractive and therefore the fuel-to-solvent ratio was fixed at 1:1 (w/w), and based on this conditions, no further improvement was observed. The model obtained can be used to gain more insight into how the factors interact and the magnitude to which they affect %SR(T, BT, DBT).

4 Conclusion

An investigation was carried out in this work into the possible improvement of extractive desulfurization of simulated fuel via the modification of ionic liquids. ILs were modified by adding molecules that could induce previously non-existent interactions with the sulfur compounds. It was observed that the presence of the π–π interactions (imidazole) does improve the performance of the IL, especially when added to the hydrophilic phosphonium-based ILs. However, the presence of a compound, which is similar to the sulfur compounds (sulfolane), lead to a significant improvement of the performance of the IL as compared to the addition of imidazole. The same can be said of the addition of PEG. Because both sulfolane and PEG do not contain aromatic rings, the π–π interaction is likely not the predominant mechanism that makes pyridinium ILs and similar ILs possess such high affinities toward the refractory sulfur compounds. Up to a 71% increase in the %SR(DBT) was observed with the addition of sulfolane to the [P4444][MeSO3] IL at a 1:1 molar ratio. A DBT sulfur removal of 81% and a partition coefficient of about 4.18 were recorded, which makes the solvent suitable for the extractive desulfurization of liquid fuel.

References

Worldwide Winter Diesel Fuel Quality Survey. Infinium (2014)

Abro, R., Abdeltawab, A.A., Al-Deyab, S.S., Yu, G., Qazi, A.B., Gao, S., Chen, X.: A review of extractive desulfurization of fuel oils using ionic liquids. RSC Adv. 4, 35302–35317 (2014). https://doi.org/10.1039/C4RA03478C

Mjalli, F.S., Ahmed, O.U., Al-Wahaibi, T., Al-Wahaibi, Y., AlNashef, I.M.: Deep oxidative desulfurization of liquid fuels. Rev. Chem. Eng. 30, 337–430 (2014). https://doi.org/10.1515/revce-2014-0001

Zhang, S., Zhang, Q., Zhang, Z.C.: Extractive desulfurization and denitrogenation of fuels using ionic liquids. Ind. Eng. Chem. Res. 43, 614–622 (2004). https://doi.org/10.1021/ie030561+

Nie, Y., Li, C.-X., Wang, Z.-H.: Extractive desulfurization of fuel oil using alkylimidazole and its mixture with dialkylphosphate ionic liquids. Ind. Eng. Chem. Res. 46, 5108–5112 (2007). https://doi.org/10.1021/ie070385v

Nejad, N.F., Soolari, E.S., Adibi, M., Beigi, A.A.M., Torkestani, S.K.: Imidazolium-based alkylsulfate ionic liquids and removal of sulfur content from model of gasoline. Pet. Sci. Technol. 31, 472–480 (2013)

Gao, H., Luo, M., Xing, J., Wu, Y., Li, Y., Li, W., Liu, Q., Liu, H.: Desulfurization of fuel by extraction with pyridinium-based ionic liquids. Ind. Eng. Chem. Res. 47, 8384–8388 (2008). https://doi.org/10.1021/ie800739w

Gao, H., Guo, C., Xing, J., Liu, H.: Deep desulfurization of diesel oil with extraction using pyridinium-based ionic liquids. Sep. Sci. Technol. 47, 325–330 (2012)

Wilfred, C.D., Kiat, C.F., Man, Z., Bustam, M.A., Mutalib, M.I.M., Phak, C.Z.: Extraction of ddibenzothiophene from dodecane using ionic liquids. Fuel Process. Technol. 93, 85–89 (2012)

Ban, L.-L., Liu, P., Ma, C.-H., Dai, B.: Deep extractive desulfurization of diesel fuels by FeCl3/ionic liquids. Chin. Chem. Lett. 24, 755–758 (2013). https://doi.org/10.1016/j.cclet.2013.04.031

Schmidt, R.: [bmim]AlCl4 ionic liquid for deep desulfurization of real fuels. Energy Fuels 22, 1774–1778 (2008). https://doi.org/10.1021/ef7007216

Li, F.-T., Liu, Y., Sun, Z.-M., Chen, L.-J., Zhao, D.-S., Liu, R.-H., Kou, C.-G.: Deep extractive desulfurization of gasoline with xEt3NHCl·FeCl3 ionic liquids. Energy Fuels 24, 4285–4289 (2010). https://doi.org/10.1021/ef100408h

Mochizuki, Y., Sugawara, K.: Removal of organic sulfur from hydrocarbon resources using ionic liquid. Energy Fuels 22, 3303–3307 (2008)

Chu, X., Hu, Y., Li, J., Liang, Q., Liu, Y., Zhang, X., Peng, X., Yue, W.: Desulfurization of diesel fuel by extraction with [BF4]− based ionic liquid. Chin. J. Chem. Eng. 16, 881–884 (2008)

Ahmed, O.U., Mjalli, F.S., Al-Wahaibi, T., Al-Wahaibi, Y., AlNashef, I.M.: Optimum performance of extractive desulfurization of liquid fuels using phosphonium and pyrrolidinium-based ionic liquids. Ind. Eng. Chem. Res. 54, 6540–6550 (2015). https://doi.org/10.1021/acs.iecr.5b01187

Stuart, B.H.: Infrared Spectroscopy: Fundamentals And Applications. Wiley, Chichester (2004)

Badawi, H.M., Förner, W., El Ali, B., Al-Durais, A.-R.A.H.: Ring inversion, structural stability and vibrational assignments of sulfolane c-C4H8SO2 and 3-sulfolene c-C4H6SO2. Spectrochim. Acta A 70, 983–990 (2008). https://doi.org/10.1016/j.saa.2007.09.049

Wang, Y., Li, H., Zhu, W., Jiang, X., He, L., Lu, J., Yan, Y.: The extractive desulfurization of fuels using ionic liquids based on FeCl3. Pet. Sci. Technol. 28, 1203–1210 (2010). https://doi.org/10.1080/10916460903066148

Asumana, C., Yu, G., Li, X., Zhao, J., Liu, G., Chen, X.: Extractive desulfurization of fuel oils with low-viscosity dicyanamide-based ionic liquid. Green Chem. 12, 2030–2037 (2010)

Tang, X.-D., Zhang, Y.-F., Li, J.-J., Zhu, Y.-Q., Qing, D.-Y., Deng, Y.-X.: Deep extractive desulfurization with arenium ion deep eutectic solvents. Ind. Eng. Chem. Res. 54, 4625–4632 (2015). https://doi.org/10.1021/acs.iecr.5b00291

Li, C., Li, D., Zou, S., Li, Z., Yin, J., Wang, A., Cui, Y., Yao, Z., Zhao, Q.: Extraction desulfurization process of fuels with ammonium-based deep eutectic solvents. Green Chem. 15, 2793–2799 (2013). https://doi.org/10.1039/C3GC41067F

Holbrey, J.D., Lopez-Martin, I., Rothenberg, G., Seddon, K.R., Silvero, G., Zheng, X.: Desulfurisation of oils using ionic liquids: selection of cationic and anionic components to enhance extraction efficiency. Green Chem. 10, 87–92 (2008)

Acknowledgment

The authors appreciate the financial support of The Research Council and Sultan Qaboos University, Muscat Oman, under the Project RC/ENG/PCED/12/02.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ahmed, O.U., Mjalli, F.S., Talal, AW. et al. Extractive Desulfurization of Liquid Fuel using Modified Pyrollidinium and Phosphonium Based Ionic Liquid Solvents. J Solution Chem 47, 468–483 (2018). https://doi.org/10.1007/s10953-018-0732-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10953-018-0732-1