Abstract

Although water-soluble synthetic polymers find wide applications as flocculants, the potential problem associated with their use is lack of biodegradability and high cost. Polysaccharides owing to their distinctive features like ability to undergo different chemical reactions, biodegradability and sustainability inspire hope to obtain effective, economical viable and safe substitute of the synthetic flocculants. In this regard, chemical modification of Cassia tora and guar gum was carried out through different substitution and grafting reactions. The modified products were tested against kaolin under laboratory conditions vis-a-vis polyacrylamide based synthetic flocculant.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Disperse systems are encountered in a wide variety of fields, especially in the chemical industry where they can be used as end products (paints, printing inks, drilling mud, cosmetics, agrochemicals and pharmaceutical formulations) or in one or several stages of the elaboration of materials such as ceramics, cements or coatings. Such applications require a good stability of the suspension or, if necessary, a controlled level of aggregation of the medium in order to improve its mechanical behavior. Other important technological processes need a fast, complete or selective solid/liquid separation of disperse media viz. papermaking, water treatment, clarification of beverages, mineral processing etc. A flocculation step is then essential in the case of submicronic or colloidal particles, which do not settle spontaneously and cannot be filtered [1].

Thus flocculation is a process whereby finely divided or dispersed particles are aggregated together to form large particles of such a size so as to cause their settling or it is the agglomeration of tiny particles to form flocs which settle and cause clarification of the system. Flocculation makes the suspension non-homogenous on a macroscopic scale [2].

Flocculants are the materials, which are used, in fast solid–liquid separations. They act on a molecular level on the surfaces of the particles to reduce repulsive forces and increase attractive forces. By the addition of flocculant (in ppm) finely divided or dispersed particles are aggregated together to form flocs of such a size so as to make them settle speedily and to clear the system [2].

Categories of Flocculants

There are two major classes of flocculants [2] depending upon their chemical composition: (1) inorganic flocculants and (2) organic flocculants.

Inorganic flocculants

These flocculants are being used since time immemorial. In this class salts of multivalent metals like aluminium and iron are commonly used viz. alum, ferric chloride etc. But inorganic flocculants have disadvantages such as:

-

(i)

Large amount of inorganic flocculant is required to cause solid–liquid separation of the dispersion and produces a lot of sludge whose disposal itself is another problem.

-

(ii)

Highly sensitive to pH.

-

(iii)

These flocculants are applicable only to a few disperse systems and do not work for others.

-

(iv)

They do not coagulate very fine particles.

Due to these disadvantages, inorganic flocculants have almost been abandoned.

Organic flocculants

One of the greatest advantage in solid–liquid separation in recent years is the development of organic polymers with remarkable abilities to flocculate sols even when added in small (ppm) quantities. These organic flocculants came into use over three decades ago. Depending upon the source these are basically of following two types (Table 1):

-

(i)

Synthetic organic flocculants: these are based on various monomers like acrylamide, acrylic acid, diallyldimethyl ammonium chloride (DADMAC), styrene sulphonic acid etc.

-

(ii)

Natural organic flocculants: these are based on natural polymers like starch, cellulose, natural gums and mucilages and their derivatives etc.

Among the organic flocculants each has got certain advantages over another as follows:

Organic flocculants can be further characterized depending upon the nature of monomer present in a polymer. If a monomer in a polymer contains ionizable groups (carboxyl, amino, sulphonic etc.) the polymer is termed as polyelectrolyte. On the basis of the ionizable groups on the monomeric units, a polymeric unit can be cationic, anionic or ampholytic. Thus based on charge, flocculants are divided into four categories [3]: non-ionic, cationic, anionic and ampholytic.

Mechanism of Flocculation

Flocculation is aggregation of suspended particles with polyelectrolytes (cationic, anionic, or ampholytic) mainly by either a bridging or a patch mechanism.

LaMer et al. and others developed a bridging theory [4–7] that provides a useful description of the ability of polymers with high molecular weights to destabilize colloidal dispersions; a summary on flocculation has been written by Gregory [3]. Destabilization by bridging occurs when segments of a polymer chain adsorb on more than one particle, thereby linking the particles together. When a polymer molecule comes into contact with a colloidal particle, some of the reactive groups on the polymer adsorb at the particle surface, leaving other portions of the molecule extending into the solution (Fig. 1a). The polymer will adsorb on the surface in a series of loops (segments extending into the solution) and trains (segments adsorbed on the surface). If a second particle with some vacant adsorption sites contacts these extended loops and tails, attachment can occur (Fig. 1b). A particle–polymer–particle aggregate is formed in which the polymer serve as a bridge.

Effective bridging requires that adsorbed polymers extend far enough from the particle surface to attach to other particles and also that some free surface is available for adsorption of the extended segments. If excess polymer is added and adsorbed, the particles are restabilzed by surface saturation and can be sterically stabilized as shown in Fig. 1c.

From this description it can be seen that the length of the polymer chain is crucial for effective bridging to occur. It also follows that a linear (i.e. non-branched) polymer would be the most effective. Longer the chain (high molecular weight), greater the chances of interacting with more than one particle. The most important thing is size of polymer in solution i.e. hydrodynamic volume rather than merely the molecular weight. Bridging is preferred mechanism for applications of non-ionic polymers with molecular weights of more than 1 million or for high molecular weight polyelectrolytes of low charge density.

The second type of polymer flocculation, described as the patch model [8, 9] or electrostatic mechanism, involves uneven distribution of charges resulting from the adsorption of discrete patches of polymer on the surface. A highly cationic polymer is adsorbed on a negative particle surface in a flat conformation. That is to say most of the charged groups are closed to the surface of the particle, as illustrated in Fig. 2. This promotes flocculation by first reducing the overall negative charge on the particle thus reducing inter particle repulsion. This effect is called charge neutralization and is associated with reduced electrophoretic mobility. In addition, the areas of polymer adsorption can actually have a net positive charge because of the high charge density of polymer. The positive regions are also attracted to negative regions on other particles, which is called heterocoagulation. The tenacious floc that results is very resistant to redispersion. Polymeric inorganic materials may also adsorb on surfaces and cause flocculation by a similar mechanism. Patch model flocculation mechanism is preferred mechanism for applications of low molecular weight polyelectrolytes with high charge density.

In addition of bridging and patch model mechanisms, two more mechanisms have been proposed namely double-layer compression [10] and sweep flocculation [11]. Double-layer compression often cited for inorganic flocculants like alum and ferric salts. A good example of destabilization by double-layer compression occurs when particles in freshwater of rivers with low ionic strength mix with high ionic strength seawater. This causes the particles to be destabilized by double-layer compression and accumulation of particles results in the formation of deltas at river mouths.

In sweep flocculation, addition of an inorganic salt produces a metal hydroxide precipitate, which entrains fine particles of other suspended solids as it settles. Sweep flocculation is the combination of destabilization and transport, is extensively used in treatments of water of variable turbidity and dissolved organic carbon in conjunction with rapid mixing, flocculation, sedimentation and filtration facilities in series. A variation of this mechanism is sometimes employed for suspensions that do not respond to polymeric flocculants. A solid material such as clay is deliberately added to the suspension and then flocculated with a high molecular weight polymer. The original suspended material is entrained in the clay flocs formed by the bridging mechanism and is removed with the clay. Sweep flocculation is used primarily in very low solids systems such as raw water clarification.

Why Flocculants Based on Biopolymers?

The words “Pollution”, “Environment” and “Ecofriendly”, have come into more and more frequent usage and the cleanliness of the world we live in has become the concern of all people. State and Central Government have created various rules and regulations against pollution. These regulations when fully effective will have profound effects, particularly on disposal practices of toxic industrial wastes.

The questions about the safety of synthetic organic flocculants have been raised in all over the world. Until 1990 the EPA maintained a list of chemicals suitable for potable water treatment in the USA. Since then the entire question of certification and standards has been turned over to a group of organizations headed by the National Sanitation Foundation, which has issued voluntary standards [2].

Environmental considerations demand to develop strong, economically viable and ecofriendly replacements of conventional synthetic flocculants, based upon the renewable organic materials which are economic and degrade naturally, if ever released in the environment. One obvious advantage of using renewable materials is the minimal net effect on global warming. Other advantages include biodegradability and sustainability. Thus, flocculants based on biopolymers have a great potential to be used as a safe and economic substitute of synthetic flocculants being used currently in various industries for solid–liquid separation.

Flocculants from Biopolymers—A Review

An intensive research effort is being made worldwide to find environmentally acceptable replacements for current synthetic flocculants used for different industries. Issues pertaining to the development of safe and effective bioflocculants are among the ones currently being actively debated in international circles. For 30 years, biopolymers based flocculants have been attracting wide interest of researchers. Intensive R&D studies on chemical modification of polysaccharides are going on in many national and international laboratories to prepare biopolymers based flocculants.

Various workers prepared flocculants by grafting of acrylamide onto hydroxyethyl cellulose, amylose, amylopectin, guar gum and alginate [12–14]. The effect of properties of the native polymers of the grafted copolymers on their flocculating action for kaolin suspension were examined and showed that their flocculating action depends on their molecular extensions in aqueous solution.

Flocculants were also prepared by grafting of polyacrylamide onto cellulose ethers (hydroxypropyl and hydroxyethyl) and was tested against effluents of electroplating, leather and spinning industries [15]. Okieimen prepared graft copolymers of carboxymethyl cellulose using ceric ion initiator and tested their efficacy as flocculant against kaolin suspension [16]. Sakurai et al. used hydroxypropylmethyl cellulose phthalate as flocculant for recovery of silver from wastewater of photographic plants [17]. Bandet et al. prepared xanthates of cellulose and amylose and tested as flocculant. It was found that xanthates derivatives of cellulose showed good flocculation efficiency for calcite and chrysocolla in the presence of a salt [18].

There are many reports in literature on preparation of flocculants from chemical modification of starch. Cationic starches with improved flocculating properties and retention capacity have been prepared by a number of workers [19–21]. Cationic starch-g-polyacrylamide copolymer showed good flocculation ability, which can be used in paper industry to increase retention of filler, water drainage rate of slurry and paper strength [22]. To further modify the flocculation properties, starches with quaternary ammonium groups have been grafted with ammonium compounds having double bonds to prepare flocculants [22].

Yang et al. prepared cationic starches by grafting of starch with acrylamide [23, 24] and used for the treatment of industrial effluents [25]. In another report anionic starches were prepared by graft copolymerization of starch with acrylamide and sodium allylsulfonate and tested against kaolin suspension [26, 27]. Harrington et al. reported that cationic starches with higher concentration of quaternary ammonium compounds required a lower dose to achieve zero potential in kaolin suspensions [28].

Feng et al. grafted acrylamide onto starch by using KMnO4 as catalyst. This acrylamide-starch graft copolymer showed good flocculation ability; it can be used in paper industry to increase the retention of filler [29]. Further Yang et al. prepared acrylamide-starch graft copolymer using ceric ion as catalyst. Result showed that the grafted product had better performance in flocculation of Na-type bentonite compared with polyacrylamide [30].

In another report Wu et al. prepared graft copolymers of starch with acrylamide and acrylonitrile using ceric ion redox system. They observed that these grafted copolymers are effective flocculating agents for wastewater from the dyeing of silk [31].

Inano grafted acrylamide and N-methyloyl acrylamide onto starch and their flocculating ability was tested for kaolin suspensions. Starch-g-polyacrylamide showed about the same flocculation action as the common synthetic polymer flocculant [32]. Zhu et al. used the binary mixture of acrylamide and acrylic acid for the preparation of grafted products of starch. It was found that starch-g-poly(acrylamide-co-acrylic acid) can be used as flocculant for kaolin [33].

Ellis et al. prepared several cationic starch derivatives from oxidized and esterified starches by reaction with tetraethyl ammonium bromide and pyridine respectively. The ability of these starch derivatives to remove suspended particles from surface water was comparable with aluminum sulfate [34]. In another report Nishiuchi et al. prepared a cationic flocculant for kaolin suspensions by reaction of corn or potato starch successively with epichlorohydrin and triethylamine [35].

Starch or dextrin was graft polymerized with water-soluble monomers to form copolymers useful as retention aids in paper manufacturing and as flocculating agents [36]. Singh reported the synthesis, characterization and testing of starch-g-polyacrylamide. It was found that the flocculant prepared from the graft copolymer was shear resistant and showed a good drag reduction [37].

Polyacrylamide was grafted onto amylopectin using ceric ion as redox initiator to prepare flocculants. It was observed that these grafted copolymers gave comparable results with Aquaset (AS 510), a commercial flocculant, against kaolin and paper mill white effluent [38].

Termes et al. studied the flocculation efficiency of cross-linked starches containing chelating groups (carboxylate, iminodiacetate, xanthate) against oxide and hydroxide mineral (hamatite, geothite, chromite, cuprite, maganite, quartz) fines. It was found that starches were capable of interacting with the mineral surface and produced the highest recoveries and grades of the minerals [39].

Khalil et al. prepared some non-ionic starch derivatives [40] containing amide groups (polyacrylamide-starch graft copolymer, carbamoylethylated starch and starch carbamate) and some anionic starch derivatives, viz. carboxymethyl starch, carboxyethyl starch, poly(acrylic acid)-starch graft copolymer, starch-2-hydroxypropylcitrate, starch-2-hydroxypropylphosphate and starch-2-hydroxypropylsulphate and evaluated as flocculants against ferric laurate in water [41]. Cationic starch derivatives bearing various amino groups, i.e. primary, secondary and tertiary or quaternary ammonium salts were also studied as flocculants for ferric laurate [42].

Carbohydrates and their derivatives are being used where high pH conditions could hydrolyze synthetic polyamides, such as in hydrometallurgical leaching of aluminium from bauxite, soda from Trona and uranium from its ores. Guar gum based flocculants are preferred when aqueous liquors are recycled since they are less likely to build up in the liquor than synthetic polymers [43].

Guar gum and some of its derivatives have been used as processing aids in the separation of certain minerals from their crude ores [44, 45] performing two independent functions as flocculation of particles in aqueous solutions and depression of slimes in froth depressants, especially in the flotation of potash and copper–nickle sulphide ores. They are used in concentration of 0.2–0.5 lb (0.1–0.25 kg) per ton of ore [46].

Matsumoto prepared flocculant by cationization of guar gum for treatment of mud from landfilling or construction, wastewater from various industries etc. [47]. Davies et al. reported that the flocculation of quartz dust could be achieved by using guar gum in suitable concentrations [48].

Mathur et al. prepared flocculant cum ion-exchangers from galactomannan guaran by a general reaction using functionalized epoxides for treatment of industrial effluents. In addition to flocculation of suspended solids, these resins were capable of removing trace metal ions, dyes, surfactants etc. from effluents [49].

Hajime et al. reported acrylethyl trimethyl ammonium bromide–chitosan graft copolymer for the flocculation of kaolin suspension. It was found that grafted chitosan worked at concentration of nearly 10 ppm and isoelectric point was observed in the same dosage [50]. The application of chitosan as flocculant to treat wastewater in papermaking and to flocculate bauxite ore has also been studied [51].

Soni et al. has reported the modification of Cassia tora and guar gum. The modified Cassia tora gum (CTG) resulted in 99.6% settling of backwater components as compared to 98.7% reported with Trufloc and Deftech-706 using 4 mg/L dosage [52]. Further, Sharma et al. prepared flocculants for kaolin suspension by chemical modification of Cassia tora and guar gum [53].

Studies were also carried out on flocculation efficiency of xanthan gum. It was found that xanthan gum increased the flocculation of zinc oxide [54] and clay suspensions [55]. It was also found that the copolymer formed by reaction of polyacrylamide with guar and xanthan gum were effective flocculants for industrial effluents treatment containing metallic and non-metallic contaminants [37, 46].

Zhang et al. reported that konjac glucomannan itself was not a good flocculating agent but after reaction with NaH2PO4 and Na2HPO4 worked as good flocculating agent in purification of water [56].

Experimental

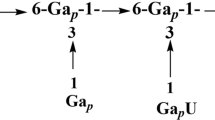

Cassia tora gum is derived from the seeds of Cassia tora Linn. a common herbaceous annual occurring weed throughout India. Methylation studies showed that backbone of the polysaccharide consists of 1→4 linked D-mannopyranose and D-glucopyranose units [57]. The ratio of D-mannopyranosyl to D-galactopyranosyl units is about 5:1 [58]. The average molecular weight of the Cassia galactomannan is 6.7×105 Da [59].

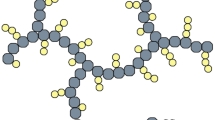

Guar gum (GG) is derived from the seeds of guar plant Cyamopsis tetragonolobus, a pod bearing legume grown commercially in India, Pakistan and the southwestern United States. It contains 75–85% guaran, the functional polysaccharide in guar gum, has a chain of (1→4)-linked-β-D-mannopyranosyl units with single α-D-galactopyranosyl units connected by (1→6) linkages to, on the average, every second main chain unit. The ratio of D-mannopyranosyl to D-galactopyranosyl units is about 1.8:1. The average molecular weight of guaran is in the range of 1–2×106 Da [60].

In our laboratory an attempt has been made to prepare modified products of CTG and guar gum via substitution and grafting reactions [61–68]. The structure and analysis of the products is given in Table 2. The modified products were tested against kaolin under laboratory conditions vis-a-vis polyacrylamide based synthetic flocculant (Table 3).

Flocculation efficiency

Kaolin suspension (2%, 100 mL) in water of pH 7 was taken in 100 mL graduated cylinder and the dilute flocculant solution (10 ppm) was added. The mixture was agitated by turning the cylinder upside down 5 times. After 5 min of settling, a graduated pipette was inserted in the middle of the cylinder and 20 mL of supernatant was drawn without disturbing the contents and filtered through a previously weighed filter paper in order to determine the dispersed particles and percent settling in the supernatant liquids of blank and flocculant treated kaolin suspension. The residue particles on filter paper were dried at 90–100 °C to a constant weight. The transmittance of supernatant liquids of blank and sample solution was measured at 700 nm.

Flocculation efficiency of the chemically modified products can be explained on the basis of bridging model as well as on charge neutralization mechanism. The products being of high molecular weight causes destabilization by bridging when segments of the polymer chain adsorb more than one particle, thereby, linking the particles together. Thus a particle–polymer–particle aggregate is formed in which polymer acts as a bridge.

Effective flocculation requires that the adsorbed polymer extend far enough from the particle surface to attach other particles so as to form extended segments for adsorption. Thus the length of polymer chain is crucial for effective bridging. In addition to this uneven distribution of charges resulting from the adsorption of polymer on the particles leads to the flocculation (patch mechanism). Thus a highly cationic polymer will adsorb on a negatively charged particle surface. This will promote flocculation by reducing the overall negative charge on the particles thus reducing the interparticle repulsion. This is also known as charge neutralization. The resulting floc is very resistant to redispersion.

Kaolin is the universal material used in laboratory for flocculation studies. Chemically it is silicate of aluminium, therefore, when dispersed in water it has a net negative charge on the silicate moiety. It is expected that a high molecular weight polymer having charged moieties will work as effective flocculant by bridging as well as patch mechanism. The synthetic polymer, derived from acrylamide and its derivatives, is widely used in industry for flocculation as it has got high molecular weight as well as net charge distribution.

The flocculation efficiency of all the chemically modified products has been studied. In the case of products synthesized by substitution reactions the flocculation is maximum with Q-CTG (99.65%) due to effective charge neutralization as well as bridging because of the cationic functional groups (quaternary ammonium groups) introduced into the backbone.

In case of CB-CTG and CB-GG, the settling of particles were 99.05% and 99.0% respectively because of the carbamoylethyl groups introduced in the biopolymer. Distribution of charges takes place due to negative charge on carbonyl oxygen and positive charge on nitrogen of the carbamoylethyl group.

Settling of particles was 98.58% with CE-CTG due to the introduced cyanoethyl groups. In this case the charge distribution is less as compared to the carbamoylethyl groups. It was observed that the flocculation was even better than Deftech (polyacrylamide based), the most widely used polymer in the industry. The settling of particles was 97.80% for CM-CTG because it has large hydrodynamic volume than other substituted products due to more hydrophilic carboxymethyl groups in the backbone. In this case a further application of the patch model in conjunction with the bridging effect was observed.

In case of graft copolymers settling of kaolin particles was maximum with CTG-g-AA (99.12%) due to effective charge distribution of amide groups. Flocculation takes place due to bridging as well as patch mechanism as discussed earlier. For CTG-g-AN the settling of particles was 98.94% due to reduced charge distribution as compared to amide groups introduced onto the galactomannan backbone. The settling of particles was 98.68% with GG-g-MMA because of the inductive effect of two methyl groups thereby reducing net charge distribution on the carbonyl group of methyl methacrylate moiety.

From the preceding discussion it can be concluded that the flocculation efficiency of most of the chemically modified products of Cassia tora and guar gum is better than Deftech and have potential to replace synthetic flocculants. These modified products can be further exploited for the treatment of many industrial effluents.

References

Lafuma F (1996) In: Roberts JC (ed) Paper chemistry, 2nd edn. Blackie Academic & Professional, London, Chap. 4

Heitner HI (1994) In: Kroschwitz JI, Howe-Grant M (eds) Encyclopedia of chemical technology, 4th edn. vol 11. John Wiley & Sons, pp 61

Gregory J (1978) In: Ives KJ (ed) The scientific basis of flocculation, Sijthoff and Noordhoff, Netherlands

Lamer VK, Healy TW (1963) Rev Pure Appl Chem 13:112

Michaels AS (1954) Ind Eng Chem 46:1485

Hocking MB, Klimchuk KA, Lowen S (1999) JMS-Rev Macromol Chem Phys, C 39(2):177

Gregory J (1983) Chemistry and technology of water-soluble polymers. Plenum press, New York, 307

Mabire F, Audebert R, Quivoron C (1984) J Colloid Interface Sci 97(1):120

Gregory J (1985) In: Moudgil J, Somasudaram P (eds) Flocculation, Sedimentation and Consolidation. Engineering Foundation, New York

Verwey EJW, Overbeek JTG (1948) Theory of the stability of lyophobic colloids. Elsevier Science, Amsterdam

Packham RF (1965) J Colloid Interface Sci 20:81

Gregory J (1981) In: Finch CA (ed) Chemistry and technology of water soluble polymers. Plenum press, New York

Burr RC, Fanta GF, Doane WM, Russel CR (1975) Starch/Stärke 27:155

Miyata N, Sakata I, Senju R (1975) Bull Chem Soc Japan 48:3367

Chauhan GS, Mahajan S, Sharma R, Kumari A, Lal H (2001) Trends Carbohydr Chem, 7:137

Okieimen FE (2003) J Appl Polym Sci 89(4):913

Sakurai S, Kawai I, Japan Kokai 78,34624 (1978) Chem. Abstr. 11735g, 89, 1978

Bandet G, Morio, M Rinaudo M (1978) Mineralurgie, 1, 19; Chem. Abstr. 112887p, 89, 1978

Mezynski L, Urbaniak G, Pol 107, 566 (1980); Chem. Abstr. 105259k, 95, 1981

Anon., Nichiden Kagaku Co. Ltd., Japan, Kokai Tokkyo Koho, 80, 142, 014 (1980); Chem. Abstr. 94000j, 95, 1981

Cherian XM, Satyamoorty P, Velayudhan NGK (1992) Starch/Stärke 44(8):301

Feng B, Wu S (1989) Hebei Gongxueychan Xuebao, 18(4), 75; Chem. Abstr. 9993b, 115, 1991

Yang T, Liu Y, Yang J(1998) Suliao Gongye, 26, 116; Chem. Abstr. 28564t, 129, 1998

Tongzai Y, Yinong L, Jun Y (1998) Gongye Shuichuli, 18, 27; Chem. Abstr. 305795k, 129, 1998

Wenzhan M, Jian H, Diachan G, Qilai L (1998) Huangshan Jishu, 27, 21; Chem. Abstr. 97926z, 129, 1998

Yao KJ, Tang YB (1992) J Appl Polym Sci 45:349

Chan WC, Chiang CY (1995) J Appl Polym Sci 58:1721

Harrington A, Engelhardt P (1979) Proc-Int. Water Conference, Eng. Soc. West Pa. 40th, 313; Chem. Abstr. 119669k, 92, 1980

Feng B, Wu S (1989) Hebei Gongxueyuan Xuebao, 18(4), 75; Chem. Abstr. 9993b, 115, 1991

Yang G, Deng M, Wang D, Wang X, Dai X, Ma P, Cui X (1990) Tianran Chanwu Yanjiu Yu Kaifa, 2(1), 8; Chem. Abstr. 281165n, 115, 1991

Wu P, Chen P (1981) Zhongguo Kexue Jishu Daxue Xuebao, 11(4), 70; Chem. Abstr. 123413b, 96, 1982

Inano M (1969) Kogyo Kagaku Zasshi, 72(10), 2298; Chem. Abstr. 68445r, 72, 1970

Zhu R, Zhao D (1989) Huaxue Shijie, 30(11), 495; Chem. Abstr. 414642z, 113, 1990

Ellis HA, Utah SI, Martins O (1982) Water Res 16(9):1433

Nishiuchi T, Kobayashi K(1977) Nippon Kogaku Kaishi, 11, 1711; Chem. Abstr. 63491y, 88, 1978

Fanta GF, Burr RC, US Pat. 604,362 (1975); Chem. Abstr. 109384j, 85, 1976

Singh RP (1995) In: Mark PN, James E, Joofai T (eds) (Polym. Other Adv. Mater. Proc. Int. Conf. Front. Polym. Adv. Mater.) 227, New York

Rath SK, Singh RP (1998) Colloids Surf 139(2):129

Termes SC, Wilfong RL(1985) Rep. Invest.-U.S. Bur. Mines, RI 8944, 21; Chem. Abstr. 40337s, 103, 1985

Khalil MI, Amal AA (2001) Starch/Stärke 53:323

Khalil MI, Amal AA (2002) Starch/Stärke 54:132

Khalil MI, Amal AA (2001) Starch/Stärke 53:84

Ramesh M, Kildea JD, US Pat. 54,78477 (1995)

Peterson LE, Opie JW (1958) Ind Eng Chem 50:1013

Peterson CT, Curtis CW, Belg. Pat. 871, 466 (1979); Chem. Abstr. 177312h, 91, 1979

Singh RP, Jain SK, Lan N(1991) In: Sivaram S (ed) Polym. Sci. (Sym. Proc. Polym. 91) 2, 716, Tata McGraw Hill, New Delhi, India

Matsumoto K, Jpn. Kokai Tokyo Koho JP 0938,415 (1997); Chem. Abstr. 229123k, 125, 1996

Davies JA, Saas K (1984) Surf Tekhnol 21(3):273

Mathur NK, Menaria KL, Mathur OP, Sharma K (1984) Pap. Semin. Chem. Behav. Appl. Weak acids, Weak base Chelating Ion Exchangers, 53

Hajime S (1995) Sozai Busseigaku Zasshi, 8(2), 42; Chem. Abstr. 177435a, 124, 1996

Fan R, Liu Q (1995) Fuzhou Daxue Xuebao, Ziran Kexueban, 23(1), 71; Chem. Abstr. 11279c, 124, 1996

Soni PL, Naithani S, Singh SV, Kapoor SK (2001) IPPTA Convention Issue, 97

Sharma BR, Kumar V, Soni PL (1999) Trends Carbohydr Chem 5:75

Tempio JS, Zatz JL (1980) J Pharm Sci 69(10):1209

Dmitrescu MN, Cincu C, Voice A, Lazar I (1991) Mater Plast 28(3–4):103

Zhang CK, Yang ZYM, Qu X (1994) Huaxua Shijie, 35(2), 83; Chem. Abstr. 317238z, 122, 1995

Soni PL, Pal R (1996) Trends Carbohydr Chem 2:33

Utz F, Lepilleur CA et al (2004) United States Patent Application, 20050026794

Bansal A (2005) Structural investigations of Cassia tora seed polysaccharides. Ph.D. Thesis, Forest Research Institute (Deemed University), Dehra Dun, India

Maier H, Anderson M, Magnuson K, Whistler RL (1993) In: Whistler RL, BeMiller JN (eds) Industrial gums: polysaccharides and their derivatives, 3rd edn. Academic Press, Inc., London, 181

Sharma BR, Kumar V, Soni PL (2002) J Appl Polym Sci 86(13):3250

Sharma BR, Kumar V, Soni PL (2003) J Macromol Sci. Part A: Pure Appl Chem 40(1):49

Sharma BR, Kumar V, Soni PL (2003) Starch/Stärke, 55(1):38

Sharma BR, Kumar V, Soni PL, Sharma P (2003) J Appl Polym Sci 89(12):3216

Sharma BR, Kumar V, Soni PL (2003) J Appl Polym Sci 90(1):129

Sharma BR, Kumar V, Soni PL (2003) Carbohydr Polym 54(2):143

Sharma BR, Kumar V, Soni PL (2004) Carbohydr Polym 58:449

Sharma BR (2004) Chemical modification of polysaccharides for industrial applications. Ph.D. Thesis, Forest Research Institute (Deemed University), Dehra Dun, India

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, B., Dhuldhoya, N. & Merchant, U. Flocculants—an Ecofriendly Approach. J Polym Environ 14, 195–202 (2006). https://doi.org/10.1007/s10924-006-0011-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-006-0011-x