Abstract

Nowadays, the production of environmentally friendly, sulfur-free fuel as a feedstock is a global requirement due to the increasing demand for ultraclean fuels. Hydrodesulfurization is the typical technique widely used in the industry that deals with severe difficulties. So, to overcome these difficulties, researchers have invented various desulfurization techniques, such as extractive, adsorptive, oxidative, or a combination of these techniques. The use of ionic liquids (ILs) in extractive desulfurization, oxidative desulfurization, and extractive–oxidative desulfurization techniques has gotten a lot of attention in the last few decades, and there have been a lot of papers written about it. In these techniques, ILs are employed as extractants and catalysts instead of traditional volatile organic solvents. This study aims to highlight the influential factors such as operating conditions, mass ratio of ionic liquid to fuel, quantity of other complementing reagents, initial sulfur content, and effects of various sulfur compounds with the key emphasis on the efficacy of ILs in both the techniques. To understand the effectiveness and multifunctional role of ILs, the influence of structure and properties of ILs, multistage extraction using ILs, regeneration and recycling of ILs are also reported in this paper. Here, a review of the interesting findings, challenges, and future perspectives to mature the performance of these techniques is discussed in detail.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The demand for ultra-deep desulfurization of fuels such as diesel, gasoline, kerosene, marine fuel, and heating oil is ever increasing in the refining industries. Production of energy is one of the most challenging issues of the modern era as energy consumption and economics are connected intimately. Fossil fuels are one of the most widely used sources for energy production worldwide. Half of the total energy obtained from fossil fuel comes from petroleum fuel (Betiha et al. 2017). The crude oil is the largest source of energy, and the major part of crude oil is usually used as transportation fuels. Sulfur content and API gravity have a strong influence on the price of crude oil. These sulfur compounds in fuel exist as thiophenes and its derivatives, mercaptans, sulfides, and disulfides (Ja et al. 2017).

The hydrodesulfurization (HDS) method is an ongoing technique in the petroleum industry. Higher operating conditions, use of expensive catalysts and hydrogen gas, production of hydrogen sulfide gas, higher capital cost, lack of safety, and inability to meet environmental standards under normal conditions are the main demerits of the HDS process (Deshpande et al. 2005; Khodaei et al. 2017; Saha et al. 2016). This prompts the development of alternative desulfurization techniques to overcome these challenges. Some of the newly developed techniques, such as extractive (Ahmed et al. 2016b; Królikowski 2019; Li et al. 2015b; Tian et al. 2003), adsorptive (Etemadi and Yen 2007; Khan and Jhung 2015; Kim et al. 2006), biodesulfurization (Li et al. 2007; Soleimani et al. 2007; Xu et al. 2019; Yi et al. 2019), shifting boiling point by alkylation (Farag 2010), oxidative desulfurization (Hao et al. 2019a; Li et al. 2020; Liu et al. 2020), and ultrasound-assisted oxidative desulfurization (Desai et al. 2021a, b), have been introduced.

Various extractants, such as acetonitrile, dimethylformamide, and sodium hydroxide, were used for the desulfurization of fuel (Abdelrahman et al. 2018; Duarte et al. 2011; Margeta et al. 2016). However, all of these are volatile organic compounds (VOCs), so it creates some deteriorating effects on the process, such as loss of solvent, loss of oil yield, and difficulty in the recovery of solvents (Chao et al. 2010). ILs are the new solvents that are promising substituents of VOCs owing to their extraordinary characteristics such as negligible vapor pressure, good solvation property, high thermal and chemical stability, and designability according to an application under question (Ebrahimi and Hashemabadi 2018). Shayegan et al. (2013) show that ILs can serve as extractants and catalysts, as well as a combination of two or more roles (Shayegan et al. 2013). The desulfurization techniques with ILs ensure high stability and regeneration ability.

As discussed above, ILs act as efficient catalysts, extractants, and both in IL-assisted processes. Imidazolium ILs are the most common type of ILs used in the fuel desulfurization process. Swapnil Dharaskar and his group have applied numerous imidazolium- and phosphonium-based ILs as extractants for the desulfurization of model fuel (MF) and real fuel (RF). At 30 °C, all ILs reached thermodynamic extraction equilibrium in 30 min (Desai et al. 2020; Dharaskar and Sillanpaa 2018a; Dharaskar et al. 2013, 2014b, 2016a). Zhang and the group have developed functionalized polyoxometalate-based IL and applied it as a catalyst for the desulfurization of MF as well as hydrotreated diesel oil and achieved the allowable sulfur limit (Zhang et al. 2014b). This synthesized catalyst can be recycled seven times without a decrease in the activity. Zhang and the group have also developed the electrophilicity-tunable IL for aerobic ODS (Zhang et al. 2020). Another group of Zhu synthesized various functionalized ILs such as graphene analogues supported by tungsten-based IL and achieved 99.3% sulfur removal at 30 °C. This work provided new ways of designing high-performance heterogeneous catalysts (Zhu et al. 2015). A similar group has developed the pyridinium-based temperature-responsive magnetic IL and applied it to the ILs-assisted ECODS process and obtained 95.3% sulfur removal at 40 °C in 10 min. Owing to the magnetic feature and temperature-responsive behavior, recovery and reuse of synthesized IL became easy and it was recycled efficiently for five consecutive cycles. These results gave a new direction to the development of the thermomorphic catalyst of the ODS system (Zhu et al. 2013). They have also developed metal surfactant-based ILs and applied them as catalysts in the desulfurization of fuel. The amphiphilic nature of these synthesized ILs played a significant role in the formation of the emulsion and reuse of catalysts (Zhu et al. 2011). Zhao and his group applied the pyridinium-based IL for the desulfurization of MF and achieved a 93.3% removal efficiency in the presence of H2O2 and formic acid (Zhao et al. 2010). A similar group has developed the environmentally benign coordinated IL from the cheap amines and Bronsted acidic IL, which is applied as a catalytic solvent for the ODS process. The effect of process parameters was optimized and obtained 98.6% and 99.8% desulfurization efficiency, respectively (Zhao et al. 2009a; c).

This work reviews recent progress and the multitasking role of ILs in extractive and oxidative desulfurization techniques considering the effects of all other influential factors on the performance of extractive desulfurization using ionic liquids (ILs-EDS), oxidative desulfurization using ionic liquids (ILs-ODS), and extractive and catalytic oxidative desulfurization using ILs (ILs-ECODS). The effects regeneration, multistage extraction along with the mechanism responsible are discussed in detail. The application of these processes on the actual fuels and their feasibility on the industrial applications are explained in detail.

Effect of sulfur compounds, its emission standards, and need of desulfurization

Air quality is significantly degraded by the pollution emitted by vehicles. Sulfur dioxide is released from several anthropogenic sources, such as excessive burning of fossil fuels, coal-burning power plants, and the use of vehicles. The emission of these gases into the environment reacts with atmospheric humidity and forms sulfates and acid rain, which damage soil and buildings and ultimately affect the ecosystems. Thereby, the production of fuels with low levels of organic sulfur compounds in fuels becomes very important. These fuels could be utilized for fuel cell applications (Etemadi and Yen 2007). Vehicles also emit NOx, sulfur, and nitrogen-containing particulate matter which can cause lung cancer, respiratory and cardiovascular diseases, chronic bronchitis, and other serious health problems. Sulfur compounds can also create deteriorating effects such as catalyst deactivation, and corrosion of pipelines, equipment, and pumps. The desulfurization of fuel is also important from an industrial point of view. To reduce the overall emissions, automobile companies also demand the same. This is because the presence of sulfur compounds deactivates the catalyst, poisoning the catalytic converters. Combustion of sulfur-containing fuels produces sulfur oxides which cause corrosion of parts of IC engines. It also affects the emission control devices by preventing the adsorption and reaction of NOx, hydrocarbon (HC), and carbon monoxide (CO) (Betiha et al. 2017).

Sulfur removal still represents a major operational and economic challenge for the petroleum refining industry. Almost all countries have brought down the allowable sulfur content in transportation fuel to 10 ppm, and it will be reduced to approximately zero shortly (Gray et al. 2003). The United States Environmental Protection Agency (USEPA) sets the standards for sulfur content in gasoline and diesel. The EPA set the maximum allowable sulfur content of 15 ppm in diesel in 2006, and currently it is 10 ppm in the USA and Europe, which can be reduced to zero ppm shortly. As of 2017, regulation in India requires on-road diesel and gasoline to follow BS-IV standards (maximum 50 ppm S) and these standards will be tightened to BS-VI (maximum 10 ppm S), in 2020. Also, newer technologies are found that can be helpful for India in achieving its goal of zero sulfur emissions (Khodaei et al. 2017).

Toxic sulfur components present in fuels

Crude oil contains an enormous amount of sulfur compounds in fuels. Some of the sulfur compounds like mercaptans, thiols, and sulfides can be removed easily by the traditional ongoing industrial process, but the other compounds like thiophene (TH), benzothiophene (BT), dibenzothiophene (DBT), and their derivatives are very difficult to remove by the HDS process (De Filippis and Scarsella 2003). The reactivity of sulfur compounds depends on initial sulfur concentration, type of sulfur compounds, API gravity, molecular weight, electron density, and steric hindrance (Song and Amer Chem 2002). Combustion of fuel releases sulfates particulate matter, sulfur oxides, and nitrogen oxides which cause harmful effects on the environment and human health (Safa et al. 2016). Table 1 represents the various aromatic and aliphatic sulfur compounds present in fuels.

Outlook

As mentioned in the Introduction section, desulfurization of fuel has become a difficult issue for petroleum refiners due to a number of disadvantages, including global warming, pollution, acid rain, vehicle engine damage, and being highly harmful to the environment and human health. As a result, environmental protection control bodies in all countries have tightened the threshold for the permitted S-content of fuels. The HDS is the most widely used technique, even though it has significant drawbacks, including extremely high operating temperatures, the consumption of expensive hydrogen gas and catalyst, and the difficulty of removing aromatic S-compounds. The nature of S-compounds has a considerable impact on the effectiveness of all desulfurization procedures. The type, structure, and physicochemical properties of ILs have a significant impact on all of the strategies covered in this article. The main focus of this article is on the efficacy of ILs in EDS, ODS, and ECODS performance. Operating conditions, initial sulfur content (ISC), oxidant and catalyst dosage, type of S-compounds, and multistage extraction are all aspects that influence the performance of these approaches, as well as the influence of ILs. The recycling impact of ILs was also investigated to see if the techniques might be used in industry. ILs are typically thought of as green solvents that are frequently used in the separation and catalysis industries. IL was originally introduced only as an extractant in the ILs-EDS technique, which extracts S-compounds via simple physical extraction. The maximum experiments were conducted on MFs, but their application to real-world fuel research did not yield the expected findings. The ILs are employed as extractants to remove the sulfones that have been generated. As a result, scientists have begun using ILs as an extractant in the ILs-ODS process, in which S-compounds are oxidized to respective sulfones in the presence of an oxidant in the first step, and then ILs are employed as extractants in the second phase to remove the created sulfones. The problem with this method is that it uses a lot of ILs, takes a long time, and is inefficient for real-world fuel studies. After that, the researchers created a novel method by merging extractive and oxidative processes, which is known as the extractive and catalytic oxidative desulfurization process (ILs-ECODS). The combination of these processes can overcome the drawbacks of the ILs-ODS and ILs-EDS processes, and it has also been found to be beneficial in real-world fuel tests. This method can reduce the use of ILs while simultaneously providing good desulfurization efficiency for both MFs and RFs. The use of all three procedures on RFs is reviewed, demonstrating that the ILs-ECODS approach is both successful and feasible for industrial use.

Ionic liquids

The definition of ILs in the current scenario is that liquids consist entirely of ions and have a melting point of less than 100 °C (Ahmed et al. 2015). Kowsari (2013) shows that ILs have a broader range of unique characteristics that falsify the earlier assumption that all ILs have the same characteristics (Kowsari 2013). It generally has low volatility and has wide applications. ILs can be safe or risky, volatile or nonvolatile, toxic or benign (Watanabe 2007). It is often assumed and stated that all ILs are green and nonvolatile, which can be wrong for some ILs. Hence, one should not generalize the common error found in the previous literature. Research on ILs increases day by day due to the well-known fact that enormous ILs can be synthesized by varying the chemical structure, and thereby the physicochemical properties of ILs can be adjusted as per the required application. Therefore, ILs are also known as ‘designer solvents’ and ‘task-specific’ (Austen Angell et al. 2012). The main concern about the industrial feasibility of ILs is their cost. Nevertheless, ILs can be economically produced on a large scale. In many applications, ILs can be recycled several times, which would reduce the overall cost. This recycling of ILs without any effect on the surrounding environment is advantageous in the present era of climate concerns (Gutowski 2018).

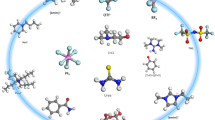

Structure of ILs and its development

ILs consist of organic and asymmetric (usually) cations and organic or inorganic anions (Welton 2018). The most effective method for the synthesis of IL is salt metathesis reactions, though there are several techniques such as anion exchange and acid–base neutralization (Prado and Weber 2016). The cation center mostly has nitrogen or phosphorus with a positive charge, while the anion has a diffused or protected negative charge. Figure 1 presents the common cations and anions used in the synthesis of ILs (Faridbod et al. 2011). Initially, ILs are broadly classified into four categories as shown in Fig. 2. Protic ILs are the simplest ILs to synthesize compared to other ILs as they can be prepared via simple proton transfer from Bronsted acid to Bronsted base, whereas aprotic ILs contain an alkyl group other than a proton and their synthesis requires specific strategies. The other two categories are inorganic ILs and solvate ILs. Inorganic ILs can have protic, aprotic, or solvate cases. Mixed alkali–molecular inorganic IL systems can also be made through mixing inorganic ILs with low melting alkali salts. Solvate ILs consist of salt and coordinating solvent, which gives rise to a chelate complex with similar kinds of properties as ILs (Austen Angell et al. 2012). In the last few decades, numerous classes of ILs have been introduced in these categories, including bio ILs (Fukaya et al. 2007), deep eutectic solvents (Królikowski 2019), supported ILs (Yu et al. 2020), polarizable ILs (Schro et al. 2020), chiral ILs (Bica and Gaertner 2008), metal salts ILs (Abbott et al. 2004), switchable polarity solvents (Phan et al. 2008), and amphiphile ILs (Falcone et al. 2020).

ILs can be synthesized and fine-tuned by changing the cation and anions to meet the specific requirements. ILs are the solvents that can be applied to a wide range of organic and inorganic components (Bradaric et al. 2003; Singh and Savoy 2019).

Ratti et al. emphasized the application of IL as a catalyst and reviewed the preparation and its applications in various separation processes (Ratti 2014). Through a survey of earlier reports, Han et al. have shown the potential of ILs compared to other volatile organic compounds and reported the function of ILs as extractants and catalysts in various fields (Han and Row 2010). Physicochemical properties of ILs were compared with those of solvents by the groups of Koel and Hardy (Handy 2011; Koel 2008).

Influential physicochemical properties of ILs

The physical chemistry of the ILs is the most significant aspect that provides the meaningful factors that estimate the properties of ILs. The physicochemical properties of ILs can be tailored as per the application. Usually, ILs are designed to have non-flammability, low combustibility, negligible volatility, a wide liquidus range, as well as an electrochemical window, and high thermochemical stability. Although ILs have a wide range of hydrogen bonding ability and polarity, they are liquid from − 93 to 327 °C. For the application of ILs for a specific purpose, physicochemical data have to be accessed. Despite the frequent use of ILs, the knowledge of these properties is still limited. Solubility, wettability, viscosity, moisture content, thermal stability, and conductivity are considered peculiar and significant properties. To understand the environmental impact of ILs, biodegradability and toxicity are also equally important to study.

The physicochemical properties of ILs depend on the nature and size of both the cation and anion. The cation of ILs plays a vital role in the variation of properties such as melting point, viscosity, and solubility with solvents (Ueno et al. 2010; Watanabe 2007). The thermal stability and melting point of ILs are important in understanding the decomposition and purity of ILs. The significant structural factors of the cation are the number of carbon atoms in the alkyl chain, its flexibility, charge density, symmetry, functional tail group, and cyclic or branched structures. These structural factors have a great effect on the properties of anions.

Typically, ILs have been considered as salts having melting point less than 100 °C. In general, halide anions reveal higher melting points, which are considered as the precursors of ILs. Typically, both ions have an influence on lowering the melting temperature. Increasing the anion size and its asymmetric substitution lowers the melting point. Similarly, the size of the cation, as well as its symmetry, also has an impact on the melting point. The thermal stability of ILs also contributes to the melting temperature. The thermal stability of ILs decreased by branching the alkyl chain length and increased by increasing the anion charge density in the case of high cation charge density. Glass transition temperatures also depend on the structure of cations, but the effect is much smaller than the melting point temperature. The glass transition temperature of common ILs is typically around − 73 °C.

ILs usually have a higher density than water, with 1–2.3 g/mL. The density strongly depends on alkyl chain length, the size of the ring in the cation, the interaction force between anion and cation, and their symmetry. The density of ILs can be increased by increasing the symmetry of cations and attachment of the function group (Faridbod et al. 2011).

ILs have a strong and wide range of wettability (hydrophilic to hydrophobic), and this can be varied by varying the cation or anion. At saturation, hydrophobic IL such as 1-butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide absorbs approximately 1.4% of the water mass (Matsuda et al. 2007). Longer alkyl chain length cations and anions like bis(trifluoromethanesulfonyl)amide, [BF4]−, and [PF6]− are much more hydrophobic than Cl− and Br− in ILs with similar cations. This hydrophobicity and other solvent immiscibility are advantageous for phase separation. Nonvolatile nature of IL is a most important advantage as it cannot be ingested by inhalation like VOCs (Handy 2011).

Moisture content in ILs may be critical for some applications but negligible for others. Furthermore, even a small percentage of water affects the viscosity of heavy oil. Therefore, the moisture content of ILs must be < 10%. It can also affect the catalyst dissolved in IL (Alexander et al. 1962; Dharaskar et al. 2016a; Fan et al. 2009; Shaban et al. 2014; Song et al. 2017).

Another critical property of ILs is biodegradation. IL is generally designated as biodegradable and non-toxic in nature, so before using it for any application, a biodegradation study must be carried out (Atefi et al. 2009). Tuning of synthesized IL is obtained by varying the length of alkyl chains connected to the ionic part of the cation. The toxicity and environmental profiles of ILs are required to be known as ILs are usually designated as environmentally friendly and ‘green solvent’(Atefi et al. 2009; Raj et al. 2018). Low-volatile ILs can also be used for high-vacuum systems. The toxicity of ILs depends on the nature of the cation and anion and the solvent used for the synthesis of ILs (Raj et al. 2019). Impurities such as moisture content, residual solvents, acids, halide ions, and unreacted VOS arise from the synthesis of ILs. These impurities may affect the spectroscopic and physicochemical characteristics of the resulting ILs. Ideally, ILs should be clear and odorless. If there are no functional groups, they should be colorless (Cieniecka-rosl et al. 2005).

Transport property plays a significant role in liquid–liquid extraction, separation, and other chemical reactions as well as electrochemistry. This mainly focuses on the viscosity of ILs and their interaction with molecular solvents. ILs are more viscous than common VOCs. At room temperature, the viscosity of ILs is in the range of 10–500 cP, which is higher than water (0.89 Cp) and other aqueous solutions. The viscosity of ILs varies with the shear rate as it is known that the larger cations make IL more viscous owing to increased van der Waals interactions. Electrostatic forces and hydrogen-bonded structures can also affect the viscosity of ILs. Endress and Abedin proved that increasing the alkyl chain length from butyl to octyl increases the viscosity and hydrophobicity and decreases the density. This is owing to the strong van der Waal force, and therefore the energy requirement of the molecular motion increases (Endres et al. 2006). ILs with the lowest viscosity are formed from small anions with a diffused negative charge. This negative charge is likely to take part in any hydrogen bonding interaction. The high viscosity of ILs can be decreased by the addition of diluents. The basicity and structure of an anion also affect the viscosity. A small anion can decrease the Van der Waals bond but increases the electrostatic interaction through hydrogen bonding. It also varies with the temperature. As temperature increases, the viscosity of ILs decreases (Dharaskar and Sillanpaa 2018a; Guangren et al. 2012; Navarro et al. 2018). Okoturo and Vander Noot reported studies on viscosity–temperature dependence and proved that most of the ILs do not follow the typical Arrhenius equation. The viscosity–temperature correlation follows the Vogel–Tammann–Fulcher (VTF) equation, which also considers glass transition temperature as an exponential term and observes a decrease in the viscosity of ILs with an increase in temperature (Okoturo and Vandernoot 2004).

Mutual solubility between IL and fuel is measured using vacuum drying, gas chromatography, and liquid chromatography. Mutual solubility between fuel oils and ILs is a crucial factor to take into account when ILs are applied as extractants because of two reasons: (1) Dissolution of ILs in fuel causes contamination of fuels and loss of the ILs, which thereby changes the quality and composition of the fuel. The solubility of the fuel in ILs leads to loss of fuel and an increase in separation cost; and (2) extraction of important HC components with sulfur compounds (Gao et al. 2016). According to the literature study, ILs are generally soluble in various organic compounds, such as acetone, methanol, ethanol, and water, but not soluble in octane, hexane, toluene, or heptane (Ferreira et al. 2014). Mutual solubilities of RF oils are measured by the weight variation of an IL saturated with RF before and after the removal of the IL. It is proven that the solubility of diesel in ILs is less compared to the solubility of gasoline in ILs. Changing the anions of ILs can change their solubility (Asumana et al. 2010; Chen et al. 2014; Luo and Barrufet 2005). To understand the application of ILs as an extractant, the solubility mechanism needs to be understood. The extraction of the organic sulfur compound, ILs with low water solubility, is desirable since the higher the water solubility, the lower the extraction ability for organic compounds. This type of behavior is due to the intrinsic equilibrium competition between water and an organic compound. Hence, mutual solubility of IL and fuel becomes another important property of the selectivity of ILs (Gao et al. 2017).

The conductivity of ILs also needs to be measured because the conductivity of ILs can be changed by exchanging anions (Faridbod et al. 2011). It depends on the mobility of cation because the diffusion coefficients of ILs cations are significantly higher than the anions. Generally, ionic conductivity is proportional to the number of charge carrier ions and their mobility (Dharaskar et al. 2013; Ghandi 2014).

Extractive desulfurization using ionic liquids (ILs-EDS)

As previously discussed, the achievement of fuel with ultra-low sulfur content is a challenging issue (Aitani and Ali 2013). ILs have unique characteristics that can help in the successful accomplishment of this goal. They have extraordinary benefits over conventional solvents, such as negligible vapor pressure, high thermal stability, designability of ILs as per the application, and moisture tolerance and can be used with reductants as well as oxidants (Dharaskar et al. 2015a). ILs are usually used in EDS and ODS of fuel. In ILs-EDS, the ILs are employed as extractants, while in ILs-ODS, the ILs are employed as catalysts, extractants, or combination of both.

Initially, in EDS, conventional solvents such as methanol, acrylonitrile, sodium hydroxide, and polyalkylene glycol were used, but now it has shifted to ILs due to their benefit. ILs have a higher density than water and volatile organic solvents and form biphasic systems. Therefore, ILs are good extractants. However, sensitivity toward moisture is a crucial factor as it affects the absorption efficiency. Various task-specific ILs can be designed by altering their cations and anions, which increases the selectivity of EDS using ILs (Domańska and Wlazło 2014). Bosmann and his group reported the first article on EDS using ILs (Bösmann et al. 2001). The workflow of the ILs-EDS process is shown in Fig. 3.

The selection of ILs for fuel desulfurization requires certain characteristics, such as that they should be immiscible in fuel, have high selectivity toward sulfur compounds, have high thermochemical stability and regeneration, and recycling of ILs must be effective. The study of the regeneration of ILs is essential to make the process economically feasible. ILs can be regenerated by either washing with water in the case of hydrophobic ILs and organic solvents such as diethyl ether, ethyl acetate, or by distillation in the case of hydrophilic ILs (Dharaskar et al. 2018b).

In 2014, Abro et al. reviewed the role of IL as an extractant in the ILs-EDS process. They have addressed various parameters affected by the ILs-EDS process, such as extraction conditions, regeneration effect, and multistage extraction. The ILs mentioned in this study are usually the common traditional ILs available commercially (Abro et al. 2014). The physicochemical properties of ILs play a significant role in the extraction process, which is discussed in this study. Various research groups have developed the task-specific ILs for the ILs-EDS process. So, in this study, the influence of these newly developed ILs and the effects of all the parameters affected by the ILs-EDS process are discussed in detail. To fully comprehend the process, the mechanism responsible for the ILs-EDS process must be examined. Because RFs contain a variety of S-compounds, it is difficult to remove all of the sulfur compounds at once. Because every S-compound acts differently, knowing the influence of these S-compounds on the ILs is critical for applying the ILs-EDS method to industrial applications.

Thermodynamic extraction equilibrium

Thermodynamic extraction equilibrium is a key factor to investigate for any separation process because it provides the time required to get the maximum yield. The short time can give high product yields or small contact equipment in the industry. As per the literature survey, the time determined by the thermodynamic extraction equilibrium study for the ILs as an extractant is directly dependent on the viscosity of the ILs (Toledo Hijo et al. 2018). High-viscosity ILs took 30 to 40 min to reach equilibrium, whereas low-viscosity ILs may take less than 10 min (Navarro et al. 2018). The feasible reason behind these changes could be that the low-viscosity ILs have better dispersion in fuel and thereby faster mass transfer of sulfur compounds from the organic phase to the IL phase (Guangren et al. 2012). The reason behind the lower extraction equilibrium time using ILs is that these ILs enhance the mass transfer between fuel and ILs.

Influence of extraction temperature

According to the literature survey, extraction operating conditions such as extraction temperature and time are very significant parameters and have a wide impact on sulfur extraction and the respective partition coefficient (KN). Extraction temperature plays an influential role in the extraction efficiency as it directly relates to the viscosity of ILs. The reported works demonstrated that when the ILs-EDS is performed with low-viscosity ILs, the KN and extraction efficiency decrease slightly with increasing temperature, while the opposite trend is observed with high-viscosity ILs (Asumana et al. 2010; Ibrahim et al. 2015; Li et al. 2015a). This trend was observed in the study by Dharaskar and Joshua raj (Dharaskar et al. 2018b; Raj et al. 2018). The same trend was also observed in some low-viscosity ILs ([Bmim][HSO4], [Hmim][HSO4], [Bmim][N(CN)2], [Emim][N(CN)2]) and high-viscosity ILs ([TDA][SA], IL(n = 60,benzyl,Cl_)/NaCl, [TBCMP][Br]) (Asumana et al. 2010; Chen et al. 2014; Kianpour et al. 2016; Wang et al. 2020). Just like the EDS of MF, the sulfur removal efficiency of RFs using low-viscosity ILs such as [C2mim][OAc] is found to be highest at low temperatures.

On the contrary, the EDS of RFs with high-viscosity ILs is enhanced with an increase in temperature. This alteration can be understood by the alteration in the viscosity of ILs with temperature. For high-viscosity ILs, as the temperature increases, the viscosity of ILs decreases, and thereby they can easily interact with the sulfur leading to high desulfurization efficiency (Jian-long et al. 2007; Li et al. 2019). The summary of this is that the low-viscosity ILs are more advantageous at room temperature in terms of energy consumption and desulfurization efficiency. In addition to this, we can also conclude that the higher extraction temperature has little or no effect on sulfur removal. Therefore, the EDS at ambient temperature is preferable as it consumes less energy.

Influence of mass ratio of ionic liquid to fuel

The influence of ILs on the ILs-EDS is usually expressed in terms of the mass ratio of ionic liquid to fuel. It is the most crucial factor because of the well-known fact of the high cost of ILs. Therefore, it is always preferable to utilize the least quantity of ILs in the desulfurization of fuel. According to the literature survey, the sulfur removal usually increases with the increase in the quantity of ILs. For example, the m(IL/MF) was analyzed for 5 min and observed the order of extraction efficiency. It follows the order of 1:5 < 1:3 < 1:2 < 1:1 < 1:1 m(IL/MF) (Wang et al. 2020). The similar trend was observed in the study of Ibrahim and his group where dicyano(nitroso)methanide-based ILs were used to examine the influence of ILs (Ibrahim et al. 2015). The effect of KN was also observed and proved that the variation in KN was not extreme with the variation in m(IL/MF) mainly in the physical extraction (Dharaskar and Sillanpaa 2018b). Variation of KN may be sensitive to chemical extraction. The ILs with low viscosity such as [Bmim][HSO4] were less sensitive than the ILs with high viscosity such as [EPy][NO3] (Jian-long et al. 2007). Though EDS efficiency increases with an increase in the mass ratio, the rate of increase is not the same. As per the data shown, the sulfur extraction efficiency of RFs using high- and low-viscosity ILs and the maximum desulfurization efficiency was obtained at 2:1 and lowest at 1:5 m(IL/RF), respectively (Gao et al. 2014a; Jiang et al. 2008; Lu et al. 2014b). The rate mainly depends on the chemical nature of ILs and how it is related to their extraction ability. The rate of increase in sulfur removal is much sensitive in the case of high-viscosity ILs. Therefore, the mass ratio of IL to fuel must be selected carefully by considering the oil recovery and recycling of ILs as they have much effect on the overall cost of the process.

Influence of initial sulfur content

The ISC of fuel is another important factor that needs to be measured to make the process feasible. As shown in Table 2, the ISC of the fuel has little or no influence on the performance of ILs-EDS. Various ILs exhibit different extraction mechanisms, but the variation of ISC is almost insignificant. However, the study of Ibrahim and his group dealt with the dcnm-based ILs and showed that the increasing ISC of fuel decreases the extraction efficiency (Ibrahim et al. 2015). This variation of desulfurization efficiency with ISC is extremely valuable when dealing with industrial oil with a wide range of sulfur contents. The insensitivity to ISC is desirable for the practical applicability of ILs-EDS.

Regeneration and recycling of ILs

The most significant feature for the selection of ILs is the regeneration and recyclability of ILs. It can compensate for the high cost of ILs. During the regeneration of sulfur-containing ILs, the S-compounds are repelled in the absence of a solvent molecule (Jiang et al. 2015). The regeneration of sulfur-containing ILs depends on two parameters. One is the type of sulfur compounds, and the other is the nature of ILs. Regeneration of hydrophilic ILs prefers dilution with water followed by distillation of ILs and recycled back for the next cycle, while the regeneration of hydrophobic ILs prefers distillation followed by adsorption (Fernandez et al. 2012; Kuzmina 2016; Mai et al. 2014). The significant advantage of regeneration of IL is the unchanged structure of ILs after regeneration. After regeneration, ILs are recycled without a significant decrease in the desulfurization efficiency. The reported literature on the regeneration of ILs is presented in Table 3. It proved that the low-viscosity ILs can be more easily regenerated than the high-viscosity ILs. The regeneration of IL compensates for the cost of ILs.

Multistage extraction using ILs

The necessity of multistage extraction becomes inevitable to meet the environmental standards, say, less than 10 ppm in a single extraction. The reason behind this may be the KN between the IL and fuel, which makes allowable sulfur level in single extraction almost impossible. In multistage extraction, after completion of the first extraction, the oil phase and the IL phase are separated. Then, a certain amount of fresh IL is added at the same experimental condition and the same procedure is repeated (Gao et al. 2008). Li et al. used [C4(Mim)2](HSO4)2 to perform a multistage extraction on FCC gasoline which reduced the sulfur content of MF from 747 to 396 ppm in a single extraction at 1:1 m (IL/RF) at 30 °C for 30 min, and it was reduced to 15 ppm after five extraction cycles (Li et al. 2019). Yu achieved 100%, 88%, and 91% S-extraction for gasoline 93, gasoline 90, and light hydrocarbon oil after four stages. They reported that multiple extraction is a promising way to achieve the allowable sulfur content in fuel. As discussed earlier, single-stage extraction cannot obtain fuel with allowable sulfur content, but if we compare the extraction ability of various ILs in a single-stage extraction, the low-viscosity ILs can give better extraction performance than the high-viscosity ILs (Yu et al. 2020). The same trend was observed for the RFs. [Et3NH]Cl-FeCl3/CuCl2 was applied for the desulfurization of FCC gasoline, and 94.30% extraction efficiency was achieved after four extraction cycles (Wang et al. 2014). Kianpour et al. (2016) used [TBCMP][Br] at room temperature at m(IL/fuel) = 0.88 for 10 min on MF containing DBT, BT, and 4,6-DMDBT, and the sulfur content was reduced to 10 ppm after four extraction cycles (Kianpour et al. 2016). The desulfurization of RF at an ultra-low sulfur level can be achieved by multistage extraction, and the use of ILs can be paid back by their excellent recyclability. The performance of ILs-EDS using some ILs-assisted multistage extraction is summarized in Table 4.

Influence of various sulfur substrates

The effect of various sulfur substrates is very essential to analyze for its practical applicability as the RF has several S-compounds present in it. The efficacy of ILs for different sulfur compounds as an extractant may vary as per the nature of sulfur compounds. The order of extraction capacity of ILs for various sulfur substrates depends on two factors: the electron density of sulfur compounds and the steric hindrance. Usually, the fuel contains various recalcitrant compounds such as TH, BT, DBT, and their derivatives. As shown in Table 5, the extraction ability of most of the ILs follows the order of DBT > BT > TH. The reason behind this is the decreasing order of electron density (DBT (5.758), BT (5.739), TH (5.696)). Gao et al. performed ILs-EDS using various pyridinium-based ILs for the desulfurization of MF containing DBT, BT, and 4,6-DMDBT and achieved the order of extraction ability of DBT > BT > 4,6-DMDBT. The extraction of DBT is greater than BT due to the higher electron density, while the lower extraction efficiency of 4,6-DMDBT is due to the steric hindrance of a methyl group attached to the 4th and 6th positions, though the electron density of 4,6-DMDBT is higher than BT (Gao et al. 2015). The same trend was observed by Yu et al. and Dharaskar et al., even in the case of TH and 3-MT (Dharaskar et al. 2018b; Yu et al. 2016). However, in the study of Domanska et al., the extraction ability of a series of imidazolium, pyridinium, and piperidinium cations and DCA, NTf2, and TCM anion-based ILs was observed to follow the order of TH > BT > DBT (Domańska and Wlazło 2014).

EDS mechanism in ILs-EDS

The interaction between S-compounds and IL plays a significant role in the extraction ability of S-compounds using ILs. The mechanism behind the ILs-EDS process needs to be understood for the success of the process. The plausible mechanism behind the ILs-EDS process is listed in Fig. 4. π–π interactions are the key mechanism underlying the desulfurization of recalcitrant sulfur compounds with traditional ILs containing aromatic cations such as imidazolium and pyridinium. As we discussed earlier, in the ILs-EDS process, the IL extracts the sulfur compound present in the fuel phase and transfers it to the IL phase. To understand the proper mechanism behind this extraction process, Moghadam et al. studied the interaction energy between [TBHPP][Cl] and DBT and performed NBO analysis using DFT calculations to understand the strength, type, and nature of interaction between IL and DBT using the Gaussian 09 program. They have derived that this IL has two alcoholic and two acidic functional groups; this IL with a glyceryl moiety is extremely advantageous due to its lack of corrosiveness, neutrality, and eco-friendliness (Moghadam et al. 2017b). A mechanism of series of acid dicationic ILs as extractants was derived by Li et al. Su et al. developed a mechanism for a series of acid dicationic ILs as extractants. They demonstrated that the π–π interaction between the sulfur compound and the cations of ILs is maintained by using H-NMR studies of BT and DILs before and after extraction. In addition, the influence of hydrogen bonding and CH–π interactions between the IL-cation and aromatic sulfides (Su et al. 2004) is studied. A DFT study of ILs-EDS mechanism using [BMIM]+[AlCl4]− for the extraction of TH, BT, and DBT is discussed. They also consider the solvent effect, structural analysis, RDG analysis, and energy decomposition analysis. They proved that both the cation and anion are significant for the π–π interaction and hydrogen bonding interaction (Li et al. 2015b). Kianpour et al. has also studied the mechanism behind the [TBCMP][Br] with DBT; he proved that there is a hydrogen bond between the OH of the carboxylic group attached to [TBCMP]+ with the sulfur atom in DBT. NBO analysis shows that the charge is transferred from lone pair of S to σ* OH (Kianpour et al. 2016). Li et al. have explained the EDS mechanism behind Cu(II) and Zn-based imidazolium ILs using the interaction effect of ILs and DBT. They claimed that the π–π induction due to the aromatic nature of both the compounds and CH–π interaction between cation and aromatic nature of DBT is responsible for the effective performance of the ILs-EDS system. Yu et al. have developed polyether-based ILs and explained that the electrostatic force, hydrogen bonding, and π–π interaction are the three significant aspects responsible for the effective extraction of S-compound using the synthesized IL (Yu et al. 2016)(Fig. 5). Another group of Jaganathan Joushua Raj has studied COSMO-RS analysis of ILs-EDS system using ester-functionalized IL and claimed that the longer alkyl chains, aromatic ring, and ester functional groups in the cation of ILs are the contributing factors for excellent extraction ability (Raj et al. 2018). Overall, the good performance of ILs-EDS depends on the CH–π interaction between cation and S-compound, π–π interaction, electrostatic attraction, hydrogen bonding interaction, and π-complexation interactions between ILs and S-compounds, and so on (Wilfred et al. 2012).

Feasible mechanism during ILs-EDS process (Abdullah et al. 2018)

ILs-EDS mechanism by polyether-based ILs (Yu et al. 2016)

Desulfurization of RFs using ILs-EDS

Application of ILs on the MFs using all the mentioned techniques is discussed by several researchers, but very few studies were done on the application of those processes on actual fuels. Application of ILs on the desulfurization of fuel is complicated than the MFs owing to the presence of more complex S-compounds. Nitrogen compounds present in fuels also create hindrance on the performance of desulfurization processes and utilization of ILs. Desulfurization of RFs using ILs-EDS processes is summarized in Table 6. It is observed that the ILs-EDS is not much effective on the desulfurization of RFs in single stage. It requires multistage extraction using ILs, which can reduce sulfur compounds to some extent but does not satisfy the allowable S-content. This proves that it requires re-/post-treatment to reach the environmental standards.

Challenges and future perspective of ILs-EDS

Nowadays, the demand for ultra-low sulfur fuels increases day by day, and many countries have committed to bringing down the allowable sulfur content to less than 10 ppm. Thus, the alternative processes will continue to be studied thoroughly because of the difficulty of the HDS process in meeting the demands. The ILs over VOCs have won global interest.

S-extraction efficiency using high-viscosity ILs is not very effective. Multistage extraction is usually required to achieve a sulfur content < 10 ppm. Even though extraction equilibrium time is also as long as 30 min, low-viscosity ILs are preferable as they give higher extraction efficiency at lower temperatures and times and offer the necessary energy consumption for regeneration and mixing. Due to the well-known fact that ILs are very expensive, the responsible factors need to be extensively studied. These factors include their regenerability, mutual solubility with oils, thermochemical stability, etc.

Application of ILs instead of common organic solvents in ODS cuts the loss of solvents and safety issues. ILs can be recycled with or without regeneration without a noticeable change in activity. The influence of the structure of ILs on properties and desulfurization has also been presented here. The properties of ILs can be tailored by altering their molecular structures. Therefore, there is still a great chance to synthesize task-specific IL for the oxidation reaction.

The reported literature focused primarily on ILs-EDS for MFs. The focus on the RF study needs to be examined as it has more complicated mixtures of sulfur and other compounds which can make the EDS difficult. This is a must for small-scale to large-scale applications.

Oxidative desulfurization using ILs (ILs-ODS)

ODS is a technique that involves first oxidizing sulfur compounds to their respective sulfoxides or sulfones and then extracting them with a suitable extractant. It can produce the ultra-low sulfur fuel at mild operating conditions. The high polarity of sulfones makes the separation easier. Oxidation reaction changes some important properties such as density, boiling point, solubility, and polarity of sulfur compounds (Green et al. 1993). Figure 6 represents the general experimental workflow of the ODS process.

As discussed earlier in the Introduction and ILs-EDS, ILs have several advantages over VOCs. However, it has a limit in terms of the co-extraction of the other required aromatic compounds in the fuel and, thereby, some of the ILs achieve low sulfur removal. Therefore, the concept of the application of various oxidants with ILs comes into the picture to increase the selectivity and sulfur removal. The first report on ILs-ODS was performed by Lo and his group in 2003 (Lo et al. 2003). In their study, [Bmim]PF6 and [Bmim]BF4 were used as an extractant for the removal of DBT in tetradecane. In the ODS process, ILs can act as phase transfer catalysts, extractants, or both. ILs can also be designed in such a way so that they can serve as oxidants. The influential factors to be analyzed in the ODS using ILs are the influence of oxidant concentration, reaction conditions (T, t), quantity of IL, and recyclability of IL. The schematic of ILs-ODS is presented in Fig. 7.

Schematic of non-catalytic ILs-ODS (Ahmed et al. 2016a)

Ibrahim and his coworkers explored the significance of ILs in desulfurization procedures in 2016. They have talked about the structure, development, and use of ILs in various processes. They also talked about the ILs-ODS pathway and its impacts on S-conversion to sulfoxides. Other reagents’ effects on the ILs-ODS pathways are not addressed in depth (Ibrahim et al. 2017). Bhutto and his crew discussed the ODS utilizing several sorts of ILs in 2016. They examined the various IL-based oxidation methods and their impact on desulfurization efficiency. They spoke about the impact of process factors on the ILs-ODS process (Bhutto et al. 2016). The ILs-aided desulfurization procedures have also been explored by Zolotareva and his research groups. They have spoken about the many sorts of ILs utilized in HDS, EDS, and ODS (Zolotareva et al. 2019). To achieve a better desulfurization efficiency, different reagents such as oxidants, catalysts, extractants, and phase transfer agents are employed in the ODS process. Understanding the usage of one reagent in the presence of other reagents is critical, the effects of all these factors, as well as the mechanism responsible for the process, were explored in this study for the two-step ODS, one-pot ODS (ECODS), and OEDS processes. With a comparison of the most recently published publications, the role of ILs in all processes as extractants, catalysts, or extractants/catalysts is also explored. In various ODS procedures, the selectivity and reactivity of various S-compounds and ISCs are compared and studied in depth. The usual ILs-ODS are discussed in Table 7, which can also be considered as an OEDS process.

Extractive and catalytic oxidative desulfurization using ILs (ILs-ECODS)

The application and the role of ILs in the ILs-ODS process depend on the way they are introduced into the system. As we have discussed, ILs can act as extractants, catalysts, or both in the ILs-ODS system. Researchers introduce ILs into the ODS system in three different ways. In the first method, ODS using catalyst, oxidant, and MF/RF is carried out at some specific temperature for a specific time, and then the upper fuel phase is removed and the separated fuel is extracted with IL for further sulfur reduction. This is the usual ILs-ODS process discussed in the previous section, which is also known as the oxidative extractive desulfurization process (OEDS). The second way is to introduce IL in the first stage and mix it with the fuel at specific temperature till the mixture reaches the thermodynamic equilibrium stage. Then, the oxidant, catalyst, and phase transfer agent, if any, are introduced to the system and the process is carried out. This process is known as two-step extractive and catalytic oxidative desulfurization (ECODS). The second method is to introduce all the reagents such as IL, oxidant, catalyst, and MF/RF. This method is known as the “one-pot ECODS process.” The schematic of the one-pot ECODS is shown in Fig. 8. The ECODS process combines the extractive (ILs-EDS) and oxidative (ILs-ODS) processes, which can overcome the disadvantage of both processes. One-pot ILs-ECODS process is more advantageous as it gives high desulfurization efficiency in a single stage and can also reduce the utilization of ILs, which is extremely significant for its economic feasibility. Table 8 summarizes the one-pot and two-step ILs-ECODS processes.

Influence of oxidant and catalyst system

The oxidant, catalyst, phase transfer agents, and pH controller are the most influential reagents for the oxidation reactions. The influence of all the reagents is carefully investigated and presented in this work. ODS was first examined using methanol as a solvent and nitrogen dioxide as an oxidant. Oxidants donate oxygen atoms to sulfur compounds and convert them into sulfoxides or sulfones. The number of oxidant-catalytic systems has been invented (Hossain et al. 2019). Out of all these, hydrogen peroxide is one of the best oxidants due to its ease of availability, low cost, non-polluting, and non-strongly corrosive nature (Ahmed et al. 2016a). The quality and quantity of oxidants play a key role in the ODS process. However, Mello and his group have shown that H2O2 obtains a very low desulfurization efficiency when used without a catalyst or pH controller (Mello et al. 2009). Therefore, several catalysts were examined with H2O2, such as acetic acid, phosphotungstic acid, polyoxometalate, solid bases, metal-based catalysts, sodium carbonate, and tungsten-based catalysts (Amani et al. 2011; Chao et al. 2010; Deshpande et al. 2005; Liu et al. 2020; Ren et al. 2015; Trakarnpruk 2006; Zhang et al. 2014b).

Generally, it was observed that oxidation performance was enhanced over the pH range of 1.4–2.2 in H2O2–HCOOH (De Filippis et al. 2009). The pH of the aqueous phase plays a key role since the decomposition rate of hydrogen peroxide to excited hydroxyl radicals changes in the case of metal-based catalysts. Another research group had proved that the oxidation rate of diesel fuel was strong when the pH of the aqueous medium was in the range of 1.9 to 2.1 in the presence of metal ions under the effect of ultrasound irradiation (Dai et al. 2008; Zhao et al. 2018).

As discussed earlier, hydrogen peroxide was proven as the best oxidizing agent for the conversion of the sulfur compound to sulfone. However, it has some drawbacks when used on large scale, such as corrosiveness, difficulty in storage in large quantities, and the presence of excess water as a by-product. To deal with these types of problems, Carnaroglio et al. applied several solid oxidants, including potassium superoxide, oxone, and sodium persulfate. Oxone was the best oxidizing agent among all other solid oxidants (Carnaroglio et al. 2014).

The catalyst promotes selectivity and enhancement of the reaction rate in the ODS process. It decomposes oxidants at a faster rate and forms more exciting free radicals. Carboxylic acid gave the best results as a catalyst for the desulfurization process. Formic acid and acetic acid both obtained a higher efficiency than the propanoic acid. Duarte et al. optimized the molar ratio of acetic acid/sulfur to 300:1 and achieved sulfur removal of 97% (Duarte et al. 2011). The effect of another catalyst such as sodium carbonate, phosphoric acid, or nickel heteropolyacids was also used by the researchers (Deshpande et al. 2005; Gonzalez et al. 2012; Wang et al. 2013).

Role of ILs in ILs-ECODS

As per the survey, the production of ultra-low sulfur fuels is both the trickiest and most important goal to obtain, considering the depletion of low sulfur-containing oil reservoirs. ILs have a significant role in achieving this goal. ILs have many benefits compared to volatile organic compounds, such as negligible volatility, moisture tolerant, and chemically and thermally stable. The designability of ILs makes them work as phase transfer catalysts, extractants, and oxidants. ILs are good solvents for the extraction of sulfur compounds because they usually have a higher density than water and organic liquids and form a biphasic system. Moisture sensitivity is also a crucial factor in determining absorption efficiency because a small number of polar compounds such as water can decrease absorption efficiency.

The general criteria for ILs to be used as an extractant in the ODS process are as follows: (1) Its partition coefficient should be high, (2) insoluble in gasoline, (3) sulfur compounds are highly selective, with no other desired compounds extracted from the oil, (4) easily recyclable and regenerable, and (5) cost-effective, as a green solvent with high thermochemical stability.

First, oxidation and extraction combinations using ILs were carried out by Lo et al. and applied for the ultra-deep desulfurization of fuel oils. He has observed that the desulfurization efficiency of simultaneous oxidation and extraction using ILs increases by an order of magnitude compared to simple extraction using ILs (Lo et al. 2003). ILs provide the oxidation conditions and also work as extractants. A transition metal or organic acid, such as acetic acid or formic acid, is required as a catalyst. He also found that [Bmim]PF6 was more effective than [Bmim]BF4. Zu et al. (Xu et al. 2012) have proposed oxidative–extractive desulfurization of DBT in the presence of H2O2 using [Bmim]BF4. However, BF4− and PF6− emit white fumes of HF, which lead to environmental concerns.

In the study of Balinge et al., carboxylic acid-based ILs were worked as catalysts as well as extractants and have shown sufficient oxidation ability. The use of acid-based ILs has led to excellent results without the addition of an external catalyst (Balinge et al. 2016). This acidic nature of ILs allows them to work as both extractants and catalysts. Thomazeau et al. have determined the acidity scale and catalytic activities (Thomazeau et al. 2003).

Jiang et al. studied various amide-based ILs for BT and DBT removal. [HCPL][TFA] evidenced the best results and achieved 100% sulfur removal in a very short time. The sulfur content of real hydrogenated diesel reduced from 659.7 ppm to 8.62 ppm after two stages, and with a similar S-removal rate, the total S-content of the straight-run diesel fuel was reduced to 89.36 ppm from 11,034 ppm (Jiang et al. 2016). Fenton-like ILs achieved 97.9% desulfurization efficiency for DBT containing MF and 69.45% for RF (Jiang et al. 2011).

Extraction–oxidation by pyridinium-based task-specific ILs (([CH2COOHPy][HSO4] and [(CH2)2COOHPy][HSO4]) were prepared by Zhang and his group. The ILs were applied as catalysts and extractants for ECODS of MF. The [CH2COOHPy][HSO4] showed better performance for DBT removal and obtained 99.9% sulfur removal at n(O/S): 6, V(MF/IL): 20/1.2 at 30 ˚C. This IL can be recycled nine times effectively (Zhang et al. 2012).

Fang et al. derived the desulfurization ability of ILs with imidazolium as a cation in the following order: TFA− > HSO4− > COO− > AlCl4− > AcO– which shows that the higher the acidity, the higher the desulfurization efficiency. He also observed the effect of imidazolium and pyridinium-based cations with HSO4− and derived that imidazolium cation has a better extraction ability than pyridinium (Fang et al. 2014).

Borja R Cabro have applied a series of ILs for ECODS of MF as well as gasoline and diesel. The ILs followed order as [C26;4-mmpy][NTf2] > [C2mim] [NTf2] > [C2mim][Et2PO4] > [C2mim][OAc]. The S-removal ability is clearly maximum for the [NTf2]− based ILs, with desulfurization of 96.5% and 82.0% for [C26;4-mmpy][NTf2] and [C2mim][NTf2], respectively (Rodríguez-Cabo et al. 2014).

In the study conducted by Guo and his research group, [C5mim]2[S2O8] and [C5mimCl][CoCl2] were synthesized and used as an oxidant and catalyst/extractant, respectively (Guo et al. 2019). They have examined the influence of IL on both extractive and oxidative–extractive desulfurization. The dosage of [C5mimCl][CoCl2] was observed for 25 min, and the sulfur removal increased from 23.5 to 97.0% when the [C5mimCl][CoCl2] dosage increased from 0.5 to 1.5 g. However, a further increase in [C5mimCl][CoCl2] up to 3 g resulted in a slight decrease in the sulfur removal to 96.0% as shown in Fig. 9a, and the influence of [C5mim]2[S2O8] dosage of 0.5 g was chosen as the optimal loading for subsequent experiments and achieved 96.9% sulfur removal as presented in Fig. 9b.

Influence of IL as a a catalyst/extractant and b an oxidant (Guo et al. 2019)

Gao et al. has performed with multiple oxidative desulfurization using four different ILs at optimized conditions. One-step oxidative desulfurization efficiency follows the order [(CH2)4SO3HMIm][Tos] > [(CH2)4SO3HMIm][ZnCl3] > [Hnmp][HSO4] > [Hnmp][ZnCl3] with the efficiency of 43.7%, 40.7%, 38.6%, and 35.2%, respectively. As shown in Fig. 10, the desulfurization efficiency of 84.7%, 73.1%, 68.2%, and 78.4% after five-step oxidation by [Hnmp][ZnCl3], [Hnmp][HSO4], [(CH2)4SO3HMIm][ZnCl3], and [(CH2)4SO3HMIm][Tos], respectively (Gao et al. 2017).

Effect of multiple ODS stages using ILs (Gao et al. 2017)

Supported ILs are advantageous as they reduce the consumption of ILs. These types of ILs are easily synthesized by coating a certain quantity of ILs on a solid carrier. Zhang et al. performed the desulfurization using acidic polymeric-based ILs-supported graphene oxide and obtained sulfur removal up to 98.3% within 1 h. The demerits of heterogeneous catalysts are the lower exposure of reactants to catalyst active sites and the requirement of high reaction time (Zhang et al. 2018).

Elwan and group synthesized pyridinium-based IL, namely butyl-4-methylpyridinium benzoate. 98.9% of desulfurization efficiency was observed at 60 °C, 30 min, m(IL/MF): 1/1, and n(O/S): 8/1. π–π interactions between IL and aromatic S-substrate were suggested to be the driving force behind the extraction ability of IL (Elwan et al. 2020).

Ge and his group developed a catalytic oxidation IL emulsion system containing IL, H2O2, and catalyst. Here, [C18H37N(CH3)3]7[PW11O39] acts both as a catalyst and as an emulsifying agent. It provides a higher interfacial surface area where the oxidation occurs. The IL emulsion acts as highly dispersed microreactors during the reaction. The S-compounds in the model oil were first extracted into the IL emulsion phase and then oxidized at IL/H2O2 interface. After the reaction, the system generates two separate layers and the organic phase is separated easily by simple decantation (Ge et al. 2011).

Sulfur compounds are extracted from the nonpolar organic fuel to the polar ILs in the photocatalytic oxidation followed by IL extraction. Here, sulfur compounds are oxidized to sulfones in the IL phase in the presence of molecular O2, H2O2, or photosensitizers and TiO2 and modified TiO2 using [Bmim]BF4 (Zhu et al. 2014). A similar type of study was done by Zaid et al. where they studied Cu-modified TiO2 photocatalyst and eutectic-based IL was used for the desulfurization of MF (Mohd Zaid et al. 2014).

Alkylation of sulfur compounds avoids side reactions during the oxidation reaction, and the separation of sulfones from fuel oil becomes easier. Rafael reported various Lewis and Bronsted acidic IL as the catalyst in alkylation desulfurization (Martnez-Palou and Flores 2011).

Influence of operating conditions

According to the previous literature, increasing oxidation time increases the desulfurization efficiency due to better contact time between immiscible phases. It allows time for polar sulfones to penetrate into an aqueous phase. Guo et al. optimized the reaction time by 65 min and achieved 98.7% DS efficiency (Guo et al. 2019). Furthermore, Balinge et al. (2016) found that increasing reaction time increased S-removal efficiency by up to 100% in 180 min at 70 °C (Balinge et al. 2016). Again, the same trend was presented by Chao et al. and suggested that by increasing the oxidation time to 3 h, the migration of sulfones into the aqueous phase increased, and 99.7% sulfur removal was attained (Chao et al. 2010). A similar trend of increasing time was observed by Zhang et al., and they obtained 98.9% sulfur removal in 30 min as shown in Fig. 11a. On the contrary, some research groups have proved that incrementing reaction time more than the optimum value could cause the decomposition of H2O2. Zhao et al. worked on the same idea and achieved a 5-h oxidation time for 99.8% sulfur removal, compared to 99% at 6 h of oxidation time (Zhao et al. 2009c). The effect of time on desulfurization efficiency using polyoxometalate-based IL and also modified IL by Mirante et al. is discussed and achieved 80 min as the optimum time as shown in Fig. 11b. The results explain why there was almost no change in desulfurization efficiency after 80 min. To make the process economically viable, the optimum time needs to be found.

Many researchers focused on the effect of reaction temperature, which has a significant impact on reagent physicochemical properties. A wide range of temperatures were investigated across the literature. Oxidation reactions are typically carried out at temperatures ranging from 30 to 90 °C (Houda et al. 2018). It is seen that when the oxidation reaction temperature increases, the sulfur removal also improves. At higher temperatures, the formation becomes peroxide speedy and improves the conversion to the respective sulfones. Some research groups suggest that a temperature higher than the optimum temperature is not favorable for sulfur removal due to the decomposition of hydrogen peroxide at a higher temperature. Therefore, oxidation using ionic liquid could be performed at mild temperatures of between 40 and 60 °C. The nature and type of ILs play an important role in determining the optimum temperature of an ionic liquid. The viscosity of IL plays a significant role in determining the optimum temperature of the reaction. Low-viscosity ILs like [BMIM][N(CN)2] and [BMIM][SCN] have a slight decreasing trend or have no effect on desulfurization efficiency and sulfur partition coefficient with temperature.

In contrast, high-viscosity ILs such as [BMIM][PF6] and [Epy][BF4] can have a moderate effect on desulfurization, and [HNMP][HSO4] has a higher effect on desulfurization efficiency with an increase in temperature (Abro et al. 2016; Chen et al. 2012a; Sander et al. 2016; Wang et al. 2011). This phenomenon can be easily understood by the relation between the viscosity of ILs and temperature. As temperature increases, the viscosity of highly viscous ILs decreases and the contact between the sulfur content and the ILs becomes more effective, resulting in high desulfurization efficiency. So, the low-viscosity ILs are more advantageous over the high-viscosity ILs as they result in high desulfurization and low energy consumption at room temperature. The influence of temperature on the oxidation reaction in the range of 40 °C to 60 °C was examined by Zhang et al. Results showed that increasing temperature promotes the performance of more than 90.1% of DBT (Zhang et al. 2017).

Nowicki et al. claimed that incrementing temperature from 30 to 50 °C enhances sulfur removal using amphiphilic imidazolium ILs and found that the best performance was obtained by [C4mim]HSO4 at both the temperatures and achieved 98.9% and 99.9% DBT removal, respectively (Nowicki et al. 2019).

The survey conducted by Liu et al. and shown in Fig. 12 shows a steep decrease in sulfur as temperature increased from 60 to 80 °C and then again from 80 to 100 °C. At 100 °C, the maximum sulfur removal was 3.1 wt% (Liu et al. 2020). Yang et al. optimized the reaction time of 60 °C for different sulfur loadings catalyzed by immobilized ionic liquid on MIL-100 (Fe) (Yang et al. 2019).

Influence of temperature on sulfur removal using imidazolium-based IL (Liu et al. 2020)

Influence of mass ratio of ionic liquid to fuel

The mass ratio of IL to fuel is a key factor in the selectivity of IL in oxidative–extractive desulfurization using ILs. It is a well-known fact that most ILs are costly, and to reduce the cost, the quantity of ILs must be as small as possible. An increase in the mass ratio of IL/fuel increases the sulfur removal. Lu et al. investigated the mass ratios of [Bmim]PF6/MF at 120 min. They observed the DBT removal of 99% at a 1:10 mass ratio, while Julião et al. achieved 84% sulfur removal using mass ratios of [Bmim]PF6/MF as 0.3:1 (Julião et al. 2010; Lu et al. 2014a).

The study by Mochizuki et al. explained that the desulfurization of DBT increased with an increase in the alkyl chain length and the mass ratio of IL/fuel. However, the mass ratio of IL/fuel is not the universal rate. It depends on the chemical nature of IL (Mochizuki and Sugawara 2008).

Chen et al. examined the influence of the mass ratio of [hnmp]Cl/ZnCl2/fuel on desulfurization efficiency and achieved 100% DBT removal at a 1:10 mass ratio of IL/fuel, which shows that the amount of IL plays a vital role in the removal. Sulfur removal increased when the IL/MF ratio was increased (Chen et al. 2015b). Desulfurization performance can be reduced after an increase in the mass ratio of IL to fuel. The reason for this was that increasing the IL/fuel mass ratio to some level reduced the O/S molar ratio, and so fewer sulfur compounds were oxidized. The selection of the mass ratio of IL to fuel needs to be done carefully as it affects the cost of the process. Recycling and regeneration of ILs can reduce the overall cost of the process.

Influence of recycling of ILs with and without regeneration

After each oxidation–extraction process, the IL can be recycled and regenerated without much reduction in activity. Recycling and regeneration of ILs are significant features for the selectivity of ILs as they can compensate for the high cost of ILs (Houda et al. 2018). Various techniques can be used for regeneration of ILs, and the selection of regeneration of sulfur-containing ILs depends on the type of sulfur compounds and the nature of ILs. If the applied IL is hydrophilic in nature, then water dilution followed by simple distillation can regenerate the IL. As per the study by Gao et al., [(CH2)4SO3HMIm][Tos] can be recycled two times under the same operating conditions (Gao et al. 2017). According to Zhang et al., synthesized acidic polymeric IL-modified graphene oxide, poly[ViEtIm][PW12O40]-rGO can be recycled eight times with a 98% desulfurization efficiency without a significant decrease in desulfurization efficiency (Zhang et al. 2018). Modified iron porphyrins in ionic liquids-based catalysts could be recycled six times with a little drop in activity (Zhao et al. 2017b). Chao et al. explained the recycling of [Bmim]BF4 and achieved five times the recycling with extremely good desulfurization (Chen et al. 2015a). Some ILs could be wasted in separation and regeneration, resulting in a small drop in DBT removal. Zhang et al. attributed the reduction in sulfur removal to the increase in DBTO2 (Zhang et al. 2014a, b). The recyclability with regeneration of various ILs is presented in Table 9.

Hao et al. examined the recycling of the used IL phase with and without regeneration as shown in Fig. 13. He observed that the sulfur removal of DBT decreased from 99.84 to 63.97% after four cycles of recycling of [Hnmp]Cl·FeCl3 ionic liquid without regeneration and that recycling with regeneration obtained 90.48% DBT removal at 30 °C (Hao et al. 2019a).

Recycling and regeneration of [Hnmp]Cl·FeCl3 (Hao et al. 2019a)

Reactivity of different sulfur substrates

Reactivity of sulfur compounds depends on two influential factors, such as electron density and steric hindrance. Zhu and his group have applied [BPy][FeCl4] on three different sulfur compounds such as DBT, BT, and 4,6-DMDBT and achieved 95.3%, 75.0%, and 54.8% desulfurization efficiency (Zhu et al. 2013). Here, the desulfurization efficiency of DBT > BT because the electron density of DBT is higher than electron density of BT, while the desulfurization efficiency of 4,6-DMDBT < DBT through the electron density of 4,6-DMDBT is almost similar as of DBT because the reactivity of 4,6-DMDBT was affected by the steric hindrance of the methyl groups (Zhu et al. 2011). The same research group has observed the reactivity order of DBT > 4,6-DMDBT > BT in the presence of MSIL [(CH3)N(n-C8H17)3]2[Mo2O11]. [Pi444][Tos] and [Pi444][MeSO3] were used for the removal of DBT and BT and achieved > 99% efficiency in 15 min and 72 min, respectively (Ahmed et al. 2016a). Table 10 summarizes the reactivity of various sulfur substrates with different types of ILs.

ILs-ECODS mechanism

Hydrogen peroxide is the most effective oxidant for the desulfurization. Usually, in the oxidation reaction, H2O2 donates oxygen atoms and the divalent sulfur atoms are converted into respective sulfone by electrophilic addition of oxygen atoms (Song and Amer Chem 2002).

The generation of biphasic systems starts with the mixing of catalyst with H2O2, fuel, and pH controller. Numerous oxidation reaction mechanisms have been proposed by researchers. Hossain et al. have observed various approaches toward the oxidation of fuel oils including H2O2 connected with acetic acid, formic acid, heteropolyacid, metal oxides, titanium dioxide, and cadmium oxide (Hossain et al. 2019). Tert-butyl hydroperoxide is another oxidant that is completely fuel soluble, unlike hydrogen peroxide, and eliminates the requirement of biphasic systems (Tang et al. 2013).

Polytungsten and quaternary ammonium-based cation also form an efficient system. Metastable emulsion droplets in diesel with some catalyst and H2O2 solution can be formed by varying the size and type of quaternary ammonium cation (Ridge et al. 2017). Wan et al. describe the mechanism with the addition of phase transfer agent as shown in Fig. 14 (Wan et al. 2012).

ECODS mechanism using phase transfer agent (Wan et al. 2012)

Balinge et al. studied carboxyl-based ILs and proposed overall mechanism as shown in Fig. 15. The mechanism suggested by the researcher explained that the hydrogen bonding interaction between S atom of DBT and H2 of the imidazolium cation plays an important role in the improvement in DS efficiency (Balinge et al. 2016).

Mechanism of ECODS using carboxyl-functionalized IL (Balinge et al. 2016)

Ge et al. studied the ECODS of gasoline using an amphiphilic catalyst ([C18H37N(CH3)3]7[PW11O39]), assembled in hydrophobic IL ([Bmim]PF6) emulsion system. The milky white IL emulsion was observed in the presence of oxidant, catalyst, and hydrophobic IL as shown in Fig. 16. The catalyst was distributed at the oxidant–IL interface and produce a film around IL droplets and acted as an emulsifying agent. Lipophilic cation of the catalyst lies on the fuel side, and the hydrophilic heteropolyanions lie on the oxidant side as shown in Fig. 17. The heteropolyanions decomposed into active species in the presence of oxidant owing to the immiscibility of IL emulsion in HC species. The S-substrates in MF were first extracted into IL phase and oxidized to respective sulfones in IL phase.

Desulfurization of real fuels using ILs-ECODS

It is observed that the ILs-EDS is not much effective on the desulfurization of RFs in single stage. It requires multistage extraction using ILs that can reduce sulfur compounds to some extent but does not satisfy the allowable S-content. This proves that it requires re-/post-treatment to reach the environmental standards. ILs-ECODS was found to be effective for the desulfurization of RFs at mild operating conditions. It was also observed that the utilization of ILs can also be reduced in this method which is beneficial for economical point of view. Design of ILs to synthesize a task-specific ILs, particularly addition of acidic group to the IL, is advantageous for high desulfurization efficiency. Table 11 summaries the application of ILs-assisted processes on desulfurization of RFs.

Challenges and future perspectives

ILs-ODS is thoroughly studied by keeping the aim straight of producing sulfur-free fuels and substitutes for expensive conventional HDS techniques. The advantages and limitations of the oxidative desulfurization process are discussed here through a thorough literature survey. The influence of oxidation temperature, time, mass ratio of IL/fuel, molar ratio of O/S, catalyst dosage, etc., has been thoroughly reviewed and presented in this paper. The most significant merit of this process is the elimination of refractory compounds which are very difficult to be eliminated by HDS at mild conditions. In ILs-ODS process, the produced sulfones during ODS have higher polarity than the original sulfides present in the fuel which can be easily extracted in the IL phase compared to only ILs-EDS. Therefore, it is proved that the ILs-ODS is better than the ILs-EDS technique. Still, some problems need to be considered, such as minimization of side reaction during oxidation reaction and treatment of waste oxidation products, synthesis of more active and cheaper ILs with high stability, selectivity and optimization of operating conditions, ILs utilization, fuel loss, analysis on fuel properties, and fuel recovery.

ILs-ECODS is the recent advancement in the usual ILs-ODS process where ILs can behave as a multitasker such as extractant, catalyst, oxidant, or combination by slightly modifying the design of conventional ILs. Low requirement of ILs and high desulfurization performance of MFs as well as RFs are the key advantages of ILs-ECODS process.

ILs can be applied as the supported ILs; ILs as a catalytic solvent, emulsion ILs, and ILs in photo-oxidation are also need to be investigated. The applicability of this process on the industrial scale still needs some more clarification of the responsible mechanism which needs more computational modeling and simulation.

Conclusion

The necessity of fuel desulfurization becomes more and more intense due to the tightening of environmental standards in terms of allowable sulfur content in the fuel. Nowadays, ILs have taken the leading position in desulfurization processes due to their unique properties. ILs help to meet the goal of achieving environmentally sustainable development owing to their green nature and make the process function at mild conditions. ILs can play the role of catalyst and extractant or both to obtain the ultra-low level of degree of desulfurization. In this article, we have tried to cover the environmental standards, types of ILs and their significant properties, role of ILs, and the influential factors which affect the ILs-assisted EDS, ODS, and ECODS processes. It was observed that the ILs give the researcher uncountable possibilities in terms of the development of new task-specific ILs by varying a huge number of anion and cation combinations. Despite their huge beneficial properties and affinity toward sulfur removal, their properties, cost, and environmental impact must be taken into consideration. This article suggests that incorporating ILs in ODS can produce ultra-low sulfur fuel under mild operating conditions. However, the development of functional ILs, supported ILs, ILs photocatalysis, and ILs emulsion, their interaction energy with the sulfur compounds, and deeper understanding of the exact mechanism responsible for the desulfurization of fuel are required to be studied further using modeling and simulation as well as experimental studies. Other issues such as treatment of waste oxidized products, their selectivity, and techno-economical evaluation of the large-scale process are also required to be solved in the future.

Availability of data and material

All data and the required materials are included in the submitted article.

References

Abbott AP, Capper G, Davies DL, Rasheed RK (2004) Ionic liquid analogues formed from hydrated metal salts. Chem Eur J 10:3769–3774. https://doi.org/10.1002/chem.200400127