Abstract

Over the past few years, the studies of CdS/CdTe solar cells have become the mainstream, which have achieved good performance of exceeding 20 %. Here, we prepare CdSe thin films by pulsed laser deposition (PLD) which is one of promising techniques to synthesize semiconductor thin films. In this paper, the optical and electrical properties as well as the crystal structure of CdSe thin films deposited under different temperatures are investigated. We find that the deposition rate adds firstly, and then decreases with the increase of substrate temperature. Transmittance spectrum suggests the absorption edges of CdSe thin films under the condition of high temperature move towards short wavelength. The band gaps of CdSe thin films are 1.948, 1.976, 2.013 and 1.978 eV at the deposition temperature of 150, 250, 350, 450 °C, respectively. X-ray diffraction analysis indicates the formation of cubic phase with a strong (111) preferential orientation. The surface morphology of CdSe thin film and the cross-sectional structure of CdSe/CdTe layer are also analyzed. Based on these studies, we further fabricate the CdSe (PLD)/CdTe solar cells that present excellent performance of response in the range of long wavelength over 900 nm and a good efficiency of near 10 % has been realized.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, photovoltaic industry has been the crucial direction of global energy science and technology, and also been a business with great potential for growth of strategic emerging domains. As we all know, there are a large number of reports on CdS/CdTe thin film solar cells, because CdS possesses a high band gap Eg of approximate 2.42 eV and a better match with CdTe layer. However, we find that few investigations with respect to CdSe/CdTe thin film solar cells are concerned. Compared to the typical materials of CdS, CdSe has been yet recognized as an attractively promising stuff with special properties, thus it also can be used to fabricate high-efficiency solar cells. A best efficiency of about 15 % of CdSe/CdTe thin film solar cells with an area of 0.08 cm2, has been achieved by The Wright Center for Photovoltaics Innovation and Commercialization of the University of Toledo [1]. But there is no systematic study reported about CdSe single thin film, especially the effect of substrate temperature on the properties of CdSe single thin film. The prepared substrate temperature can not only affect the properties of CdSe single thin film, but also affect the formation of the interface of CdSe/CdTe. Therefore, a systematic research is meaningful. CdSe, like CdS, belongs to II~VI type compound semiconductor materials, which can be used for fabricating photoelectric detectors and solar cells [2]. The band gap Eg of CdSe that approaches 1.72 eV [3], which is regarded as a kind of direct band gap semiconductor material, is slightly lower than that of CdS (~2.4 eV). It seems that this weakness may produce a detrimental effect on the CdSe/CdTe PVs, however, the study of Paudel [1] has demonstrated that employing CdSe as a window layer in the CdSe/CdTe solar cells can enhance the response in the region of long wavelength occurred so-called red shift, and also achieve better efficiency. In spite of the narrow band gap of CdSe thin films, the element Se in the interface of CdSe/CdTe owns a distinct advantage over element S in the interface of CdS/CdTe, because element Se has a better solubility than S in the CdTe layer [4]. Under the high temperature, ternary compound of CdTe x Se1−x in the interface of CdSe/CdTe can be formed, when Se diffuses into the absorbed CdTe layer. Owing to bowing effects [1, 4], the newly formed CdTe x Se1−x presents a lower band gap Eg than that of the only CdTe thin film, which may give rise to an excellent response in the realm of long wavelength up to 910 nm. Like others, the same manners are able to be done to increase the photons of short wavelength by reducing the thickness of CdSe thin films, where the absorption of CdSe thin films for photons can be decreased. Therefore, by means of controlling the thickness of thin film, we observe that blue shift is generated in the region of short wavelength, in other words, which may compensate the shortcomings of using CdSe thin film as a window layer. All in all, CdSe thin film provides a viable way to seek for new materials to facilitate the development of the CdTe-based solar cells.

As reported, there are a variety of manufacture techniques for CdSe thin films, such as magnetron sputtering method [1, 4], chemical bath deposition (CBD) [5, 6], molecular beam epitaxy (MBE) [7], thermal evaporation [8], pulsed laser deposition (PLD), etc.

Due to particular merits, currently, pulsed laser deposition (PLD) [10] has been extensively applied to prepare all kinds of semiconductor materials. In contrast with other techniques, PLD can easily replicate the chemical ingredient of the target onto the glass substrate with fluorine doped tin oxide (FTO) so that it is able to make the stoichiometry of the target the same as the substrate, like molecular beam epitaxy (MBE). Because the process of utilizing PLD yields a rapid rise in temperature (>1011 Ks−1), which leads to target elements and compounds evaporate fastly [11]. What is more, due to the strong ablated surface temperature, it makes the particles have a high kinetic energy of 1–100 eV, and improves the mobility of the grains grown on the substrate. Many parameters of PLD equipment, including laser number, pulse energy, the distance between target and substrate, substrate temperature, can be accommodated to optimize the properties of the fabricated polycrystalline films. Here, we primarily analyze how the substrate temperatures affect the properties of CdSe thin films and the performance of CdSe (PLD)/CdTe solar cells.

2 Experimental details

In this study, we prepared all CdSe samples about 100 nm thick. The substrate temperatures were modified from 150, 250, 350, to 450 °C, respectively, which displayed a significant impact on the performance of CdSe layer. Before conducting this experiment, transparent conductive glass FTO (SnO2: F, surface conductivity 20 Ω/cm2) should be cleaned up sequentially using detergent solution, deionized water and isopropyl alcohol in the ultrasonic bath. And then CdSe thin films were deposited by PLD on the cleaned FTO substrates. To gain good quality, free-risking pinhole thin film, each other parameter of the pulsed laser equipment was fixed to the optimized condition. During the process of preparation, the vacuum chamber was evacuated to 3.0 × 10−3 Pa to avert the affect of particles in the air. The substrate was fixed onto a holder fitted with a resistive-type heater, which could make the suitable temperature to carry out films [11]. At the same time, the holder was able to forward or reverse to make films become more uniform.

The synthesized CdSe thin films were characterized by UV–Vis–NIR spectrophotometer (PerkinElmer Lambda 950) possessing the spectral range of 300–1000 nm to study the optical properties. The thickness of films deposited on different temperatures was measured by probe surface profilometer (Ambios Technology XP-2). The crystal structure of the films was researched by X-ray diffraction (XRD) (Dan Dong Hao Yuan DX-2700) with using Cu (Kα) 1.54 Å X-ray. The surface morphology of CdSe thin film and the cross-sectional structure of CdSe/CdTe double layers were measured by scanning electron microscopy (SEM) (Hitachi S-4800).

CdTe layer was grown on CdSe thin film by close spaced sublimation (CSS) [12, 13] under a relatively high temperature of 586 °C, which could produce a strong interdiffusion in the interface of CdSe/CdTe. Source to substrate distance was ~5 mm, and the temperature gradient of two heat sources was maintained as around 70 °C. During the process of deposition, the pressure of Ar was controlled to be 1.6 kPa. To obtain the better quality of CdTe layer, the optimal conditions of preparation were adopted. The thickness of the CdTe thin film was kept as around 4–6 μm to make sure that the photons were sufficiently absorbed. The fabricated CdSe/CdTe layers were treated by using the usual CdCl2 saturated solution, and were annealed at 385 °C for 35 min to form the rich Te layer, which can increase the p-type property of CdTe thin film [14, 15]. A thickness of about 70 nm of ZnTe:Cu back contact layer grown by PLD under room temperature was covered on the etched CdTe layer. After that, the completed ZnTe:Cu layer was activated in the chamber of the PLD instrument with the inflated N2 pressure of ~2×104 Pa at 200 °C for 50 mins, which was able to promote the element Cu to diffuse into the junction [17, 18]. Finally, Au electrode (~130 nm) was sequentially carried out by vacuum thermal evaporation [16], and then the whole solar cells were divided into many small areas of ~0.0707 cm2. It was most important to control each detail to manufacture the best performance solar cells (Fig. 1).

3 Results and discussion

3.1 Deposition rate

Previously, it has been reported that the substrate temperature had a significant impact on the deposition rate, especially at high temperature. It was of importance to investigate the deposition rate in the case of different temperature conditions. As shown in Fig. 2, a relatively higher deposition rate of CdSe thin film was achieved at low temperature than that of CdSe thin film at high temperature. With the increase of temperature, the deposition rate increased firstly and then decreased. Particularly, at the temperature of 250 °C, the deposition rate emerged the largest value, which indicated that the grains of CdSe thin film were well adherent to the FTO substrate. A relatively high temperature could facilitate the growth of grains, which was contributed to the increased rate. When the substrate temperature was over 250 °C, there was a slight decrease from 29.4 to 26.5 nm/min. However, a rapid decrease was observed from 26.5 to 16.6 nm/min at 450 °C. The phenomenon of decreased deposition rate over 250 °C could be interpreted as the re-evaporation of thin films [19].

3.2 Optical properties

As shown in Fig. 3, all prepared CdSe thin films had relatively sharp absorption edges, suggesting that a good crystallinity could be attained. However, the absorption edge of 150 °C was largely sharper compared to that of other temperatures. Furthermore, the highest transmittance was more than 80 %, indicating the photons enabled to well penetrate the thin films without much loss. As the temperature elevated from 150 to 450 °C, a pronounced change of the location of the absorption edge was noticed. There was a blue shift produced in the range of short wavelength. The curve of 150 °C nearly approached that of 250 °C after 800 nm, which showed that the low temperature had a slight influence on the properties of transmittance. On the contrary, under the high temperature, the curve of 350 °C was absolutely different from the case of 450 °C.

To understand more properties of CdSe thin films deposited by PLD, the band gaps of thin films at different temperatures were estimated according to the Fig. 4. Some formulas we might need were shown as below:

where T was the transmittance of photons, d was the thickness of thin films under different temperatures, and α was usually defined as the absorption coefficient in many reports [20–22].

Due to CdSe pertaining to direct band gaps semiconductor materials, therefore, the value of n was set as 1/2, h was famous Planck constant, υ was highly regarded as the frequency of light, and Eg was considered to be the band gap of thin film. Interestingly, we could plot the curve of (αhυ)2 versus hυ utilizing the above formulas. When the value of αhυ was extensively calculated as zero, the intercept of hυ axis was the band gap, accordingly.

As seen in Fig. 4, the band gaps of CdSe thin films grown at 150, 250, 350, 450 °C were roughly evaluated as 1.948, 1.976, 2.013 and 1.978 eV, respectively. With the increase of substrate temperature, the band gaps of thin film exhibited an increased trend, which might probably result in reducing short-circuit loss.

3.3 Crystal structure

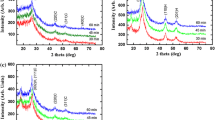

Figure 5 showed the XRD patterns of CdSe thin films manufactured with various temperatures on the FTO substrates, respectively. Several well defined diffraction peaks which were identified as (111), (220), (311), were observed clearly using the JPDS data. Nevertheless, starting from the bottom of the picture, the preferential orientation of all deposited thin films was primary (111) plane corresponding to 2θ = 25.1°, 2θ = 25.1°, 2θ = 25.4°, 2θ = 25.4°. As the temperature increased, the mainly sharp diffraction peaks had slightly shifted from 25.1° to 25.4°. Especially, at higher temperature, the major peak became sharper and narrower compared to other relatively lower temperature, which might indicate that thin films made at higher temperature had a better crystallinity. In addition, the XRD patterns also revealed that all films were polycrystalline, and all of these four films were cubic phase, which mean that cubic phase should be stable phase no matter the films were fabricated at higher temperature or lower temperature. As shown in Fig. 5, when the temperature went up to 450 °C, the diffraction peak of (311) disappeared, and there was no new peak emerged, while the intensity was substantially stronger than that of others.

3.4 SEM images analysis

In order to further study the grains and the surface morphology, the CdSe thin film of optimal temperature of 150 °C was characterized by using scanning electron microscope (SEM). From Fig. 6a, we found that the surface of CdSe thin film prepared at 150 °C was quite compact, and there was no clear grain boundary observed. However, when the film was annealed in dry air ambient at 385 °C for 35 min, a uniform surface could be achieved. After annealing, the grains underwent regrowth from about 20–200 nm. As shown in Fig. 6b, grain boundary was distinct, but several voids were found, which might form the recombination center to lower the performance of solar cells.

For CdSe/CdTe double layers, the cross-sectional structure images were studied as presented in Fig. 7. We found that four interfaces of FTO/CdSe were all quite clear, which suggested that interdiffusion between FTO layer and CdSe layer was relatively less. However, the difference we observed in the four interfaces of CdSe/CdTe was absolutely opposite. There was no obvious boundary. Therefore, it might be able to certify that the element Se had a better solubility in the CdTe absorbed layer and the CdSe window layer was consumed more, which also qualitatively accounted for the formation of CdTe x Se1−x being similar to CdS/CdTe solar cell.

3.5 Solar cell characteristics

Based on these results, to understand the influence of CdSe thin films deposited at different temperatures for CdSe/CdTe solar cell devices, the completed CdSe thin films were carried out to solar cells with the structure of FTO/CdSe (PLD)/CdTe (CSS)/ZnTe:Cu (PLD)/Au without anti-reflecting coatings (ART), respectively. Virtually, the CdSe/CdTe solar cells were characterized by using current density–voltage (J–V) measurements under an AM1.5 illumination. Consequently, the parameters of efficiency (η), fill factor (FF), short circuit current density (Jsc) and open circuit voltage (Voc) were seen clearly, which were listed in the following Table 1. The best performance of each set with an area of 0.0707 cm2 was chose. It could be observed that the solar cell with the CdSe thin film prepared at 150 °C showed an excellent efficiency of 9.7 %, the highest Voc of 688.3 mV, the best FF of 61.8 %, in comparison with other cells. However, its Jsc was mildly lower than that of CdSe (250 °C)/CdTe solar cell and CdSe (350 °C)/CdTe solar cell, but substantially higher than that of CdSe (450 °C)/CdTe solar cell. It might be due to few recombination centers formed in the interface of CdSe/CdTe with CdSe window layers prepared at 150 °C, which had a better match with CdTe layer. Although CdSe (PLD)/CdTe photovoltaic device has achieved a good result with an efficiency of near 10 %, it still has a long distance compared to the best performance of CdS/CdTe solar cell with an efficiency of more than 20 % [23]. Hence, we will optimize all sets of parameters to improve the performance of CdSe (PLD)/CdTe solar cells (Fig. 8).

We also measured the quantum efficiency (QE) to study the Jsc variations and the results were shown in Fig. 9. For all cells, there was a red shift occurred in the range of long wavelength over 900 nm, which was supposed to be a representative merit ahead of CdS/CdTe solar cell. For the normal CdS/CdTe solar cell, the absorption edge was around 860 nm, which was near 50 nm lower than that of CdSe/CdTe solar cell. It was because that Se element possessed a higher solubility in CdTe thin film than S element, more amounts of Se diffused into CdTe thin film which could form ternary compound CdTe1−x Se x in the CdSe/CdTe interface. Due to bowing effect, the band gap of CdTe in CdSe/CdTe solar cell was lower than 1.42 eV, leading to a good response in the region of long wavelength over 860 nm. According to the Fig. 9, we found that CdSe (450 °C)/CdTe solar cell presented a poor response in both short wavelength and long wavelength, which reduced the light current collection and gave rise to a relatively smaller Jsc recorded in Table 1. In the process of cell preparation, the CdSe (150 °C) thin film with a bad crystallinity possessed a good effect on the performance of CdSe/CdTe solar cell. A profound reason should be given. From the cross-sectional pictures of four cases as shown in the Fig. 7, we observed that there was no clear boundary in the interfaces of four CdSe/CdTe heterojunctions, which suggested a good match was formed in the interface of CdSe/CdTe heterojunction. From the quantum efficiency pictures as shown in the Fig. 9, we knew the solar cell with using CdSe (150 °C) as a window layer had the best spectral response in the range of 300–550 nm than other solar cells. Before, the group of Naba R. Paudel had proved that the element Se possessed a better solubility in the CdTe absorbed layer. Therefore, it might be because more amounts of element Se diffused into CdTe absorbed layer than other temperatures, which not only led to the largely reduced thickness of CdSe thin film, but also formed a perfect interface of CdSe/CdTe double layers. The largely reduced thickness of the CdSe thin film could lower the light absorption. Because of a perfect interface, there were few defect recombination centers and there was a similar spectral response in the range of 550–910 nm compared to CdSe (250 °C)/CdTe solar cell and CdSe (350 °C)/CdTe solar cell. The substrate temperature might have a significant influence on the formation of CdSe/CdTe interface, which played a more important role than the crystallinity of the CdSe thin film. Despite CdSe (PLD)/CdTe solar cell had a good response (≥65 %) in the realm of 500–800 nm, we would continue to improve the experiments to further obtain an anticipated performance.

4 Conclusions

We have studied the influence of substrate temperatures on the optical and electrical properties, as well as crystal structure of CdSe thin films fabricated by pulsed laser deposition (PLD). As the substrate temperature increases, the deposition rate goes up firstly, and then decreases. In addition, the transmittance is enhanced in the region of short wavelength. The band gap of CdSe layer shows an increasing trend with the increase of substrate temperature. From the XRD patterns, we know that CdSe thin films we made are all polycrystalline and a good crystallinity is achieved. Surface morphology analysis shows that CdSe thin film we prepared is very compact, and the cross-sectional images of CdSe/CdTe double layers prove that element Se has a better solubility in CdTe absorbed layer. Not only a perfect interface of CdSe/CdTe is obtained, but also the band gap of CdTe layer is reduced, which makes CdSe/CdTe solar cell possess a better response in the range of over 860 nm. A good efficiency of near 10 % has been attained by CdSe (150 °C)/CdTe solar cell, and the photocurrent of CdSe/CdTe solar cells has been enhanced in the range of long wavelength as we expected. Our results also provide a kind of different technique to produce CdSe thin films to further improve the performance of CdTe-based solar cells.

References

N.R. Paudel, Y. Yan, Appl. Phys. Lett. 105, 183510 (2014)

S. Antohe, V. Ruxabdra, H. Alexandru, J. Cryst. Growth 237–239, 1559–1565 (2002)

A.V. Kokate, U.B. Suryavanshi, C.H. Bhosale, Sol. Energy 80, 156–160 (2006)

N.R. Paudel, J.D. Poplawsky et al., IEEE J. Photovolt. 5, 1492–1496 (2015)

S.K. Sarkar, G. Hodes, J. Phys. Chem. B 109, 7214 (2005)

P.P. Hankare, S.D. Delekar, M.R. Asabe, P.A. Chate, V.M. Bhuse, A.S. Khomane, K.M. Garadkar, B.D. Sarwade, J. Phys. Chem. Solids 67, 2506 (2006)

J.C. Kim, H. Rho, L.M. Smith, H.E. Jackson, Appl. Phys. Lett. 75, 214 (1999)

J. Taylor, T. Kippeny, S.J. Rosenthal, J. Cluster Sci. 12, 571 (2001)

M.A. Hernandez-Perez, J. Aguilar-Hernandez et al., Phys. E 40, 2535–2539 (2008)

B. Li, J. Liu, X. Guowei, L. Rongtao, Appl. Phys. Lett. 101, 153903 (2012)

C. Ding, Z. Ming, B. Li, Mater. Sci. Eng. B 178, 801–806 (2013)

X. Huo, X. Peng, W. Liu, Mater. Electron. 24, 2479–2484 (2013)

M.A. Cousins, K. Durose, Thin Solid Films 361, 253–257 (2000)

A. Rios-Flores, J.L. Pena, Sol. Energy 84, 1020–1026 (2010)

M.A. Islam, M.S. Hossain et al., Thin Solid Films 546, 367–374 (2013)

U.S. Avachat, N.G. Dhere, J. Vac. Sci. Technol. A 24, 1664–1667 (2006)

W. Wang, G. Xia, J. Zheng, J. Mater. Sci. Mater. Electron. 18, 427–431 (2007)

J.V. Li, J.N. Dueow, IEEE J. Photovolt. 3, 1095–1099 (2013)

Z. Ming, C. Ding, B. Li, Mater. Electron. 25, 1901–1907 (2014)

S. Hachiya, Y. Onishi, J. Appl. Phys. 110, 054319 (2011)

M. Rusu, I. Salaoru, Int. J. Mod. Phys. B 18, 1287–1297 (2004)

O. Toma, L. Ion, M. Girtan, Sol. Energy 108, 51–60 (2014)

See http://investor.firstsolar.com/releasedetail.cfm?ReleaseID=828273 for First Solar Press Release

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant: 61574094) and matching support from the State of Kansas via Kansas Technology Enterprise Corporation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bao, Z., Yang, X., Li, B. et al. The study of CdSe thin film prepared by pulsed laser deposition for CdSe/CdTe solar cell. J Mater Sci: Mater Electron 27, 7233–7239 (2016). https://doi.org/10.1007/s10854-016-4689-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4689-9