Abstract

Films were prepared from 2% solutions of biodegradable poly-3-hydroxybutyrate [P(3HB)] and investigated. The polymer was synthesized by the Cupriavidus necator B-10646 bacterium cultivated using various carbon sources (glucose and glycerol of different degrees of purity, containing 0.3 to 17.93% impurities). Glycerol as the substrate influenced molecular-weight properties and crystallinity of the polymer without affecting its temperature characteristics. The P(3HB) specimens synthesized from glycerol had reduced Mw (300–400 kDa) and degree of crystallinity (50–55%) compared to the specimens synthesized from glucose (860 kDa and 76%, respectively). The low-crystallinity P(3HB) specimens, regardless of the degree of purity of glycerol, produced a beneficial effect on the properties of polymer films, which had a better developed folded surface and increased hydrophilicity. The values of the highest roughness (Ra) of the films synthesized from glycerol were 1.8 to 4.0 times lower and the water angles 1.4–1.6 times smaller compared to the films synthesized from glucose (71.75 nm and 87.4°, respectively). Those films performed better as cell scaffolds: the number of viable NIH fibroblasts was 1.7–1.9 times higher than on polystyrene (control) or films of P(3HB) synthesized from glucose.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Development of new environmentally friendly materials, which will completely degrade without releasing toxic products, joining the global cycles, should be the priority for critical technologists of the twenty-first century. Annual production of synthetic plastics has exceeded 360 million tons, and they largely accumulate in the biosphere, posing a global environmental threat [1, 2]. Therefore, considerable research effort has been devoted recently to the production of new-generation biodegradable materials for various applications, which is in line with the concept of safe sustainable industrial development.

There is a specific demand for biocompatible materials for biomedical applications, to be used in contact with tissues of human body. Improvement of the methods of regenerative medicine based on tissue engineering is impossible without creating new, highly functional and specific, materials and constructing systems capable of mimicking biological functions of a living organism. The discovery of polyhydroxyalkanoates (PHAs)—microbial polymers—has been a major event for biotechnology of novel materials [3,4,5,6,7,8,9]. Being high-performance materials, PHAs are thermoplastic, processable from different phase states by various techniques, biodegradable, and highly biocompatible. Therefore, they are very promising materials in diverse applications—from municipal engineering and agriculture to pharmacology and biomedicine. PHAs have great potential as materials for regenerating damaged skin, repairing the defects of soft tissues and bones, and manufacturing sutures and various implants [10,11,12,13,14,15]. PHAs comprise polymers composed of different fractions of various monomer units, which have dissimilar physicochemical properties [16,17,18]. The best studied and most available PHA—polymer of 3-hydroxybutyric acid [poly-3-hydroxybutyrate, P(3HB)]—is a thermoplastic material with a degree of crystallinity above 70%. This polymer is highly biocompatible because hydroxybutyric acid is a natural metabolite of cells and tissues in higher animals and humans [19]. Therefore, P(3HB) is suitable for contact with blood, and P(3HB) implants elicit mild immune response, causing no adverse responses of cells and tissues in vivo, with no pronounced inflammation and formation of coarse fibrous capsules around the implant [11, 12, 14,15,16,17,18,19,20,21,22,23]. Taken together, this suggests good potential of this polymer as material for fabricating various implants. P(3HB), as well as other PHAs, is an attractive and promising material for restoring damaged tissues and organs because this polymer, unlike polylactides and polyglycolides, is bioresorbed in vivo by true biological degradation performed by enzymes of blood and tissues and macrophage cells. P(3HB) degradation occurs at relatively slow rates, which are comparable with the rates of not only recovery of skin and soft tissues but also reconstructive osteogenesis—a process that takes a long time [11, 12, 24].

PHA cost, however, limits the increase in PHA production and restricts the scope of PHA applications. As raw carbon sources are responsible for about 40–50% of the PHA production cost, it is important to expand the range of feedstocks by using new available substrates. As PHA-producing microorganisms have broad organotrophic potential, they can be grown on various substrates, which include both individual compounds and combined carbon sources, including wastes [3, 5, 8, 9]. Other essential prerequisites for reducing PHA production costs are using high productivity PHA producing strains and developing effective biosynthesis processes.

A promising substrate for large-scale production of PHAs is glycerol, whose manufacture scale has been growing together with the increased production of biodiesel, which is a renewable energy source—an alternative to oil [25]. Glycerol is a by-product, amounting to about 10%, when biodiesel is produced by transesterification of animal and vegetable fats and oils (rapeseed, mustard, soybean, and palm). The amounts of impurities in glycerol vary depending on its degree of purity. In industrial glycerol grades, the water content varies between 5.3 and 14.2%; methanol content—0.001 to 1.7%; NaCl-traces—5.5%; K2SO4—0.8 to 6.6% [26].

The search of the literature showed the potential of glycerol, including crude glycerol, and the ability of representatives of various taxa to utilize it for PHA synthesis. However, as microorganisms have different physiological properties and sensitivity to impurities contained in crude glycerol, the overall productivity of the process and polymer yields can be decreased and polymer properties such as molecular weight can be changed to a greater or lesser extent [27,28,29,30,31]. Our recent studies demonstrated that Cupriavidus necator B-10646 cells were able to synthesize high contents of the P(3HB) homopolymer and PHA copolymers from purified and crude glycerol not only in laboratory experiments but also in the processes scaled up to pilot production [32, 33].

As noted above, PHAs are represented by polymers with various chemical compositions. PHA composition and properties vary widely, and they are chiefly determined by the physiological and biochemical characteristics of PHA producing strains and conditions of carbon nutrition. Despite the significance of studies of PHAs synthesized using different processes, the available evidence is far from being exhaustive. Moreover, the literature data differ substantially, even in descriptions of the studies using PHAs with similar chemical compositions [16,17,18]. The data on P(3HB) molecular weight may differ by two orders of magnitude, from 58 to 1580 kDa, and melting point reported in different studies varies between 162 and 197 °C. The data on how the basic properties of certain PHAs vary depending on the conditions of bacterial culture and how these differences influence the properties of polymer products are contradictory as well. P(3HB) synthesized by Ralstonia eutropha PHB-4 from fructose had higher molecular weight than the polymer synthesized using soybean oil or waste cooking oil [34, 35]. Furthermore, substitution of glycerol-containing vegetable oils for glucose resulted in changes of molecular weight and degree of crystallinity of P(3HB) synthesized using Ralstonia eutropha H16 and noticeably affected the structure and properties of electrospun nonwoven fibers [36]. However, there are no available literature data on the effects of glycerol or its degree of purity on the properties of the films or other products of PHAs synthesized from glycerol.

Therefore, the purpose of the present study was to investigate the properties of films of poly-3-hydroxybutyrate synthesized by Cupriavidus necator B-10646 from different carbon sources.

Materials and Methods

Bacteria

We used a wild-type strain of a hydrogen-oxidizing bacterium from the collection of the Laboratory of Chemoautotrophic Biosynthesis at the IBP SB RAS, Cupriavidus necator B-10646. The strain is registered in the Russian National Collection of Industrial Microorganisms (VKPM). It is capable of synthesizing P(3HB) at high yields [37].

Cultivation of Bacteria, Culture Medium and Monitoring C-Substrates

To cultivate bacteria in shake flask culture, an Innova 44 constant temperature incubator shaker (New Brunswick Scientific, U.S.) was used. Inoculum was prepared by resuspending the museum culture maintained on agar medium. Museum culture was grown in 1.0 L glass flasks half-filled with saline liquid medium, with the initial concentration of glycerol from 5 to 10 g/L. In the first phase, cells were cultivated for 25–30 h. To activate the culture and prepare the inoculum, we used Schlegel’s mineral medium as a basic solution for growing cells: Na2HPO4H2O—9.1; KH2PO4—1.5; MgSO4H2O—0.2; Fe3C6H5O77H2O—0.025; CO(NH2)2—1.0 (g/L) [38]. Nitrogen was provided in the form of urea, and, thus, no pH adjustment was needed. The pH level of the culture medium was stabilized at 7.0 ± 0.1. A solution of iron citrate (5 g/L), which was used as a source of iron, was added to reach a concentration of 5 ml/L. Hoagland’s trace element solution was used: 3 ml of standard solution per 1 L of the medium. The standard solution contains H3BO3—0.288; CoCl26H2O—0.030; CuSO45H2O—0.08; MnCl24H2O—0.008; ZnSO47H2O—0.176; NaMoO42H2O—0.050; NiCl2—0.008 (g/L).

Homopolymer of 3-hydroxybutyric acid was synthesized from a sole carbon source at a concentration of 10–15 g/L. The main carbon substrate contained various carbon compounds, which were sterilized by membrane filtration using Opticap XL300 Millipore Express SHC filters (U.S.):

-

glucose (China, purity: 98%);

-

purified glycerol: content of glycerol 99.7(wt.%); chloride < 0.001; heavy metals < 5 (µg/g); moisture 0.09 (wt.%); fatty acid & ester 1.0 max (wt.%); sulfate < 0.002; total organic impurities 0.5–1.0 (wt.%); individual organic impurities 0.1 (wt.%) (Dutch glycerol refinery, Netherlands) (Glycerol-I);

-

glycerol refinery B.V (Dutch glycerol refinery, Netherlands): glycerol—99.7; chloride < 0.001; moisture—0.09; fatty acid and ester—1.0; sulfate < 0.002; organic total impurities—0.5–1.0; individual organic impurities—0.1 (% mass); heavy metal < 5 (µg/g) (Glycerol-II);

-

glycerol crude (M.V.R. PINA Consultoria Tecnica, Brazil): glycerol—82.07; chloride—4.35; Material Organic Non-Glycerol (MONG)—0.13; methanol—0.13; ash—6.59; moisture—9.88 (% mass); pH 5.8 (Glycerol-III).

The first-phase cell culture was transferred into larger (2–3-L) flasks, and cells were cultured for 30–35 h in the medium of the same composition but without nitrogen source and with the carbon substrate concentration of 10–15 g/L.

During the course of cultivation, samples of culture medium were taken for analysis. Concentration of glucose was determined spectrophotometrically at 490 nm by the glucose oxidase method using a Fotoglucoza kit (Impact Ltd., Moscow, Russia). Glycerol concentration was determined by the method based on glycerol oxidation with sodium periodate in the sulfuric acid solution to formaldehyde and by colorimetric analysis using chromotropic acid [39].

P(3HB) Recovery

P(3HB) was recovered from cell biomass, which had been condensed in an ASF20 ultrafiltration installation (Vladisart, Russia) to 500 g/L and dried in an LP10R freeze dryer (ilShinBioBase, Korea) to residual moisture content of 5% in the recovery unit. PHA recovery was performed in two stages: in Stage 1, the biomass was degreased with ethylene; in Stage 2, polymer was recovered using dichloromethane. Then, polymer solution was filtered to remove cell walls, and polymer was precipitated with ethanol.

P(3HB) Analysis

Intracellular polymer content at different time points was determined by analyzing samples of dry cell biomass. Intracellular PHA content and composition of extracted polymer samples were analyzed using a GC–MS (6890/5975C, Agilent Technologies, U.S.). Both lyophilized cells and extracted polymer were subjected to methanolysis in the presence of sulfuric acid, and polymer was extracted and methyl esterified at 100 °C for 3 h. Benzoic acid was used as an internal standard to determine total intracellular PHA.

Molecular weights and molecular weight distributions of P(3HB) were examined with a gel permeation chromatograph (Agilent Technologies 1260 Infinity, U.S.) with a refractive index detector, using an Agilent PL gel Mixed-C column. Chloroform was the eluent. Calibration was done using polystyrene standards (Fluka, Switzerland, Germany). Molecular weights (weight average, Mw, and number average, Mn) and polydispersity (Ð = Mw/Mn) were determined.

Thermal analysis of P(3HB) specimens was performed using a DSC-1 differential scanning calorimeter (METTLER TOLEDO, Switzerland). The specimens were heated at a rate of 5 °C/min to 200 °C, then cooled to − 20 °C, held for 20 min and re-heated to 320 °C. Melting point (Tmelt) and thermal degradation temperature (Tdegr) were determined from peaks in thermograms using the “Star E” software.

X-ray structure analysis and determination of crystallinity of P(3HB) (Cx) were performed employing a D8ADVANCE X-ray powder diffractometer equipped with a VANTEC fast linear detector, using CuKa radiation (‘Bruker, AXS’, Germany). The scan step was 0.016°, measurement time in each step 114 s, and scanning range from 5° to 60° (from 48° to 60° there only was a uniformly decreasing background); the registered parameter was intensity of X-rays scattered by the sample; 55°/0.016° = 3438 times. The degree of crystallinity was calculated as a ratio of the total area of crystalline peaks to the total area of the radiograph (the crystalline + amorphous components). Measurement accuracy: point measurement accuracy ± 0.4 PPS, with the lowest intensity 1.5 PPS and the highest intensity 32 PPS; the error in determination of the degree of crystallinity, which was calculated based on multiple measurements, was 2% or less.

Preparation and Characterization of P(3HB) Films

Films were prepared by casting a 2% polymer solution in dichloromethane in degreased Teflon-coated molds, and then the films were left to stay in a laminar flow cabinet (Labconco, U.S.) for 72 h until complete solvent evaporation took place. Discs of diameter 10 mm were cut out using a template. The membranes were sterilized using H2O2 plasma in a Sterrad NX sterilization system (Johnson and Johnson, U.S.).

Film thickness was measured using a «LEGIONER» EDM-25-0.001 digital micrometer.

The surface structure of the polymer films was examined by scanning and atomic-force electron microscopies. Prior to microscopy, 5 × 5 samples were sputter coated with platinum (at 10 mA, 3 × 20 s), with an Emitech K575X sputter coater (Quorum Technologies Limited, U.K.). SEM images were obtained using an S5500 electron microscope (Hitachi, Japan). The roughness of film surface was determined by atomic-force microscopy (AFM) in semicontact mode (Integra Aura, NT-NDT, Russia). The arithmetic mean surface roughness (Ra) and the root mean square roughness (Rq) were determined based on 10 points, as the arithmetic averages of the absolute values of the vertical deviations of the five highest peaks and lowest valleys from the mean line of the profile of the surface, using conventional equations. Sites of areas 20 × 20 µm were examined, and 2 × 2 µm sites with local maxima and minima were selected; they were analyzed at a higher resolution, and the roughness of each sample was calculated as the average of three measurements [40].

The surface properties of the films were examined using a contact angle measuring device DSA-25E (Krüss, Germany) with DSA-4 Windows software. Drops of water and diiodomethane, 1.5 µL each, were alternately placed on the sample surface with microsyringes, and moments of interaction between each liquid and sample surface were video recorded. Contact angles of these liquids were measured by processing the frame of a stabilized drop in a semiautomatic mode, by the “Circle” method, which is embedded in the software package. The results of measurements were used to calculate interfacial free energy, surface tension, and cohesive forces (erg/cm2) by the Owens, Wendt, Rabel and Kaelble method [41]. A minimum of six measurements were taken for each surface; means and standard deviations were calculated.

Mechanical Analysis

Mechanical properties of the films were investigated using an electromechanical tensile testing machine Instron 5565 (U.K.). At least five samples were tested for each blend type. Measurements were conducted at ambient temperature. The speed of the crosshead was 1 mm/min at ambient temperature. Young’s modulus (E, MPa) was automatically calculated by the Instron software (Bluehill 2, Elancourt, France). To obtain Young’s modulus, the software calculated the slope of each stress–strain curve in its elastic deformation region. Measurement error did not exceed 10%.

Cell Cultivation

Adhesive properties of film surfaces and the ability of the films to maintain cell proliferation potential were investigated in experiments with mouse fibroblast NIH 3T3 cells, which were seeded onto films (5 × 103 cells/cm2) placed in 24-well plates. Fibroblasts were cultured using conventional procedure, in DMEM medium supplemented with fetal bovine serum 10%—and a solution of antibiotics (streptomycin 100 µg/mL, penicillin 100 IU/mL) (Gibco, Invitrogen) in a CO2 incubator with CO2 level maintained at 5%, at a temperature of 37 °C. The medium was replaced every three days.

Analysis of cell morphology and cell counting were performed in 1, 4, and 7 days after seeding, using Giemsa stain. The films with attached cells were washed in phosphate buffer to remove the culture medium, fixed with May-Grünwald solution, washed in phosphate buffer again, and stained with Romanovsky-type stain. Cells were visualized and counted using a Biolam P2-1 microscope (LOMO) at × 300 magnification in 10 fields of view. To confirm the results quantitatively, the cells were stained with DAPI and FITC fluorescent stains (Sigma); cells were counted using an Axiovert 40 fluorescence microscope (Carl Zeiss).

Viability of cultured fibroblast NIH 3T3 cells was evaluated using 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide (MTT) (Sigma) assay. Viability evaluation was based on the ability of dehydrogenases of living cells to reduce 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide to formazan, which characterizes mitochondrial activity, estimates the abundance of living cells, and indirectly indicates the ability of cells to proliferate on the matrices. MTT solution (50 µL) and complete nutrient medium (950 µL) were added to each well containing a polymer. After 3.5 h incubation, the medium and MTT were replaced by DMSO to dissolve MTT-formazan crystals. After 30 min, the supernatant was transferred to the 96-well plate, and optical density was measured at wavelength 540 nm, using a Bio-Rad 680 microplate reader (Bio-Rad LABORATORIES Inc., U.S.). The number of cells was determined from the calibration graph.

Statistics

Statistical analysis of the results was performed by conventional methods, using the standard software package of Microsoft Excel. Arithmetic means and standard deviations were found. The statistical significance of results was determined using Student’s t test (significance level: P = 0.05).

Results

Properties of PHAs Synthesized from Different Carbon Substrates

The previously developed process of P(3HB) synthesis from glycerol was scaled up to pilot production [32, 33], and polymer was produced in amounts sufficient for integrated studies of its properties and for fabrication of polymer products.

PHA specimens, synthesized by C. eutrophus B-10646 on glycerol of different degrees of purity, were a homopolymer of 3-hydroxybutyric—P(3HB) (Fig. 1).

P(3HB) specimens synthesized from glucose and glycerol of different degrees of purity were investigated to determine their chemical composition and physicochemical properties.

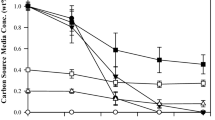

Molecular weight properties of PHAs are among their basic properties, which determine whether the polymer can be processed into products and what mechanical characteristics these products will have. The polymer synthesized from glucose had the highest degree of crystallinity (76%) and weight average molecular weight (860 kDa), with polydispersity of 2.12. All P(3HB) specimens synthesized from glycerol had higher polydispersity, suggesting greater heterogeneity of carbon chain fragments, and Mw values that were lower at least by a factor of 2 (Fig. 2).

Those differences were most pronounced in the polymer synthesized from crude glycerol. Glycerol has been reported to function as a chain transfer reaction (CT) agent in P(3HB) polymerization, resulting in the formation of low molecular weight. In case of a CT reaction, the P(3HB) chain number increases in inverse proportion to the polymer molecular weight [27, 28].

Poly-3-hydroxybutyrate, as well as many other PHAs, is a semi-crystalline polymer. The ratio of amorphous to crystalline regions in such polymers varies depending on what monomer units they are composed of and on their proportions. P(3HB) has been generally considered as a high-crystallinity polymer, with the crystalline region prevailing over the amorphous region and Cx ranging between 65 and 80% [4, 14, 17]. Slight differences were found between the Cx values of P(3HB) specimens. The Cx values of the P(3HB) specimens synthesized from glycerol were reduced (50–55%), i.e. the amorphous and crystalline regions were nearly equal to each other and the polymer was more amorphous (Table 1; Fig. 3).

The melting points and the thermal degradation temperatures of the P(3HB) specimens synthesized from glycerol were similar to the corresponding parameters of the P(3HB) synthesized from glucose: 172–178 and 295–296 °C, respectively (Table 1; Fig. 4).

Thus, P(3HB) specimens synthesized from glycerol had lower degrees of crystallinity and molecular weights than P(3HB) specimens synthesized from glucose, but they had similar thermal properties.

Surface Structure and Physical–Mechanical Properties of Films of P(3HB) Synthesized by C. eutrophus B-10646 from Glucose and Glycerol

P(3HB) films were prepared from 2% P(3HB) solutions by solution casting followed by solvent evaporation. The film thickness (average of 10 measurements) was 5.507 µm (the error was 0.026). Segments of equal thickness were selected and discs of diameter 10 mm were cut out and used in the experiments.

SEM images of solution-cast films prepared from P(3HB) synthesized from glucose and glycerol of different degrees of purity are shown in Fig. 1a. The surface of the films of P(3HB) synthesized from glucose was smooth, even, and practically pore-free. The surface of the films prepared from P(3HB) synthesized from purified and distilled glycerol with low impurity content was rough, with large randomly oriented folds, and numerous, 0.5 to 3.0 µm, pores. The films prepared from P(3HB) synthesized from the glycerol purified to the highest degree showed the highest porosity, up to 1250 pores per 1 mm2. The surface of the films prepared from the polymer synthesized from crude glycerol was dense and practically pore-free, like the surface of the films prepared from the polymer synthesized from glucose, but, in contrast to the latter, it had uniformly oriented folds. However, the folds were more shallow and uniformly oriented in contrast to the randomly oriented folds on the surface of the films prepared from P(3HB) synthesized from purified glycerol.

An important parameter of polymer products, e.g., implants, is physicochemical reactivity of the surface. Surface topography and chemical and phase compositions are factors determining protein adhesion, cell attachment, and response of surrounding tissue. Surface roughness is a major parameter of scaffolds in cell and tissue engineering. Nanometer roughness may determine cell adhesion, spreading, and motility and synthesis of specific proteins [42]. However, some data suggest that cell adhesion is greater on rough surfaces than on polished ones, while other studies show that cells behave in a similar fashion on surfaces with different degrees of roughness [43].

Examination of polymer films using atomic force microscopy showed the effect of the carbon source and the degree of purification of glycerol on surface roughness (Fig. 5b; Table 2). The polymer specimen synthesized from glucose had the highest arithmetic mean surface roughness (Ra) and root mean square roughness (Rq)—71.749 and 80.283 nm, respectively; the specimen synthesized from crude glycerol exhibited the lowest roughness parameters: 17.36 and 23.25, respectively. The films of P(3HB) synthesized from purified and distilled glycerol had similar roughness parameters, which were lower than those of the polymer synthesized from glucose and higher than those of the polymer synthesized from crude glycerol.

The ten-point average peak-to-valley height varied between 190 and 241 nm, being significantly higher in the films prepared from the polymer synthesized from distilled glycerol compared to the films of P(3HB) synthesized from the two other carbon substrates (184.03–190.6 nm). Even small variations in surface profile may cause a change in cell response, ranging from a slight increase in cell activity to considerable inhibition thereof. However, various cell types exhibit different sensitivities to variations in the surface roughness and topography.

Hydrophilic/hydrophobic balance of the surface is a major parameter that indirectly characterizes biological compatibility and affects cell adhesion and viability [44]. The hydrophilic/hydrophobic balance is estimated by measuring water contact angle. This value is also used to determine such important surface parameters as cohesive forces, surface tension, and interfacial free energy. Surface energy is an important parameter, which can affect behavior of cells [45, 46].

The study of the surface of the P(3HB) films based on contact angle measurements showed that the type of carbon substrate affected surface properties considerably (Fig. 6). The water contact angles on the films prepared from P(3HB) synthesized from glycerol (55.7° and 64.3° for purified and crude glycerol, respectively) were significantly lower than on the films of P(3HB) synthesized from glucose (87.42°) (Table 3). Likewise, calculations based on water and diiodomethane contact angels showed that the dispersive and polar components of the surface energy were about 1.5 times higher for the polymer specimens synthesized in the media with purified and crude glycerol than in the media with glucose. That was indicative of the beneficial effect of glycerol as carbon substrate on the properties of P(3HB) and P(3HB)-based films, which had a more hydrophilic surface.

Mechanical Properties of the Films Prepared from P(3HB) Synthesized from Glucose and Glycerol

The study of mechanical properties of the films (Table 4) showed that mechanical strength of the films synthesized from glycerol was somewhat inferior to the strength of the films synthesized from glucose (2071.2 MPa).

Films of the polymer synthesized from crude glycerol had the lowest values of Young’s modulus (1436.8 MPa). Tensile strength of these films was substantially lower (12.46 MPa) than the tensile strength of the three other films, which exhibited comparable values. All films prepared from the P(3HB) synthesized from glycerol showed somewhat lower elasticity than the films of the P(3HB) synthesized from glucose.

Biological Properties of the Films Prepared from P(3HB) Synthesized from Glucose and Glycerol

Biocompatibility of cell scaffolds is to a great extent determined by physicochemical reactivity of their surface. The main factors that regulate cell growth and function are scaffold surface topography, roughness, structure, and chemical and phase compositions. The initial behavior of the cell on the surface largely determines subsequent processes of cell differentiation and proliferation.

Polymer films differing in their surface topography and properties were investigated for their potential as cell scaffolds in the culture of NIH 3T3 mouse fibroblasts using MTT assay and fluorescent stains. The films did not produce any negative effects on the morpho-functional properties of cells compared to the control (polystyrene). Direct contact with polymer films of all P(3HB) types did not cause any impairment of the biological properties of blood cells; no cytotoxicity was detected. However, cell counts on polystyrene (control) and on the films of P(3HB) synthesized from glucose were comparable and significantly lower than cell counts on the films of P(3HB) synthesized from glycerol, whatever its purity (Figs. 7, 8). The study of morphology of fibroblasts cultured on four film types using FITC and DAPI dyes showed that on the films of P(3HB) synthesized from glycerol, cells were larger than on other types of films: their average sizes were 378.23 ± 46,421.13 ± 80, and 370.20 ± 61.70 µm2 on the films of P(3HB) synthesized on purified, distilled, and crude glycerol, respectively. On polystyrene (control) and on the films of high-crystallinity polymer synthesized from glucose, cell sizes were 180.05 ± 42.40 and 200.45 ± 54.60 µm2, respectively. The average cell counts on the films of P(3HB) synthesized from glycerol were 1.8 times higher than the cell counts on the films of P(3HB) synthesized from glucose. Fibroblasts were uniformly distributed over the film surface; triangular cells with 3–4 protrusions prevailed (Fig. 7a, b).

The number of cells detected using fluorescent dyes (Fig. 7) was comparable to the number of cells determined in MTT assay (Fig. 8). The number of viable and physiologically active cells in the control (polystyrene) and on the films of P(3HB) synthesized from glucose was about 1.4–1.5 ± 0.15 × 105 cells/cm2. The number of cells on the films of the polymer synthesized from glycerol, whose degree of crystallinity was considerably reduced, was significantly higher, reaching 2.5 ± 0.17 × 105, 2.70 ± 0.21 × 105, and 2.6 ± 0.20 × 105 cells/cm2, on the films of P(3HB) synthesized on purified, distilled, and crude glycerol, respectively. No statistically significant (P ≤ 0.05) differences were found between those films.

Thus, films prepared from P(3HB) synthesized from different carbon sources using conventional cultivation techniques did not exhibit cytotoxicity upon direct contact with NIH 3T3 fibroblasts and had high biocompatibility. The number of viable cells on all types of films prepared from P(3HB) synthesized from glycerol was higher than on the films of P(3HB) synthesized from glucose and on polystyrene (control).

Discussion

Biodegradable materials that have attracted much research recently include polymers of monocarboxylic acids such as lactic, glycolic, butyric acids, etc. Polymer of 3-hydroxybutyric acid [P(3HB)], a representative of polyhydroxyalkanoates (PHAs), along with polylactide, is becoming a material of choice for biomedicine. These polymers have high potential as materials for reconstructive medicine, including cell and tissue engineering [14, 15].

A major issue of PHA biotechnology is reducing PHA production costs to increase the availability of these polymers [6, 8]. This aim can be achieved by improving biosynthesis processes and using new PHA producing strains and substrates. A promising substrate for biotechnology, including synthesis of degradable biopolymers, is glycerol—a basic waste of the steadily growing biodiesel production [25]. The data on the possible unfavorable effects of glycerol on the growth of PHA producers and PHA properties have been reported in a number of studies [47, 48]. Therefore, in this research, we produced and investigated films of P(3HB) synthesized from different carbon substrates: three grades of glycerol and glucose.

Films were prepared from solutions of the polymers that differed in the degree of crystallinity and molecular weight properties. Polymer specimens synthesized using glycerol, regardless of the degree of its purity, had higher polydispersity (3.42–3.89) and lower weight average molecular weight, about 304–416 kDa. The lower Mw of the polymer synthesized from glycerol as the main carbon substrate corresponds to the notion suggesting that glycerol functions as a chain transfer reaction (CT) agent in P(3HB) polymerization, resulting in the formation of low molecular weight. In case of a CT reaction, the P(3HB) chain number increases in inverse proportion to the polymer molecular weight [32, 33]. However, the relevant literature data are not without contradictions. A number of studies showed a decrease in the Mw of P(3HB) synthesized from glycerol to 260–400 kDa [26, 27], but very high values of Mw of P(3HB) synthesized from glycerol, reaching 790–960 kDa, were reported as well [30]. Molecular weight is a very significant parameter of polymers including PHAs, whose Mw varies widely: (10–100) × 104.

The degree of crystallinity of polymer specimens synthesized from glycerol was also considerably lower (50–55%) than the Cx of P(3HB) synthesized from sugars and other substrates (70–80%). Some other studies reported comparable results. The Cx of P(3HB) synthesized from glycerol by Cupriavidus sp. USMAHM13 was 49% [49], and the Cx of P(3HB) synthesized from glycerol by Cupriavidus necator IPT 026 ranged between 52 and 62% [31]. P(3HB) synthesized from fructose by Ralstonia eutropha PHB-4 had higher molecular weight than the polymer synthesized from soybean oil or waste cooking oil [34, 35]. When rapeseed or olive oil, containing glycerol, was substituted for glucose, P(3HB) synthesized by Ralstonia eutropha H16 had lower molecular weight and degree of crystallinity compared to the polymer synthesized from glucose [36].

The films prepared in this study differed in their microstructure, hydrophilic/hydrophobic balance, and surface properties. The surfaces of the films of the polymer synthesized from glycerol were folded to varying degrees and porous, in contrast to the smooth films of P(3HB) synthesized from glucose. Films prepared from P(3HB) synthesized from purified glycerol had the highest porosity, while the films of the P(3HB) synthesized from crude glycerol and glucose were practically pore-free. As surface topography of cell scaffolds had been reported to affect cell adhesion and proliferation, polymer films were investigated using AFM to measure their roughness parameters. The study revealed a significant effect of the carbon substrate on surface roughness. The polymer synthesized from glucose had the highest roughness (Ra) and root mean square roughness (Rq): 71.749 and 80.283 nm, respectively. The specimen synthesized from crude glycerol had the lowest Ra and Rq: 17.36 and 23.25 nm, respectively. Films of P(3HB) synthesized from purified and distilled glycerol had comparable roughness parameters, which were lower than those of the films of P(3HB) synthesized from glucose and higher than those of the films of P(3HB) synthesized from crude glycerol. This is consistent with the studies reporting that surface properties of the PHA films were determined by the polymer chemical composition and properties. Roughness parameters varied widely, between 92.5 and 290.8 nm or more, and the addition of polyethylene glycol to the polymer solution increased the roughness of the films to 588.8 nm [50]. There are data suggesting that incorporation of monomer units other than 3HB into the poly-3-hydroxybutyrate chain decreased the surface roughness of the films, which became smoother [20, 51]. Another work [36], like the present study, revealed that changes of carbon nutrition conditions (replacement of glucose by olive and rapeseed oils) decreased molecular weight and degree of crystallinity of P(3HB) and affected the properties of nonwoven electrospun mats, including the diameter of ultrafine fibers and their arrangement.

Water contact angle on the films of P(3HB) synthesized from glycerol was considerably lower than on the films of P(3HB) synthesized from glucose (55.7° and 64.3° for purified and crude glycerol, respectively, versus 87.42° for glucose). The dispersive and polar components of interfacial free energy were 1.5 times higher for the polymers synthesized from purified and crude glycerol than for films of P(3HB) synthesized from glucose. Thus, glycerol as carbon substrate produced a favorable effect on the properties of P(3HB), and the films prepared from that polymer had more hydrophilic surface and reduced crystallinity, but their mechanical strength was somewhat decreased. At the same time, literature data suggest that hydrophilic/hydrophobic balance, which determines surface energy and other parameters, does not always produce the same effect on cells: functions of cell structures may be enhanced on hydrophilic or hydrophobic surfaces [52].

PHAs, including poly-3-hydroxybutyrate, are highly biocompatible and, thus, are regarded as the most popular materials for tissue engineering. Very many studies reported successful use of PHA scaffolds in growing and differentiating cells of various origins [14, 15, 21, 24]. Research carried out by our team showed that polymer scaffolds of the homopolymer P(3HB) and copolymers containing 4-hydroxybutyrate, 3-hydroxyvalerate, and 3-hydroxyhexanoate monomer units in the 3-hydroxybutyrate chain in the form of microparticles, nonwoven membranes, dense and porous films, including those modified by plasma treatment or laser cutting, had high biocompatibility, ensuring better proliferation of eukaryotic cells than polystyrene (control) or polylactide scaffolds. Scaffolds of copolymers containing 4-hydroxybutyrate [P(3HB-co-4HB)] monomer units, which had the lowest crystallinity (20–40%), were found to be the most favorable for cell growth and differentiation [23, 53,54,55,56].

All films of P(3HB) synthesized from various carbon substrates were studied in the culture of fibroblasts and showed high biological compatibility. Glycerol used as carbon substrate improved the properties of films, facilitating cell proliferation and increasing the number of viable cells.

Conclusions

Biodegradable polymer of 3-hydroxybutyric acid [P(3HB)] synthesized using the Cupriavidus necator B-10646 bacterium cultivated on glucose and glycerol of different degrees of purity (containing 0.3 to 17.93% impurities) was used to prepare polymer films, which were investigated as scaffolds for cell engineering. Films were prepared from 2% P(3HB) solutions by solution casting followed by solvent evaporation. The degree of purity of glycerol affected molecular-weight properties and degree of crystallization of the polymer, reducing both parameters. The P(3HB) specimens synthesized from glycerol had reduced Mw (300–400 kDa) and degree of crystallinity (50–55%) compared to the specimens synthesized from glucose (860 kDa and 76%, respectively). The low-crystallinity P(3HB) specimens, regardless of the degree of purity of glycerol, produced a beneficial effect on the properties of polymer films, which had a better developed folded surface and increased hydrophilicity. Those films performed better as cell scaffolds: the number of viable NIH fibroblasts was 1.7–1.9 times higher than on polystyrene (control) or films of P(3HB) synthesized from glucose.

References

Hejase HJ, Hejase AJ, Tabsh H, Chalak HC, Wamitu SN, Pavel S (2018) Advances in business and management. Scientific Research Publishing Inc, Irvine, pp 106–133

Plastics-the Facts 2019. Demand and Waste Data (2019) Plastics Europe. AISBL, Brussels

Chen GQ (2010) Plastics completely synthesized by bacteria: polyhydroxyalkanoates. In Plastics from bacteria. Springer, Berlin

Sudesh K, Abe H, Doi Y (2000) Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Prog Polym Sci 25:1503–1555

Volova TG, Shishatskaya EI, Sinskey AJ (2013) Degradable polymers: production, properties, applications. Nova Science Pub Inc, New York

Chen GQ, Jiang XR, Guo Y (2016) Synthetic biology of microbes synthesizing polyhydroxyalkanoates (PHA) synthetic and systems. Biotechnology 1:236–242

Rajan KP, Thomas SP, Gopanna A, Chavali M (2017) Polyhydroxybutyrate (PHB): a standout biopolymer for environmental sustainability. In. Handbook of ecomaterials. Springer, Cham

Koller M, Maršálek L, Mirand M, Braunegg G (2017) Producing microbial polyhydroxyalkanoate (PHA) biopolyesters in a sustainable manner. New Biotechnol 37:24–38

Koller M (2019) Polyhydroxyalkanoate biosynthesis at the edge of water activity-haloarchaea as biopolyester factories. Bioengineering 6:1–34

Dawes EA (2012) Novel biodegradable microbial polymers. Springer, Dordrecht

Wu LP (2014) Polyhydroxyalkanoates (PHA): biosynthesis, industrial production and applications in medicine. Nova Scienses Publ. Inc., New York

Volova TG, Vinnik YuS, Shishatskaya EI, Markelova NM, Zaikov GE (2017) Natural-based polymers for biomedical applications. Apple Academic Press, Toronto

Kavitha G, Rengasamy R, Inbakandan D (2018) Polyhydroxybutyrate production from marine source and its application. Int J Biol Macromol 111:102–108

Singh AK, Srivastava JK, Chandel AK, Sharma L, Mallick N, Singh PS (2019) Biomedical applications of microbially engineered polyhydroxyalkanoates: an insight into recent advances, bottlenecks, and solutions. Appl Microbiol Biotechnol 103(5):2007–2032

Tarrahi R, Fathi Z, Özgür M, Doustkhah E, Khataee A (2020) Polyhydroxyalkanoates (PHA): From production to nanoarchitecture. Int J Biol Macromol 146:596–619

Laycock B, Peter H, Pratt S, Werker A, Lant P (2013) The chemomechanical properties of microbial polyhydroxyalkanoates. Prog Polym Sci 38:536–583

Laycock B, Halley P, Pratt S, Werker A, Lant P (2014) The chemomechanical properties of microbial polyhydroxyalkanoates. Prog Polym Sci 39:397–442

Volova TG, Zhila NO, Shishatskaya EI, Sukovatiy AG (2012) Database "Physico-chemical properties of polyhydroxyalkanoates of various structures. Biosynthesis conditions and producers" №2012620288. Priority Date: 31.01.2012

Reusch RN, Sparrow AW, Gardiner J (1992) Transport of poly-β-hydroxybutyrate in human plasma. Biochim Biophys Acta 1123:33–40

Zhang J, Shishatskaya EI, Volova TG, Silvae LF, Chen GQ (2018) Polyhydroxyalkanoates (PHA) for therapeutic applications. Mater Sci Eng C 86:144–150

Chen GQ, Wu Q (2005) The application of polyhydroxyalkanoates as tissue engineering materials. Biomaterials 26:6565–6578

Shishatskaya EI, Voinova ON, Goreva AV, Mogilnaya OA, Volova TG (2008) Biocompatibility of polyhydroxybutyrate microspheres: in vitro and in vivo evaluation. J Mater Sci Mater Med 19(6):2493–2502

Shishatskaya EI, Volova TG (2004a) A comparative investigation of biodegradable polyhydroxyalkanoate films as matrices for in vitro cell. Int J Mol Sci 15(8):915–923

Misra SK, Valappil SP, Roy I, Boccaccini AR (2006) Polyhydroxyalkanoate (PHA)/inorganic phase composites for tissue engineering applications. Biomacromol 7:2249–2258

Fernández-Dacosta C, Posada JA, Kleerebezem R, Cuellar MC, Ramirez A (2015) Microbial community-based polyhydroxyalkanoates (PHAs) production from wastewater: techno-economic analysis and ex-ante environmental assessment. Bioresour Technol 185:368–377

Mothes G, Schnorpfeil C, Ackermann JU (2007) Production of PHB from crude glycerol. Eng Life Sci 7:475–479

Hsiao LJ, Lee MC, Chuang PJ, Kuo YY, Lin JH, Wu TM, Li SY (2018) The production of poly(3-hydroxybutyrate) by thermophilic Caldimonas manganoxidans from glycerol. J Polym Res 25:85–92

Tsuge T, Ko T, Tago M, Abe H (2013) Effect of glycerol and its analogs on polyhydroxyalkanoate biosynthesis by recombinant Ralstonia eutropha: a quantitative structure-activity relationship study of chain transfer agents. Polym Degrad Stab 98:1586–1590

Ashby RD, Solaiman DKY, Strahan GD (2011) Efficient utilization of crude glycerol as fermentation substrate in the synthesis of poly(3-hydroxybutyrate) biopolymers. J Am Oil Chem Soc 88:949–959

Cavalheiro JM, Raposo RS, de Almeida MC et al (2012) Effect of cultivation parameters on the production of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and poly(3-hydroxybutyrate-4-hydroxybutyrate-3-hydroxyvalerate) by Cupriavidus necator using waste glycerol. Bioresour Technol 111:391–397

Campos MI, Figueiredo TVB, Sousa LS, Druzian JI (2014) The influence of crude glycerin and nitrogen concentrations on the production of PHA by Cupriavidus necator using a response surface methodology and its characterizations. Ind Crops Prod 52:338–346

Volova T, Demidenko A, Kiselev E, Baranovskiy S, Shishatskaya E, Zhila N (2019) Polyhydroxyalkanoate synthesis based on glycerol and implementation of the process under conditions of pilot production. Appl Microbiol Biotechnol 103:225–237

Volova TG, Kiselev EG, Zhila NO, Shishatskaaya EI (2019) Synthesis of PHAs by hydrogen bacteria in a pilot production process. Biomacromol 20:3261–3270

Taniguchi I, Kagotani K, Kimura Y (2003) Microbial production of poly(hydroxyalkanoate)s from waste edible oils. Green Chem 5:545–548

Hyakutake M, Saito Y, Tomizawa S (2011) Polyhydroxyalkanoate (PHA) synthesis by class IVPHA synthases employing Ralstonia eutropha PHB(-)4 as host strain. Biosci Biotechnol Biochem 7:1615–1617

Irorere V, Bagheriasl S, Blevins M, Kwiecień I, Stamboulis A, Radecka I (2014) Electrospun fibres of polyhydroxybutyrate synthesized by Ralstonia eutropha from different carbon sources. Int J Polym Sci. https://doi.org/10.1155/2014/705359

Volova TG, Shishatskaya EI (2012) Shtamm bakterii VKPM B-10646—produtsent poligidroksialkanoatov i sposob ikh polucheniya (bacterial strain VKPM B-10646—a producer of polyhydroxyalkanoates and a method of their production). RF Patent No. 2439143

Schlegel HG, Gottschalk G, Von Bartha R (1961) Formation and utilization of poly-β-hydroxybutyric acid by Knallgas bacteria (Hydrogenomonas). Nature 191:463–465

Nakamura M, Iso H, Kitamura A et al (2016) Comparison between the triglycerides standardization of routine methods used in Japan and the chromotropic acid reference measurement procedure used by the CDC lipid standardization programme. Ann Clin Biochem 53:632–639

ISO 468. (1982) Surface roughness. Parameters, their values, and general rules of specifications

Owens DK, Wendt RC (1969) Estimation of the surface free energy of polymers. J Appl Polym Sci 13:1741–1747

Xavier SP, Carvalho PSP, Beloti MM, Rosa AL (2003) Response of rat bone marrow cells to commercially pure titanium submitted to different surface treatments. J Dent 31:173–180

Boskhomdzhiev AP (2010) A study of biodegradation and biocompatibility of polyhydroxyalkanoates-based polymer systems [summary of the thesis for the degree of Candidate of Biological Sciences]. A.N. Bakh Institute of Biochemistry RAS, Moscow

Ou W, Qiu H, Chen Z, Xu K (2011) Biodegradable block poly(ester-urethane)s based on poly(3-hydroxybutyrat-co-4-hydroxybutyrate) copolymers. Biomaterials 32:3178–3188

Hallab NJ, Bundy KJ, O’Connor KJ, Moses RL, Jacobs JJ (2001) Evaluation of metallic and polymeric surface energy and surface roughness characteristics for directed cell adhesion. Tissue Eng 7:55–71

Kennedy SB, Washburn NR, Simon CG, Amisa JE (2006) Combinatorial screen of effect of surface energy on fibronectin mediated osteoblast adhesion, spreading and proliferation. Biomaterials 27:3817–3824

De Paula FC, De Paula CBC, Gomez JGC, Steinbüchel A, Contiero J (2017) Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) production from biodiesel by-product and propionic acid by mutant strains of Pandoraea sp. Biotechnol Prog 33:1077–1084

Hsiao LJ, Lee MC, Chuang PJ, Kuo YY, Wu TM, Li SY (2018) The production of poly(3-hydroxybutyrate) by thermophilic Caldimonas manganoxidans from glycerol. J Polym Res 25:85–92

Ramachandran H, Amirul AA (2014) Bioconversion of glycerin pitch into a novel yellow-pigmented P(3HB-co-4HB) copolymer: synergistic effect of ammonium acetate and polymer characteristics. Appl Biochem Biotechnol 172:891–909

Surguchenko V, Ponomareva A, Efimov A, Nemets E, Agapov I, Sevastianov V (2012) Characteristics of adhesion and proliferation of mouse NIH/3T3 fibroblasts on the poly(3-hydroxybutyrate-co-3-hydroxyvalerate) films with different surface roughness values. Messenger of Transplantology and Artificial Organs 41:72–77

Zhang J, Cao Q, Li S et al (2013) 3-Hydroxybutyrate methyl ester as a potential drug against Alzheimer’s disease via mitochondria protection mechanism. Biomaterials 34:7552–7562

Links J, Boyan BD, Blanchard CR, Lohmann CH, Liu Y, Cochran DL, Dean DD, Schwartz Z (1998) Responce of MG63 osteoblast-like cells to titanium and titanium alloy is depend on surface roughness and composition. Biomaterials 19:2219–2232

Shishatskaya EI, Volova TG (2004b) Acomparative investigation of biodegradable polyhydroxyalkanoate films as matrices for in vitro cell. Int J Mol Sci 15(8):915–923

Volova T, Goncharov D, Sukovatyi A, Shabanov A, Nikolaeva E, Shishatskaya E (2014) Electrospinning of polyhydroxyalkanoate fibrous scaffolds: effect on electrospinning parameters on structure and properties. J Biomater Sci Polym Ed 25(4):370–393

Volova TG, Tarasevicha AA, Golubev AI, Boyandin AN, Shumilova AA, Nikolaeva ED, Shishatskaya EI (2015) Laser processing of polymer constructs from poly(3- hydroxybutyrate). J Biomater Sci Polym Ed 14:1–19

Surmenev RA, Chernozem RV, Syromotina DS, Oehr C, Baumbach T, Krause B, Boyandin AN, Dvoinina LM, Volova TG, Surmeneva AA (2019) Low-temperature argon and ammonia plasma treatment of poly-3-hydroxybutyrate films: surface topography and chemistry changes affect fibroblast cells in vitro. Eur Polymer J 112:137–145

Acknowledgements

The reported study was funded by RFBR and KKRF Grant No. 19-43-240012 “Biological and physical principles of production of new generation biomaterials”. The work was carried out as part of the State Assignment of the Ministry of Education and Science of the Russian Federation No. FSRZ-2020-0006. The authors would like to express their special thanks to Krasnoyarsk Regional Center of Research Equipment of Federal Research Center «Krasnoyarsk Science Center SB RAS» for providing equipment to ensure the accomplishment of this project.

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest in the publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shishatskaya, E., Nemtsev, I., Lukyanenko, A. et al. Polymer Films of Poly-3-hydroxybutyrate Synthesized by Cupriavidus necator from Different Carbon Sources. J Polym Environ 29, 837–850 (2021). https://doi.org/10.1007/s10924-020-01924-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01924-3