Abstract

CdTe films were prepared on Fluorine-doped tin oxide substrate by RF magnetron sputtering and close spaced sublimation (CSS) methods, respectively. These CdTe films were then treated with a wet CdCl2 heat process at different temperatures. The structural and optical properties of CdTe films were investigated by X-ray diffraction, scanning electron microscope and UV–Visible spectrophotometer. The results reveal that both types of CdTe films have a better crystalline and larger grain size after CdCl2 heat treatment. However, the (422) peak has a more preferential orientation than (511) peak after CdCl2 activation for CdTe films prepared by sputtering method, while these two peaks almost have the same intensity for CSS-prepared CdTe films. The transmittance of CdTe films prepared by CSS is apparently lower than sputtered CdTe films. Correspondingly, the efficiency of solar cells with CSS-prepared CdTe is 7.3, 2.6 % of sputtered CdTe films.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

CdTe is one of the most promising photovoltaic materials available for use as low-cost, high-efficiency thin film solar cells due to its direct band gap of 1.5 eV and high optical absorption coefficient (>104 cm−1) [1]. Now the highest efficiency of CdTe thin film solar cells is 17.3 %, achieved by First Solar [2]. CdTe thin films can be prepared by various technologies such as vacuum thermal evaporation, close spaced sublimation (CSS) [3], electro-deposition [4], RF magnetron sputtering [5], etc. Among these methods, CSS and RF magnetron sputtering have particularly great potential in industrial production. RF sputtering is more suitable to industrial production, while the efficiency of solar cells prepared by this method is lower than CSS. Therefore, further investigations are needed to compare CdTe thin film properties prepared by these two methods.

Appropriate CdCl2 heat treatment is very important for the preparation of CdTe solar cell; otherwise, as-deposited CdTe films would have many undesirable characteristics such as small grains, short minority carrier lifetime and high resistivity due to a large number of grain boundaries [5]. However, after a proper CdCl2 activation, CdTe films would recrystallize and results in larger grains, which could promote diffusion at the CdS/CdTe interface and lead to better efficiency of solar cell [6]. Generally, the CdCl2 activation can be realized by two methods. One is dry method that the prepared CdTe films undergo a heat treatment in CdCl2 vapor atmosphere. The other is wet method, CdTe films will be immersed into a CdCl2 solution, and then the CdTe films processed a activation at 380–500 °C. Researches existed mainly focus on CdCl2 activation of CSS-prepared CdTe films [7, 8], however, more thorough studies are still in need to confirm the appropriate activation process as well as the photovoltaic property of activated CdTe films.

In this paper, CdTe films were prepared on Fluorine-doped tin oxide (FTO) substrates by RF magnetron sputtering and CSS methods, and then were activated by wet CdCl2 heat treatment. Comparison of surface morphology and microstructure was made between samples obtained from these two different ways. It may help to identify the advantages and disadvantages of each method, so as to provide more instructions for improving CdTe solar cells.

2 Experimental

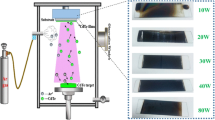

The substrates used in this work were commercial FTO coated glass; the substrates were cleaned sequentially with chromic acid and de-ionized water in an ultrasonic bath. The CSS deposited CdTe films were prepared in a quartz vacuum chamber for 4 min at 2.6 Pa, the source and the substrate were heated by halogen lamps, the temperatures were 640 and 550 °C, respectively. The distance between them was 5 mm. CdTe films prepared by RF magnetron sputtering method were deposited with the substrate temperature at 300 °C for 45 min. The sputtering forward power was 250 W, reflect power was 18 W. The sputtering gas used was Ar and the total gas pressure was 0.5 Pa.

For wet CdCl2 treatment, the CdTe films were immersed into a saturated CdCl2 solution (1 g/60 ml ethanol) for 5 s [7]. Then CdTe films were heated in rapid annealing furnace for 30 min. The working gas was high purity air with the flow of 0.5 L/min, and the pressure maintains at 75 kPa, activation temperature varied from 340 to 420 °C. In order to investigating the performance of CdTe solar cells, 120 nm CdS films were prepared on FTO substrate by RF sputtering method. Then CdTe films were deposited on CdS films by CSS and sputtering method, followed by a CdCl2 treatment and copper gold back contact deposition. The cell area is 0.07 cm2.

The thickness of films was measured by a Vecco Dektak-150 Stylus Surface Profiler. The crystalline and orientation of the films were characterized by X-ray diffraction (XRD) using Cu Kα (1.5406 Å) radiation, and their morphology were observed by a scanning electron microscope (SEM). UV–Vis–NIR transmittance spectra of the films were measured by a Cary 5,000 spectrophotometer.

3 Result and discussion

3.1 Structure and morphology

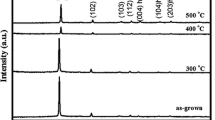

Figure 1 shows XRD patterns of CSS-prepared CdTe thin films before and after CdCl2 activation at different temperatures. The thickness of CdTe films was about 3.1 μm. The as-deposited sample and activated sample both exhibit cubic crystal structure with a preferred orientation of (111) plane. Peak (111), (311), (400), (422) and (511) becomes stronger with temperature increasing from 340 to 380 °C, indicating that CdTe films have better polycrystalline characteristic after CdCl2 activation. CdTe films could have large grain size and grain boundary passivation at 380 °C, and therefore the activation temperature is usually set at 380 °C [9]. However, temperature higher than 420 °C usually brings undesirable results on film microstructure. Almost all peaks decrease dramatically in such cases, probably due to that CdCl2 has evaporated at high temperature [5]. CdCl2 may act as sintering agent, when chlorine play an important role during the post activated process. Figure 2 is the XRD patterns of polycrystalline CdTe films prepared by RF magnetron sputtering. The thickness of the films was about 2.9 μm. Peak (111), (311), (422) and (511), all of which indicates CdTe cubic phase, are also clearly manifested. In addition, intensity of all peaks increase as temperature grows, also indicating CdTe films could have better polycrystalline with activation temperature increasing.

From the comparison between CdTe films prepared by these two different methods, it could be confirmed that an appropriate activation temperature of CdCl2 from 340 to 380 °C could improve the regularity of CdTe crystal lattice. For activated CSS-prepared CdTe films, all peak intensity declines remarkably when activation temperature over 420 °C. In comparison, the intensity of XRD peaks for sputtered CdTe films continue increase after activated temperature reaching 420 °C. Moreover, there is no (400) diffraction peak on Fig. 2, and the (422) peak has a more preferential orientation than (511) peak after CdCl2 activation for sputtering-prepared CdTe films; while these two peaks almost have the same intensity for CSS-prepared CdTe films.

The micrographs of CSS-prepared CdTe films activated at different temperatures are shown in Fig. 3, where crystallites grow bigger and the as-deposited CdTe film present better crystalline after being activated at a temperature from 340 to 380 °C. While the crystallinity and the profile of grain deteriorated when temperature reach 420 °C, it is consistent with XRD results. Fig. 4 is the SEM image of CdTe films prepared by RF magnetron sputtering and have been activated at different temperatures. Microstructure characteristics can hardly be indicated for samples without CdCl2 activation, while the profile of grain is clearly revealed by increasing activation temperature.

After activation, some dark color materials are found on the surface of CdTe film prepared by both approaches, which gradually decreased with activation temperature increasing. Such materials could be oxides and oxychlorides residue since CdTe films activated by CdCl2 in O2 atmosphere is very likely to have Cl residue containing Cd, Te, Cl, and O at surface [10]. From Figs. 3 and 4, it is easy to find that CSS-prepared CdTe films have larger grain size than CdTe films deposited by sputtering; one possible reason is CSS method has higher deposited temperature than sputtering.

3.2 Optical properties

Figures 5 and 6 are optical transmission spectra of CdTe films activated at different temperatures. The absorption edges of all samples are around 800 nm. Transmission of CdTe films decreased with activation temperature increasing, indicating that films activated at high temperatures can absorb more light. For CSS-prepared samples, the effect of activation on absorption is not remarkable; while a significant decease could be found for sputtering-prepared samples. This result substantiates that activation process could improve crystal quality of CdTe films notably. Considering two type films have similar thickness, we found CSS-prepared CdTe films have higher absorbance than CdTe films deposited by sputtering.

The optical band gap of different CdTe films in Table 1 are determined by Tauc’s plots using the data of reflectance and transmittance spectra [11]. The band gap (E g ) values can be calculated by plotting (αhν)2 versus hν of the graph. The band gap values extracted from these plots are in the range of 1.44–1.51 eV, it is correspond to CdTe band gap [1].

Here ‘A’ is a constant, ‘α’ is the absorption coefficient, ‘d’ is the thickness of the films, ‘R’ is the reflectance of the films, ‘T’ is the transmittance of the films, ‘hν’ is the photo energy, E g is the optical band gaps of CdTe films. For direct band gap transition ‘n’ is 1, while for indirect band gap transition ‘n’ is 2.

3.3 Performance of solar cells

Figure 7a, b show the current density versus voltage (J–V) characteristic of CdS/CdTe solar cells activated at 380 °C. The performance of both two type solar cells are shown in Table 2. The photovoltaic performance of the solar cells based on CSS-prepared CdTe films is better than sputtering-prepared CdTe films, mainly because CSS method could obtain CdTe films with larger grain size and better crystalline than sputtering. In this study, the efficiency of two type solar cells was lower than highest efficiency that has been reported. This could be caused by the absence of Nitric acid Phosphate etching (NP etching) during the preparing. NP etching will remove CdCl2 residue as well as some CdTe from the substrates and therefore help to form a better ohmic contact for CdTe. Another possible cause is Cu/Au back electrodes were not optimized. The content of Cu in back electrodes often affects the performance of solar cells notably [12, 13]. During post treatments, Cu may diffuse at different interfaces within CdTe cells. For this reason, if the thickness of evaporated Cu films is too thick, the diffusion of Cu atoms from the back electrodes into CdTe films may result in a large number of defects cross the junction, and makes CdTe solar cells not stable [14].

4 Conclusion

We investigated the characteristics of CdCl2 heat treatment on CdTe films prepared by RF magnetron sputtering and CSS. CdTe films obtained in both methods have a preferred orientation of (111) plane. All films presented better crystalline after a CdCl2 activation conducted at a temperature varying from 340 to 380 °C. Compared with CSS method XRD spectra, there is no (400) diffraction peak in sputtering method XRD spectra. SEM suggests CSS could prepare CdTe films with larger crystal grains than sputtering. The transmission of CSS-prepared films is apparently lower than sputtering-prepared films. The transmission of both types of CdTe films decreased with activation temperatures increasing. For sputtering-prepared films, there is a significant decrease of transmission, indicating that activation condition has great influence on recrystallization. The CdTe solar cells based on CSS manifests better photovoltaic performance than sputtering-prepared films.

References

D. Bonnet, P.V. Meyers, J. Mater. Res. 13, 2740 (1998)

First Solar, First solar sets world record for CdTe solar PV efficiency (2011). http://investor.firstsolar.com/releasedetail.cfm?ReleaseID=593994.

M. Arif Khan, N.A. Shah, A. Ali, M. Basharat, M.A. Hannan, A. Maqsood, J. Coat. Technol. Res. 6(2), 251–256 (2009)

A.E. Rakhshani, J. Appl. Phys. 81, 7988–7993 (1997)

Jaehyeong. Lee, Curr. Appl. Phys. 11, S103–S108 (2011)

B. McCandless, L. Moulton, R. Birkmire, Prog. Photovoltaics. 5, 249 (1997)

N.A. Shah, A. Ali, S. Hussain, A. Maqsood, J. Coat. Technol. Res. 7(1), 105–110 (2010)

M.A. Flores Mendoza, R. Castanedo Pérez, G. Torres Delgado, J. Márquez Marín, A. Cruz Orea, O. Zelaya Angel, Sol. Energ. Mat. Sol. C. 95, 2023–2027 (2011)

A. Romeo, D.L. Btzner, H. Zogg, A.N. Tiwari, Thin Solid Films 420, 361–362 (2000)

David.W. Niles, Donna. Waters, Doug. Rose, Appl. Surf. Sci. 136, 221–229 (1998)

O. Paredes, C. Córdoba, J. Benavides, Superf. Vaco. 9, 89–91 (1999)

H.C. Chou, A. Rohatgi, N.M. Jokerst, E.W. Thomas, S. Kamra, J. Electron. Mater. 25, 1093 (1996)

J. Zhou, X. Wu, Y. Yan, S. Asher, J. Da Silva, S. Wei, L. Weinhardt, M. Bär, C. Heske, in Thin-Film Compound Semiconductor Photovoltaics, MRS Symposia Proceedings No. 1012 (Materials Research Society, Pittsburgh, 2007), p. 1012–Y13–03

D.L. Bätzner, A. Romeo, H. Zogg, R. Wendt, A.N. Tiwari, Thin Solid Films 387, 151 (2001)

Acknowledgments

This work was done at Shanghai Center for Photovoltaics and supported by the solar energy plan of Chinese Academy of Sciences (Project No.KGCX2-YW-384), by the Innovation Program of Shanghai Municipal Education Commission (No. 11ZZ02) and by the Scientific Foundation for the Returned Overseas Chinese Scholars, State Education Ministry is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huo, X., Peng, X., Liu, W. et al. Comparison between the effects of CdCl2 heat treatment on CdTe films prepared by RF magnetron sputtering and close spaced sublimation methods. J Mater Sci: Mater Electron 24, 2479–2484 (2013). https://doi.org/10.1007/s10854-013-1121-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1121-6