Abstract

Two new chitosan-grafting copolymers (chitosan-g-PAM-AA and C-chitosan-g-PAM-AA) as sludge conditioners (flocculation and aggregation) have been prepared by employing ceric sulfate as a free radical initiator under nitrogen atmosphere in aqueous solution. The optimum condition for synthesizing chitosan-grafting copolymer was determined by orthogonal experiments. The structure, morphology and property of the obtained graft polymers were characterized by FT-IR, XRD, SEM, TGA and contact angle. Further, the municipal activated sludge dewatering performance of the synthesized copolymers was evaluated by the filter cake moisture content. Herein, the effects of pH value and dewatering temperatures of activated sludge, loading dosage or cationic degree of C-chitosan-g-PAM-AA on the filter cake moisture content were investigated. The synthesized amphoteric flocculant C-chitosan-g-PAM-AA showed a highly effective flocculation capability for activated sludge compared with chitosan-g-PAM-AA, chitosan, polyacrylamide (PAM). Also, the lowest filter cake moisture content was up to 61.41%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As countries urbanization and industrialization speeding up, the yield of the sludge increases year by year. There contains above 95% water in the sludge. The moisture content of sludge directly affects the environment due to enriching in heavy metals and refractory organic compounds [1, 2], and increases the cost of the sludge disposed. Flocculation is a method of sludge dewatering or coordinating by agglomerating solid, which materially improved the dewatering rate of many types of sludge, including those used in mining, papermaking, wastewater treatment, and oil-field applications [3,4,5]. Recently, polymeric flocculants with aggregate properties (chain length, charge density, branching, etc.) were increasingly used for the aggregation of sludge due to their high dewatering efficient.

Chitosan chemically prepared by N-deacetylation of naturally-occurring chitin is nontoxic, biodegradable and biocompatible, which have been widely applied in biomedicine, pharmacology and water treatment [6,7,8,9]. Especially, there are plenty of amino groups (–NH2) and hydroxyl groups (–OH) in chitosan’s molecular structure [6]. The active amino groups (–NH2) in chitosan molecule could be protonated with H+ in water [10], which exhibited prominent static attraction and adsorption. However, natural chitosan applications were limited because of its poor solubility and hydrophilicity. So far, many modification methods have been reported, such as etherification, esterification, advanced oxidation, ultrafiltration/microfiltration, crosslinking and graft copolymerization with the hydrophilic group on the chitosan backbone [11, 12]. Among these modification methods, graft polymerization was a conventional and effective method to improve chitosan performance [11]. The literatures had respectively reported on the synthetic graft copolymeric flocculants of acrylamide (AM) [13,14,15,16], acrylic acid (AA) [17, 18], N,N-di-methyl-N-methacryloxyethyl-N-(3-sulfopropyl) ammonium (DMMSA) [19], (2-methacryloyloxyethyl) trimethyl ammonium chloride (DMC) [20] or both AM and N,N-dimethyl diallyl ammonium chloride (DMDAAC) were grafted onto chitosan [19]. Moreover, it was reported that polyacrylamide and PAA was water-soluble polymer with high flocculating efficiency [21]. Therefore, grafting PAM and PAA onto chitosan might improve the flocculating performance and increase the solubility of chitosan. Also, the effect of polymers on colloidal stability was mainly due to adsorption, bridging and electrostatic attraction of macromolecules on particle surfaces [22,23,24].

It is known that sludge colloids in water are usually negatively charged. Cationic copolymers were typically used for sludge flocculation and dewatering in wastewater treatment because of their charge neutralization [25, 26]. Therefore, chitosan was modified by introducing a cationic group to graft chitosan, which played a significant role in sludge flocculation and dewatering. This is because the charge units or cationic centers in these polymers were concentrated on several sections along the backbone of the polymer chain to form charge clusters. According to neutralization and chain bridging adsorption mechanism of flocculation, such a copolymer might be an efficient flocculant of sludge dewatering. Wherein, quaternization [18, 27] and addition reaction [19, 28] were the simple and efficient ways to improve the positive charges of polymers. Consequently, copolymerization of AA, AM, cationic monomer DMDAAC and chitosan were suggested to improve the flocculation capacity and extend the application area of chitosan. Additionally, it is reported that the amphoteric flocculants had wonderful dewatering performance for various sludges and resulted in the low filter cake moisture content (FCMC) [29, 30].

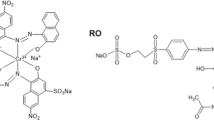

In this paper, the grafting of AM and AA onto chitosan (Scheme 1) and grafting of DMDAAC, AM and AA onto chitosan (Scheme 2) using ceric sulfate as redox initiator in acetic acid solution were explored referring to the proposed initiating mechanism on chitosan-g-PDMDAAC [25]. Thus, the obtained copolymers were expected to possess satisfying sludge conditioning performance. Herein, their dewatering performances were investigated by detecting FCMC. Their structure, morphology and thermostability along with hydrophilicity were characterized by infrared spectroscopy (IR), X-ray powder diffraction (XRD), scanning electron microscopy (SEM), thermogravimetric analysis (TGA) and contact angle testing. To the best of our knowledge, the grafting reaction starting from chitosan, AM and AA or chitosan, AM, AA and DMDAAC, and the obtain copolymer were further used in the activated sludge conditioning process, which have not been reported by far. In view of the flocculants could be tailored to give a desired filtration rate or the filter cake moisture content (FCMC), flocculation characteristics about AM and AA grafted chitosan polymers (chitosan-g-PAM-AA, anion copolymer), cationic grafted chitosan polymers (C-chitosan-g-PAM-AA, amphoteric copolymer), PAM and chitosan were studied. It suggested that DMDAAC group on C-chitosan-g-PAM-AA played an important role in sludge dewatering under the same conditions.

Materials and Methods

Materials

Biochemical reagent grade chitosan (deacetylation degree 80–95%, viscosity 50–800 mPa s) and PAM (non-ionic, molecular weight 5–6 million) were purchased from Sinopharm Chemical Reagent Co. Ltd, Shanghai, China. All other chemicals were of reagent grade and were used without further purification. The activated sludge is from the Changchun city sewage treatment plant in Jilin province, China (pH ≈ 6.5, and solid concentration < 5%).

Synthesis

Synthesis of the Graft Chitosan Polymer Chitosan-g-PAM-AA

Chitosan-g-PAM-AA was synthesized which is described in Scheme 1. Referring to the literatures [14, 31], grafting reactions were carried out in 250 mL three-necked flask by first dissolving an exact amount of chitosan in 1% acetic acid solution followed under N2 atmosphere. Subsequently, the mixture was treated with a predetermined amount of ceric sulfate solution for 20 min to facilitate free radical formation on chitosan. Finally, the mixed solution of AM and AA was added and the polymerization proceeded at a certain temperature. After reacting for 3–5 h, the polymerization was stopped. Slurry was precipitated in absolute ethyl alcohol. The product was filtered and washed with 3 × 10 mL ethyl alcohol and 3 × 10 mL distilled water, respectively. The filtered product was dried in vacuum oven at 50 °C for 4 h. The homopolymer was purified by Soxhlet extraction using alcohol and ethylene glycol as solvent, and dried at 50 °C for 12 h. Thus, the desired product chitosan-g-PAM-AA was synthesized.

Synthesis of the Cationic Graft Chitosan Polymer C-Chitosan-g-PAM-AA

C-chitosan-g-PAM-AA was synthesized as described in Scheme 2. On the basic of the optimum reaction condition for synthesizing chitosan-g-PAM-AA, different amount of DMDAAC were introduced the above reaction. The grafting copolymer C-chitosan-g-PAM-AA was also obtained.

The grafting copolymerization parameters, percent grafting (PG) and grafting efficiency (GE) were calculated from the following Eqs. 1 and 2 according to the reported procedure [13].

where W0, W1 and W2 are the weight of chitosan, graft copolymer and monomer, respectively.

Characterization

FT-IR spectra were determined as KBr pellets using a Shimazdu IRAffinity-1 instrument (Japan) in the range of 4000–500 cm−1. SEM of chitosan and graft copolymer was collected with a SEM SU8000-Series from HITACHI (Japan), at 1.5 kV. The crystal phase of chitosan and graft copolymers were characterized by XRD (XRD-6100, Shimadzu, Japan) equipped with graphite monochromatized Cu Ka radiation (λ = 1.54056 Å), employing a scanning rate of 6°/min, in the 2θ range from 10° to 60°. The TGA curve was obtained with a synchronous thermal analyzer (SDT-Q600, TGA, USA) under nitrogen atmosphere with a 10 °C/min heating rate from room temperature to 800 °C. The hydrophilicity was characterized by testing the contact angle between water and the corresponding surface of chitosan or chitosan grafted compound with a contact angle testing apparatus (DSA 25, KRÜSS GmBH, Germany). The cationic degree (CD) of C-chitosan-g-PAM-AA was determined by bottom titration referring to the reported literature [32].

Flocculation Studies

The dewaterability of grafted polymer to the activated sludge was determined by investigating FCMC [1, 33]. Sludge (50.0 g) was added to a 100 mL glass reactor equipped with a temperature controller and a mechanical stirrer, and pH of sludge was adjusted by adding HCl (1.0 mol L−1) or NaOH (1.0 mol L−1). Then, the dewaterability of flocculant was respectively evaluated at a constant speed of 100 rpm for 30 s, followed by a slow stirring at 40 rpm for 5 min and the obtained slurry precipitated for 20 min then was filtered by vacuum. Sequentially, the cake was removed and dried in an oven at 105 °C until a stable weight was obtained. FCMC was calculated according with Eq. 3 [33].

where W1 is the weight of wet filter cake after filtration and W2 is the weight of filter cake after drying to constant weight at 105 °C for 4 h.

Results and Discussion

Orthogonal Experiment

The flocculants played an important role in sludge conditioning process. The natural polymer chitosan is closely concerned due to its good bactericidal and relative flocculation. To explore the application in sludge conditioning process, the polymerization of chitosan grafting AA, AM and DMDAAC was studied. Herein, initiator concentration, AA/AM molar ratio, reaction temperature and reaction time were important factors influencing PG and GE. The orthogonal experiment was a good method for finding optimal reaction condition as well as saving time and reducing resource [15, 17]. In the present work, orthogonal experiments were carried out at three levels for each factor. The experimental results and analytical data for experimental results are listed in Table 1. The values of ∑/3 represent average value of PG or GE for three different experiments at each level of a factor, respectively. A high value of ∑/3 indicates that PG or GE is high at a level of a factor. Δ Represents the difference between the maximum value and minimum value at PG or GE of a factor. A higher value of Δ indicates that the effect of the factor on PG or GE is higher.

It is seen from Table 1 that the effect order of factors on PG and GE were identical and as follows: initiator concentration > reaction temperature > reaction time > AA/AM molar ratio. Therefore, initiator concentration had the greatest influence and AA/AM ratio had the smallest influence. The optimized reaction condition was as follows: initiator concentration 0.50 × 10−3 mg L−1, AA/AM molar ratio 1:1, reaction temperature 60 °C and reaction time 3 h. The optimum reaction condition of the experiment was repeated thrice. The average PG and GE of chitosan-g-PAM-AA obtained were 358.30% and 91.66%, respectively.

In the experiment, it is found that a high concentration of initiator might initiate a larger number grafting sites which resulted in higher grafting degree. Simultaneously, PG and GE increased with reaction temperature increased. Because the increase of reaction temperature resulted in grafting sites generating at greater rate as well as accelerating the diffusion and mobility of the monomers from the aqueous phase to the backbone [34].

In addition, C-chitosan-g-PAM-AA was synthesized by adding different amount of DMDAAC to the above reaction mixture under the optimum reaction condition for synthesizing chitosan-g-PAM-AA. The obtained experiment results are summarized in Table 2. The average PG, GE and cationic degree (CD) of C-chitosan-g-PAM-AA obtained were 336.67%, 87.33% and CD 13.47% (added 20% total monomer), 291.67%, 78.33% and CD 19.83% (added 30% total monomer), 280.00%, 76.00% and CD 27.48% (added 40% total monomer), respectively. The reason of the decrease PG and GE was reduce the collision probability among the monomers molecules with increasing monomer loading.

Characterization

Infrared Spectroscopy Analysis

FT-IR of chitosan and graft copolymers is showed in Fig. 1. In FT-IR spectra of chitosan, the bands of 2914 cm−1 and 2866 cm−1, 1080 cm−1 were attributed to the C–H stretching vibration and C–O stretching vibration of the primary alcohol, respectively. Absorption band at 1166 cm−1 was ascribed to anti-symmetric stretching of C–O–C bridge, 1072 cm−1 and 1026 cm−1 were ascribed to skeletal vibration involving C–O stretching, which were characteristics of its saccharide structure (Fig. 1a) [35, 36]. The strong peaks around 3415 cm−1 was attributed to the stretching vibration of O–H, the extension vibration of N–H, and intermolecular hydrogen bonds of the chitosan. Band at 1654 cm−1 was attributed to residual acyl group. However, band at 1589 cm−1 was attributed to bending vibration peak of primary amine N–H in chitosan, which was disappeared in the grafting copolymer chitosan-g-PAM-AA (Fig. 1b) and C-chitosan-g-PAM-AA (Fig. 1c). The additional peak about 1671 cm−1 (Fig. 1b) or 1669 cm−1 (Fig. 1b) and 1535 cm−1 were attributed to C=O stretching vibration, and C–N stretching vibration along with N–H bending vibration of PAM. Bands around 1610 cm−1 and 1556 cm−1 (Fig. 1b), 1537 cm−1 (Fig. 1c) and 1407 cm−1 (Fig. 1b), 1424 cm−1 (Fig. 1c) were ascribed to asymmetrical COO ~ stretching and symmetrical COO ~ stretching vibration. The peaks at around 896 and 615 cm−1 were also characteristic of PAA [17, 18]. It suggested that PAA have formed corresponding salts in (Fig. 1b, c) [37, 38]. Besides, the band over 1700 cm−1 respectively presented in Fig. 1b, c, which were attributed to C=O on alkyl ketone, carboxylic acid. In Fig. 1c, band around 1645 cm−1 and 3037 cm−1 might be respectively ascribed to stretching vibration absorption peak of C=C and =C–H on DMDAAC. The peak (around 3564 cm−1) widen, which was ascribed to free hydroxyl of chitosan, free amino group of chitosan and PAM have red-shifted. The new peaks (2948 cm−1 and 2881 cm−1) were due to the introduction of CH3 in DMDAAC. A new peak 2081 (Fig. 1b) and 2090 cm−1 (Fig. 1c) was ascribed to the formation of C=NH+ groups [39]. In conclusion, the grafting reaction was inferred from the reported reaction mechanism [40, 41]. It indicated that the graft copolymer copolymer C-chitosan-g-PAM-AA have been synthesized, but its structure was different with chitosan-g-PAM-AA.

XRD Patterns Analysis

X-ray diffraction spectra of chitosan, chitosan-g-PAM-AA and C-chitosan-g-PAM-AA are showed in Fig. 2. The XRD pattern of chitosan (Fig. 2a) showed two major peaks at 2θ = 12° and 2θ = 20°, respectively, which declared chitosan was highly crystalline material. The reflection at 2θ = 12° was put down to hydrated crystals of low crystallinity and corresponded to form I, while reflection at 2θ = 20° was identified as representative of the equivalent of form II [42, 43]. The XRD spectra of chitosan-g-PAM-AA (Fig. 2b) showed evident crystalline peaks compared with that of chitosan. Chitosan-g-PAM-AA showed the peak at 2θ = 12° and a single broad absorption at 20° decreased drastically. It suggested that chitosan-g-PAM-AA samples became almost amorphous and hydrogen bonding ability of chitosan reduced after grafting of monomers onto chitosan backbone [13]. This would efficiently break the regularity of chitosan chains, which resulted in formation of amorphous copolymer [44]. The XRD spectra of grafted chitosan (Fig. 2c) showed peak at 2θ = 12° disappeared while broad absorption at 20° ascribing to the crystallinity of chitosan sequentially decreased and many crystalline areas between 2θ = 25–35°. This was due to monomer DMDAAC, AM and AA grafting onto chitosan backbone, while no such peaks were visible in XRD of chitosan itself [45]. Thus, Fig. 2b, c indicated that monomer had grafted onto chitosan.

SEM Patterns Analysis

It is evident from the SEM micrographs of chitosan, chitosan-g-PAM-AA and C-chitosan-g- PAM-AA morphological changes (Fig. 3). Figure 3a, b are SEM images of chitosan which were flaky. Figure 3c, d are SEM images of chitosan-g-PAM-AA, wherein distinct morphological differences were discernible in their surface topography. They presented the clustered regular structure. Herein innumerable thin column-like structure deposited over the visible surface. It might be because AA grafted onto chitosan formed salt with –NH2 protonized on chitosan chain or sodium ion in the reaction system to make it thin column-like structure, However, it was irregular deposited, which resulted in the corresponding XRD pattern of chitosan-g-PAM-AA decreasing. C-chitosan-g-PAM-AA (Fig. 3e, f) showed the appearance of clustered irregular beads [45, 46]. It was concluded that DMDAAC, AM and AA had grafted onto chitosan by comparing Fig. 3e, f with Fig. 3c, d, these conclusions were consonant with that of the corresponding XRD pattern. C-chitosan-g-PAM-AA (Fig. 3e, f) showed the appearance of clustered irregular beads [45, 47], which made C-chitosan-g-PAM-AA possess a larger specific surface area. It was helpful to advance sludge dewatering.

Thermogravimetric Analysis

The wt% variation of chitosan, chitosan-g-PAM-AA and C-chitosan-g-PAM-AA with heating temperature is shown in Fig. 4. Obviously, chitosan had higher thermal stability than chitosan-g-PAM-AA and C-chitosan-g-PAM-AA. As was obtained in previous investigations [48, 49], the weight losses at 50–170 °C was attributed to the process in PAA forming anhydride with the evolution of water or related to the elimination of water adsorbed and bound to the salt in chitosan-g-PAM-AA. However, in the TGA curve of C-chitosan-g-PAM-AA, the weight loss was lower than that of chitosan-g-PAM-AA, which was ascribed to quaternary ammonium salt DMDAAC decomposition. The weight losses at 200–500 °C was assigned not only to the formation of Na2CO3 [48, 49] (PAA) but also to the corresponding loss of ammonia and water by imidization and dehydration [50] (PAM) but also to main chain (chitosan, PAM, PAA and DMDAAC) degradation. Above 500 °C the mass loss was almost negligible.

Hydrophilicity Analysis

Contact angle is a most important parameter to evaluate the material surface hydrophilicity (wetting property) [51]. The material hydrophilicity directly influences on its solubility in water. Herein, the determinand was pressed into slice under 30 MPa pressure, and the water wetting property to slice was tested (Fig. 5). The results are summered in Table 3. As was shown Table 3, contact angle of Chitosan (83.0°), chitosan-PAM-AA (75.9°) and C-chitosan-PAM-AA (68.3°) was gradually decreased as PAM, PAA and PAM, PAA, DMDAAC grafted to chitosan, which indicated their hydrophilicity was as following: C-chitosan-PAM-AA > chitosan-PAM-AA > chitosan. It suggested that the water solubility of C-chitosan-PAM-AA was maybe the strongest, chitosan was the poorest. Also, in the experiment, it is found that C-chitosan-PAM-AA and chitosan-PAM-AA were easily dispersed in the water, while chitosan was difficultly to be dispersed and floated on the surface of the water.

Flocculation Experiment

Effect of the Dosage on the Sludge Dewatering Efficiency

The effects of flocculants dosage on the flocculating properties of chitosan, PAM, chitosan-g-PAM-AA and C-chitosan-g-PAM-AA were investigated (Fig. 6). As shown in Fig. 6, chitosan, chitosan-g-PAM-AA and C-chitosan-g-PAM-AA all initially decreased slowly, decreased rapidly, increased slightly, and then increased more rapidly. In lower dosages situations, it is difficult to execute electrical neutralization because of insufficient charge, leading to weak bridge-aggregation. When the dosage was 40 mg L−1, FCMC after sludge dewatering reached the lowest 72.58% (chitosan), 68.71% (chitosan-g-PAM-AA) and 66.43% (C-chitosan-g-PAM-AA), respectively. Also, the dewatering efficiency of C-chitosan-g-PAM-AA was best followed by chitosan-g-PAM-AA and then chitosan. This possible reason was that: (1) C-chitosan-g-PAM-AA bearing cation along with a clustered irregular beads structure of chitosan-g-PDMDAAC were useful in improving the charge-neutralizing and bridging adsorption ability to sludge dewatering [1, 52, 53]; (2) the flexible polyacrylamide chain grafted onto the inflexible chitosan backbone sequentially increased chitosan flexibility, which was contribute to binding intensity between flocculants and colloids [13]. Therefore, re-dispersion rooting in the competition of bridging and charge neutralization could be avoided to some extent [54]. Nonetheless, superfluous dosages resulted in the flocculation efficiency decreasing. This maybe is because the repulsion force of residual positive charge led to sludge system instability after neutralizing the negative charge of sludge colloids. As a consequence, FCMC increased. But, PAM showed decreased slowly, then, leveled off. When the dosage of PAM was 40 mg L−1, FCMC after sludge dewatering reached the lowest 77.06%, because PAM did not possess charge-neutralizing ability to the negative charge of sludge colloids. The dewatering performance of chitosan and chitosan-g-PAM-AA were superior to PAM because of amino group on chitosan and chitosan-g-PAM-AA might adsorb negative charge.

Effect of pH Value and on the Sludge Dewatering Efficiency

It is reported that acid or alkali might lead to the surface properties of the sludge flocculation changed [53, 55]. However, the effects of the activated sludge pH value on the flocculating performance of chitosan and PAM have been reported in our previous work [53]. Figure 7 shows the effects of the activated sludge pH value on the flocculating performance of C-chitosan-g-PAM-AA and chitosan-g-PAM-AA. Herein, they display similar profiles, and their sludge conditioning performance was gradually increased in turn chitosan-g-PAM-AA (Fig. 7b) and C-chitosan-g-PAM-AA (Fig. 7a). It mainly depended upon cationic charge neutralization. Their FCMC initially slightly decreased, slowly decreased when the pH changed from 2.0 to 4.0, then 6.0 and respectively reached minimum 69.97% (chitosan-g-PAM-AA), 67.34% (C-chitosan-g-PAM-AA) at pH 6.0, then FCMC rapidly increased when pH increased from 6.0 to 10.0. In short, C-chitosan-g-PAM-AA exhibited better sludge flocculating dewatering properties than that of chitosan-g-PAM-AA under weak acid condition. The main reason is that: (1) excessive hydrogen ions repulsed the positive charges of the polymer, which made the electrostatic attraction between the positively charged C-chitosan-g-PAM-AA and the negatively charged colloids in the sludge be weakened (pH 2–5); (2) the effect of charge neutralization between C-chitosan-g-PAM-AA flocculant and sludge with negative surface charges led to sludge aggregation and settlement (pH 5–7) [22]. However, Under alkali conditions, the positive charges of DMDAAC grafted onto chitosan chains took preference to neutralize with hydroxyl ion along with the ionized carboxyl group [13, 28], which weakened their charge neutralization abilities for negative colloid particles. Especially, when pH exceeded 9, the sludge dewatering became more difficult, and FCMC rapidly increased. Besides, the flocculation of chitosan-g-PAM-AA was lower than that of C-chitosan-g-PAM-AA, which attributed to the fact that re-dispersion resulted from charge reversion in addition to the competition of bridging and charge neutralization [56, 57].

Effect of Temperature on Dewatering Performance

It is known that the temperature of raw sludge was important to flocculating effects on actual sludge dewatering. Figure 8 exhibits FCMC at natural pH in dosage of 40 mg L−1 of flocculants at various temperatures (ranging from 0 to 35 °C). It was clear that FCMC decreased as temperature of raw sludge increased under same loading of different flocculants after the activated sludge was dewatered. FCMC was lowest at 35 °C (C-chitosan-g-PAM-AA: 61.41%). This might be because a higher temperature resulted in the increase of sludge colloids movements and collision to generate easily larger particles. Also, the increase of temperature was beneficial to bridging flocculation effects. Both of them resulted in the decrease of FCMC [15]. FCMC was lower when C-chitosan-g-PAM-AA was added into activated sludge compared to that of chitosan and chitosan-g-PAM-AA under the identical temperature. The result mainly resulted from the charge neutralization of C-chitosan-g-PAM-AA.

Effect of CD and PG of Polymer Flocculants on Dewatering Performance

Furthermore, the effects of CD of polymer flocculants on sludge dewatering were researched under the same conditions. FCMC decreased with the increase of CD from 72.17% (CD 13.76%; PG 330%) to 66.43% (CD 19.82%; PG 295%), then slightly decreased 65.61% (CD 27.51%; PG 285). It might be due to cooperative effects of bridging flocculating and charge neutralization mechanisms of polymer flocculants. On the one hand, based on bridging flocculating mechanism, higher PG was beneficial to increase molecular weight of flocculants, and improve its actual flocculating capacity. On the other hand, the cationic groups of NH3+ on chitosan backbone would be efficiently shielded by longer and more PAM and PAA branch chains. According to the viewpoint of the charge neutralization mechanism, flocculating performances would become bad. With PG increased further, CD decreased, effects of charge neutralization might be predominant, as a result the flocculating properties decreased at last [16, 58]. In terms of the charge neutralization flocculation mechanism, at a proper CD% of flocculants, the negative charge on sludge colloid surface could be efficiently neutralized and aggregated into sediments. However, if CD of flocculants was too high, the literature indicated that not all cationic sites of C-chitosan-g-PAM-AA were accessible for interactions due to steric hindrances [58] and the excessive cation would enwrap and re-stabilize suspension partially in water, which made the final flocculating effects decrease.

Conclusions

Chitosan-grafting copolymer chitosan-g-PAM-AA was successfully synthesized. The optimized grafting conditions of synthesized chitosan-g-PAM-AA were obtained as follows: initiator concentration 0.50 × 10−3 mg L−1, AA/AM molar ratio 1:1, reaction temperature 60 °C and reaction time 3 h. Furthermore, DMDAAC was introduced into the above optimum reaction process, and successfully synthesized C-chitosan-g-PAM-AA with different CD in better PG and GE. Finally, the activated sludge treatment of the grafting copolymers chitosan-g-PAM-AA and C-chitosan-g-PAM-AA were investigated comparing with PAM and chitosan. FCMC was found to be appropriate parameters for assessing sludge dewaterability. Results indicated that the sludge dewaterability appropriate loading dosage, pH value, temperature was respectively 37.5–45.0 mg L−1, 4.5–7.0, and 15–35 °C. CD of C-chitosan-g-PAM-AA was important factor for the flocculating effects. Besides, the grafting of AM and AA onto chitosan backbone improved corresponding solubility and structure of chitosan, thus made it more convenient and effective to be used in activated sludge dewatering. Meanwhile, the grafting of cationic monomer (DMDAAC) onto chitosan backbone enhanced the cationic properties of copolymer, further improved its flocculating ability. The benefit of adding C-chitosan-g-PAM-AA was demonstrated by improving both sludge filterability and cake properties with FCMC significantly reduced. Moreover, the modification of natural polymers is ongoing in our laboratory.

References

Zheng HL et al (2014) Characterization and evaluation of dewatering properties of PADB, a highly efficient cationic flocculant. Ind Eng Chem Res 56:2572–2582

Liu B et al (2018) Rapid and efficient removal of heavy metal and cationic dye by carboxylate rich magnetic chitosan flocculants: role of ionic groups. Carbohydr Polym 181:327–336

Ye Q, Zhang Z, Ge X (2003) Highly efficient flocculant synthesized through the dispersion copolymerization of water-soluble monomers induced by γ-Ray irradiation: synthesis and polymerization kinetics. J Appl Polym Sci 89:2108–2115

Moody GM (2007) Polymeric flocculants. In: Williams PA (ed) Handbook of industrial water soluble polymers. Wiley, Oxford

Lin QT et al (2015) Synthesis, characterization, and secondary sludge dewatering performance of a novel combined silicon-aluminum-iron-starch flocculant. J Hazard Mater 285:199–206

Kiechel MA, Schauer CL (2013) Non-covalent crosslinkers for electrospun chitosan fibers. Cabohydr Polym 95:123–133

Fast SA, Kokabian B, Gude VG (2014) Chitosan enhanced coagulation of algal turbid waters—comparison between rapid mix and ultrasound coagulation methods. Chem Eng J 244:403–410

Vakili M et al (2014) Application of chitosan and its derivatives as adsorbents for dye removal from water and wastewater: a review. Carbohydr Polym 113:115–130

Agbovi HK et al (2018) Design of amphoteric chitosan flocculants for phosphate and turbidity removal in wastewater. Carbohydr Polym 189:360–370

Jaafari K (2004) Simulation of a fixed bed adsorber packed with protonated cross-linked chitosan gel beads to remove nitrate from contaminated water. Chem Eng J 99:153–160

Wang JP et al (2013) Synthesis, characterization and application of a novel starch-based flocculant with high flocculation and dewatering properties. Water Res 47:2643–2648

Wu H et al (2017) Evaluation of starch-based flocculants for the flocculation of dissolved organic matter from textile dyeing secondary wastewater. Chemosphere 174:200–207

Wang JP et al (2008) A chitosan-based flocculant prepared with gamma-irradiation-induced grafting. Bio Tech 99:3397–3402

Ali SKA, Singh RP (2009) An investigation of the flocculation characteristics of polyacrylamide-grafted chitosan. J Appl Polym Sci 114:2410–2424

Lu YB et al (2011) Preparation of strong cationic chitosan-graft-polyacrylamide flocculants and their flocculating properties. Ind Eng Chem Res 50:7141–7149

Yuan B et al (2010) The flocculating properties of chitosan-graft-polyacrylamide flocculants (I)—effect of the grafting ratio. J Appl Polym Sci 117:1876–1882

Ge HC, Pang W, Luo DK (2006) Graft copolymerization of chitosan with acrylic acid under microwave irradiation and its water absorbency. Carbohydr Polym 66:372–378

Yazdani-Pedram M, Retuert TJ (2000) Hydrogels based on modified chitosan, 1-synthesis and swelling behavior of poly(acrylic acid) grafted chitosan. Macromol Chem Phys 201:923–930

Zhang J et al (2003) Synthesis and characterization of chitosan grafted poly(N,N-dimethyl-N-methacryloxyethyl-N-(3-sulfopropyl) ammonium) initiated by ceric(IV) ion. Eur Polym J 39:847–850

Wang JP et al (2009) Synthesis and characterization of a novel cationic chitosan-based flocculant with a high water-solubility or pulp mill wastewater treatment. Water Res 43:5267–5275

Blanco Á et al (2009) Polymeric branched flocculant effect on the flocculation process of pulp suspensions in the papermaking industry. Ind Eng Chem Res 48:4826–4836

Yang Z et al (2012) Evaluation of the flocculation performance of carboxymethyl chitosan-graft-polyacrylamide, a novel amphoteric chemically bonded composite flocculant. Water Res 46:107–114

Gui Z et al (2009) Synthesis, characterization and flocculation performance of zwitterionic copolymer of acrylamide and 4-vinylpyridine propylsulfobetaine. Eur Polym J 45:1403–1411

Kokufuta E, Takahashi K (1986) Adsorption of poly(diallyldimethylammonium chloride) on colloid silica from water and salt solution. Macromolecules 19:351–354

Du Q et al (2017) Evaluation of the starch-based flocculants on flocculation of hairwork wastewater. Sci Total Environ 601–602:1628–1637

Matilainen A, Vepsäläinen M, Sillanpää M (2010) Natural organic matter removal by coagulation during drinking water treatment: a review. Adv Colloid Interface Sci 2:189–197

Sajomsang W (2008) Synthesis of methylated chitosan containing aromatic moieties: chemoselectivity and effect on molecular weight. Carbohydr Polym 72:740–750

Wang JP (2007) Gamma radiation-induced grafting of a cationic monomer onto chitosan as a flocculant. Chemosphere 66:1752–1757

Qi L et al (2017) The effects of physicochemical properties of sludge on dewaterability under chemical conditioning with amphoteric polymer. J Polym Environ 25:1262–1272

Watanabe Y, Kubo K, Sato S (1999) Application of amphoteric polyelectrolytes for sludge dewatering. Langmuir 15:4157–4164

Patil MK, Nayak PL (2011) Graft copolymerization of vinyl monomers onto chitosan: III: graft copolymerization of acrylamide onto chitosan for antibacterial activity. Int J Plant Sci 2:210–219

Luo XY et al (2011) Optimization of synthesis conditions and structural characterization of the two sexes chitosan. Nonferrous Met Sci Eng 2:32–37

Liao Y et al (2014) UV-initiated polymerization of hydrophobically associating cationic polyacrylamide modified by a surface-active monomer: a comparative study of synthesis, characterization, and sludge dewatering performance. J Ind Eng Chem Res 53:11193–11203

Tian DT, Xie HQ (2008) Synthesis and flocculation characteristics of konjac glucomannan-g-polyacrylamide. Polym Bull 61:277–285

Peniche C et al (1999) Self-curing membranes of chitosan/PAA IPNs obtained by radical polymerization: preparation, characterization and interpolymer complexation. Biomater 20:1869–1878

Argüelles-Monal W, Peniche-Covas C (1988) Study of the interpolyelectrolyte reaction between chitosan and carboxymethyl cellulose. Macromol Rapid Commun 9:693–697

Wang HF et al (1997) Studies on chitosan and poly(acrylic acid) interpolymer complex. I. preparation, structure, pH-sensitivity, and salt sensitivity of complex-forming poly(acrylic acid): chitosan semi-interpenetrating polymer network. J Appl Polym Sci 65:1445–1450

Li QY, Wang XL, Liu ShP (1996) Infrared spectroscopic qualitative study of carboxylicacid and carboxylate structure. Nat Sci J 12:67–70

Zhang H, Peng QJ, Li YM, Zhang R (2005) Modern organic spectroscopy. Chemical Industry Press, Bejing

Li W et al (1993) Chemical modification of biopolymers-mechanism of model graft copolymerization of chitosan. J Biomater Sci Polym 4:557–566

Zhang R et al (2007) Preparation of copolymer of dimethyldiallylammonium chloride and chitosan and its application. Trans China Pulp Pap 22:46–49

Dung P et al (1994) Water soluble derivatives obtained by controlled chemical modifications of chitosan. Carbohydr Polym 24:209–214

Wu Y et al (2005) Synthesis and characterization of a novel amphiphilic chitosan–polylactide graft copolymer. Carbohydr Polym 59:165–171

Joshi JM, Shinha VK (2007) Ceric ammonium nitrate induced grafting of polyacrylamide onto carboxymethyl chitosan. Carbohydr Polym 67:427–435

Ali SKA, Singh RP (2009) Microwave enhanced synthesis of chitosan-graft-polyacrylamide. J Appl Polym Sci 114:2410–2424

Sen G et al (2009) A novel polymeric flocculant based on polyacrylamide grafted carboxymethyl starch. Carbohydr Polym 77:822–831

Mun GA et al (2008) Studies on graft copolymerization of 2-hydroxyethyl acrylate onto chitosan. React Funct Polym 68:389–395

Filipović J et al (1997) The thermal degradation of some alkali metal salts of poly(itaconic acid). J Therm Anal 49:335–341

Kalagasidis Krušić M et al (2004) Polyacrylamide and poly(itaconic acid) complexes. Eur Polym J 40:793–798

Van Dyke JD, Kasperski KL (1993) Thermogravimetric study of polyacrylamide with evolved gas analysis. J Polym Sci Part A 31:1807–1823

Tavana H et al (2004) Contact angle measurements with liquids consisting of bulky molecules. J Colloid Interface Sci 279:493–502

Yang Z et al (2013) Flocculation of both anionic and cationic dyes in aqueous solutions by the amphoteric grafting flocculant carboxymethyl chitosan-graft-polyacrylamide. J Hazard Mater 254–255:36–45

Wang D et al (2016) Synthesis, characterization and evaluation of dewatering properties of chitosan-grafting DMDAAC flocculants. Int J Biol Macromol 92:761–768

Bratskaya S et al (2005) Effect of polyelectrolyte structural features on flocculation behavior: cationic polysaccharides vs. synthetic polycations. Macromol Mater Eng 290:778–785

Raynaud M et al (2012) Compression dewatering of municipal activated sludge: effects of salt and pH. Water Res 46:4448–4456

Sarkar AK et al (2013) Amylopectin grafted with poly (acrylic acid): development and application of a high performance flocculant. Carbohydr Polym 95:753–759

Sharma BR, Dhuldhoya NC, Merchant UC (2006) Flocculants—an ecofriendly approach. J Polym Environ 14:195–202

Zhang WX et al (2010) The flocculating properties of chitosan-graft-polyacrylamide flocculants (II)—test in pilot scale. J Appl Polym Sci 117:2016–2024

Acknowledgements

The research was supported by Beijing Guoneng Zhongtian Environmental Protection Technology Co. Ltd. of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, J., Chen, Q., Li, J. et al. Preparation and Dewatering Property of Two Sludge Conditioners Chitosan/AM/AA and Chitosan/AM/AA/DMDAAC. J Polym Environ 27, 275–285 (2019). https://doi.org/10.1007/s10924-018-1342-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1342-0