Abstract

This paper presents the fabrication and characterization of CdS thin film solar cells synthesized by chemical bath deposition using acid as a complexing agent with pH values between 10.1 and 11.3. We studied the influence of pH control of the reaction solution on the structural and optical properties of chemically deposited CdS thin films. Different films thicknesses of CdS were deposited onto a glass substrate. The structural surface morphology of as-deposited CdS thin films was characterized by scanning electron microscope, x-ray diffraction, profilometer, and ultraviolet–visible spectroscopy. The investigation of the effect of the synthesis method on the change the ammonium hydroxide by buffer pH 11 contributed in increases the growth kinetics, resulting thicker films. The films show high absorption and band gap values were found from 2.38 to 2.58 eV with different time deposition. The results are quite appreciable and high efficiency can be obtained from these CdS thin-film solar cells.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Over the last decade, thin films of II–VI semiconductor compounds are the most promising to build solar panels with the world record for highest efficiency. For example, cadmium sulfide (CdS) has received intensive attention, since its band gap lie very close to the range of maximum theoretically attainable energy conversion efficiency [1]. CdS is an inorganic compound of yellow solid color. Also, it has a wide band gap, a high electron affinity and a high-gain photoconductivity, and it is known to be an excellent heterojunction partner for p-type cadmium telluride or p-type copper indium diselenide. It has been widely used as a window material in high efficiency thin film solar cells based on cadmium telluride or copper indium diselenide [2–5]. In these kinds of devices, light penetrates the CdS layer and is absorbed in the p-type semiconductor close to the p–n junction [6]. Also, CdS is an interesting crystal material in the areas of photodetectors, semiconductor lasers, nonlinear integrated optical devices, optoelectronic devices, etc. Wide band gap materials is really important, because this characteristic is related to the possibility of fabricating light emitting diodes or laser heterostructures for emission in the visible spectral range [7], however, this area is out of this research work. In the last decade, the interest to develop CdS films as semiconductor active layers in thin-film transistors has increased significantly. And then, the studies on CdS film deposition have been focused on obtaining CdS films with better structural, electrical and optical properties, in order to increase their performance in optoelectronic devices, such as solar cells.

CdS films can be deposited by different deposition techniques such as Chemical Bath Deposition (CBD), metal organic vapor-phase, vacuum evaporation, spray pyrolysis, thermal evaporation, chemical vapor deposition, metal organic vapor-phase epitaxy, close space vapor transport, photochemical deposition, radio frequency sputtering, vapor transport deposition, screen printing, electro deposition, pulsed laser deposition, etc. [7]. However, the method widely used for this kind of the deposition is the CBD technique, because with it is possible the deposition of different metal chalcogenide thin films easily. That means that with the CBD process, the precipitation from the solution of a compound on a suitable substrate can be controlled. The CBD method offers many advantages over others deposition methods more common, because with it is easy to carry out the deposition of the semiconducting materials too. The principal advantages of this method are that one can control the film thickness and deposition rate by varying the solution pH. Also, large areas can be deposited controlling the deposition temperature and reagent concentration. These advantages make it as a reproducible and low-cost process [8–11]. Due to the simplicity and the very economical experimental facilities needed in the film deposition, the CBD is the best method to obtain low-cost CdS thin films that have optimal features for photovoltaic device applications [12–19]. In the present work, we reported the deposition of good quality CdS thin film by CBD method at 60 °C with different time deposition to study their properties and to have a better efficiency in the solar cells. In this work, we have focused on the influence of the control of the pH parameter of the reaction solution on the properties of chemically deposited CdS films. For this, we used the CBD technique to deposit CdS thin films using different types of solutions. The differences between the reaction solutions was, that, in one of them, ammonia was substituted completely by sodium citrate as the complexing agent and pH from 10.1 to 11.3 values buffers were included in the precursor solution to attain the pH required value and to control the pH of the solution during the whole deposition process. Both kinds of deposited CdS films were studied to determine the influence of the pH control in the reaction solution on the properties of the films. The results are quite appreciable and a high efficiency can be obtained from these CdS thin films and can be useful for solar cells applications.

Experiments

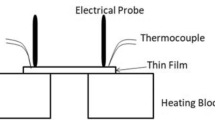

The process to analyze the CdS thin films by chemical-bath-deposited method was carried out in [20], but in this research work we only used three different pH levels with different time’s deposition, 30, 45, and 60 min. In the same way as in [20, 21], we deposited the CdS polycrystalline thin films on 25 mm × 75 mm glass substrates from a chemical bath containing 25 ml of ammonium hydroxide (NH4OH) and 150 ml of deionized water. Before the deposition, the glass substrates were cleaned with acetone and methanol ultrasonically, and then rinsed with deionized water, and subsequently it was dried by argon. The beaker containing the mixed solution was placed in the water bath tank with a magnetic force after the water bath temperature reached the set temperature value. The glass substrate was then kept vertically in the beaker and, we began to count the deposited time. The bath was maintained under constant stirring during the deposition. The temperature was regulated at 60 °C for different deposited time, and we got three samples. After deposition, the CdS film was washed with distilled water to remove the loosely adhered CdS particles on the film and finally dried in argon. The summary compositions of the chemical bath are presented in the Table 1. Where, we present the composition of the chemical bath, temperature, thickness, Eg, and the time duration of the film deposition of three samples with three different deposition times to produce nine samples with different thickness. The surface and cross-sectional morphology of films were observed using field emission scanning electron microscope (SEM). The structure of the films was analyzed by the x-ray diffraction (XRD). Optical transmission measurements have been done at room temperature with polarized light at normal incidence in the wavelength range from 200 to 900 nm.

Results and Discussion

The chemical bath deposition of high quality CdS thin films for solar cells applications are based on the chemical precipitation of CdS in the bath. The precipitation control can be achieved by controlling the free cadmium metalions concentration; generally ammonia is used as a complexing agent. In this research work, the fabrication and characterization of CdS thin film for solar cells applications synthesized by chemical bath deposition using acid as a complexing agent with pH values between 10.1 and 11.3. Several techniques were used for the structural, morphological, optical, and electrical characterization of the Cds thin films. We obtained nine samples of the CdS thin film solar cells with three deposition times of 30, 45, and 60 min. The diffractogram of as-deposited CBD-CdS samples are showed in Fig. 1. The patterns show the increasing presence with deposition time of polycrystalline structure in these films, displaying diffraction lines at 26°, 44°, and 53°, situated on a broad reflection produced by the amorphous substrate. In the Fig. 1(a), the four peaks are produced by the (002), (220), and (311) crystalline planes, respectively, of the hexagonal CdS structure. The increase in intensity of the crystalline peaks with deposition time is due to the increase of the film thickness. This presented very low intensity in the thinnest films; it was an expected result due to the small quantity of material compared to the thicker films. The relative intensity of the reflection indicates a preferred orientation along the (002) direction. These results are in agreement with the structural data reported in the literature for chemically deposited CdS films prepared with a similar reaction solution. The Fig. 1(b) shows the XRD patterns for the second sample of the CdS thin films. These patterns also display the (002), (110), and (201) diffraction lines of the hexagonal CdS structure. However, the (311) diffraction line does not appear or it is very weak. The intensity of the peaks also increases with deposition time. The ratio of the (002) peak intensity is larger than the one for the others films, indicating a stronger (002) preferred orientation. It is known that the surface mobility of adsorbed species at the substrate surface has a strong influence on the crystalline structure during the growth process. In the Fig. 1(c), the pH in the solution is 11.3, which means a higher concentration of OH− ions and thus faster generation of S2− ions by the thermal hydrolysis of thiourea.

(a) X-ray diffraction patterns of CdS thin films deposited at 60 °C, pH 10.1, deposition times of 30 (red), 45 (green), and 60 (blue) min and thicknesses 273, 398, and 529 nm, respectively. (b) X-ray diffraction patterns of CdS thin films deposited at 60 °C, pH 10.6, deposition times of 30 (red), 45 (green), and 60 (blue) min and thicknesses 90, 120, and 160 nm, respectively. (c) X-ray diffraction patterns of CdS thin films deposited at 60 °C, pH 11.3, deposition times of 30 (red), 45 (green), and 60 (blue) min and thicknesses 40, 56, and 66 nm, respectively (Color figure online)

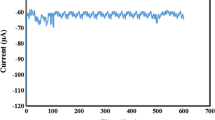

The optical properties such as transmittance, absorption coefficient and band gap energy of CdS thin films are determined from the variation of the optical transmission with wavelength (λ) in the range from 200 to 900 nm. Figure 2 shows the optical transmission and reflection spectra for the CdS thin film solar cells (for the three samples with different deposition times). They have the same absorption edge at ~500 nm. The transmission of the films at larger wavelengths than the absorption edge is between 70 and 90% and drops to 10% at lower wavelengths. The reflectance of the films is between 10 and 20% over the entire wavelength range. In these spectra the absorption edge of CdS is also manifested at about 500 nm. The oscillations of both transmission and reflection of the films in the semi-transparent region are due to interference with the light reflected at the substrate–layer interface.

(a) Optical transmission and reflection spectra of CdS thin films deposited at 60 °C, pH 10.1, deposition times of 30, 45, and 60 min and thicknesses 273, 398, and 529 nm, respectively. (b) Optical transmission and reflection spectra of CdS thin films deposited at 60 °C, pH 10.6, deposition times of 30, 45, and 60 min and thicknesses 90, 120, and 160 nm, respectively. (c) Optical transmission and reflection spectra of CdS thin films deposited at 60 °C, pH 11.3, deposition times of 30, 45, and 60 min and thicknesses 40, 56, and 66 nm, respectively (Color figure online)

The optical band gap energy (E g ) of the CdS thin films have been determined by extrapolating the linear portion of the curves of (αhν)2 versus (hν) as shown in Fig. 3. From the Fig. 3, it is observed that all the films have direct band gap values of 2.38–2.58 eV for the films with different ammonia concentration. The deviation of the energy gap values from the standard bulk value of 2.42 eV is due to the use of greatly wide range of ammonia concentration in the present CBD process. Hence, the CdS thin films can be considered to be good for use as visible transmitting thin films since the range of band gap for visible transmitting film is 1.5–3.0 eV.

(a) Band gap energy values of CdS thin films deposited at 60 °C, pH 10.1, deposition time of 60 min, and thickness 529 nm. (b) Band gap energy values of CdS thin films deposited at 60 °C, pH 10.6, deposition time of 60 min, thickness 160 nm. (c) Band gap energy values of CdS thin films deposited at 60 °C, pH 11.3, deposition time of 60 min, thickness 66 nm

Figure 4 shows SEM images of the three samples of the CdS thin films at different deposition times. It is observed that the surface morphology of as-deposited films is almost smooth and no grains are observed clearly at a low molar concentration, see Fig. 4(a). The size of the grain in the deposited films has been observed with the high pH values. Thus, the change in the surface features and the improvement in the grain growth are clearly noticed from the SEM images of the film deposited at a higher concentration. The films deposited in pH buffered conditions (10.6 and 11.3) are having predominant grains (Fig. 4b–c). The developments of uniformly distributed roughly spherical grains grown perpendicular to the surface of the substances are observed for these films. The estimated average grain size is observed to be increasing with the increase of the concentration of ammonia. The SEM photo (see Fig. 4c) shows a surface of some porous homogeneous film having a grain size between 107 and 125 nm.

(a) SEM photos of CdS thin films deposited at 60 °C with deposition time of 60 min, thickness 529 nm, and with pH 10.1, for 20, 5, 2, and 1 µm. (b) SEM photos of CdS thin films deposited at 60 °C with deposition time of 60 min, thickness 160 nm, and with pH 10.6, for 20, 5, 2, and 1 µm. (c) SEM photos of CdS thin films deposited at 60 °C with deposition time of 60 min, thickness 66 nm, and with pH 11.3, for 20, 5, 2, and 1 µm

Conclusions

CdS thin films were deposited on glass substrate by CBD method. The optimal deposition parameters were used to be T = 60 °C, deposition time equal to 30, 45, and 60 min. For the sample 3, the film thickness was 66 nm and band gap 2.44 eV, this is an evidence of disorder effects or presence of amorphous components in the film. The use of the buffer also increases the growth kinetics, resulting in thicker films. However, the optical properties, such as energy band gaps at the critical points of the electronic band structure of CdS, are not affected by the use of the buffer; with this analysis a high efficiency can be obtained from these CdS thin-film solar cells.

References

A. Mondal, T.K. Chaudhuri, P. Pramanik, Deposition of cadmium chalcogenide thin films by a solution growth technique using triethanolamine as a complexing agent. Sol. Energy Mater. 7(4), 431–438 (1983)

I. Oladeji, L. Chow, C. Ferekides, V. Viswanathan, Z. Zhao, Metal/CdTe/CdS/Cd1-xZnxS/TCO/glass: a new CdTe thin film solar cell structure. Sol. Energy Mater. Sol. Cells 61, 203–211 (2000)

M. Contreras, M. Romero, B. To, F. Hasoon, R. Noufi, S. Ward, K. Ramanathan, Optimization of CBD CdS process in high-efficiencyCu(In, Ga)Se2-based solar cells. Thin Solid Films 403, 204–211 (2002)

H. Khallaf, I.O. Oladeji, L. Chow, Characterization of CdS thin films grown by chemical bath deposition using four different cadmium sources. Thin Solid Films 516, 7306–7312 (2008)

K. Sivaramamoorthy, S. Asath Bahadur, M. Kottaisamy, K.R. Murali, Properties of CdS films deposited by the electron beam evaporation technique. J. Alloys Compd. 503(1), 170–176 (2010)

J. Aguilar-Hernández, J. Sastré-Hernández, R. Mendoza-Pérez, G. Contreras-Puente, M. Cárdenas-García, J. Ortiz-López, Photoluminescence studies of CdS thin films annealed in CdCl2 atmosphere. Sol. Energy Mater. Sol. Cells 90(6), 704–712 (2006)

P.P. Hankarea, P.A. Chateb, D.J. Sathec, CdS thin film: synthesis and characterization. Solid State Sci. 11(7), 1226–1228 (2009)

B.R. Sankapal, S.D. Sartalea, C.D. Lokhandeb, A. Ennaouia, Chemical synthesis of Cd-free wide band gap materials for solar cells. Sol. Energy Mater. Sol. Cells 83(4), 447–458 (2004)

J.G. Vázquez-Luna, R.B. Lopez Flores, M. Rubin-Falfán, L.D.C. Gómez-Pavón, R. Lozada-Morales, H. Juarez-Santiesteban, O. Starostenko, O. Zelaya-Angel, O. Vigil, O. Guzmán, P. del Angel, A. González, CdS thin-films deposited by a modified chemical-bath deposition method. J. Cryst. Growth 187, 380–386 (1998)

O. De Melo, L. Hernández, O. Zelaya-Angel, R. Lozada-Morales, M. Bercerril, E. Vasco, Low resistivity cubic phase CdS films by chemical bath deposition technique. Appl. Phys. Lett. 65, 1278 (1994)

B. Dogil, M. Lepek, Structural effect of CdS thin films grown by a quasi-rheotaxy technique. J. Mater. Sci. Lett. 12, 1514–1515 (1993)

J.N. Ximello-Quiebrasa, G. Contreras-Puentea, J. Aguilar-Hernándeza, G. Santana-Rodriguezb, A. Arias-Carbajal Readigos, Physical properties of chemical bath deposited CdS thin films. Sol. Energy Mater. Sol. Cells 82(1–2), 263–268 (2004)

B. Ullrich, R. Schroeder, Green single- and two-photon gap emission of thin-film CdS formed by infrared pulsed-laser deposition on glass. IEEE J. Quantum Electron. 37, 1363 (2001)

H. Wang, Y. Zhu, P.P. Ong, Rotary target method to prepare thin films of CdS/SiO2 by pulsed laser deposition. J. Cryst. Growth 220, 554–559 (2000)

M. Khanlary, P. Townsenda, B. Ullrich, D.E. Hole, Ion-beam luminescence of thin-film CdS on glass formed by pulsed-laser deposition. J. Appl. Phys. 97, 023512 (2005)

M.A. Contreras, M.J. Romero, B.T.E. Hasoon, R. Noufi, S. Ward, K. Ramanathan, Optimization of CBD CdS process in high-efficiency Cu(In, Ga)Se2-based solar cells. Thin Solid Films 403, 204–211 (2002)

T. Minemoto, T. Matsui, H. Takakura, Y. Hamakawa, T. Negami, Y. Hashimoto, T. Uenoyama, M. Kitagawa, Theoretical analysis of the effect of conduction band offset of window/CIS layers on performance of CIS solar cells using device simulation. Sol. Energy Mater. Sol. Cells 67, 83–86 (2001)

H. Moualkia, S. Hariech, M.S. Aida, N. Attaf, E.L. Laifa, Growth and physical properties of CdS thin films prepared by chemical bath deposition. J. Phys. D Appl. Phys. 42, 135404 (2009)

J.N. Alexander, S. Higashiya, D. Caskey, H. Efstathiadis, P. Haldar, Deposition and characterization of cadmium sulfide (CdS) by chemical bath deposition using an alternative chemistry cadmium precursor. Sol. Energy Mater. Sol. Cells 125, 47–53 (2014)

X. He, W. Liu, C. Zhu, G. Jiang, CdS thin films deposited by CBD method on glass. Chin. J. Chem. Phys. 24(4), 471–476 (2011)

F. Ouachtari, A. Rmili, B. Elidrissi, A. Bouaoud, H. Erguig, P. Elies, Influence of bath temperature, deposition time and S/Cd ratio on the structure, surface morphology, chemical composition and optical properties of CdS thin films elaborated by chemical bath deposition. J. Mod. Phys. 2, 1073–1082 (2011)

Acknowledgments

This project has been funded by the CONACyT-Mexico Grant CB-169062 and also it has been partially funded by PROMEP: RedesTemáticas de Colaboración under the project titled: Fuentes de Energías Alternas and by the ECEST-SEP (Espacio Común de Educación Superior Tecnológica) program under the mobility scheme for professors and students.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vázquez-Monroy, F., García-Barrientos, A., Hoyo-Montaño, J.A. et al. Fabrication and Characterization of CdS Thin Film Synthesized by CBD Deposited from pH-Controlled Growth Solutions for Solar Cells Applications. Metallogr. Microstruct. Anal. 5, 62–68 (2016). https://doi.org/10.1007/s13632-015-0253-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-015-0253-x