Abstract

In this study the biodegradation characteristics of aromatic aliphatic copolyester Ecoflex was assayed with five different bacterial strains isolated from different kinds of environments and living at diverse optimum of temperature. The biodegradation properties of selected strains (Brevibacterium luteolum, Bacillus thuringiensis, Aeromonas media, Geobacillus kaustophilus and Serratia sp.) were assessed through several plate assays oriented to their proteolytic, lipolytic, esterolytic and cellulolytic abilities; catalase activities were measured too. In addition the bacterial hydrolytic abilities for polyhydroxybutyrate, polylactic acid and polybutyrate adipate terephthalate were obtained using specific culture media including also a specific Ecoflex agar. The biodegradation dynamics of selected strains were evaluated mainly by the incubation of Ecoflex foils with a specific bacterium during a period from 3 days until 16 weeks and the change of the degradability of the Ecoflex surface in nitrogen has been assessed by nonisothermal chemiluminescence measurements from 40 to 250 °C. Scanning electron microscope observation of inoculated foils was applied too. The comparison of the results showed the complexity of biodegradation phenomena. The concentration of oxygenated products measured by reached the maximum after 2 weeks of cultivation for strains G. kaustophilus and B. thurigiensis, after 4 weeks of cultivation for strain B. luteolum, and 8 weeks of cultivation for strains Serratia sp. and A. media. Each strain evidenced its own hydrolytic optimum at different periods, but almost all tested strains demonstrated a decline of hydrolysis up to 16 weeks of incubation. This study demonstrated that nonisothermal chemiluminescence examining momentaneous oxidation state of the polymer surface is a valuable technique to follow the biodegradation dynamics on polymeric film, while the Ecoflex agar is able to select useful polymer-degrading bacteria.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Different biodegradable polymers are used for the production of mulching foils exploited in agriculture practice. The biodegradable polymers offer numerous advantages compared to conventional plastic materials regarding mainly their low impact to environmental pollution due to their degradation by environmental fungal and bacterial microbiota [1–3]. Among them the aliphatic/aromatic copolyesters have excellent mechanical properties conferred by the aromatic moieties, while aliphatic structures ensure easy oxidisability and thus biodegradability [2, 4, 5]. An interesting example of such a copolyester is the polybutyrate adipate terephthalate, known with the commercial name—Ecoflex® (BASF, Germany), that is widely used for the production of mulching foils for agriculture purposes since 1998. Ecoflex is used during the vegetation period (approximately 4 months) where several degradation phenomena take place simultaneously.

Under composting conditions, the chemical structure of Ecoflex allows a gradual decomposition of polymer which takes approximately 3 months [6]. During this period the material is converted completely to water and CO2 by fungi or bacteria through their enzymatic pool [7]. Microorganisms possess enzyme systems which react with the specific structures of these copolyesters [8, 9] that can vary in hydrolysis of the terminal bonds (exo-mechanism) and interior bonds of the polymer (endo-mechanism). Some research shows that the bacterial enzymes catalyze the cleavage of the ester bond at aliphatic components of aliphatic–aromatic copolyester, preferentially from the terminus of the polymeric chains [10]. These enzymes belong to groups of lipases, esterases and chitinases [2, 11, 12]. The common tests used for the determination of hydrolytic activities such as proteolytic, lipolytic, cellulolytic activity are agar plate assays. Semi-quantitaive analysis can be reached by this methods and the principle of these assays is the application of equivalent media with unique carbon source.

Many studies were done in order to describe the chemical structure of polymers and their biodegradability [13–16], but the structural intermediates formed under microbial attack during a long period are usually unknown.

In order to describe the biodegradation process of Ecoflex, induced by bacteria, we have combined and compared two different approaches. The first approach is a microbiological strategy which included the selection of different bacterial isolates based on the characterization of their hydrolytic and catalase activities and their ability to degrade Ecoflex, polyhydroxybutyrate (PHB) and polylactic acid (PLA). The second approach was oriented to the chemiluminescence measurement (CL) of oxygenated structure appearing in Ecoflex due to bacterial degradation together with the state of degradation of the Ecoflex matrix.

Chemiluminescence is a sensitive tool for measurement of concentration of hydroperoxides and carbonyl groups during degradation of various polymers. For example in the case of polyolefins, a disproportionation of secondary peroxyl radicals provides more than 400 kJ/mol of heat that is sufficient for excitation of suitable energy acceptor such as carbonyl groups or singlet oxygen. According to Russel’s scheme, currently used for interpretation of chemiluminescence emission from oxidized polymers [17, 18], these moieties are formed in one step of secondary peroxyl recombination. However, in the case of heterochain polymers where the light intensity is usually lower (with exception of polyamides) [19], the excitation may occur as the step subsequent to the exothermic elementary process of any pair of free radical termination provided that the suitable acceptor of energy is present. Then formally the light emission which reflects the rate of polymer degradation may be proportional to the product of the rate of the decomposition of initiating source and concentration of energy acceptor, e.g. such as hydroperoxides and carbonyl groups. If hydrolysis is involved together with direct attack of oxygen, the increasing concentration of more reactive terminal group (carboxyls and alcohols) that are oxidized much easier than original polymer, may complicate the interpretation of chemiluminescence runs. Some investigations were already performed in order to describe degradation processes of PLA, Ecoflex and cellulose initiated by abiotic factors (temperature, UV radiation, light) [20, 21].

When comparing to papers of Abrusci et al. [17, 22–24] our experimental trial was performed for a longer period up to 16 weeks. An attempt has been also done to clarify whether oxidation in Ecoflex was a primary degradation process caused by physico-chemical factors, or whether prior bacterial enzymatic hydrolysis was required to prepare the polymer for oxidation (Fig. 1).

Materials and Methods

Bacterial Strains and Ecoflex Foil Cultivation

The five bacterial strains employed in this study were selected on the basis of their hydrolytic abilities. Strain BHI-B6H-T Brevibacterium luteolum was isolated from textile substrate inside a crypt [25]. Bacillus thuringiensis CM9T-R2A-D was obtained from an epoxide statue [26]. Strains M9-G-18-28-S-D Aeromonas media and LB10-G-30-55-W-W Geobacillus kaustophilus were isolated form hot-spring related samples, sediment with 28 °C of temperature and water with 55 °C, respectively [27]. Strain M9-CHR-4-3-W Serratia sp. was recovered from an iced branch of Danube River at a temperature of 3 °C [27]. All isolates were maintained on LB10 agar media composed of 1 g l−1 peptone, 0.5 g l−1 yeast extract, 0.5 g l−1 NaCl and 15 g l−1 of agar at their environmental temperature of isolation.

Changes of Ecoflex foils were observed from 3 days until 16 weeks after the cultivation of each strain on foil. Incubation temperatures were 28 °C for B. luteolum, B. thuringiensis and A. media; 55 °C for G. kaustophilus and 3 °C for Serratia sp., temperatures that reflect the temperatures of the environments from which the strains were isolated.

Ecoflex foils were analyzed by chemiluminescence (CL) and observed by scanning electron microscope (SEM) after 3 days, 2, 4, 8 and 16 weeks.

Chemiluminescence Measurements and Microscope Observation

A loopful of a fresh overnight culture were picked from LB10 Petri dishes and washed twice in 0.9% physiological saline (PS). One-hundred-fifty micro litre of sample diluted to final OD600 = 0.5 in PS were inoculated on Ecoflex foil sample. Inoculated foils with bacterial isolates were placed at appropriate temperature (3, 28 and 55 °C) in the dark to avoid photo-degradation and incubated 3 days and 2, 4, 8 and 16 weeks. After such time, the chemiluminescence was measured and compared with 0 days incubation (control experiment). CL measurements were performed in a Lumipol 3 photon-counting instrument manufactured at the Polymer Institute of the Slovak Academy of Sciences. The film samples (circular cuts of Ecoflex) were weighed on aluminum pan (9 mm in diameter) and placed in the sample compartment. The gas flow of nitrogen through the sample cell was set to 3.0 L h−1. The purging of the gas through the CL compartment was started 20 min before the start of measurement. The temperature in the sample cell of the apparatus increased linearly with time from 40 °C up to 250 °C at the rate 5 °C min−1. The signal of the photocathode was recorded at a 10-s data collection interval. All samples were prepared and measured in triplicate and average curve chemiluminescence intensity temperature was plotted. The position of respective curves on the temperature axes did not differ more than in 1 °C.

Scanning electron microscopy was performed with a JEOL JSM-7500F (Tokyo, Japan) FESEM in Gentle Beam (GB-LOW) observation mode where incident electrons are decelerated just before they hit the specimen to reduce the incident-electron penetration and the charging of the specimen thus allowing the observation non-conductive samples. The GB mode provides high-resolution images at low accelerating voltages from 100 V to 3 kV (2.5 kV was used for all samples in this work) without damaging the specimen surface. All SEM analyses were performed in duplicate.

Hydrolytic Activities

The proteolytic activity of microorganisms was analyzed with casein agar and gelatin medium. Casein agar was composed of skim milk (250 ml) sterilized at 100 °C for 30 min (daily within 3 days) and Nutrient agar No 2 (750 ml; Biomark, Pune, India) sterilized by autoclaving. Immediately after the third sterilization of skim milk, Nutrient agar No 2 was added. Gelatin medium contained 0.5 g l−1 KH2PO4, 0.25 g l− 1 MgSO4, 4 g l−1 gelatin and 15 g l−1 of agar in distilled H2O. The medium was sterilized by autoclaving and poured into Petri dishes Grivalský et al. [27].

Lipase activity was tested on Spirit blue medium (Himeda, Mumbai India) following the instructions of the manufacturer. Spirit blue agar, 32.15 g, was suspended in 1000 ml of distilled water and heated by boiling in order to dissolve the medium completely. Medium was sterilized by autoclaving then cooled to 50 °C. Then, 30 ml of the lipase substrate (1 ml of Tween 80 dissolved in 400 ml warm distilled water, added 100 ml of olive oil, stirred vigorously and autoclaved) was added to the medium.

Esterase activity was detected on Tween 80 agar composed of 10 g of peptone, 5 g NaCl, 100 mg CaCl2, 15 g of agar in 1 l of distilled H2O. The medium was adjusted to pH 7.5, autoclaved and cooled to about 60 °C. Then, 10 ml of separately autoclaved Tween 80 was added. Esterase producing microorganisms showed a precipitation of calcium salt and fatty acids around their colony.

Celullolytic ability was checked on Congo Red agar plates; this medium contained 0.5 g l−1 KH2PO4, 0.25 g l−1 MgSO4, 2 g l−1 cellulose, 0.2 g l−1 Cong-red, 2 g l−1 gelatine, 15 g l−1 agar in distilled H2O. The pH of the medium was adjusted to 6.8–7.2 and autoclaved.

Amylases were assayed on agar medium containing 10 g l−1 soluble starch, 5 g l−1 peptone, 5 g l−1 yeast extract, 0.5 g l− 1 MgSO4·H2O, 0.01 g l− 1 FeSO4·7H2O, 0.01 g l−1 NaCl, 15 g l−1 agar and distilled H2O.

All the agar assays were performed in triplicate and the positive reaction, except of Tween 80 agar, was displayed as a zone of clearance (hydrolysis) around the assayed bacterial colonies.

Catalase Enzyme Activity Determination

In order to assess the catalase activity, bacterial cultures were grown in 5 ml of Luria–Bertani medium (10 g tryptone, 5 g yeast extract and 5 g NaCl in 1000 ml) at 3, 28 or 55 °C depending on the type of strain. Grown cultures were transferred (0.5 ml) to 50 ml of Luria–Bertani medium and incubated at 3, 28 or 55 °C under shaking at 200 rpm. When growth reached the middle of the exponential phase (optical density 0.5 at 610 nm), the cells were harvested by centrifugation at 6000 rpm for 10 min at 4 °C and washed with phosphate buffered saline solution (PBS buffer; 8.0 g l−1 NaCl; 0.2 g l−1 KCl; 1.44 g l−1 Na2HPO4; 0.24 g l−1 KH2HPO4; pH 7.0) and frozen. The mechanical disruption of frozen cells was performed in 50 mM sodium phosphate, 2 mM EDTA (pH 7.5) at 4 °C with glass beads (diameter 0.4 μm) using the Disruptor Genie (Scientific Industries, New York, USA) for 5 min. The homogenates were centrifuged at 14,000 rpm for 10 min. Supernatants were used for the determination of enzymatic activities. Catalase (CAT; EC 1.11.1.6) activity was determined at pH 7.0 by monitoring the decomposition of H2O2 at 240 nm with an extinction coefficient of 43.6 M−1 cm−1. One unit of catalase activity (U) was defined as the amount of enzyme that catalyzes the decomposition of 1 lmol of H2O2 per minute [28].

Ecoflex, PHB and PLA Plate Assays

In order to assess the degradation abilities of studied strains for biodegradable polymers three different media containing respectively Ecoflex, polyhydroxybutyrate (PHB) and polylactic acid (PLA) (provided by Polymer Institute, SAS) were prepared.

One gram of Ecoflex, PHB or PLA granules were dissolved in 30 ml of dichloromethane. To each solution were added 150 ml of a basal medium composed of 1 g l−1 KH2PO4, 1 g l−1 (NH4)2SO4, 0.2 g l−1 MgSO4·7H2O, 0,01 g l−1 FeCl3, 0,05 g l−1 NaCl, 0,05 g l−1 CaCl2, 0,25 g l−1 Yeast extract, 0,1 g l−1Triton X and 15 g l−1 of agar according to Ishigaki et al. [29]. Then, media were stirred at 70 °C until dichloromethane was evaporated, which takes approximately 20 h. The media were sterilized by autoclaving and poured on Petri dishes. The time of sterilization was too short to expect any significant changes in the structure of polymer. The assays were performed for each strain in triplicate.

Results and Discussion

Scanning Electron Microscope Observation

Scanning electron micrographs in Fig. 2 show the Ecoflex samples after 3 days and 16 weeks of incubation. After 3 days of incubation all Ecoflex samples were coated by bacteria. Also after 16 weeks the presence of bacteria was evident indicating that the polymer is a good source of nutrients. The most extended degradation was observed in sample where G. kaustophilus was inoculated; here mechanical cracks and fissures appeared. G. kaustophilus is a thermophilic bacterium cultivated at 55 °C, perhaps such temperature might also contribute to the deformation of Ecoflex film.

SEM analysis after three days and 16 weeks of incubation with bacteria. Ecoflex foils were incubated with: a Brevibacterium luteolum at 28 °C. b Bacillus thurigiensis at 28 °C. c Serratia sp. at 3 °C. d Geobacillus kaustophilus at 55 °C. e Aeromonas media at 28 °C. The control sample of the figure is an Ecoflex foil, without any inoculated bacteria, incubated at 28 °C

Hydrolytic Properties and Catalase Activity

All five bacteria showed positive lipolytic, proteolytic and cellulolytic reactions respectively on Spirit blue medium, milk agar and Congo red assay (Table 1). Strains B. thuringiensis, Serratia sp., and G. kaustophilus tested positive for proteolytic activity on gelatin medium. A. media and Serratia sp. showed esterase activity on Tween 80 medium. Only the strain B. luteolum displayed negative results on starch agar.

Polyesters PHB and PLA were degraded by all bacteria, but the most intensive activities were displayed by G. kaustophilus and A. media (Table 1).

All isolates were able to produce catalases with different activity. The strain B. luteolum showed highest catalase activity reaching the value of 586.6 U/ml; the lowest catalase value was produced by the strain B. thuringiensis with 20.6 U/ml (Table 1).

These results evidenced how the selected strains have a complete enzymatic outfit which allow them to degrade different kind of substances, although the best lipolytic and esterolytic activities were expressed by bacteria (B. thuringiensis and Serratia sp.) that did not exhibit an excellent degradation of PHB and PLA. G. kaustophilus showed weak lipolytic and esterolytic activities, but it was capable of rapidly hydrolyzing PHB and PLA. These findings are somehow in contrast with previous studies [11, 12] which conferred to lipases and esterases a crucial role in polymers degradation, but only A. media exhibited a link between lipase-esterase activity and PHB-PLA degradation (Table 1).

Analysis on Ecoflex-Agar Plate Assay

The growth of bacteria cultivated on Ecoflex-agar was also observed at different intervals of time: 3 days, 2, 4 and 8 weeks. Degradation activities are shown on Table 2 and Fig. 3a. The strain B. luteolum had the lowest degradation activity observed after 4 weeks of cultivation. Strain G. kaustophilus exhibited the best result even after 3 days of cultivation. B. thurigiensis and G. kaustophilus reached the value “++++”, which represents the extension of hydrolytic zone to the whole Ecoflex-agar plate, after 2 weeks of cultivation. All tested bacteria showed a regular progression, visualized by the increasing of the hydrolytic zone, up to 8 weeks (Fig. 3b; Table 2), it means that the cells and/or their enzymes were still active during this period of time.

Ecoflex agar plate assay. a Plates after 3 days of incubation with bacteria. A Brevibacterium luteolum at 28 °C. B Bacillus thurigiensis at 28 °C. C Serratia sp. at 3 °C. D Geobacillus kaustophilus at 55 °C. E Aeromonas media at 28 °C. b Dashed line showing the expanding degradation zone on Ecoflex agar medium

Comparing the previous plate assays for lipases (Spirit blue agar), esterases (Tween 80) and on PHB and PLA agar with the Ecoflex degradation results highlights the poor correspondence of Ecoflex breakdown with the hydrolase tests. Therefore, in order to isolate Ecoflex degrading bacteria is preferable to use this substrate in the cultivation medium than other ones [3, 30].

Nonisothermal Chemiluminescence Test on the Momentaneous State of Ecoflex Samples

Several studies regarding the chemical structure, the biotic and abiotic degradability and biotechnology applications of this kind of polymer were performed [3, 14, 31, 32], but data concerning the characterization of its degradation by bacteria and the factors responsible of its biodegradation during a long period of incubation are missing. This copolyester is depolymerized by lipase-like hydrolyses [11, 12], while the effect of enzymatic oxidation is unknown. CL method was used to measure hydroperoxide formation in biopolymer degradation in several studies [17, 21–24].

It is to be noted that in inert atmosphere the chemiluminescence signal reflects the three mutually superimposed processes. At the lowest temperature it is the annealing of defect structures and structural abnormalities, at medium temperatures it is the bimolecular decomposition of hydroperoxides, and at the highest temperatures it is the scission of bonds linking the macromolecular chains. The structural defects and hydroperoxides that are formed by the bacterial attack of the Ecoflex surface are converted by heat to radicals, whose recombination provides the energy necessary for the excitation of potential emitters that are molecules of oxygen and carbonyl groups. Secondary alkylperoxyl radicals, which are formed from various initiating events, including for example bimolecular decomposition of hydroperoxides, are particularly “efficient” in such a process. They provide triplet carbonyls and singlet oxygen in a step which takes place in parallel (Fig. 4).

In a free radical process the rate of free radical recombination is directly linked with the production of defect structures or decomposition of hydroperoxides. It is therefore obvious that the intensity of the light emission is proportional to the rate of polymer degradation.

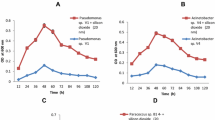

The chemiluminescence response on samples of Ecoflex inoculated with bacteria B. luteolum, B. thuringiensis, Serratia sp., G. kaustophilus and A. media after 3 days and 2, 4, 8 and 16 weeks (16 weeks should correspond to complete degradation of Ecoflex in agricultural fields) was rather complex (Fig. 5). The increase of chemiluminescence intensity above that of the control experiment indicated that the surface of the Ecoflex became temporarily less stable while subsequent decrease (samples after 16 weeks from the inoculation) indicated the consumption of the oxygenated structures and degradation products.

The chemiluminescence—temperature run is apparently composed from two mutually superimposed lines, first is the peak situated at lower temperature. The second line ended at ramp temperature of the experiment. Each line was developing in time after inoculation in dependence on the type of bacterial enzymatic system inducing the degradation (Fig. 5). To understand the tendency deconvolution of experimental lines by two gaussian lines the Origin 8.1 program was used, as shown in the Fig. 6. In this Figure, the peak (line 1) represents the process of decomposition of oxygenated structures (hydroperoxides) probably affected by carbonyl compounds. As shown by Abrusci et al. [23] there occurs the significant reduction of carbonyls during biodegradation while hydroperoxides may temporarily increase.

With time after inoculation the intensity of the chemiluminescence intensity—temperature records changed so that it reached the maximum value of the first peak within 2 to 4 weeks (B. luteolum, B. thuringiensis and G. kaustophilus). Serratia sp. and A. media achieved the maximum of the first peak at 8 weeks after inoculation.

The development of the line 2 describes the residual oxidative state of the Ecoflex matrix [21] (Fig. 6). The chemiluminescence intensity of the second process (line 2) was not in correlation with cultivation time, as expected, probably caused by filtration effect of bacterial layer on Ecoflex surface (Fig. 7).

It follows from the Ecoflex agar tests that the most distinct differences were observed after the first 3 days of cultivation (Table 2; Fig. 3a). At the same time, chemiluminescence runs for the oxygenated structure from the first deconvoluted peak indicated that the lowest amount of oxygenated structure were formed in the case of isolate B. luteolum (−) then follow A. media (+) and Serratia sp. (+). The temperature of the peak maximum shifts from 150 almost to 240 °C culminating for the isolate B. thuringiensis (++) at 245 °C and finally moves back to 180 °C for the isolate G. kaustophilus (+++) (Fig. 8). Except of the isolate B. luteolum agar plate tests for times longer than 2 weeks do not differ much each from the other (Table 2).

Evolution of the first deconvoluted process with temperature of nonisothermal chemiluminescence run. Ecoflex foils after 3 days of incubation with: (A) Brevibacterium luteolum at 28 °C. (B) Bacillus thurigiensis at 28 °C. (C) Serratia sp. at 3 °C. (D) Geobacillus kaustophilus at 55 °C. (E) Aeromonas media at 28 °C (−,+,++ and +++ correspond with the spreading of the hydrolytic zone in Ecoflex agar tests, Table 2)

The concentration of oxygenated products (hydroperoxides, carbonyls and carboxyls) measured by CL reached a maximum after 2 weeks of cultivation for isolates G. kaustophilus and B. thurigiensis, after 4 weeks of cultivation for isolate B. luteolum and 8 weeks of cultivation for isolates Serratia sp. and A. media.

The intensity of the maximum for oxygenated products decayed in the order B. luteolum > B. thuringiensis ~ A. media > G. kaustophilus > Serratia sp.

A possible explanation is considering the mechanism of the oxidative process occurring first as the spreading of the oxidative zone along the surface and subsequently entering layers of polymer beneath. When spreading along the surface is finished, the lower oxidized layers do not give as intense chemiluminescence emission as superficial layer simply because of filtration effect. Three days of cultivation test thus determines the sequence of degradation efficiency of bacterial enzymatic systems. The development in longer time cannot be seen on agar plate test while CL test gives a much more distinct picture (Figs. 9, 10).

The evolution of values of Imax for different time of Ecoflex incubation as found from first peak of deconvoluted chemiluminescence-temperature runs. (A) Brevibacterium luteolum at 28 °C. (B) Bacillus thurigiensis at 28 °C. (C) Serratia sp. at 3 °C; (D) Geobacillus kaustophilus at 55 °C. (E) Aeromonas media at 28 °C

The evolution of values of I250 with time of Ecoflex incubation found from the second line of deconvoluted chemiluminescence-temperature runs. (A) Brevibacterium luteolum at 28 °C. (B) Bacillus thurigiensis at 28 °C. (C) Serratia sp. at 3 °C; (D) Geobacillus kaustophilus at 55 °C. (E) Aeromonas media at 28 °C

All strains had the ability to degrade Ecoflex, but they reached the maximum hydrolytic power at different times. It is evident that generalized exoenzyme assays are not useful to assess the strain ability to degrade Ecoflex, therefore polymer-specific media are necessary to assess these feature.

The developed Ecoflex-based agar permitted to compare the biodegradation power of bacteria in this medium with CL measurements. Though Ecoflex agar assay was in concordance with CL measurements only after 3 days of cultivation, this medium can be used to select potential Ecoflex-degrading bacteria.

Conclusions

This study demonstrated that chemiluminescence is a valuable technique to follow the biodegradation dynamics on polymeric film. Furthermore the Ecoflex agar is able to select useful polymer-degrading bacteria. Such kinds of selected bacteria can be applied to the direct degradation of Ecoflex mulching foil in soil, or to set composting-systems where such bacteria contribute to the easy degradation of this polymer. In the future it would be interesting to apply a similar strategy in order to study the abilities and dynamics of different fungal strains and perhaps to try the investigation of a more challenging and elaborate microbial community.

References

Artham T, Sudhakar M, Venkatesan R et al (2009) Biofouling and stability of synthetic polymers in sea water. Int Biodeterior Biodegrad 63:884–890

Novotný Č, Erbanová P, Sezimová H et al (2015) Biodegradation of aromatic-aliphatic copolyesters and polyesteramides by esterase activity-producing microorganisms. Int Biodeterior Biodegrad 97:25–30

Witt U, Einig T, Yamamoto M et al (2001) Biodegradation of aliphatic-aromatic copolyesters: evaluation of the final biodegradability and ecotoxicological impact of degradation intermediates. Chemosphere 44:289–299

Chen Y, Tan L, Chen L et al (2008) Study on biodegradable aromatic/aliphatic copolyesters. Braz J Chem Eng 25:321–335

Müller RJ, Kleeberg I, Deckwer WD (2001) Biodegradation of polyesters containing aromatic constituents. J Biotechnol 86:87–95

Mostafa HM, Sourell H, Bockisch FJ (2010) The mechanical properties of some bioplastics under different soil types for use as a biodegradable drip tubes. Agric Eng Int 12:1–16

Shah AA, Hasan F, Hameed A, Ahmed S (2008) Biological degradation of plastics: a comprehensive review. Biotechnol Adv 26:246–265

Allen AD, Anderson WA, Ayorinde F, Eribo BE (2011) Isolation and characterization of an extracellular thermoalkanophilic P(3HB-co-3HV) depolymerase from Streptomyces sp. IN1. Int Biodeterior Biodegrad 65:777–785

Bornscheuer UT (2002) Microbial carboxyl esterases: classification, properties and application in biocatalysis. FEMS Microbiol Rev 26:73–81

Trinh TF, Cooper DG, Marić M, Nicell JA (2008) Biodegradation of a synthetic co-polyester by aerobic mesophilic microorganisms. Polym Degrad Stab 93:1479–1485

Hu X, Thumarat U, Zhang X, Tang M, Kawai F (2010) Diversity of polyester-degrading bacteria in compost and molecular analysis of a thermoactive esterase from Thermobifida alba AHK119. Appl Microbiol Biotechnol 87:771–779

Shah AA, Kato S, Shintani N et al (2014) Microbial degradation of aliphatic and aliphatic-aromatic co-polyesters. Appl Microbiol Biotechnol 98:3437–3447

Albertsson ACH, Karlsson S (1993) Aspects of biodeterioration of inert and degradable polymers. Int Biodeterior Biodegrad 31:161–170

Belal EB (2013) Biodegradation of aliphatic-aromatic coplyester under thermophilic conditions. Res J Environ Earth Sci 5:677–690

Lee SH, Kim IY, Song WS (2014) Biodegradation of polylactic acid (PLA) fibers using different enzymes. Macromol Res 22:657–663

Li R, Gao B, Sun J et al (2016) Synthesis, characterization of a novel lignin-based polymer and its behavior as a coagulant aid in coagulation/ultrafiltration hybrid process. Int Biodeterior Biodegrad 113:334–341.

Abrusci C, Marquina D, Santos A et al (2009) Biodeterioration of cinematographic cellulose triacetate by Sphingomonas paucimobilis using indirect impedance and chemiluminescence techniques. Int Biodeterior Biodegrad 63:759–764

Matisová-Rychlá L, Rychlý J (1996) Inherent relations of chemiluminescence and thermooxidation of polymers, Chapter 12. In: Clough RL, Billingham NC, Gillen KT (eds) Polymer durability. ACS advances in chemistry. Washington DC, p 175–193

Zlatkevich L (1989) Luminescence techniques in solid state polymer research, Marcel Dekker Inc., New York

Matisová-Rychlá L, Bukovský V, Rychlý J, Pleteníková M (2007) Chemiluminescence—a novel method in the research of degradation of paper. I: the effect of light on stacked sheets of paper. Macromol Symp 247:340–349

Rychlý J, Rychlá L, Stloukal P et al (2013) UV initiated oxidation and chemiluminescence from aromatic-aliphatic co-polyesters and polylactic acid. Polym Degrad Stab 98:2556–2563

Abrusci C, Marquina D, Santos A et al (2007) A chemiluminescence study on degradation of gelatine biodegradation by bacteria and fungi isolated from cinematographic films. J Photochem Photobiol A Chem 185:188–197

Abrusci C, Pablos JL, Corrales T et al (2011) Biodegradation of photo-degraded mulching fi lms based on polyethylenes and stearates of calcium and iron as pro-oxidant additives. Int Biodeterior Biodegrad 65:451–459

Abrusci C, Pablos JL, Marin I et al (2012) Photodegradation and biodegradation by bacteria of mulching films based on ethylene-vinyl acetate copolymer: effect of pro-oxidant additives. J Appl Polym Sci 126:664–1675

Pangallo D, Kraková L, Chovanová K et al (2013) Disclosing a crypt: microbial diversity and degradation activity of the microflora isolated from funeral clothes of Cardinal Peter Pázmány. Microbiol Res 168:289–299

Pangallo D, Bučková M, Kraková L et al (2015) Biodeterioration of epoxy resin: a microbial survey through culture-independent and culture-dependent approaches. Environ Microbiol 17:462–479

Grivalský T, Bučková M, Puškárová A et al (2016) Water-related environments: a multistep procedure to assess the diversity and enzymatic properties of cultivable bacteria. World J Microbiol 32:42

Roggenkamp R, Sahm H, Wagner F (1974) Microbial assimilation of methanol induction and function of catalase in Candida boidinii. FEBS Lett 41:283–286

Ishigaki T, Sugano W, Nakanishi A et al (2004) The degradability of biodegradable plastics in aerobic and anaerobic waste landfill model reactors. Chemosphere 54:225–233

Díaz A, Katsarava R, Puiggalí J (2014) Synthesis, properties and applications of biodegradable polymers derived from diols and dicarboxylic acids: from polyesters to poly(ester amide)s. Int J Mol Sci 15:7064–7123

Amjadi M, Yoon YJ, Park I (2015) Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes–Ecoflex nanocomposites. Nanotechnology 26:375501

Tachibana Y, Maeda T, Ito O et al (2009) Utilization of a biodegradable mulch sheet produced from poly(lactic acid)/Ecoflex®/modified starch in Mandarin orange groves. Int J Mol Sci 10:3599–3615

Acknowledgements

The acknowledgements are due to Grant Agency VEGA 2/0122/15, 2/0161/14 and 2/0167/14, and also to Slovak Research and Development Agency for the project APVV-15-0528.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grivalský, T., Rychlý, J., Rychlá, L. et al. Aerobic Biodegradation of Aromatic Aliphatic Copolyester Induced by Bacteria Obtained from Different Environments. J Polym Environ 26, 680–690 (2018). https://doi.org/10.1007/s10924-017-0980-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-0980-y