Abstract

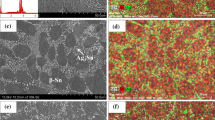

The phase transformation and microstructural evolution of Sn–Ag solder alloys under heat treatment, with a focus on the Ag3Sn phase, were investigated to address the need for reliable lead-free solder alternatives in electronic packaging. Initially, the solder alloy exhibited a fine eutectic structure with well-dispersed Ag3Sn particles and a polycrystalline grain structure devoid of any strong crystallographic texture. Following heat treatment, significant microstructural changes were observed, including the coarsening of the Ag3Sn phase and the development of a preferred grain orientation, suggesting recrystallization and grain growth. XRD analysis revealed a decrease in the intensity of the Sn phase peaks and an increase in the coarseness of the Ag3Sn peaks post-heat treatment, indicating phase evolution and redistribution of silver within the alloy. The EBSD results supported the SEM findings, showing elongation and growth of grains and a shift in texture. These changes imply that heat treatment can significantly alter the mechanical properties of Sn–Ag solders, particularly affecting creep resistance and hardness due to the evolution of anisotropic mechanical properties. The study provides essential insights into the selection and optimization of solder materials for high-reliability applications in the electronics industry.

Similar content being viewed by others

Data availability

The data that support the findings of this study are openly available at https://doi.org/10.17632/789hrxhtpw.1.

References

F. van der Hoek, Soldering and brazing, in Handbook of Precision Engineering: Volume 5 Joining Techniques. ed. by A. Davidson (Macmillan Education UK, London, 1972), pp.110–229

K. Suganuma, Advances in lead-free electronics soldering. Curr. Opin. Solid State Mater. Sci.. Opin. Solid State Mater. Sci. 5(1), 55–64 (2001). https://doi.org/10.1016/S1359-0286(00)00036-X

M. Hedemann-Robinson, The EU directives on waste electrical and electronic equipment and on the restriction of use of certain hazardous substances in electrical and electronic equipment: adoption achieved. Eur. Energy Environ. Law Rev. 12, 52–60 (2003)

S. Jayesh, J. Elias, Experimental investigation on the effect of Ag addition on ternary lead free solder alloy –Sn–0.5Cu–3Bi. Met. Mater. Int.. Mater. Int. 26(1), 107–114 (2020). https://doi.org/10.1007/s12540-019-00305-3

IEEE Xplore Reference Download 2024.1.17.6.31.42.

Y. Cui, J.W. Xian, A. Zois, K. Marquardt, H. Yasuda, C.M. Gourlay, Nucleation and growth of Ag3Sn in Sn-Ag and Sn-Ag-Cu solder alloys. Acta Mater. Mater. 249, 118831 (2023). https://doi.org/10.1016/J.ACTAMAT.2023.118831

Y. Liu, K.N. Tu, Low melting point solders based on Sn, Bi, and In elements. Mater Today Adv 8, 100115 (2020). https://doi.org/10.1016/J.MTADV.2020.100115

F. Wang, H. Chen, Y. Huang, L. Liu, Z. Zhang, Recent progress on the development of Sn–Bi based low-temperature Pb-free solders. J. Mater. Sci. Mater. Electron. 30(4), 3222–3243 (2019). https://doi.org/10.1007/s10854-019-00701-w

L. Zhang, Z. Liu, Inhibition of intermetallic compounds growth at Sn–58Bi/Cu interface bearing CuZnAl memory particles (2–6 μm). J. Mater. Sci. Mater. Electron. 31(3), 2466–2480 (2020). https://doi.org/10.1007/s10854-019-02784-x

S. Liu, S. Xue, P. Xue, D. Luo, Present status of Sn–Zn lead-free solders bearing alloying elements. J. Mater. Sci. Mater. Electron. 26(7), 4389–4411 (2015). https://doi.org/10.1007/s10854-014-2659-7

F. Hadian, H. Schoeller, E. Cotts, Correlation between the growth of voids and Ni3Sn4 intermetallic compounds at SnAg/Ni and SnAgCuBiSbNi/Ni interfaces at temperatures up to 200°C. J. Electron. Mater. 49(1), 226–240 (2020). https://doi.org/10.1007/s11664-019-07727-0

M. Xiong, L. Zhang, Interface reaction and intermetallic compound growth behavior of Sn-Ag-Cu lead-free solder joints on different substrates in electronic packaging. J. Mater. Sci. 54(2), 1741–1768 (2019). https://doi.org/10.1007/s10853-018-2907-y

Y. Ma et al., Effects of graphene nanosheets addition on microstructure and mechanical properties of SnBi solder alloys during solid-state aging. Mater. Sci. Eng. A 696, 437–444 (2017). https://doi.org/10.1016/J.MSEA.2017.04.105

J. ShanthiBhavan, A. Pazhani, P.S. Robi, A. Ambi, U. Tg, V. Kc, EBSD characterization of graphene nano sheet reinforced Sn–Ag solder alloy composites. J. Mater. Res. Technol. 30, 2768–2780 (2024). https://doi.org/10.1016/j.jmrt.2024.04.043

P.W. Voorhees, The theory of Ostwald ripening. J. Stat. Phys. 38(1), 231–252 (1985). https://doi.org/10.1007/BF01017860

Acknowledgements

The authors acknowledge the support from British Council’s Going Global Partnerships Grant (IND/CONT/G/23-24/26). The authors would like to thank Mr. Colin Thorneycroft, Development Officer—Manufacturing, Materials, and Metrology at Coventry University, for his help and support in conducting the experiments.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

Jayesh Shanthi Bhavan contributed toward conceptualization, methodology, formal analysis, investigation, writing—original draft preparation, and visualization. Jayesh Shanthi Bhavan led the project, designed the experiments, conducted the EBSD analysis, and drafted the manuscript. Ashwath Pazhani contributed toward software, validation, formal analysis, resources, data curation, and writing—review and editing. Ashwath Pazhani contributed to the analysis of the XRD and SEM data, assisted with the interpretation of results, and reviewed and edited the manuscript. Unnikrishnan TG contributed toward supervision, project administration, funding acquisition, and writing—review and editing. Unnikrishnan TG provided guidance on the experimental design, supervised the research activities, and contributed to the critical revision of the manuscript for important intellectual content.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Declaration of generative AI and AI-assisted technologies in the writing process

During the preparation of this work, the authors used ChatGPT to rephrase the literature and improving language. After using this tool/service, the authors reviewed and edited the content as needed and take full responsibility for the content of the publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shanthi Bhavan, J., Pazhani, A. & Unnikrishnan, T.G. EBSD characterization of Ag3Sn phase transformation in Sn–Ag lead-free solder alloys: a comparative study before and after heat treatment. J Mater Sci: Mater Electron 35, 1577 (2024). https://doi.org/10.1007/s10854-024-13349-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-13349-y