Abstract

The ever-increasing energy demand and fossil energy consumption accompanied by the worsening environmental pollution urge the invention and development of new, environmentally friendly and renewable high-performance energy devices. Among them, the supercapacitor has received massive attention, and the various electrode materials and polymer electrolytes have been exploited. The carbon-based electrodes and electrolytes derived from biomass are highly trusted as idea candidates for supercapacitors due to their attractive structure, abundance, low cost, renewability, and environmentally friendliness. This review will highlight the available characteristics of materials, synthetic strategies, and improvement approach of biomass-derived electrodes and electrolytes for application in supercapacitors. Future relative research trends also will be briefly discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

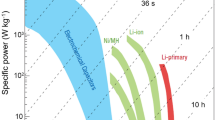

In recent years, as the energy demand and fossil energy consumption is increasing rapidly and environmental pollution is getting worse, it is urgent to invent and develop new, environmentally friendly, and renewable high-performance energy conversion and storage devices [1, 2]. Supercapacitor is a new type of energy storage system between secondary battery and physical capacitor, which has received massive attention as energy storage owing to its ultrahigh power density, long life cycles, and rapid charge/discharge rate. It is usually categorized into pseudocapacitors, the capacitance of which originates from reversible Faradaic reactions of electroactive species, and electrical double-layer capacitors with capacitance arising from the reversible electrostatic adsorption of ions at the interface of electrode/electrolyte based on the charge-storage mechanism [3]. However, there is still a certain gap to be narrowed between the electrochemical performance of supercapacitors and the increasingly stringent market requirements, such as fast discharge speed, high self-discharge rate, and low specific capacitance.

The electrochemical performance of supercapacitors is significantly affected by the electrode materials. Metal oxides (such as Co3O4, MnO2, and NiO), conductive polymers (such as polyaniline, polypyrrole, and polythiophene), and carbon materials are widely used for supercapacitor electrodes. Besides, novel electrode materials, such as metal phosphites, metal sulfide, and porous organic polymer, have been developed at present. Metal phosphites [4] show high electrical conductivity and high specific capacitance as pseudocapacitive materials for electrodes. Metal sulfides [5] possess superior electrical conductivity and are commonly compounded with other materials. Porous organic polymers exhibit electronic conductivity for its extended π-conjugated systems and significant pseudocapacitance for good redox activity, but its rate performance and cycling stability are inferior because of the low electrochemical stability, and much efforts have been made to overcome it [6]. Among these electrode materials, carbon materials, including activated carbons [7], carbon fibers [8], templated carbons [9], carbon aerogels [10], carbon nanotubes [11], and graphene [12], are most widely studied for its much better cycle performance, along with the large specific surface area, various pore structure, good electrochemical conductivity, and stability. Carbon materials derived from renewable biomass have drawn tremendous attention in recent years, such as cellulose, chitin, chitosan, and lignin, which have low cost, attractive structure, abundance, renewability, and environmentally friendliness compared to traditional carbon materials. Especially, many biomass resources are rich in heteroatoms such as O, N, and S to be converted into heteroatom self-doped carbon materials [13,14,15,16,17] with higher specific capacitance.

At the same time, new electrolytes with high conductivity and superior electrochemical stability have been studied to improve the electrochemical performance of supercapacitors [18]. The supercapacitors are widely assembled with liquid electrolytes, which are usually toxic and corrosive involving the risk of leakage. To reduce the risk of electrolyte leak, polymer electrolytes formed by placing liquid electrolytes into polymer matrix are developed as ionic conductors and separators between electrodes [19, 20], possessing a wide potential window, a high ionic conductivity, excellent stability, and mechanical strength. The formation of polymer electrolytes can cause huge resource consumption and environmental concerns. Thus, biomass-based electrolytes from cellulose, starch, chitosan, alginate, soybean protein, and so on have gained more and more attention recently for the advantages of renewability, low cost, environmentally friendliness, and superior mechanical properties.

In this review, we provide a summary of the recent development in research of carbon-based electrode and polymer electrolyte derived from biomass materials, such as cellulose, chitin, chitosan, lignin, alginate, starch, and gelatin, emphasizing the characteristics, synthetic strategies, improvement approach, and their relationship with electrochemical performance of biomass-derived electrodes and electrolytes in supercapacitors. Finally, the current challenges and future directions of biomass-derived carbon electrodes and electrolytes are briefly discussed.

Biomass-derived carbon materials in supercapacitor electrodes

Carbon materials possess various structures, low density, ideal stability, nontoxic, and high conductivity and are most widely used for supercapacitor electrodes, including activated carbons, template carbons, carbon nanotubes, graphene, and carbon aerogels. To reduce the energy shortages and environmental pressure, the carbon materials derived from biomass, such as cellulose, lignin, alginate, starch, chin, and chitosan, have been considered as significant candidates of electrode materials with the advantages of abundance, unique nature structure, low cost, and environmentally friendliness.

Cellulose-derived carbon

Cellulose is the most abundant natural polymer with low density, low cost [21], biocompatibility, and large amount of hydroxyl groups for chemical modification. Cellulose-derived carbon has been applied in sustainable energy storage such as supercapacitor electrodes. Chen et al. [22] prepared hierarchical porous carbon using straw cellulose by carbonization and activation, exhibiting excellent electrochemical performance with a specific capacitance of 358 F/g and outstanding cycling stability (capacitance retention of 95.6% over 10,000 cycles) in H2SO4 electrolyte. Lu et al. [23] produced porous carbon from microcrystalline cellulose with intrinsic defects and nitrogen, oxygen doping by carbonization and thermal treatment in a reducing environment as Fig. 1 showed, which was used in a supercapacitor electrode delivering a high specific capacitance of 426 F/g at 0.25 A/g in 1 M H2SO4 electrolyte and capacitance retention about 90% after 60,000 cycles at a current density of 5 A/g. Cui et al. [24] developed methylcellulose/NaHCO3 flake precursors and obtained wing-like porous carbon sheets after carbonization giving an obvious enhancement in potassium storage for their large surface area, open framework, and enlarged interlayer spacing. The assembled potassium-ion hybrid supercapacitor with porous carbon sheets as electrode materials showed an excellent energy density of 108 Wh/kg at a power density of 280 W/kg. Zhang et al. [25] assembled an all-nanofiber asymmetric supercapacitor using NiCo2O4 as cathode, a nanocellulose membrane as separator, and nanocellulose-derived porous carbon as anode with a three-dimensional hierarchical porous structure and an ultrahigh surface area of 2046 m2/g, demonstrating a good electrochemical performance with the capacitance of 64.83 F/g at 0.25 A/g. The rich O self-doping in cellulose-derived carbon offers excellent capacity for electrodes.

Schematic illustration of the preparation of microcrystalline cellulose-derived porous carbon with intrinsic defects and N, O doping. Republished with permission of Royal Society of Chemistry, from Microcrystalline cellulose-derived porous carbons with defective sites for electrochemical applications, Zhao, X. S.; Zhu, Zhonghua; Duignan, Timothy; Xiao, Changlong; Sun, Xiaoming; Gaddam, Rohit Ranganathan; Zhuang, Linzhou; Lu, Hao, 7, 39, 2019; permission conveyed through Copyright Clearance Center, Inc [23]

Carbon aerogels based on cellulose possess high porosity and interconnected 3D networks as electrode materials with good mechanical stability. Wan et al. [26] developed a highly conductive cellulose-derived carbon aerogel matrix with self-stacked multilayer FeOCl for an anode material, delivering an ultrahigh specific capacitance of 647 F/g at 2 mA/cm2 in 1 M Na2SO4 electrolyte and good cycle stability with capacitance loss less than 10% after 10,000 cycles, in which the carbon aerogel matrix significantly increased the mechanical stability and charge-storage kinetics. The nanofiber and nanoplate structures of carbon aerogels can be manipulated through the control of carbonization temperature. Zhang et al. [10] used wood cellulose to fabricate carbon aerogels by freeze-drying and high-temperature carbonization and revealed that the independent nanofibers structure and volume shrinkage increased with temperature while the nanoplate structure decreased. The carbon aerogels carbonized at 800 °C possessed the highest specific surface and total pore volume with a specific capacitance of 172.7 F/g and a specific capacitance of 89.43% after 5000 cycles. Yang et al. [27] firstly fabricated 3D hybrid aerogels from 2,2,6,6-tetramethylpiperidine-l-oxyl radical-oxidized cellulose nanofibril (TOCN)/GO aqueous solution by ion-exchange and freeze-drying and further obtained carbonized TOCN/RGO aerogels through carbonization at 1100 °C showing high specific capacitance of 394.5 F/g at 0.5 A/g and 99.77% capacitance retention after 10,000 cycles. The capacity and cycle stability of cellulose-derived activated carbons and carbon aerogels are shown in Table 1. Compared to activated carbons, carbon aerogels based on cellulose have more developed pore structure and 3D networks providing rapid ion transport channels and thus carbon aerogels tend to show more outstanding electronic conductivity and cycle stability.

Among various cellulose and its derivatives, bacterial cellulose and carboxymethyl cellulose-derived carbon exhibit relatively excellent electrochemical performance and get more extensive attention. Bacterial cellulose (BC) consists of pure cellulose produced by microorganism fermentation of Gluconacetobacter xylinus without hemicellulose and lignin. Besides the advantages of lightweight, nontoxicity, high flexibility, industrial-scale production, and excellent biodegradability, BC has an ultrahigh water holding capacity to hold dopants because of the hydrophilic nature, and an ultrafine three-dimensional (3D) network structure composed of nanofibers as a desired precursor to produce porous carbons. Lei et al. [30] prepared a highly N/S dual-doped carbon derived from BC with 3D structure by absorption swelling, possessing excellent wettability, fast ion-transportation, and a high specific capacitance of 202 F/g at a current density of 1.0 A/g. Chen et al. [29] prepared N-self-doped carbon nanofiber aerogels via in situ growth of zeolitic imidazolate frameworks (ZIF8) nanocrystals on the surface of BC gel due to electrostatic interaction followed by dry-freezing and carbonization at 90 °C, exhibiting specific capacitance about 224 F/g at 0.5 A/g, high energy density of 31.04 Wh/kg at a power density of 250 W/kg, and good capacity retention about 97% at 5 A/g after 10,000 cycles.

Carboxymethyl cellulose (CMC), one of the cellulose derivatives, has water solubility and sustainability and is rich in carboxyl and hydroxyl groups with a high content of oxygen, based on which CMC has been considered as a promising candidate for the creation of O-self-doping carbon electrodes. Lee et al. [31] prepared porous carbon turbostratic structures from an aqueous CMC solution by ice-templating and carbonization, possessing a high specific area of 724.35 m2/g and well-developed pore structures without activation, as well as excellent specific capacitance about 210 F/g at 1A/g and an outstanding capacitance retention about 100% after 10,000 cycles at 10 A/g in a 6.0 M KOH electrolyte. Shu et al. [28] fabricated hierarchical porous carbon materials from carboxymethyl cellulose, bacterial cellulose, and citric acid through a one-step carbonization/activation process, exhibiting a high specific capacitance of 350 F/g at 0.5 A/g, good capacitance retention of 96% after 10,000 cycles, and excellent rate capability of 254 F/g at 15 A/g.

The porous carbon derived from biowaste rich in cellulose is considered as a prospective electrode material due to low cost and sustainable characteristics. The specific surface area of them is limited to hundreds of square meters per gram, calling for templates or activation with the activation reagent such as KOH and K2CO3 to enhance the porous structure. Cigarette butts containing lots of cellulose acetate have been used to prepared nitrogen-doped carbon with urea as the nitrogen source via carbonization, activation, and hydrothermal method, and the obtained hierarchical porous carbon had a high specific surface area of 1633.37 m2/g, advantageous specific capacitance of 330.1 F/g at 0.5 A/g, and high cycling stability of 93.48% after 10,000 cycles [32]. Chestnut shell-derived hierarchical porous carbon was prepared through the activation with KHCO3, possessing a BET surface area of 2298 m2/g, a good specific capacity of 387 F/g at 2 A/g, an excellent rate capability of 303 F/g maintained at 50A/g, and high capacity preservation of 98.68% after 10,000 cycles at 30 A/g [33]. Chaturvedi et al. [34] prepared porous carbon for supercapacitor electrode materials using anaerobically treated fruit and vegetable waste as a source containing calcium and silicon-based inorganic impurities as hard templates to create hierarchical pores during carbonization, and the porous carbon had a specific surface area of 2502 m2/g and a capacitance of 235 F/g at 1 A/g in acidic aqueous.

In terms of performance improvement, heteroatoms doping of cellulose-derived carbon can provide extra pseudocapacitances and increase the surface wettability. It is a facile and low-cost approach to enhance the electrochemical performance of carbon-based electrodes. Urea and melamine are widely used as the main nitrogen source to prepared N-doped carbon [16, 35]. Kim et al. [36] prepared N-doped porous carbon using Mg/K/Mg center dot K-nitrate-urea-cellulose mixture by the efficient and exothermic pyrolysis, high-temperature carbonization, and subsequent washing treatment, showing a specific capacitance of 279 F/g at 1 A/g and a good rate capability of 235 F/g at 30 A/g in the two-electrode system. Chen et al. [12] fabricated graphene@mesoporous nitrogen-doped carbon nanosheets with the sandwich-like structure using cellulose as precursor and melamine as the nitrogen source, which exhibited good specific capacitance of 264 F/g at 1 A/g, and outstanding cyclic stability with 99.9% retention after 2500 cycles. Thiourea is another additive to achieve N, S co-doping of the cellulose-derived electrode material. Ding et al. [37] prepared an ultralight and superelastic hard carbon aerogel by carbonizing self-assembling BC/thiourea aerogel as shown in Fig. 2, and further fabricated the supercapacitor presenting areal capacitance of 0.97 F/cm2 and capacitance retention of 86% at 20 A/g. Song et al. [38] produced N and S co-doped porous carbon utilizing cellulose as precursors, a 9.5% NaOH and 4.5% thiourea aqueous as doping reagent and solvent by an all-in-one pyrolysis strategy, and the porous carbon showed appropriate heteroatom functionalities with 3.82% N and 1.94% S, and a high specific capacitance of 288 F/g at 0.5 A/g in KOH electrolyte for the three-electrode system. The comparison of cellulose-derived carbon and heteroatom-doped carbon materials is shown in Table 2. The redox reaction of heteroatoms offers extra pseudocapacitances to improve the capacity of carbon materials, and the increased surface wettability can accelerate the electron transport rate of electrode materials.

Schematic illustration of the preparation process of BC/thiourea carbon aerogel. Reproduced from Robust, Superelastic Hard Carbon with In Situ Ultrafine Crystals, Xiaoping Yang, Wei-Hong Zhong, Yunhua Yu, et al., 30, 3, 2019 with permission from John Wiley and Sons [37]

Besides, the electrochemical properties of cellulose-derived carbon electrode can also be improved by the incorporation of nanostructured pseudocapacitive materials with redox kinetics. The hybridization of metal oxides, such as NiMoO4 and Co3O4 with carbonaceous species, has been widely applied. Wang et al. [39] developed a hierarchical porous material by loading Co3O4 nanoparticles and NiMoO4 nanorods on cellulose-based carbon aerogel frameworks, delivering an improved specific capacitance of 436.9 C/g at 0.5 A/g and capacitance retention of 70.7% at 5.0 A/g. Zhao et al. [40] used BC adsorbing organophosphorus pesticides as a carbon precursor to fabricated a loose 3D carbon skeleton, which then absorbed cobalt salt further transformed into Co3O4 nanoparticles anchored on the carbon skeleton for electrode material. The electrode showed an ultrahigh specific capacitance of 785 F/g at 0.5 A/g and excellent cycling stability with capacity retention over 93.0% after 5000 cycles. Compared with metal oxides, conducting polymers feature lightweight, low cost, and simple preparation process for composite electrodes. Zhuo et al. [41] prepared a hierarchical porous carbon aerogel from cellulose loading conductive polymer polypyrrole (PPy), and the obtained hybrid exhibited a good specific capacitance of 387.6 F/g at 0.5 A/g and high cycling stability with a capacitance retention of 92.6% after 10,000 cycles in 1.0 M H2SO4 electrolyte. Zhang et al. [42] fabricated compressible carbon and mechanically robust aerogels using bamboo cellulose nanofibers as precursor via low-temperature lyophilization and high-temperature pyrolysis, and further coated carbon aerogels with polypyrrole by in situ oxidative polymerization. The prepared core-sheath composites were applied in a symmetrical supercapacitor delivering a good specific capacitance of 268.5 F/g at a current density of 0.5 A/g, and an energy density of 23.8 Wh/kg at a power density of 450.4 W/kg. As shown in Table 2, the capacity of the compound of carbon and pseudocapacitive materials is much higher than carbon materials thanks to the redox kinetics of metal oxides or conducting polymers. However, the cycle stability is not satisfactory because of the restricted solid attachment between two species and the agglomeration of iron oxide nanoparticles during the charging-discharging processes, which need further optimization.

Chitin/chitosan-derived carbon

Chitin, a polysaccharide mainly found in zygomycetes fungi, crustaceans (such as the shell of shrimp and crab), insects, and other arthropods, received extensive attention as a carbon precursor due to its high carbon content, abundant resource, low cost, nontoxicity, renewability, and biodegradability. It is composed of β-(1,4)-linked-2-acetamido-2-deoxy-d-glucopyranose units, possessing numbers of amidogen and hydroxyl groups and a considerable amount of nitrogen (~ 6.9 wt%) to be a promising precursor of N-enriched porous carbon. The nitrogen-containing carbon materials derived from chitin have been successfully synthesized and employed as electrode materials for supercapacitors. Wang et al. [9] synthesized a hierarchical porous carbon from chitin with KMnO4 as template precursor and activating agent, and it had a huge specific surface area and substantial nitrogen and oxygen functional groups as well as an outstanding specific capacitance of 412.5 F/g at 0.5 A/g, and excellent electrochemical stability with only 0.4% capacitance loss after 10,000 cycles. Recently, chitin nanofibers have attracted much attention for fabricating nanogels and areogels as precursors for N-doped carbon with hierarchical porosity, large surface area, and good electrochemical performance. Chitin-derived carbon tends to keep excellent morphology after pyrolyzation thanks to the stiffness of chitin chains providing great opportunities for well-done nanostructure. Zheng et al. [43] prepared chitin nanogels by sol–gel transition of chitin in NaOH/urea solvent and pyrolyzed them at 800 °C obtaining N-doped porous carbon nanospheres having ordered micropores centered at about 0.6 nm, high surface area of 1363 m2/g, specific capacitance of 192 F/g at 0.5 A/g, and capacitance retention of 81% at 10 A/g. Ding et al. [44] fabricated nanofibers aerogel from chitin isolated from marine biomass by hydrogen bond crosslinking as the precursor of N-enriched carbon nanofiber aerogel with a high specific surface area up to 1597 m2/g, high nitrogen content up to 7.65%, the largest electrochemical capacitance of 221.0 F/g at 1.0 A/g, and good retention capability of 92% over 8000 cycles at 5.0 A/g in a 6.0 mol/L KOH electrolyte.

Direct pyrolysis of heteroatom-rich biomass is an alternative method for heteroatom-containing carbon electrode materials. Chitin-based heteroatom-doped carbons derived from shells of crab and shrimps, cicada slough, squid gladius, and so on are utilized as electrode materials for supercapacitors. Cicada slough contains plentiful chitin along with proteins, amino acids considered as nitrogen sources, sulfur, and phosphorous. Jia et al. [45] used it to prepare porous carbon with high heteroatom functionalities at about 12.06% atomic ratio of N, O, S, P, and high specific surface area of 1676 m2/g, showing a high specific capacitance of 355 F/g at 1 A/g and an excellent rate capability of 284 F/g at 30 A/g. Zhou et al. [46] prepared cicada slough-derived carbon by pre-carbonization in air and KOH activation and the as-prepared porous carbon with KOH/char weight ratio of 2/1 showed greatest electrochemical performance with a specific capacitance of 266.5 F/g at 0.5 A/g and a good rate capability of 196.2 F/g at 20 A/g. The squid gladius has considerable amount of chitin and less impurities requiring short process to be converted into chitin compared with shells of crab and shrimps. It was carbonized into O, N-doping activated carbon via KOH activation with a nitrogen content of 4.04 wt% and large surface area of 1129 m2/g for supercapacitor electrodes delivering maximum specific capacitance of 204 F/g and 100% capacitance retention after 25,000 cycles in 1 mol/L H2SO4 electrolyte [7].

Chitin is insoluble in common solvents such as dilute acid, and it requires special solution systems to dissolved chitin at low temperature including LiOH/KOH/urea aqueous solution and NaOH/urea aqueous system. Compared to chitin, chitosan, a partially deacetylated derivative of chitin possesses better solubility with substantial amino group (-NH2), and the chitosan with low molecular weight or high degree of deacetylation (not less than 55%) is soluble in kinds of dilute acid. Taking this into account, Gao et al. [47] prepared carbon microspheres by pyrolyzing the chitin microspheres from a chitin/chitosan blend solution, and the improved nanopores/nanochannels of microspheres were generated via dissolution and removing chitosan with acetic acid. The as-prepared carbon microspheres had improved specific surface area of 1450 m2/g as a substrate of polyaniline nanoclusters for symmetric supercapacitor exhibiting excellent cycling stability of 90.6% capacitance retention after 10,000 cycles. The solubility of chitosan also makes it easy to prepare uniform blends with other soluble raw materials. Yuan et al. [48] synthesized the hybrid porous carbon via activating the mixture of chitosan and gelatin prepared through simple solution blending and freeze-drying. Gelatin can not only bring heteroatoms into the carbon skeleton for kinds of functional groups (–OH, –NH2, –COOH) on its main chain, but also change the microstructure and increase the porosity of chitosan-based carbon. The obtained carbon material exhibited an ultrahigh specific capacitance of 331 F/g at 1 A/g and well-done cycle stability with 90% capacitance retention after 10,000 cycles at 10 A/g. Up till now, the carbonization of chitosan into carbon electrode materials has attracted great attention for the high N content of chitosan to introduce N into the carbon framework. Genovese et al. [49] studied chitosan-derived activated carbon electrode material in various aqueous liquid and solid polymer electrolytes, proving that chitosan-activated carbon is compatible with neutral, acidic, and alkaline liquid electrolytes and advanced solid polymer electrolytes such as Li2SO4-polyacrylamide solid electrolyte.

Chitosan has massive amino groups (–NH2) and hydroxyl groups (–OH) on its chain which give it a strong affinity for transition-metal ions. The composites of chitosan and mental have been studied as precursors for stable carbon electrode materials. Zhang et al. [50] fabricated graphene-like carbon nanosheets through simple one-step carbonization of chitosan-containing textile sludges, obtained by using chitosan derivative to remove reactive dye from aqueous solution, with Fe2(SO4)3 as graphitization catalyst. The as-prepared graphene-like carbon nanosheets showed a good capacitance of 195 F/g at 1 A/g and outstanding cycling stability with 3.4% capacitance loss after 2500 cycles as electrode materials for supercapacitors, attributed to the ultrathin (near 3.2 nm thickness) graphene-like nanosheets structure and co-doping of Fe and N. Hao et al. [11] used chitosan-coated oxygen-containing carbon nanotubes to remove toxic metal ions of Cu(II) and Cr(VI) and further carbonized the metal ions-adsorbed adsorbents producing Cu- and CrN-loaded carbon composites with a specific capacitance of 114.9 F/g at 2 mV/s, respectively, superior to pure chitosan-coated carbon nanotubes.

Pyrolysis of chitosan or chitin through several conventional methods, such as direct activation and two steps carbonization followed by activation has been widely applied in producing N-doped porous carbons for supercapacitor. Cheng et al. [51] prepared N-doped hierarchically porous carbon by carbonization and activation of chitosan and betaine hydrochloride polyelectrolyte formed via reaction between amino groups in chitosan and carboxylic acid group in betaine hydrochloride (Fig. 3). The obtained N-doped porous carbon displayed a pore volume of 2.24 cm3/g, an ultrahigh specific area of 3300 m2/g, large amount of O (17.16 at.%) and N (2.23 at.%), and excellent electrochemical performance with high capacitance of 367 F/g at 0.1 A/g, and superior retention capability of 94% after 20,000 cycles at 4 A/g. In addition, hydrothermal carbonization (HC) is another traditional method to fabricate N-doped porous carbon from chitosan or chitin for supercapacitor using water as the carbonization medium at mild processing temperature, and the control of HC time can increase doped N content, active N species, turbostratic structure, mesoporosity, and specific surface area resulting in significant effect on the supercapacitance performances. Tong et al. [52] prepared an N-doped porous carbon for supercapacitor from chitosan by controlling HC with highly time-dependent physicochemical and electrochemical properties, exhibiting outstanding specific capacitance around 406 F/g in a three-electrode system and 274 F/g in a two-electrode system. Wu et al. [53] fabricated oxygen- and nitrogen-containing carbon via one-pot ionic liquid-assisted HC carbonization of chitosan, during which ionic liquids played as nitrogen sources, structure-directing agent, and dispersant. The ordered lattice of graphite-like structures with carbon quantum dots on the surface provided supercapacitor performance with a specific capacitance of 355 F/g at 0.2 A/g in 1 M H2SO4 in a three-electrode system. Zhou et al. [54] prepared supramolecular hydrogels by mixing chitosan and zinc chloride (as a chemical activation agent) solution and then made nitrogen-rich hierarchically porous carbon via HC having a high specific surface area of 1067 m2/g and nitrogen content of 6.36 at% as well as delivering a good specific capacitance of 228.7 F/g at 1 A/g, superior rate capability of 84.9% retention at 10 A/g and long-term electrochemical stability with 1.7% capacity loss after 5000 cycles.

The synthesis of chitosan and betain hydrochloride-based polyelectrolyte precursor. Republished with permission of Royal Society of Chemistry, from ultrahigh-surface-area nitrogen-doped hierarchically porous carbon materials derived from chitosan and betaine hydrochloride sustainable precursors for high-performance supercapacitors, Jian Cheng, Qinqin Xu, Xia Wang, Zaiquan Li, Fuzhong Wu, Jiaojing Shaoa and Haibo Xie, 3, 5, 2019; permission conveyed through Copyright Clearance Center, Inc [51]

Microwave heating is an excellent carbonization method with high heating efficiency and rate [55, 56] and has been used in the rapid pyrolysis of chitin and chitosan. For the poor microwave-absorbing ability of biomass to be transformed into porous carbon in this way, ZnCl2 is widely introduced as microwave absorber and porogen for its good microwave-absorbing ability. However, the pore-creating ability of ZnCl2 is limited due to its nonetching activation mechanism. Thus, various alternative methods have been reported to obtain chitin or chitosan-derived porous carbon with the absence of ZnCl2 via microwave heating. Chen et al. [57] used wheat-straw-derived char as a microwave absorber and KOH as an activation agent to prepare porous carbons via microwave heating, and post-oxidation reactions between oxygen in the air and active sites in the carbons resulted in the doping of oxygen (contents up to 21.6–28.2%). The as-prepared carbon materials had a high specific surface area of 1905 m2/g, a proper hierarchically pore distribution with mesopore ratios of 45.6–59.0%, good capacitive performances with a high specific capacitance of 325 F/g at 0.5 A/g, and a superior capacitance retention of 81.0% at 10 A/g. Chen et al. [58] used chitin as carbon precursor and chloride dihydrate (CuCl2·2H2O) as microwave absorber and porogen to directly synthesize nitrogen-rich porous carbon by only microwave heating process within 10 min (Fig. 4). The obtained porous carbon gained nitrogen retention up to 5.2%, a superior specific capacitance of 227 F/g at 0.5 A/g, a capacitance retention of 84.8% at 10 A/g and 67.7% at 50 A/g in 6 mol/L KOH electrolyte. Chen et al. [59] converted chitosan hydrogel beads into porous carbons with KOH as a chemical porogen and water wrapped in hydrogel beads as a physical porogen transformed into steam to create mesopores, and the porous carbons material possessed N content of 3.4% and high O content of 17.5% introduced into carbons by the post-oxidation in air atmosphere, as well as high capacitance retention of 87.5% from 0.5 to 10 A/g.

The scheme of the rapid microwave-assisted synthesis of chitin-based porous carbon. Reproduced from Rapid synthesis of chitin-based porous carbons with high yield, high nitrogen retention, and low cost for high rate supercapacitors, Weimin Chen, Min Luo, Xin Wang, et al., 44, 2, 2019 with permission from International Journal of Energy Research [58]

As mentioned above, the incorporation of heteroatoms is a promising approach to enhance the electrochemical performance of biomass-derived carbon. Furthermore, multiple heteroatoms doping, such as nitrogen/sulfur co-doping and nitrogen/boron co-doping, is proved to have a synergistic effect. Huo et al. [60] fabricated N/S co-doped hierarchical porous carbons from freeze-dried mixture containing chitosan as carbon precursor, CaCl2 as activator, urea as foaming agent, and methanesulfonic acid as sulfur source by one-step carbonization and activation, in which methanesulfonic acid reacted with chitosan molecules forming hydrogen bonds to dope controllable sulfur and to construct a uniform planar network, further giving porous carbons good electrochemical performance such as a specific capacitance of 272 F/g at 1.0 A/g and an excellent rate capability of 172 F/g at 100 A/g in 6.0 M KOH electrolyte. Lin et al. [61] prepared N/B co-doped porous carbon by one-step carbonization and activation of the chitosan/KOH mixture at high temperature, followed by hydrothermal reaction with boric acid to dope boron atoms. The electrochemical double-layer supercapacitor with N/B co-doped porous carbon as electrode material delivered a high specific capacitance of 316 F/g at 0.2 A/g and an excellent capacitance retention of 94.08% after 10,000 cycles at 10 A/g in the 6 M KOH electrolyte. More heteroatoms co-doped chitosan-derived carbon materials and its electrochemical properties are listed in Table 3.

Transition-metal oxides are considered as excellent pseudocapacitive materials to be integrated with chitosan-derived carbon for effectively facilitating the surface wettability, the pore structure, and electrochemical performance of carbon materials in supercapacitor field. Ken et al. [62] used N-doped chitosan nanofibers and nickel nitrate as precursors and KNO3 as a pore-forming agent to form N/NiOx co-doped hierarchical porous carbons nanosheets through freeze-drying and carbonization, which exhibited a higher specific capacitance of 614.6 F/g at 1 A/g than that of carbon nanosheets undoped Ni, and the assembled supercapacitor achieved a high energy density of 20.3 Wh/kg at a power density of 240.9 W/kg and retained 85.61% of the initial capacitance after 10,000 cycles. Liu et al. [63] used graphene-dispersed chitosan hydrogel as precursor to prepare the B, N-doped porous carbon and further anchored Co and Ni oxide nanoparticles on it via chemical reduction and calcining at high temperature. The Co and Ni species significantly improved the graphitic degree and the composite exhibited extremely high capacitance of 1266.7 F/g at 1 A/g and good stability. Lin et al. [64] prepared chitosan-derived porous carbon through directly carbonized with KOH as the activator and grow MnO2 on the surface of it through the redox reaction between KMnO4 and it to form MnO2-doped holey carbon showing an outstanding capacitance of 460 F/g at 0.2 A/g and an excellent capacitance retention of 91.67% over 10,000 cycles at 10 A/g in 6.0 M KOH electrolyte in a three-electrode system. Wang et al. [66] fabricated Co/N-doped porous carbon material using chitosan, urea, and cobalt acetate as the precursor of carbon, nitrogen, and cobalt, respectively, with F127 as dispersant for Co/CoOx particles at high pyrolysis temperature. It delivered an overpotential of 259 mV, small Tafel slope of 99 mV/dec, and a high stability of 83% current density retention after 6 h electrochemical test as electrode in hydrogen evolution reaction in 1 M potassium hydroxide electrolyte. Al-Farraj et al. [65] embedded NiFe2O4 nanoparticles into nitrogen-doped carbon matrix derived from chitosan, and the obtained nanocomposite exhibited good specific capacitance of 958.33 F/g at 5 mV/s, excellent cyclic stability of 91.25% after 6000 cycles, and energy density of 43.75 Wh/kg at a power density of 516.25 W/kg. The electrochemical performance of transition-metal-doped chitosan-derived carbon materials is generalized in Table 3. Compared to heteroatom co-doped carbon materials, the transition-metal oxides/heteroatom co-doped carbons tend to exhibit much higher capacitance indicating that the transition-metal oxides doping has higher efficiency to provide pseudocapacity, but the cycle stability are inferior for the restricted solid attachment between two species and the agglomeration of iron oxides nanoparticles.

The porous carbons from chitosan probably lack 3D interconnected porous framework. To improve the structure stability in the preparation of chitosan-derived carbon materials is a challenging task for extensive applications as electrode materials. Tan et al. [67] fabricated N-doped carbon using nanocomposites of chitosan and graphene quantum dots (GQDs) as the precursor, preserving the 3D interconnected frameworks due to GQDs, a zero-dimensional carbon with extraordinary chemical stability and mechanical flexibility and delivering an ultrahigh specific capacitance of 545 F/g at 1 A/g and superior cyclic stability of 88.9% capacitance retention after 5000 cycles at 10 A/g as the electrode materials for supercapacitors. MOFs, a framework bridging metal ions/clusters with organic ligands, have been employed as self-sacrificial templates to prepare chitosan-derived nanoporous carbon with a desirable structure. Zhong et al. [68] prepared hierarchically porous carbon by pyrolysis of MOF-5/chitosan composites followed by a wash using acid, and it exhibited a high ratio of meso-/macropore volume to micropore of 1.47 and an outstanding specific surface area of 2375 m2/g, as well as a good specific capacitance of 199.9 F/g. Liu et al. [69] synthesized carbon nanosphere@vanadium nitride derived from MOF of chitosan as carbons source, NH4VO3 and F127, and the prepared nanohybrid material delivered a high specific capacitance of 300.4 F/g. The hard template strategy is an important way to enhance the structure stability during the pyrolysis of chitosan precursor utilizing silica, metal oxide, and advanced zeolite imidazole frameworks (ZIF). Liu et al. [70] prepared honeycomb-like hierarchically porous carbon derived from chitosan with nanosized SiO2 particles as hard template for mesopores by a one-pot template removal utilizing polytetrafluoroethylene binder and carbonization process. The as-prepared porous carbon had superior specific surface areas of 1011 m2/g and a high specific capacitance of 250.5 F/g at 0.5 A/g in 6 mol/L KOH electrolyte in a three-electrode system, and the assembled supercapacitor exhibited outstanding cycling stability with capacity enhanced to 107% after 5000 cycles at 10 A/g. Li et al. [71] used chitosan cryogel as basic material added ZIF-7 and carbonized it at 950 °C obtaining coral structural ZIF-7-coated chitosan fibers with an internal resistance lower than 2 Ω and a high specific capacitance of 173.1 F/g.

In recent years, flexible electrode materials attracted more and more attention for flexible supercapacitors with excellent electrochemical performance when repeatedly folded. Chitin/chitosan-derived carbon materials have been explored for flexible electrode. Yue et al. [72] developed a carbon fibrous film through direct carbonization of chitin fiber cloth, possessing polyhedron carbon-scale stacking microstructure and mechanically foldable flexibility as well as specific capacitance of 114.9 F/g at 1 A/g and outstanding cycling stability with capacitance retention about 94.0% after 5000 cycles at 1 A/g. Liu et al. [73] fabricated a foldable composite electrode containing N-self-doped carbon sheet derived from chitosan, microfibrillated cellulose fiber framework, and in situ PANI, which could perform well when folded with a high specific capacitance of 1688.8 mF/cm2 (139.6 F/g), long-term cycling stability more than 84% capacitance retention after 5000 cycles, and an energy density of 11.75 mW·h·cm−3 at the power density of 25 mW·cm−3.

Lignin-derived carbon for supercapacitor electrode

Lignin is the second most abundant biomass on earth after cellulose as a main constituent (15%-30% by weight) of plant skeleton and byproduct of the pulp and papermaking process, with advantages of low cost, ready availability, and renewability. Unlike cellulose and hemicelluloses, it possesses three-dimensional structures consisting of methoxylated phenylpropane composed of sinapyl, coniferyl, and p-coumaryl alcohols, leading to its very stable molecular structure that is hard to break down into available carbon precursors for electrodes. Much progress has been made to prepare lignin-derived carbon as supercapacitor electrode materials, such as activated carbon and porous carbon-based materials, commonly using a two-step approach (carbonization and activation). Zeng et al. [74] prepared porous activated carbon from lignin and carbonaceous mudstone mixture by activation treatment with HNO3, exhibiting a high specific capacitance of 110.1 F/g at 1 A/g which is three times of the untreated carbon electrode. Zhang et al. [75] proposed a novel bacterial activation method to depolymerize the macromolecular lignin through removing numbers of thermally stable G units and side chain structures, resulting in more developed pore structures and graphitization during the carbonization, and thus the obtained porous carbon exhibited an excellent specific capacitance of 428 F/g at 1 A/g and good cycling stability with a capacitance retention of 96.7% at 5 A/g after 10,000 cycles.

The biomass containing a large amount of lignin is widely used as a raw material of porous carbons for electrodes without extraction process. Tea waste has high content (70–80%) of lignin, cellulose, hemicelluloses, and polyphenol, with rich protein as nitrogen-containing compounds. It has been used to fabricate activated carbon with high graphitization degree via carbonization and activation with KOH, showing excellent cycle stability with capacitance retention 96.66% after 16,000 cycles at 4 A/g and ultrahigh power density of 33,494.70 W/kg at an energy density of 19.45 Wh/kg [76]. Tisawat et al. [77] prepared activated carbon from coconut shell functioned with quinone derivatives to provide pseudocapacitance behavior via solvent-free method, exhibiting an outstanding specific capacitance of about 485 F/g at 1.0 A/g, low resistance of 2.25 Ω and excellent cycling performance with a capacitance loss of 1.2% after 1000 cycles. Wang et al. [78] obtained ultrathin graphene-like porous carbon nanosheets from sustainable pine bark precursors with potassium formate as nontoxic activation agent, which possessed very small thickness of about 3.8 nm, high mesopore proportion and a huge specific surface area of 1816.4 m2/g, as well as good capacitive performance in supercapacitor with a specific capacitance of 128.1 F/g at 1 A/g, excellent rate capability of 76.3% at 40 A/g, and outstanding cycling stability with only 6.1% capacitance loss over 10,000 cycles in TEABF4/AN electrolyte. Zou et al. [79] produced nitrogen-doped hierarchical porous carbon from biomass bamboo fungus by two-step pyrolysis processes, which was performed in a large specific surface area of 1708 m2/g and high mesopore percentage about 25.5% along with a high specific capacitance of 228 F/g.

The traditional two-step approach tends to require a long production duration up to 16 h and produce microporous carbons with undeveloped mesopore/macropore structure. More effective one-step approaches have been developed to produce lignin-derived carbon electrode materials. Sun et al. [80] made lignin self-assemble onto the pore internal surface of the wood as well as the surface of Ni2+ catalyst and activator crystals, and completed catalytic graphitization, Na2CO3 activation, and Ni-doping synchronously. The obtained electrode materials had a specific capacitance of 163.7 F/g. Microwave heating combined with humidified nitrogen is proposed as a one-pot method to prepare lignin-derived porous carbons with oxygen-enriched hierarchical structures. Wang et al. [81] synthesized high-performance porous carbon from enzymatic hydrolysis lignin directly via only of microwave heating in 8 min with solid KOH to make sufficient micropores and to reduce the time-consuming drying process (Fig. 5). The fabricated carbon electrode showed a high specific capacitance (338 F/g at 1 A/g) and capacitance retention of 86% at 10 A/g, and the assembled supercapacitor delivered an energy density of 17.1 Wh/kg in Na2SO4 electrolyte. Chen et al. [82] converted lignin into hierarchical porous carbon via microwave heating in humidified N2, using KOH as the chemical activating agent. The obtained porous carbon had hierarchical pore distribution with a mesopore ratio of 65.8% and a surface oxygen content of 16.5%. They also combined microwave heating in humidified N2 with water vapor plasma modification to prepare lignin-derived hierarchical porous carbon exhibiting a high specific capacitance (254.6 F/g at 0.5 A/g) and an excellent rate capability (retention rate of 75.6% at 10 A/g), in which water vapor plasma modification led to further development of the porosity, 11.6% increase in specific surface area, and 33.43% oxygen-doping [83].

Schematic illustration of synthesis of enzymatic hydrolysis lignin-derived porous carbon [81]. Reproduced from Direct Microwave Conversion from Lignin to Micro/Meso/Macroporous Carbon for High-Performance Symmetric Supercapacitors, Xiaoyan Zhou, Weimin Chen, Pei Yang, et al., 6, 18, 2019 with permission from ChemElectroChem [58]

There are several reports on carbon aerogels (CA) derived from lignin with well-developed porous structures and excellent conductivity. Cai et al. [84] prepared 3D structural CA via dissolving lignin and cellulose in BMIMCL, regenerating in deionized water, freeze-drying, and carbonization, showing a specific capacitance of 166 F/g at 0.1A/g and outstanding capacitance retention of 98.6% after 1000 cycles. Zhang et al. [85] produced lignin-derived carbon aerogels by ultrafast freezing of lignin/KOH solutions, freeze-drying, and in situ activation (Fig. 6), possessing abundant mesopores, macropores, and oxygenated groups, a high specific surface area (1681.6 m2), and a good specific capacitance (189 F/g at 1 A/g), a high energy density (26.25 Wh/kg at 1000 W/kg), and excellent capacitance retention (97.4% after 10,000 cycles). Nevertheless, there are a small number of reports on the composite membrane from lignin used as electrodes. Wang et al. [86] transformed lignin into porous conductive carbon structures by femtosecond laser direct writing and prepared a composite membrane by mixing MoS2 into the lignin/PAN composite for supercapacitors exhibiting a high specific capacitance of 16 mF/cm2 at 10 mV/s. Cui et al. [87] synthesized MnO2 nanoparticles on a RGO/lignin-based porous carbon composite membrane by electrodeposition for supercapacitor electrode, showing a mass specific capacitance of 135 F/g and an area specific capacitance of 1136 mF/cm2 at 1 mA/cm2 attributed to the conductive pathway of the porous carbon framework and the large surface area of the MnO2 nanoparticles. These reports show the potential of a composite membrane containing lignin-derived carbon for supercapacitor electrodes.

Schematic illustration of the preparation of lignin-derived carbon-sheet aerogel (CSA) and carbon-fiber aerogel (CFA). Adapted with permission from Ultrafast-Freezing-Assisted Mild Preparation of Biomass-Derived, Hierarchically Porous, Activated Carbon Aerogels for High-Performance Supercapacitors, Youfang Zhang, Chenyang Zhao, Wee Kit Ong, et al., 7, 1. Copyright (2019) American Chemical Society [85]

Carbon nanofibers (CNFs) have an ultra large accessible surface area, structural stability, and excellent ion conductivity to be applied for supercapacitor electrodes. Recently, the electrospinning method is proposed for preparing carbon nanofibers. It has the advantages of low cost, convenient operation, simple equipment, and continuous production compared with traditional preparation methods such as self-assembly, hydrothermal synthesis, and chemical vapor deposition. However, lignin is poorly soluble and refractory with low plasticity limiting its application in electrospinning and calling for liquefaction technology to convert it into electrospinning precursor liquid. Jiang et al. [88] converted lignin to liquefied carbon by mixing it with phenol and liquefied at 160 °C, and then doped it into polyacrylonitrile as an electrospinning precursor to prepare activated carbon nanofibers by electrospinning and high-temperature activation, exhibiting a good specific capacitance of 273 F/g at 0.5 A/g and a capacitance retention of 210 F/g under 10 A/g. Polyacrylonitrile (PAN) is commonly selected to blend with lignin as electrospinning precursor for its high char yield, easy spinnability, high mechanical strength, and good flexibility. Jayawickramage et al. [89] prepared carbon nanofibers for electrodes from electrospun blends of PAN with lignin through thermal stabilization, carbonization, and activation by CO2, and the assembled supercapacitor exhibits a specific capacitance of 128 F/g and an energy density of 59 Wh/kg at a power density of 15 kW/kg in an ionic liquid electrolyte. Dai et al. [90] prepared N, S co-doped graphene-modified lignin/PAN-based CNFs by electrospinning, carbonization, and activation, during which graphene could capture NH3, SO2, and HCN released from lignin and PAN to increase the heteroatoms content. The lignin/PAN CNFs-based supercapacitor exhibited a high specific capacitance of 267.32 F/g and an excellent cycling stability with a capacitance retention of 96.7% after 5000 cycles in KOH electrolyte. Yun et al. [91] fabricated ZnO doping CNFs from lignin, pitch, PAN, and zinc acetate by one-step electrospinning and heat treatment without any activation, in which pitch increased the carbon yield and conductivity and reduced the cost. Nevertheless, PAN is expensive and nonrenewable, restricting its further application of green and bio-renewable CNFs. Thus, developing alternative bio-renewable materials for CNFs, such as cellulose, is worth studied to produce CNFs by electrospinning technology. Cao et al. [92] used phosphoric acid to improve the flexibility and spinnability of lignin through the esterification reducing hydrogen bond interaction between lignin molecules, and further prepared CNFs from modified lignin and cellulose-acetate with high flexibility, possessing high surface areas, good flexibility, and high specific capacitance of 346.6 F/g, which is a bio-renewable CNF for electrodes. The lignin-derived carbon materials mentioned above are listed in Table 4, including normal activated carbon, CA, and CNFs. As shown in Table 4, the CNFs prepared by electrospinning methods deliver superior specific capacitance along with excellent rate capability, which benefits from larger accessible surface area of nanofibers and stable porous structure brought by electrospinning.

Kraft lignin differs from native lignin in chemical structure and its complexity is preserved and even enhanced in the extraction process. During the Kraft process, cellulose and hemicellulose are separated from lignin in a digester with a strong base and sodium sulfite under high temperatures and pressures. Carbon electrode materials from kraft lignin gain increasing attention for its plentiful heteroatoms. Liu et al. [93] prepared the O, N, and S co-doped hierarchical porous carbons via direct self-activated pyrolysis of kraft lignin, possessing 3D highly interconnected structure with high specific surface areas (1307 m2/g), plentiful oxygen, nitrogen, and sulfur co-doping (9.84–19.91 wt%), and the assembled symmetric supercapacitor showed a high specific capacitance (244.5 F/g at 0.2 A/g), good rate capability (initial capacitance retention of 81.8% at 40.0 A/g), and excellent cycling stability (retention of 91.6% over 10,000 cycles). Schlee et al. [8] developed purely Kraft lignin-derived carbon fiber mats by electrospinning, stabilization in air, subsequently carbonization in N2, and an activation in CO2, and the carbon fiber mats possessed many oxygen functional groups, a specific capacitance of 155 F/g at 0.1 A/g and good cycle stability with retention of 94% after 6000 cycles in KOH electrolyte.

Lignosulfonate is a water-soluble derivative of lignin and a cheap bio-material as wastes of the sulfite pulping process, providing sulfur self-doping for supercapacitor electrodes. Tian et al. [94] developed multilevel porous carbon from sodium lignosulfonate with polyaniline-coated polystyrene spheres as the nitrogen source and template of macropores, KOH as activation agent, and the multilevel porous carbon showed a high specific surface area of 1454.7 m2/g, high nitrogen and sulfur content of 2.1 and 4.3 wt% respectively, and the fabricated supercapacitor delivered a high specific capacitance of 269 F/g and excellent cycling stability with capacitance retention of 98.4% after 10,000 cycles. Zhang et al. [95] prepared compact biochar-based materials for electrodes from sodium ligninsulfonate, p-phenylenediamine, and graphene oxide, through the evaporation process at 90 °C and low-temperature pyrolysis treatment at 400 °C, showing ultra-high specific capacitance of 480 F/g at 1 A/g and good cycling stability in 1 M H2SO4 electrolyte.

Other biomass-derived carbons

Alginate-derived carbon

Alginate, a polysaccharide linear anionic biopolymer consists of β-D-mannuronate (M) and α-L-guluronate (G) residues, can be easily extracted from brown algae and bacteria with cheap price, nontoxicity, environmentally friendliness, and large production about 30,000 metric tons annually. Besides, alginate possesses rich oxygen-containing functional groups such as carboxyl and hydroxyl groups and superior carbon content to be used as an ideal O-self doped carbon precursor for supercapacitor electrodes with a self-activation effect. Sun et al. [96] constructed 3D interconnected porous carbons derived from potassium alginate via self-activation process, and the porous carbons delivered a high specific capacity of 279 F/g at 1 A/g and excellent capacitance retention of 96.6% after 10,000 cycles for its high oxygen content, large surface area, and 3D interconnected structure. Sodium alginate (SA) has been widely studied as precursor for carbon electrodes since it is easily obtained from marine biomass and displays a 3D hierarchical porous framework after carbonization. Wang et al. [97] employed sodium alginate as carbon precursor and KNO3 as the oxidant by integrated gunpowder chemistry-assisted exfoliation and KOH activation, obtaining a porous carbon nanosheet with the ultrahigh specific surface area of 2788 m2/g, a specific capacitance of 226.9 F/g at 1 A/g, excellent cycling stability of 94% capacitance retention after 10,000 cycles, and well-done energy density of 65.6 Wh/kg at 43.75 kW/kg in ionic liquid electrolyte. Bai et al. [98] fabricated hierarchical oxygen-enriched porous carbon by carbonization of SA and BC composite followed by KOH activation at 700 °C for high-performance supercapacitor electrodes exhibiting outstanding specific capacitance of 302 F/g at 0.5 A/g, a good capacitance retention of 75.2% at 10 A/g, and high cycling stability with a 93.8% capacitance retention in 6 M KOH electrolyte due to the macro/mesoporosity and massive oxygen functional groups.

As mentioned above, the co-doping of two heteroatoms, such as N,O co-doping, N,S co-doping, has been employed to further improve the electrochemical performances of alginate-derived carbons due to the synergistic effect. Zhao et al. [99] prepared crosslinked SA gel via the electrostatic interaction between carboxylate in SA and cationic diammonium obtained from diammonium cations reacting with hydrochloric acid, and carbonized the SA gel particles obtaining N–O co-doped hierarchically porous carbon with an ultrahigh specific area of 3794 m2/g, high specific capacity of 269.0 F/g at 1 A/g, and superior cycling stability of 92.09% after 5000 cycles at 5 A/g in the three-electrode system. Hu et al. [100] prepared N,O co-doped hierarchically porous carbons by freeze-drying-assisted carbonization of SA and urea as porogenic agent and nitrogen source without any other activator, which exhibited a high specific surface area of 1179 m2/g, desirable oxygen and nitrogen contents of 13.8 wt% and 6.7 wt%, high capacitance of 305 F/g at 1 A/g, and well-done rate ability of 73.8% retention at 20 A/g. Huang et al. [101] fabricated polyaniline (PANI)/SA hydrogel using hydrogen bonding and entanglement between SA and PANI and then carbonized it to form N,S co-doped hierarchically porous carbon (NSC), in which PANI served as the N source and the SA provided massive oxygen and facilitated the porosity by Na+, and ammonium sulfate mineral from oxypolymerization served as N,S-enriched active agent. The NSC had high contents of oxygen (12.8 atom%), nitrogen (8.4 atom%) and sulfur (1.4 atom%) exhibiting excellent specific capacitance of 309 F/g at 0.5 A/g. Ye et al. [102] prepared 3D interconnected hierarchical porous activated carbon aerogels from SA and PANI by oxypolymerization, freeze-drying, and carbonization/activation at 700 °C, possessing high surface areas of 1695 m2/g and proper content of O (13.76%) and N (2.84%) and ultrahigh specific capacitance of 342 F/g at 2 A/g in 3 M H2SO4 electrolyte. Cui et al. [103] also used urea as nitrogen source adding KOH as activating agent to large-scale produced nitrogen-doped SA-derived nanocarbons displaying interconnected porous, ultrahigh specific surface area of 3313 m2/g, abundant nitrogen (about 7.2 wt%) and oxygen (about 7.4 wt%) elements, high specific capacitance of 267 F/g at 1 A/g and outstanding capacitance retention of 76.8% at 100 A/g.

Iron oxides are proved to be a promising material to fabricate hybrid composites with carbon for supercapacitor electrodes because of its high theoretical capacitance. Conventional methods such as thermal decomposition, hydrothermal decomposition, chemical precipitation and co-precipitation have been widely applied. Wang et al. [104] synthesized MnO2 nanoflakes on Ni foam by chemical deposition, then coated a thin layer of SA via electrophoretic deposition and calcined them into carbon enhancing the conductivity and protecting the crystal from dissolving. The as-prepared composite exhibited an ultrahigh specific capacitance of 412 F/g at 1 A/g and the excellent capacitance retention of 95.7% after 10,000 cycles. Conventional methods are based on deposition restricting solid attachment between two species resulting in poor durability for the agglomeration of iron oxide nanoparticles during charging-discharging processes. Inspiringly, the -COO− groups in the G units of SA possess a strong capability to chelate various metal ions such as Co2+, Ni2+, Cu2+, Cr3+, and Fe3+ by ion-exchange process forming an “egg-box” model structure that can be used to synthesize hybrid composites. Zhai et al. [105] prepared Cu-doped carbon aerogels (Cu-CA) via freeze-drying and one-step carbonization of hydrogels formed by chelating SA with metal cations Cu2+, and the Cu-CA had a hierarchical nanostructure, uniform Cu doping, and an outstanding specific capacitance up to 414.4 F/g with a potential voltage window of -0.6–0 V maintaining at 224.8 F/g after 1000 cycles in the solution of 6 M KOH. Li et al. [106] used SA to coordinate with Fe3+ via chelation effect preparing a carbon and Fe3O4 composite by the sol–gel method, which had two-dimensional sheet-like structure, and nanosize and homogenously distributing Fe3O4 particles on the surface as well as excellent electrochemical performance as a supercapacitor electrode with an outstanding specific capacitance of 550 F/g at 1 A/g and good capacitance retention of 89% after 2000 cycles.

Starch-derived carbon

Starch is a polysaccharide comprising branched amylopectin with α (1 → 4), α (1 → 6) glycosidic linkages and helical amylose with α (1 → 4) glycosidic linkages and contains 49% of oxygen. It is cheap, renewable, biodegradable and environmentally friendly, and it can be produced from a variety of crops allowing high application prospects as precursor to derive porous carbon materials for supercapacitors. Gao et al. [107] used starch-derived carbon foam material as negative electrode and hierarchical porous sphere MnCo2O4 as positive electrode fabricating asymmetric supercapacitor displaying excellent specific energy of 42.27 Wh/kg at the specific power of 400 W/kg under an output potential difference of 1.6 V and good cycling stability. Cao et al. [108] synthesized hierarchical porous carbons (HPCs) employing starch magnesium nitrate raw materials via an exothermic pyrolysis, high-temperature thermal treatment, and subsequent acid washing, in which magnesium nitrate acted as an oxidant and provided MgO template removed by acid for creating micro- and mesopores. The HPCs had a huge specific surface area about 2300 m2/g and delivered superior specific capacitance of 229 F/g at 1 A/g, good rate capability with capacitance of 211 F/g at 10 A/g, and excellent cycling stability with capacitance retention of 94% after 10,000 cycles at 2 A/g in a 6 M KOH electrolyte. The iron oxides doping can improve the electrochemical performance of starch-derived carbon in the same way as mentioned. Samdani et al. [109] synthesized the composite of nanostructured Co3O4 and bio-inspired carbon (BIC) via a pyrolysis of corn starch and subsequently hydrothermal synthesis, showing ultrahigh specific capacitance of 473 F/g at 1 A/g as electrode material and assembling all-solid-state symmetric supercapacitor with an energy density of 17 Wh/kg at a power density of 184 W/kg.

Starch grains tend to swell, split, and form a homogeneous gelatinized solution in water at an appropriate temperature (generally 60–80 °C), which is called gelatinization accompanied by the disconnection of hydrogen bonds between crystalline and amorphous starch molecules. Based on this, the sol–gel method is appropriately applied to the preparation of starch-derived porous carbon-based electrodes. Liu et al. [110] prepared starch-based gel by mixing starch with the KOH solution at 85 °C and removing the water, then fabricated 3D-reticular porous carbon via the carbonization of the gel and the in situ activation of KOH solution, which delivered a high specific capacitance of 372 F/g at 0.5 A/g at a wide potential window of 0–2.6 V in 2 M KOH electrolyte and an outstanding energy density of 24.5 Wh/kg at a power density of 695 W/kg in 2 M [BMIm]BF4/AN electrolyte. Zhong et al. [111] fabricated starch-derived porous carbon-based electrode by the carbonization of carbon cloth soaked in the gel from the mixture of starch and KOH, and this binder-free electrode exhibited 272 F/g at 1 A/g and a capacitance retention of 75.9% at 50 A/g.

Recently, many kinds of starch with different origination, such as potato starch, sweet potato starch, and corn starch, have been studied as precursors of porous carbon in supercapacitor electrodes with excellent performance. Wang et al. [112] fabricated 2D amorphous carbon nanosheets (CNs) via burning corn starch above a Ni foam and further coated CNs with a CoO/CoF2 composite film significantly enhancing the electron collection efficiency, and the as-prepared electrode had a high specific capacitance of 12.00 F/cm2 at 5 mA/cm2, superior rate capability, and good cycling stability. Xing et al. [113] employed three raw materials, taro, sweet potato, and potato as the carbon precursor to prepare starch-based porous carbons by carbonization and KOH activation, and found that degrees of graphitization of porous carbon was influenced by the amylopectin content in starch. The taro starch had the highest amylopectin content (84%) among three raw materials and taro starch-derived carbon possessed the highest degree of graphitization and the best electrochemical performance with a good specific capacitance of 397 F/g, outstanding capacity retention of 97% over 20,000 cycles, and a superior energy density of 22.59 Wh/kg at a power density of 148 W/kg in 6 M KOH electrolyte.

Chemical activation is a widely used approach to facilitate the porous structures of starch-derived carbon with the chemical agents such as KOH, NaOH, and ZnCl2. Guo et al. [114] prepared HPCs through one-step carbonization/activation of starch as precursors and KOH as activating agents, which possessed 3D interconnected hierarchically porous structure and an ultrahigh specific surface area of 2259.54 m2/g as well as an excellent specific capacitance of 385.7 F/g at 1 A/g in a three-electrode system. However, the strong activation effect of KOH and NaOH may degrade the starch into small molecular and obtain a smaller proportion of carbon atoms resulting in the low yield of carbon. Compared to KOH, ZnCl2 is a milder activation reagent to create hierarchical pores and high yield of carbon materials by dehydrating and crosslinking reaction with precursor when temperature increase. Kasturi et al. [115] employed Artocarpus heterophyllus seed as carbon precursor containing a rich source of starch, vitamin, minerals, phytonutrients, and protein, and ZnCl2 as activating agents to produce biomass-derived material possessing abundant nitrogen species (2.1 at. wt%), high specific surface area (1841 m2/g), and exceptional porous architecture. The coin cell all-solid-state supercapacitor with the as-prepared electrode and Manihot esculenta starch-based biopolymer electrolyte showed an outstanding specific capacitance of 240 F/g at 0.5 A/g with a coulombic efficiency of 97% after 2000 cycles and superior specific energy of 17 Wh/kg at a power density of 3823 W/kg. Yu et al. [116] synthesized ultrathin N-doped porous carbon nanospheres/polyaniline (HPCN/PANI)composite by one-step pyrolysis of wheat flour, urea and ZnCl2 followed by in situ polymerization of aniline (Fig. 7). The HPCN/PANI possessed extremely high specific capacitance of 783 F/g and the assembled asymmetric supercapacitor with it as anode delivered a desirable specific capacitance of 81.2 F/g.

Schematic illustration of synthesizing HPCN/PANI compositors. Reproduced from Construction of Ultrathin Nitrogen-Doped Porous Carbon Nanospheres Coated With Polyaniline Nanorods for Asymmetric Supercapacitors, Pingping Yu, Qunliang Wang, Lingxia Zheng, and Yanfeng Jiang, 7, 2019 with permission from Front Chem [116]

Agar-derived carbon

Agar is a kind of macromolecular polysaccharide with galactose as the main component, which can be extracted from red algae. It is low cost, easily available, biodegradable, and contains a certain amount of oxygen possessing potential as a carbon precursor to derive O-doped carbon-based electrode materials. Vijayakumar et al. [117] used agar as carbon source deriving carbon electrode material and utilized it in a symmetric supercapacitor which exhibited a high specific capacitance of 170 F/g at 0.5 A/g, good rate property with 70 F/g capacitance at 50 A/g, and cyclic stability with high capacitance retention about 85% after 15000 cycles in Na2SO4 electrolyte. Hu et al. [118] synthesized N/O co-doped porous carbon from the mixture of agar, potassium citrate, and urea through one-step pyrolysis. The prepared carbon delivered an excellent specific capacity of 357 F/g at 1 A/g in 6 M KOH electrolyte, good rate performance of 267 F/g at 50 A/g, and long-term stabilization of 95.6% retention after 10,000 cycles.

Agar can form a stable hydrogel to stabilize the dispersed state of nanoparticles and the multitudinous –OH groups of agar can make strong intermolecular interaction between them to avoid aggregation and shrinkage. Thus, it have been used to compound with various nanoparticles. Xie et al. [119] prepared a carbon material through carbonization of agar with graphene oxide nanosheets (GONs). Agar hydrogel could not only fix the monolayer-dispersed state of GONs but also provided abundant –OH groups strong interacting with the functional groups on GONs averting aggregation and shrinkage of the carbonized particles, resulting in the large surface area of about 1200 m2/g of the carbon materials exhibiting a good capacitance of 115 F/g, high rate performance with 70% at 80 A/g, and outstanding cycling stability retaining almost 100% after 10,000 cycles at 5 A/g. Huang et al. [120] used a mixture of agar and b-cyclodextrin (b-CD) as carbon precursor, MnO2 nanorods as the template to form nanotunnels inserted hierarchical-porous carbon, in which agar hydrogel stabilized the dispersed state of MnO2 nanorods and –OH groups of agar built strong interactions with b-CD. The resulted carbon material showed a high specific surface area of 1441 m2/g, excellent capacitance of 253.1 F/g at a scan rate of 5 mV/s, good rate performance of 80.3% at 100 mV/s, and cycling stability higher than 100% after 6000 cycles at 20 mV/s.

Protein-derived carbon

Despite the extensive application on converting carbohydrates into carbon electrode materials, proteins have not been widely studied in energy storage. Proteins contain abundant N and O atoms on their polypeptide chains as potential precursor of heteroatom-doped carbon with enhanced capacitance, surface wettability, and electronic conductivity. Demir et al. [121] used pea protein as precursor to fabricate N and O dual-doped porous carbons by two-step pyrolysis and KOH activation, featuring a large surface area of 3500 m2/g, high N/O contents of 2.5/17.9 at% as well as a remarkable capacitance of 413 F/g at 1.0 A/g in 1 M KOH electrolyte, good cycle stability of 91.6% after 20,000 cycles, and high rate capability of 210 F/g at 30 A/g. Song et al. [122] produced protein-derived N/O-doped hierarchically porous carbon materials from sericin, a waste protein, by pre-carbonization and KOH activation, which had excellent electrochemical performances as supercapacitor electrode with a high specific surface area of 2723 m2/g, a high specific capacitance of 287 F/g at 0.5 A/g, a good cyclic stability with 93% capacitance retained after 10,000 cycles at 5 A/g, and excellent rate capability with 74% capacitance retained at 0.5 A/g. Niu et al. [123] used commercial protein powder as precursor to obtain protein-based microporous carbon by KOH activation with high nitrogen content of 15.29 at.%, outstanding capacitance of 336 F/g at 1 A/g, good rate capacity of 173 F/g at 10 A/g, and cycling stability of 83% after 10,000 cycles at 10 A/g.

However, most proteins would lose their structure during carbonization since the polypeptide chains of protein become flexible above glass-transition temperature. To preserve their structure during carbonization is one of the biggest challenges in applying proteins as carbon precursors. The silica template has been introduced to preserve the hierarchically porous structure of N-doped carbon from protein [124], but its preparation is time and energy consuming and the hydrogen fluoride used to remove the template is corrosive and harmful for the environment. In another way, Yang et al. [125] incorporated Ca2+ into the protein fiber matrix to obtain well maintained interconnected fibrous structure during pyrolysis (Fig. 8), in which Ca2+ improved the thermal stability of the protein and the calcium salt/oxide served as a template to both generate pores and provided a solid support. The obtained carbon fibers showed a high areal specific capacitance of 64 μF/cm2 at 0.5 A/g and excellent cyclic stability with capacitance retention of 98% after 5000 cycles at 10 A/g.

Schematic illustration of synthesizing N-doped graphitic carbon fibers. Reproduced from Highly nitrogen-doped graphitic carbon fibers from sustainable plant protein for supercapacitor, Jingqi Yang, Yixiang Wang, Jingli Luo, Lingyun Chen, 121, 2018 with permission from Industrial Crops and Products [125]

Protein-derived carbons have been compounded with high-conductive graphene materials for higher performance in supercapacitors. Xie et al. [126] coated graphene with the soy-protein-derived N/O co-doped amorphous carbon forming a sandwiched porous architecture through a one-pot hydrothermal process followed by carbonization in an argon atmosphere and further thermally oxidization in air. The as-prepared material exhibited a high specific capacitance of 221 F/g at 0.2 A/g and retained 153 F/g at 20 A/g in 6 M KOH electrolyte as well as superior cycling performance with a retention of 96% after 2000 cycles at 2 A/g. Ma et al. [127] used graphene oxide sheets (GOs) as both template and catalyst for the hydrothermal carbonization of egg proteins and the resulting egg protein-derived carbon/rGO composite was activated by KOH to obtain highly porous carbon material, showing an outstanding specific capacitance of 482 F/g at 0.1 A/g, excellent rate capability of 280 F/g at 20 A/g and cycling stability about 100% capacitance retention after 10,000 cycles at 5 A/g.

Gelatin is fat-free, high-protein and cholesterol-free. As a noncrystalline mixture is obtained by irreversibly partial hydrolyzation of collagen in animal skin, connective tissues, and bones, it is low cost, abundant, sustainable, and rich of nitrogen as an idea precursor of nitrogen-doped carbon applied in supercapacitor electrodes. Niu et al. [128] prepared a ternary (O, N, S)-doped microporous carbon nanosheets by low temperature (600 °C) pyrolysis of fish skin and KOH and the fish skin was firstly transformed into gelatin by KOH. The as-prepared carbon nanosheets delivered a high volumetric capacitance of 300 F·cm−3 at the 1 A/g and maintained capacitance of 235 F·cm−3 even at 200 A/g. Li et al. [129] fabricated a N-self doped 3D cross-coupled macro-mesoporous carbon network from the NaNO3-gelatin biopolymer aerogel by salt-template strategy, which exhibited an ultrahigh specific surface area of 2872.2 m2/g, high energy density of 92 Wh/kg at a power density of 1 kW/kg as electrode in 4 V EMIBF4 ILs, and retained an energy density of 39 Wh/kg at an ultrahigh power density of 200 kW/kg. Hu et al. [130] prepared mesoporous nitrogen-doped carbon films via carbonization of gelatin/copper hydroxide nanostrands film. This free-standing carbon film was employed as a binder-free supercapacitor electrode showing superior specific capacity of 316 F/g at 0.5 A/g, and excellent capacitance retention of 92.9% after 11,000 cycles.

The composites of gelatin-derived carbon with iron oxide and graphene oxide perform better applied in supercapacitor electrodes. Zeng et al. [131] fabricated a nitrogen-doped hierarchical porous carbon derived from composite of gelatin and graphene oxide by a combined nano-CaCO3 template, solvation, volatilization, and KOH activation, which possessed a large surface area of 1091 m2/g and combination of electrical double layer with pseudocapacitance capacitance and delivered an excellent specific capacitance of 234 F/g at 0.5 A/g. Peng et al. [132] synthesized nickel phosphide nanoparticle self-inlaid carbon nanosheet frameworks using a nickel nitrate-assisted gelatin, in situ substrate-free chemical blowing pyrolysis and low-temperature phosphorization method, and the obtained carbon nanosheet as a positive electrode of supercapacitor exhibited an excellent specific capacity of 145 mAh/g at 0.5 A/g, a superior rate capability of 70% capacity retention at 10 A/g. Sun et al. [133] prepared composite electrode of nitrogen-doped hierarchical porous carbon and alpha-MnO2 nanowires via a template method, had structures of inserting one-dimensional nanowires into 3D interconnected porous, outstanding specific capacitance of 204.6 F/g at 1 A/g and well-done cycling stability with 97.2% retention after 5000 cycles. Yang et al. [134] used gelatin and melamine as the carbon sources, cobalt acetate as the source of Co3O4 obtaining 2D carbon nanosheets with cobalt oxide nanoparticles on the surface (GM-C@Co3O4) through the hydrothermal reaction and carbonization. The morphology of GM-C@Co3O4 composite could be tuned by the amount of cobalt acetate. GM-C@Co3O4 displayed an ultrahigh specific capacitance of 1503 F/g at 1 A/g and assembled GM-C@Co3O4//GM-C supercapacitor exhibited an energy density of 48.4 Wh/kg at a power density of 1502 W/kg.

Table 5 displayed the electrochemical performance of porous carbon-based electrode materials derived from alginate, starch, or gelatin. They are classified into three types: porous carbons without external doping, heteroatoms co-doped porous carbons, and composites of transition-metal oxides/conductive polymers with carbon materials to show the benefit brought by two main methods on improvement of electrochemical performance. Both external heteroatom doping and composite with transition-metal oxides/conductive polymers are proved to significantly enhance the specific capacitance of carbon materials through offering pseudocapacitance and the latter method performs much better. Nevertheless, the rate capability of composites is lower than other two types for the relatively slow ion transfer caused by restricted solid attachment between two species. Besides, the composites exhibited inferior cycle stability caused by complex factors related to structural integrity, electronic properties, and electrochemical behavior of pseudocapacitive materials. The phenomenon is applicable to other biomass-derived carbon materials combined with the data reports and data in the first few parts. Thus, external heteroatom doping is a more comprehensive approach to improve the electrochemical properties of biomass-derived carbon materials, and composites need further improvement on the rate capability and cycle stability through changing the structure, composition, and so on.

Biomass applied in supercapacitor electrolytes

Supercapacitors are widely assembled with liquid electrolytes, but the liquid electrolytes are usually toxic, corrosive, and have a risk of leakage. One of the methods to overcome the problem is the formation of polymer electrolytes with a wide potential window, high ionic conductivity, excellent stability, and mechanical strength. However, the formation of polymer electrolytes can cause huge resource consumption and environmental concerns. Hence, developing renewable, low cost, environmentally friendly biomass-based electrolytes has gained more and more attention. Biomass materials, such as cellulose, starch, chitosan, alginate, and soybean protein, have been applied in supercapacitor electrolyte in recent years.

Cellulose-based electrolytes

Cellulose possesses the advantages of high chemical/thermal stability, good mechanical strength, and flexibility, indicating its possibility to be involved in polymer electrolyte. Kim et al. [135] incorporated lithium trifluoromethanesulfonate into modified methylcellulose to synthesize a transparent, flexible, and eco-friendly polymer electrolyte, with good conductivity of nearly 1 mS/cm and negligible change in its performance after being recycled and reused 20 times. Jiao et al. [136] prepared the electrolyte separator made of nanofibrillated cellulose (NFC) and poly(4-styrenesulfonic acid) with high conductivity of 0.2 S/cm at 100% relative humidity. The NFC worked as three-dimensional template providing good ionic conductivity through nanopores in the electrolyte.