Abstract

Proteins can be made into polymer materials through plasticization. Here, wheat gluten is plasticized with its own tryptic hydrolysate. Wheat gluten hydrolysate largely consists of small molecular weight peptides as measured by size exclusion chromatography and sodium dodecyl sulfate-polyacrylamide gel electrophoresis. Elastic modulus decreases 3.8 times at hydrolyzed wheat gluten contents of 0.2–0.4 mass fraction. Differential scanning calorimetry shows a 100 °C reduction of the glass transition temperature from 0.0 to 0.5 mass fraction hydrolyzed wheat gluten content. Compared to glycerol, hydrolyzed wheat gluten is not as efficient a plasticizer. However, hydrolyzed wheat gluten has a similar effect on the protein structure as glycerol as measured with Fourier transform infrared (FTIR) spectroscopy. The glass transition temperature is found to strongly correlate with the state of glutamine and proline in the protein and FTIR results can be used to predict the glass transition temperature at a given plasticization level.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Protein plasticization is an important topic in understanding how native structural proteins function in vivo or how proteins might be utilized in structural applications in vitro. Compared to proteins in aqueous solution, i.e., enzymes and receptors, structural proteins highly interact with one another in a solid-like state and instead of being completely in solution are “plasticized”. Plasticized proteins form a gel where plasticizer molecules locally solvate portions of the protein. An ensemble of structural proteins is usually insoluble and has enough plasticizer to allow small solvated protein portions to change conformation. The solvent is molecularly dispersed around the protein chains, increasing the distance between protein–protein interactions and decreasing the local friction coefficient and viscosity [1]. Plasticization acts to lower the glass transition temperature, Tg, of the protein. As temperature increases, Tg is the temperature at which a polymer transitions from a brittle, glassy state to a ductile, rubbery state. Mechanically, the protein has reduced stiffness and increased toughness and elongation to break as plasticization increases. This has been observed by increasing the relative humidity when testing keratin (from hair, feather, hoof, or horn), collagen (from skin or joint), or silk [2]. Thus, plasticization can be measured by characterizing the Tg or modulus of the plasticized protein.

The increasing interest in green chemistry provides an opportunity to use proteins as renewable polymer materials. Structural and storage proteins can be found as the by-products of the food and agriculture industries. Wheat gluten, corn zein, whey protein, soy protein, and feather keratin can all be obtained economically and in relatively high quantities to justify use in biobased commodity polymers [3, 4]. For commodity use, the preferred processing method is to plasticize the protein and thermally process it under heat and pressure to obtain a cohesive polymer of useful properties [5–13]. The resulting polymer has a glass transition temperature and maybe a melting temperature, Tm, and crosslinks through disulfide bonds but can be processed over and over again by heating. While the protein native conformation is lost, the resulting thermoformed polymer is of reasonable modulus and stress and strain at break to make a useful material. Thermoformed protein films more importantly have reduced oxygen and carbon dioxide permeability making them attractive as barrier layers for synthetic polyolefins, which have reduced water vapor permeability but high oxygen and carbon dioxide permeability [14–20].

Wheat gluten is of particular interest because of its large availability as more consumers prefer “gluten-free” products. Wheat gluten is the storage protein of wheat and is composed of 3 full proteins: gliadin (0.49 mol fraction), high molecular weight glutenin (0.06 mol fraction), and low molecular weight glutenin (0.45 mol fraction). Wheat gluten is the minority fraction of wheat flour but provides bread dough with elasticity. The molecular weight distribution of wheat gluten proteins actually varies because of covalent cross-linking between several cysteine amino acids on the proteins [21, 22]. Wheat gluten can be plasticized and thermoformed into useful polymeric materials [15, 23]. It also serves as a model protein to study plasticization because there are many literature reports of wheat gluten plasticization with plasticizers of varying polarity using a variety of techniques. Water is the most basic plasticizer and the Tg as measured with modulated differential scanning calorimetry (MDSC) decreases from Tg = 175 °C for native wheat gluten to Tg = 50–0 °C with 0.1–0.2 mass fraction of water, showing that water is a very efficient plasticizer [24, 25]. Noel et al. found a higher Tg for native wheat gluten than Micard and Guilbert because Noel et al. extrapolated the Tg data of water plasticized wheat gluten at various water mass fractions back to zero concentration whereas Micard and Guilbert directly measured it. Pouplin et al. [26] measured the Tg of water (18 Da), glycerol (92 Da), and sorbitol (182 Da) plasticized wheat gluten with dynamic mechanical thermal analysis (DMTA). The plasticization efficiency, shown by the reduction of Tg with plasticizer mass fraction, decreases with increasing plasticizer molecular weight. However, when Tg is plotted as a function of plasticizer mole fraction, a continuous curve is obtained. Water is an impractical plasticizer for commodity polymers because it will easily exchange with the environment. Higher molecular weight and boiling point plasticizers like glycerol and sorbitol are more practical because of decreased migration or plasticizer loss. Wheat gluten and corn gluten have been plasticized with a variety of plasticizers of varying molecular weight and polarity [27, 28]. Corn gluten is more hydrophobic than wheat gluten and more amphiphilic plasticizers are more efficient. Diethanolamine and triethanolamine produce a broad Tg for wheat gluten compared to glycerol. For the amine plasticizers, the lower temperature region of the broad Tg overlaps room temperature and produces more extensible films when tested at room temperature. For those films, high relative humidity conditions show that water will take over as the plasticizer and reduce the extensibility for high amine content wheat gluten films. Indeed, too much plasticizer results in the plasticizer existing as a separate phase and does not plasticize but simply detracts from the polymer properties [9]. The plasticization of the individual wheat gluten components has also been studied [24, 29]. All components plasticize similarly with water. Gliadin could be plasticized with tetraethylene glycol and glycerol to the same extent but less of the higher molecular weight tetraethylene glycol is needed to produce the same Tg with less plasticizer loss. Wheat gluten can also be internally plasticized by covalent substitution onto protein amino acid side groups or the peptide bond moieties in the protein backbone [30–32]. Internal plasticization solves the problem of plasticizer migration but does not have the same efficiency as smaller, non-covalently bound plasticizers [33].

In this paper, the plasticization of wheat gluten with peptides from its own tryptic hydrolysate is studied, which are very chemically compatible with wheat gluten. These peptides are of low molecular weight and contain various amine, hydroxyl, and hydrophobic groups originating in the different amino acids comprising the protein. Thus, the peptides could mimic the properties of the various plasticizers studied previously but in one ensemble of molecules. However, the peptides would not be as low in molecular weight as water, glycerol, or most of the other polar plasticizers used and thus should not suffer from the same migration problems. Plasticization is characterized by measuring the Tg with differential scanning calorimetry (DSC) and elastic modulus, stress at break, and strain at break with uniaxial tensile testing. The effect of the plasticizer on the protein structural and chemical properties is measured using Fourier transform-infrared (FTIR) spectroscopy.

Experimental

Materials

Wheat gluten (WG) was obtained from MP Biomedicals LLC, Solon, OH. Type I trypsin from bovine pancreas was obtained from Sigma-Aldrich, St. Louis, MO. For purposes of calculating molar fractions, wheat gluten was treated as a mixture of gliadin (Gd, UniProt P04721, 0.49 mol fraction, 30,403 Da), high molecular weight glutenin (GtH, UniProt P08488, 0.06 mol fraction, 70,867 Da), and low molecular weight glutenin (GtL, UniProt P10386, 0.45 mol fraction, 34,928 Da).

Wheat Gluten Hydrolysis

2 g of WG was dispersed in 80 ml of pure water at 37 °C to achieve a concentration of 25 mg ml−1. 30 mg of trypsin was then added to the solution to give an enzyme-to-substrate ratio of 1:67 wt wt−1 and the pH was adjusted to 8 with 1 M NaOH. Solution conditions were maintained at pH 8 and 37 °C for 48 h to allow for hydrolysis. The resulting product is referred to as “trypsin hydrolyzed wheat gluten (THWG)”. The hydrolysis time has been empirically determined to be the point of maximum hydrolysis before the onset of peptide aggregation and the hydrolysis time is much longer than those in other studies [21, 34–36].

Size-Exclusion Chromatography (SEC)

SEC was performed on WG and THWG using the Superdex 200 HR column on the ÄKTApurifier 10 fast protein liquid chromatography (FPLC) system (GE Healthcare Biosciences, Pittsburgh, PA). Samples were prepared by dissolving the protein in 0.1 M acetic acid, vortexing, centrifuging at 4,000 rpm for 15 min, and injecting 0.5 ml of the supernatant into the column. The column was eluted with 0.1 acetic acid at 0.5 ml min−1.

Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE)

A Mini-PROTEAN Tetra Electrophoresis System with a precast Tris–HCl gel (Bio-Rad Laboratories, Hercules, CA) consisting of 4 % stacking gel and 15 % separating gel was used for SDS-PAGE. Reducing sample buffer was prepared by adding 2-mercaptoethanol (Sigma-Aldrich, Saint Louis, MO) to Laemmli sample buffer (Bio-Rad, 62.5 mM Tris–HCl, pH 6.8, 25 % glycerol, 2 % SDS, 0.01 Bromophenol Blue) for a final concentration of 5 %. Dried protein samples (1 mg) were suspended in 300 μl sample buffer, centrifuged at 4,000 rpm for 5 min, and the supernatants (10 μl) were used to load the gel. Electrophoresis was done at a constant current of 20 mA for 100 min. The gel was stained with Bio-Rad Biosafe Coomassie Stain.

Sample Preparation

THWG was mixed with WG on a Brabender Three-Piece Mixer attached to a Prep-Center® drive (C.W. Brabender® Instruments, Inc., South Hackensack, NJ). First, WG was added into the mixer at 40 °C. Then the appropriate amount of THWG was added while keeping the total mass at 40 g. Mixing proceeded for 15 min at 50 rpm. Shear heating caused the sample temperature to increase above the 40 °C set point. The final mixing temperatures were: WG:THWG (wt:wt) = 1:0 (40 °C), 0.95:0.05 (42 °C), 0.8:0.2 (53 °C), 0.7:0.3 (63 °C), 0.65:0.35 (58 °C), 0.6:0.4 (56 °C), 0.55:0.45 (45 °C), 0.5:0.5 (40 °C), and 0:1 (40 °C). Following mixing, 5 g of each sample was placed between two Teflon-coated aluminum foil sheets and pressed in a Carver Press Autofour/30 Model 4394 (Carver, Inc., Wabash, IN) at 120 °C and 88,964 N for 2 min. Pressing stress varies radially. The resulting pressing stresses using the overall diameter of the pressed films were 5.3 MPa (0.8:0.2), 3.6 MPa (0.7:0.3), and 2.3 MPa (0.65:0.35 and 0.6:0.4). The resulting thin film was then removed and air-cooled to room temperature [3, 19, 20, 37]. The films were most cohesive and of uniform thickness in the middle. Thus, to obtain the best samples and keep the pressing stress constant at 11 MPa, 2 tensile samples were extracted side-by-side from the middle of each film over an equal surface area.

Mechanical Testing

Test samples were prepared according to ASTM D882 for thin plastic films. The samples were 2.54 cm wide by 10.16 cm long and had a 5.08 cm gage length. Film thickness was measured with a digital micrometer and was 0.03 cm (0.8:0.2), 0.02 cm (0.7:0.3), and 0.013 cm (0.65:0.35 and 0.6:0.40) where the thickness variation is also reflected in the pressing stress variation. Mechanical testing of the films was performed at a crosshead speed of 2.54 cm/min using a TA.HDplus (Stable Micro Systems, Surrey, UK) mechanical tester equipped with a 100 kg load cell. Elastic modulus, E, was calculated from the linear region after correcting for the toe region. Stress at break and strain at break were taken as the point of visible sample breakage and rapid decline in measured force. Samples were tested immediately after preparation at 25 °C and 30 % relative humidity to avoid environmental influences on the proteins and peptides over time [3, 13, 20]. A minimum of 15 films was tested and results are reported as average values with standard deviations. At 0.2 mass fraction THWG, the films were brittle and difficult to handle so they were softened in an oven at 60 °C for 1 min then loaded into the tensile grips while soft, allowed to cool to room temperature, and tested.

Differential Scanning Calorimetry (DSC)

Thermal analysis was performed on a TA Instruments (New Castle, DE) DSC Q100 with 4–6 mg samples in a nitrogen atmosphere. In the first cycle, the sample was equilibrated at 0 °C and then heated to 160 °C at a rate of 10 °C/min, equilibrated at 160 °C for 1 min, and then cooled back to 0 °C. In the second cycle, the sample was heated to 300 °C at a rate of 10 °C min−1. The procedure is based on ASTM D3418 and has been used previously for biopolymers [9, 24, 33, 38]. The glass transition temperature was found from the inflection in the heat flow versus temperature curve on the second heat cycle according to ASTM D3418. Samples were tested in triplicate with averages and standard deviations reported.

Fourier Transform-Infrared (FTIR) Spectroscopy

A Thermo-Nicolet 6700 FTIR spectrometer (Thermo Fisher Scientific, Inc., Waltham, MA) with a Smart Orbit diamond attenuated total reflectance (ATR) cell was used to characterize the plasticized wheat gluten films. The spectrum was collected with a total of 64 scans and a resolution of 4 cm−1. Spectra were tested in triplicate with averages and standard deviations reported.

Results and Discussion

THWG Peptides

Trypsin hydrolyzes wheat gluten to mostly ≤10 kDa fragments with some residual 25 kDa protein and a larger fraction of 37 kDa protein remaining (Fig. 1a). SDS-PAGE confirms the SEC result (Fig. 1b). Trypsin hydrolyzes the C-terminus of lysine (K) and arginine (R) but is less likely to do so if either is connected to a C-terminal proline (P). The PeptideCutter tool of ExPASy predicts that GtH will be fully hydrolyzed by trypsin but that the R35 of GtL and the R95 and R233 of Gd have a smaller probability of being hydrolyzed. The longest segment in Gd would be amino acids 22–161 with a molecular weight of 16,581 Da and in GtL would be amino acids 24–151 with a molecular weight of 15,043 Da. Since the SEC results do not show peptides in this molecular weight range and both Gd and GtL are ca. 30–35 kDa, it appears more likely that some complete or nearly complete Gd and GtL proteins survive the trypsin hydrolysis. This is possible because Gd has two sites with a lower probability of hydrolysis and the insoluble glutenin fraction is known to be hydrolysis resistant [21, 39].

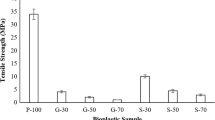

Mechanical Properties

Although a wide range of plasticization levels is studied, there exists a “sweet spot” of THWG plasticization from 0.2 to 0.4 mass fraction where thermally processed films exhibit easier processability as evidenced by a decreasing pressing stress with increasing THWG content (Experimental, Sample Preparation). Also at 0.2–0.4 THWG mass fraction, the materials have good polymer mechanical properties and can be tested (Fig. 2a). Also shown is glycerol plasticized WG. Over similar mass fraction, glycerol is much more efficient at plasticization as evidenced by the lower modulus at the same mass fraction of plasticizer. When viewing E as a function of plasticizer mass fraction, the two curves resemble those of polymers tested at two different temperatures as a function of time, so that time–temperature superposition could be used to build a master curve [1]. It has been suggested that plasticization efficiency is better described by analyzing Tg and E as a function of the number of plasticizer molecules relative to the number of protein molecules [4, 26]. To normalize the molecular weight difference between plasticizers, the elastic modulus is re-plotted as a function of moles plasticizer/moles WG using 6 kDa as the THWG molecular weight and 37,340 Da as the WG molecular weight, which is found as the weighted average of the 3 WG protein fractions (Fig. 2b). The black line is a logarithmic fit through the data indeed showing resemblance to a master curve with the dashed line showing the transition from glassy to rubbery behavior with increasing plasticizer concentration. The time–temperature superposition analogy is accurate in that higher numbers of plasticizer molecules perform more local solvation of protein chains that reduce molecular friction, which manifests as increased protein molecular motion, just like higher temperature would allow more protein molecular motion. This is measured as a decrease in modulus and causes the transition from glassy to rubbery behavior. The modulus behavior of the WG:THWG 0.6:0.4 falls below the master curve and may be an indication that there is excess water in this system that aids plasticization. Thermogravimetric analysis (TGA) shows the water content to be as high as 5 % by weight in this plasticization region, which could result in some additional plasticization [24, 25]. As THWG plasticizer content is increased, the films become more flexible as measured by an increase in the material’s strain to break (Fig. 2c). Stress to break also decreases with an increase in THWG content. The outlier is 0.2 mass fraction THWG, which was the most difficult to test and the result may reflect the difficulty loading the test strips into the tensile tester grips.

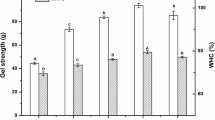

Glass Transition Temperature

As the amount of THWG is increased, the Tg of WG:THWG materials is reduced (Fig. 3a). Interestingly, a synergistic behavior is observed because the Tg of THWG is measured to be higher than some WG:THWG blends. The lines are fits to the Couchman-Karasz equation using Tg = 180 K for glycerol. The Couchman-Karasz equation has been found to fit biopolymer glass transition temperature data very well [4, 33, 40]. The Tg of THWG is treated as a fitting parameter by omitting the measured THWG Tg from the fit and finding the highest correlation coefficient. For THWG, the Couchman-Karasz Tg = 300 K. Also plotted are glycerol plasticized WG data from Pouplin et al. [26]. The Tg behavior mimics the elastic modulus behavior with glycerol showing more plasticization efficiency at equal mass fraction. When plotted against plasticizer mole fraction, a continuous curve independent of the plasticizer type is found with a reasonable goodness of fit of r2 = 0.70 (Fig. 3b) although the WG:glycerol materials are largely glycerol by mole fraction [26]. In the 0.2–0.4 THWG mass fraction range, the Tg onset is 93–53 °C, respectively, but this is the plasticization region that yields a soft or slightly rubbery film that can be tested at room temperature (Fig. 3c). There could be several reasons why the onset of Tg is higher than room temperature but the films are testable. First, the onset of the glass transition as measured with DSC is usually higher than that measured with DMTA, with DMTA giving more accurate results [26]. Second, the 5 % water fraction, while low, is enough to lower Tg considerably and may lower the Tg range to coincide with room temperature [24, 25]. Amine-containing plasticizers did not lower Tg as much as glycerol but did broaden the Tg region so that the lower end of the glass transition overlapped with room temperature. The high content of amines, specifically on plentiful glutamine (Q) amino acids in THWG may act similarly. Glutamine contains an amide on the end of its side group and comprises 35.1 mol% of Gd, 31.6 mol% of GtL, and 32.0 mol% of GtH and there is a secondary amine in each peptide bond.

Structural Changes

FTIR spectroscopy can reveal information about the state of the protein secondary structure and individual amino acids within the protein [34, 35, 41]. As more THWG or glycerol plasticizer is added to WG, the Amide I absorbance, representative of C=O in the peptide bond, shifts from a predominantly random coil structure (~1,635–1,640 cm−1) to a more ordered β-sheet structure (<1,630 cm−1) (Fig. 4a). For glycerol, a critical point is reached at ~ 0.2 mass fraction where the structure reverts back to a random coil structure. This critical point is termed the “critical plasticization” and is the point where Tg of the plasticized WG nears room temperature (compare Fig. 3a, Fig. 4a for glycerol, the actual Tg may be higher than room temperature but the onset of the Tg range is at or near room temperature) [4]. THWG behaves similarly except the critical plasticization point occurs at higher plasticizer mass fraction, reflective of the lower mole fraction of THWG peptide available for plasticization. The critical point occurs at 0.45 mass fraction THWG but this material is too soft to press into cohesive films.

For glycerol plasticized WG, the IR absorbance ratio 1,240/1,025 cm−1 shows the amount of protein, described by the Amide III absorbance at 1,240 cm−1, to the amount of glycerol, described by the ν(CO) absorbance at 1,025 cm−1 (Fig. 4b). Amide III describes δ(NH) and ν(CN) in amide groups, especially in the peptide bond [41]. The ratio decreases as the plasticizer amount increases. It is possible to accurately predict the glass transition temperature from this ratio simply because it describes the decrease of Tg with increasing glycerol content (Fig. 5). The same ratio shows similar behavior in THWG plasticized WG but for a different reason. In the absence of glycerol, the 1,025 cm−1 absorbance is dominated by γw(CH2) on proline (P) and ν(CC) on glutamine (Q), the two most abundant amino acids in WG and THWG [42, 43]. FTIR vibrations are more discernible for higher masses of chemical groups [42]. P and Q comprise 48.8 mol% of Gd, 44.3 mol% of GtL, and 52.5 mol% of GtH. The addition of THWG plasticizer induces more hydrogen bonding on NH groups in the peptide bond and Q side groups and Amide III decreases. Concurrently, there is increased vibration of the CH2–CH2 portions of the P and Q side groups, which cannot hydrogen bond with plasticizer but instead will try to hide from the polar plasticizer. The ratio is a good predictor of Tg for THWG plasticized WG because it can discern highly mobile portions of the protein relative to immobile portions and not just the increased presence of plasticizer like with glycerol (Fig. 5).

A simple model can be proposed to explain how plasticizer orders protein into β-sheets but still plasticizes. As more plasticizer is added to WG, plasticizer molecules form bridges between protein molecules and create an increasingly ordered, β-sheet structure (Fig. 6a). Typical β-sheets are formed from the direct hydrogen bonding of peptide bond NH in one protein molecule to peptide bond CO in another protein molecule. Here, the β-sheets are larger because of the plasticizer molecule in the β-sheet, between the two protein molecules. These β-sheets are envisioned to be more flexible than typical β-sheets where two protein molecules are directly hydrogen bonded to one another. Between the β-sheet layers are some amide groups on the end of Q amino acids hydrogen bound to plasticizer. However, there are more highly mobile hydrophobic groups on P and Q that are constantly vibrating to hide from polar plasticizer. For glycerol, this structure is easy to envision (Fig. 6b). In the case of THWG, the plasticizer is not completely polar but contains hydrophobic groups as well. THWG is of much lower molecular weight than WG and has an easy time finding preferred bonding spots with the protein. THWG similarly connects the protein molecules with hydrogen bonding between protein molecules and Q amino acids but also dramatically increases the number of vibrating hydrophobic groups (Fig. 6c). THWG increases free volume but there are less molecules and they are too large to be as efficient a plasticizer as glycerol. Large THWG molecules extensively hydrogen bond with WG and themselves and can only moderately reduce the local friction coefficient so produce a more rigid structure than glycerol plasticized WG. For THWG plasticized WG, Amide I and 1,240/1,025 cm−1 reach an asymptote in the range of 0.20–0.45 mass fraction THWG, or the “sweet spot” for plasticization where films could be handled and tested (Fig. 4). The depth of the glass transition, measured as a change in heat flow, ΔH (J/g), also shows a plateau in the “sweet spot” plasticization range of 0.20–0.45 THWG (Fig. 3a). This indicates a saturation of hydrogen bonding within the plasticized WG structure because THWG levels >0.45 mass fraction shift Amide I back towards a random coil structure where the WG protein β-sheets are broken by too much THWG (Fig. 3a). This produces a soft material that is unprocessable and cannot be made into films for testing. Pure THWG is high in β-sheet content (Fig. 4a) with a lot of hydrogen bonding between amide groups in the peptide bond and Q side groups (Fig. 4b) and a high Tg (Fig. 3a). On the master curve in Fig. 2b, the transition from glassy to rubbery behavior delineated by the dashed line may be related to the plasticization of Q in the protein. There are on average 33 Q amino acids per protein chain. Thus, it would take 33 mol of plasticizer per mole of protein to saturate the Q amide side groups and cause the glass to rubber transition. This saturation of Q side groups appears to be the β-sheet ordering mechanism and it has been shown that an abundance of Q aids β-sheet formation [44, 45].

A simple model for plasticization of WG at optimal plasticization levels to produce flexible, testable films: a β-sheet formation with the addition of plasticizer, b a flexible structure produced with glycerol between β-sheet layers, c THWG addition produces a structure more flexible than WG alone but not as flexible as glycerol plasticized WG

Conclusions

It was shown that wheat gluten, a storage protein, could be plasticized with its own tryptic hydrolysate. While wheat gluten peptides were not as efficient at plasticization as small molecular weight polar molecules, the peptides influenced the wheat gluten structure similarly to glycerol. Modulus and glass transition temperature decreased upon plasticization. Analysis of the Amide III absorbance at 1,240 cm−1 and the γw(CH2) on proline (P) and ν(CC) on glutamine (Q), both at 1,025 cm−1, using FTIR spectroscopy showed that the glass transition could be predicted as a function of plasticization. Low plasticizer concentration ordered the protein into flexible β-sheets and high plasticizer concentration disordered the protein and the effect was independent of the type of plasticizer.

References

Ferry JD (1980) Viscoelastic properties of polymers. Wiley, New York

Vincent J (1990) Structural biomaterials. Princeton University Press, Princeton

Barone JR, Schmidt WF, Liebner CFE (2005) J Appl Polym Sci 97:1644

Athamneh A, Griffin M, Whaley M, Barone JR (2008) Biomacromolecules 9:3181

Galietta G, Di Gioia L, Guilbert S, Cuq B (1998) J Dairy Sci 81:3123

Redl A, Morel MH, Bonicel J, Vergnes B, Guilbert S (1999) Cereal Chem 76:361

DiGioia L, Guilbert S (1999) J Agric Food Chem 47:1254

Gennadios A, Weller CL, Hanna MA, Froning GW (1996) J Food Sci 61:585

Gao C, Stading M, Wellner N, Parker ML, Noel TR, Mills ENC, Belton PS (2006) J Agric Food Chem 54:4611

Reddy N, Chen L, Yang Y (2013) Ind Crops Prod 43:159

Jagadeesh D, Reddy DJP, Rajulu AV (2011) J Polym Environ 19:248

Krochta JM (2002) In: Gennadios A (ed) Protein-based films and coatings. CRC Press LLC, Boca Raton, pp 1–41

Barone JR, Schmidt WF, Gregoire NT (2006) J Appl Polym Sci 100:1432

Galus S, Mathieu H, Lenart A, Debeaufort F (2012) Innov Food Sci Emerg Technol 16:148

Gontard N, Guilbert S, Cuq J-L (1993) J Food Sci 58:206

Guillard V, Chevillard A, Gastaldi E, Gontard N, Angellier-Coussy H (2013) Eur Polym J 49:1337

Kim KM, Marx DB, Weller CL, Hanna MA (2003) J Am Oil Chem Soc 80:71

Sothornvit R, Olsen CW, McHugh TH, Krochta JM (2003) J Food Sci 68:1985

Barone JR, Dangaran KL, Schmidt WF (2006) J Agric Food Chem 54:5393

Barone JR, Dangaran KL, Schmidt WF (2007) J Appl Polym Sci 106:1518

Wang J-S, Zhao M-M, Zhao Q-Z, Bao Y, Jiang Y-M (2007) J Food Sci 72:C103

Wieser H (2007) Food Microbiol 24:115

Gontard N, Guilbert S, Cuq J-L (1992) J Food Sci 57:190

Noel TR, Parker R, Ring SG, Tatham AS (1995) Int J Biol Macromol 17:81

Micard V, Guilbert S (2000) Int J Biol Macromol 27:229

Pouplin M, Redl A, Gontard N (1999) J Agric Food Chem 47:538

Di Gioia L, Guilbert S (1999) J Agric Food Chem 47:1254

Irissin-Mangata J, Bauduin G, Boutevin B, Gontard N (2001) Eur Polym J 37:1533

Sanchez AC, Popineau Y, Mangavel C, Larre C, Gueguen J (1998) J Agric Food Chem 46:4539

Dicharry RN, Ye P, Saha G, Waxman E, Asandei AD, Parnas RS (2006) Biomacromolecules 7:2837

Dong J, Asandei AD, Parnas RS (2010) Polymer 51:3164

Woerdeman DL, Veraverbeke WS, Parnas RS, Johnson D, Delcour JA, Verpoest I, Plummer CJG (2004) Biomacromolecules 5:1262

Budhavaram NK, Miller JA, Shen Y, Barone JR (2010) J Agric Food Chem 58:9549

Ridgley DM, Ebanks KC, Barone JR (2011) Biomacromolecules 12:3770

Ridgley DM, Claunch EC, Barone JR (2012) Soft Matter 8:10298

Athamneh A, Barone JR (2009) Smart Mater Struct 18:104024

Barone JR (2009) J Polym Environ 17:143

Barone JR, Medynets M (2007) Carbohydr Polym 69:554

Batey IL (1985) J Appl Biochem 7:423

Barone JR, Medynets M (2007) Carbohydr Polym 69:554

Krimm S, Bandekar J (1986) In: Anfinsen CB, Edsall JT, Richards FM (eds) Advances in protein chemistry. Academic Press Inc, Orlando, pp 181–364

Gunzler H, Gremlich H-U (2002) IR spectroscopy. Wiley-VCH, Weinheim

Barth A (2000) Prog Biophys Mol Biol 74:141

Perutz MF, Johnson T, Suzuki M, Finch JT (1994) Proc Natl Acad Sci USA 91:5355

Sikorski P, Atkins E (2005) Biomacromolecules 6:425

Acknowledgments

C.S. Tuck and A. Latham were participants in the NSF-REU Site: Bioprocess Engineering for Sustainability at Virginia Tech. Funding from NSF-EEC-1156645 is greatly appreciated. Special thank you to Zhiyuan Lin for the DSC experiments and to Chip Frazier for use of his thermal analysis laboratory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tuck, C.S., Latham, A., Lee, P.W. et al. Wheat Gluten Plasticized with Its Own Hydrolysate. J Polym Environ 22, 430–438 (2014). https://doi.org/10.1007/s10924-014-0696-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-014-0696-1