Abstract

A series of single-phase Fe-substituted hollandite (Ba,Cs)1.33(Fe,Ti)8O16 compositions with the chemical formula Ba1.33−xCsxFe2.66−xTi5.34+xO16 (x = 0, 0.1, 0.2, 0.667, and 1.33) were systematically investigated using both experimental and computational methods to establish possible links between crystal chemistry, Cs retention, thermochemistry and chemical durability. A phase transition from monoclinic to tetragonal was observed as a function of both Cs content and temperature. Elemental analysis revealed that Cs retention was significantly improved for the hollandite with higher Cs content. High-temperature melt solution calorimetry and sublattice-based thermodynamic simulations confirmed a high degree of thermodynamic stability in the Fe-substituted compounds which was enhanced in compositions with higher Cs content. This trend can be primarily attributed to two factors: (1) a decreasing ratio of the average ionic radii of B-site cations to that of A-site cations and (2) an increasing tolerance factor. Based on a reoptimized sublattice model, a pseudo-ternary phase diagram was generated to predict the optimal composition possessing the highest Cs content and A-site occupancy, which had not been experimentally explored. Leaching tests further verified that high Cs-containing compositions have significant chemical durability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hollandite is a promising family of crystalline ceramic materials used to immobilize radioactive alkali and alkaline earth elements (e.g., Cs and Ba) in high-level waste (HLW). Compared to borosilicate glasses currently used as commercial waste matrices, hollandite-based ceramics present superior thermodynamic stability and chemical durability, and higher Cs loading [1,2,3,4,5,6,7].

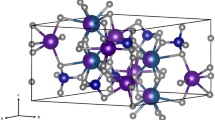

Hollandite has the general formula A+/2+x(B2+/3+/4+,Ti4+)8O16, where 0 ≤ x ≤ 2. A-sites are occupied by Cs+ and (or) Ba2+, and numerous cations with different valences can be substituted for Ti4+ on B-sites, such as Zn2+, Al3+, Fe3+, Ga3+ and Cr3+ [4, 5, 8,9,10,11]. The hollandite structure consists of eight corner and edge sharing (B,Ti)O6 octahedra, which interlink and form a three-dimensional framework with 2 × 2 tunnels to accommodate A-site cations [4, 9, 10, 12]. Hollandite can adopt either a tetragonal (space group I4/m) or a monoclinic (space group I2/m) symmetry depending on the ratio of the average ionic radii of B-site cations to that of A-site cations (RB/RA). When tunnel cations are large enough, the framework exhibits shear-type collapse and the tetragonal symmetry will reduce to a monoclinic symmetry [2].

Although a wide range of hollandites have been fabricated, many potential issues still exist [13] including the appearance of secondary and Cs-parasitic phases [9, 14], severe Cs loss [9] and the requirement for elevated temperatures during melt-processing [14]. An Fe-substituted hollandite is a promising candidate according to several studies [2, 8, 9, 15] over the past decade. Firstly, the melting point of Fe2O3 (~ 1565 °C) is much lower than that of refractory oxides (e.g., Al2O3, MgO, Cr2O3, etc.) used to form other types of hollandite. Therefore, it should be easier to obtain dense Fe-substituted hollandite via conventional sintering as well as reduce the temperature for melt-processing. Secondly, the ionic radius difference between Fe3+ and Ti4+ on B-sites provides a large enough space for Cs+ cations to be accommodated into the tunnel structure without forming Cs-parasitic phases as compared to Al- and Ga-substituted hollandites [8, 9, 15].

Thermodynamic stability and chemical durability are two vital properties for assessing the performance of waste forms. Several related studies have been conducted on Al-, Zn- and Ga-substituted hollandites [2,3,4,5, 16, 17]; however, there is little information on Fe-substituted hollandite [2]. In this work, a broad compositional range of single-phase Fe-substituted hollandite (Ba,Cs)1.33(Fe,Ti)8O16 phases from the Ba end member to the Cs end member was successfully synthesized via solid-state reactions. Changes in the crystal chemistry as a function of Cs content and temperature were analyzed by high-temperature X-ray diffraction and high-temperature Raman spectroscopy. Cs retention was determined by energy dispersive X-ray spectroscopy measurements. Enthalpies of formation from constituent oxides were measured by high-temperature oxide melt solution calorimetry. Results from calorimetric measurements were reinforced by calculations based on a reoptimized sublattice model. An isothermal pseudo-ternary diagram was subsequently generated from the reoptimized sublattice model as an example to demonstrate its capability to extrapolate phase equilibrium behavior to regions not yet experimentally explored. Effects of ratio of the average ionic radii of B-site cations to that of A-site cations (RB/RA), tolerance factor (tH), optical basicity (Λ) and symmetry on enthalpies of formation were discussed. Furthermore, phase formation and stability of Fe-substituted hollandite with respect to other competing phase assemblages were estimated. Finally, chemical durability was measured by a leaching test.

Experimental

Sample synthesis

A series of Fe-substituted hollandite with the chemical formula Ba1.33−xCsxFe2.66−xTi5.34+xO16 (x = 0, 0.1, 0.2, 0.667, and 1.33) were synthesized using a solid-state reaction route (as shown in Table 1). For simplicity, they are denoted as Ba1.33Fe2.66Ti5.34O16 (H1), Ba1.23Cs0.1Fe2.56Ti5.44O16 (H2), Ba1.13Cs0.2Fe2.46Ti5.54O16 (H3), Ba0.667Cs0.667Fe2Ti6O16 (H4), and Cs1.33Fe1.33Ti6.67O16 (H5) throughout this paper.

Reagent-grade powders of barium carbonate, BaCO3 (Sigma-Aldrich, 99.98%), cesium carbonate, Cs2CO3 (Alfa Aesar, 99.9%), iron(III) oxide, Fe2O3 (Alfa Aesar, 99.9%) and titanium oxide (anatase), TiO2 (Inframat Advanced Materials, 99.9%) were used as starting materials. Stoichiometric amounts of raw powders were mixed and added into high-density polyethylene (HDPE) bottles with ethyl alcohol and yttrium-stabilized zirconia (YSZ) grinding media (Inframat Advanced Materials) for 24 h. The post-ball milling slurry was dried in an oven overnight. As-dried powders were ground in an agate mortar and pestle. Heat treatment processes, including calcination and sintering, were performed in a box furnace. Hollandite samples were prepared as follows: (1) H1–H5 were calcined in air at 1000 °C for 5 h to decompose carbonates, then wet ball milled for another 24 h and dried again, (2) the dried H1 was ground, cold pressed into pellets, and sintered in air at 1300 °C for 5 h; (3) the dried H2–H5 were ground, cold pressed into pellets, and sintered in air at 1200 °C for 5 h. To reduce potential volatilization of Cs and Ba at elevated temperatures during sintering, alumina crucibles were covered with alumina lids and the pressed pellets were immersed in additional calcined powders. As-sintered pellets H1–H5 were crushed and ground into powders for further experiments.

To study whether sintering impacted enthalpies of formation, selected samples were directly synthesized in a box furnace as powder samples. Specifically, remaining powder sample H1 obtained after step (1) was calcined at 1300 °C for 5 h, while remaining powder samples H4 and H5 obtained after step (1) were calcined at 1200 °C for 5 h. These calcined powder samples H1, H4, and H5 were denoted as H1 (C), H4 (C), and H5 (C), respectively, and only used for calorimetric measurements described in “Calorimetric measurements” section.

Characterization

Room temperature X-ray diffraction (RT-XRD) measurements were conducted by Rigaku Ultima IV diffractometer with monochromatic Cu Kα radiation (λ = 1.54 Å) to analyze the crystal structure of hollandite samples H1–H5. The data were collected from 15° to 70° 2θ with a 0.02° step size. Microstructure and chemical composition of hollandite samples were investigated by a Hitachi SU6600 scanning electron microscopy (SEM) equipped with energy dispersive X-ray spectroscopy (EDS) analysis (Oxford). Samples were not coated prior to EDS measurements to avoid contamination. EDS composition was reported as the average composition of at least ten different sites over representative X-ray microstructure maps. Back-scattered electron (BSE) imaging mode was selected to observe homogeneity and morphology of samples. Inductively coupled plasma-mass spectroscopy (ICP-MS) was used to measure Cs concentrations in leaching solution, and inductively coupled plasma-atomic emission spectroscopy (ICP-AES) was used to measure Ba, Ga, and Ti concentrations in leaching solution. A lithium metaborate (LM) fusion preparation with nitric acid digestion was used to dissolve solid samples for ICP-MS and ICP-AES analysis for leaching tests.

To study evolution of the bulk structure as a function of temperature, high temperature (HT)-XRD was performed on H1–H4 using monochromatic Cu Kα radiation in a Bruker D8 Advance diffractometer with an Anton Paar HTK 1200 heating stage. Powder samples were mounted on a high purity (99.6%) alumina sample plate. Data were collected using a fixed divergence slit in the range of 10° ≤ 2θ ≤ 80° with a 0.025° step size. The measured samples were first heated from RT to 450 °C with an increment of 25 °C and then to 1000 °C with an increment of 50 °C, afterward the samples were cooled to 400 °C with an increment of 100 °C, to 250 °C with an increment of 50 °C, and then to RT with an increment of 25 °C.

Evolution of local structure with different temperatures was also recorded by HT-Raman spectroscopy with 20-second integration time and 20 accumulations using a WITec instrument with 633 nm laser and 5 mw output power. H1 and H2 were heated up from RT to 350 and 150 °C, respectively, which were high enough to induce the M–T phase transition. The Linkam scientific instruments were used as temperature assembly with link 1.2.5.1300 software used for temperature control with accuracy ± 1 °C. Enthalpy (ΔHc) of the monoclinic–tetragonal (M–T) phase transition of samples H1 and H2 was determined by Netzsch 404 C Pegasus DSC to assess their effect on thermodynamic stability. Samples were placed in alumina crucibles, heated to 500 °C at first, then cooled down to 100 °C and held for 10 min under dry Ar atmosphere to exclude the potential heat effect from water content. Afterward, the samples were heated up to 500 °C and cooled down to RT again. The baseline of the same empty alumina crucible under the same experimental condition was recorded for subtraction.

High-temperature oxide melt solution calorimetry

High-temperature oxide melt solution calorimetry was performed using an AlexSYS 1000 calorimeter (SETARAM) operating at 702 °C. In a drop solution calorimetry experiment, approximately 5 mg weighed powder sample was loosely pressed into pellets and dropped from room temperature into the molten sodium molybdate (3Na2O·4MoO3) solvent in a platinum crucible in the calorimeter. Detailed instrument and experimental procedure can be found by Navrotsky [18, 19]. To stir the melt and improve sample dissolution, the calorimeter assembly was flushed with dry air at ~ 48 mL/min and dry air was bubbled through the solvent at ~ 5 mL/min. At least six successful drops were performed for each composition to obtain statistically reliable data. The calorimeter was calibrated utilizing the heat content of high purity α-aluminum oxide (Alfa Aesar, 99.997%). This methodology is well established and has been described in prior reports [18, 19].

Leaching test

Leaching tests following guidelines of the product consistency test (PCT) (Method-B) were performed on H1 and H3–H5 to assess aqueous chemical durability [20, 21]. Samples were ground and washed with water. As-prepared samples with a constant 1:10 ratio of sample mass to water volume were placed in stainless steel vessels. The vessels were closed, sealed, and placed in an oven at 90 ± 2 °C for 7 days. Once cooled, post-leaching solutions were analyzed. For each composition, three replicates were prepared to acquire reliable data. Normalized elemental release (NL) was calculated using Eq. (1):

where NLi= normalized elemental release (g/m2) of element “i” (e.g., Cs and Ba), Ci = concentration of element “i” in post-leached solution (g/L), fi= measured fraction of element “i” in pre-leached samples (unitless), SA = surface area of samples (m2), and V = water volume (mL). Specific surface area of each crushed sample was measured by Brunauer–Emmett–Teller (BET) analysis. It is notable that fractional elemental release (FR) values for Ga-substituted hollandite instead of NL values were reported in our previous publication [4]. In prior work, the FR values were more accurate than NL values, because the surface areas were estimated based on particle sizes after sieving. In this work, however, specific surface areas were accurately measured via the BET method and thereby NL values were reported.

Development and reoptimization of sublattice model

A set of thermodynamic functions were generated by Utlak et al. [22] based on the calculation of phase diagrams (CALPHAD) methodology which successfully characterized the equilibrium behavior of hollandite compositions considered for potential HLW systems. Within that effort, a sublattice model was further developed using the compound energy formalism (CEF) to represent the non-stoichiometry of the hollandite solid solution phase, which was based on the hollandite general formula A2B8O16 where A is a monovalent or divalent atom, and B has a valence between 2 and 5 [9, 14]. In the current effort, the model is constrained such that only Fe3+ and Ti4+ are present on the B-sites of the Fe-substituted hollandite [11]. Hence, a four sublattice CEF hollandite model can be defined as:

where Va represents tunnel vacancies. Details regarding the hollandite CEF sublattice model and potential to obtain Gibbs energies for hollandite compositions have been described by Utlak et al. [22].

Although enthalpies of formation of Fe-substituted hollandites were previously reported by Utlak et al. [22] based on the sublattice model, it was necessary to reoptimize the original model considering the experimentally determined data of the current effort to derive reliable calculated values. Consequently, the Gibbs energies of hollandite end members as well as Ba and Cs titanate end members also needed to be correspondingly adjusted to well represent enthalpies of formation (Table S1) while retaining good agreement between the computed and measured Fe-hollandite stoichiometries obtained by Utlak et al. [22].

Results and discussion

Crystallography

Room temperature XRD patterns of synthesized samples H1–H5 described in Table 1 are displayed in Fig. 1a. The spectra indicate single-phase hollandite with either a tetragonal (space group: I4/m) or monoclinic (space group: I2/m) structure, depending on the level of Cs substitution for Ba (as shown in Table 2). BaFeTi7O16 (PDF#53-1179) and Ba4Fe8Ti16O48 (PDF#51-1899) were used as model structures of tetragonal and monoclinic, respectively. In Fig. 1a, two major families of lattice planes {310} and {220} of samples H1–H5 displayed a shift to smaller 2θ. This shift indicates that the unit cell expands with increasing Cs content, which has been confirmed by prior studies [4, 5, 10, 11, 23, 24]. Moreover, H1 and H2 are monoclinic, while H3–H5 are tetragonal. The inset in Fig. 1a clearly shows that intensity of monoclinic planes—(−202), (202), (−301), (301), (−103), and (103)—is gradually reduced and then they are merged into tetragonal planes—(220) and (310)—which indicates that the M–T phase transition occurs as the Cs content increases.

a RT-XRD patterns of H1–H5 with different Cs content; b According to Zhang and Burnham’s prediction [28], the region above the black dash corresponds to tetragonal and the region below the blue dot dash line corresponds to monoclinic, while the region between the lines is an undetermined zone. The red straight line is the criterion predicted by Post et al. [27]. The data labeled as black squares are from this work, and the data displayed as open square are from Bailey et al. [12] T and M are short for tetragonal and monoclinic, respectively

It is attractive to establish a general guideline which can effectively demarcate tetragonal and monoclinic regions, since monoclinic hollandite is reported to be less stable than the tetragonal analogues according to previous studies [2, 5, 25]. Two prior models have been used to predict the symmetries of hollandite since the 1980s, Post et al. [26] and Zhang and Burnham [27], respectively. However, Zhang and Burnham’s tetragonal criterion is generally considered more applicable due to a number of exceptions that have been found in the model of Post et al. [27]. According to this criterion, hollandite adopts tetragonal if \( R_{\text{A}} > \sqrt 2 \left( {R_{\text{O}} + R_{\text{B}} } \right) - R_{\text{O}} \) [27]. To better illustrate the phase boundary of the M–T transition in this work, Fig. 1b was drawn where RB and RA were calculated using the Shannon effective ionic radii: Ba2+ = 1.42 Å and Cs+ = 1.74 Å in eightfold coordination, while Fe3+ = 0.645 Å (high spin) and Ti4+ = 0.605 Å in sixfold coordination (Table 2) [15]. In Fig. 1b, H3–H5 having tetragonal symmetry fall into the tetragonal region as expected, while H1 and H2 exhibiting monoclinic symmetry are located in the undetermined region where hollandite could adopt either monoclinic or tetragonal symmetry. Moreover, a similar investigation of Cs content-dependent M–T phase transition of Ba1.2−xCsxFe2.4−xTi5.6+xO16 (0 ≤ x ≤ 0.6) hollandite was reported by Bailey et al. [11]. Due to the uncertain symmetry in the mixed phase region, Zhang and Burnham’s tetragonal criterion is an effective guideline to follow when intentionally designing tetragonal hollandite-based waste forms.

HT-XRD spectra of H1–H4 with partial 2θ range are shown in Fig. 2a–d to clearly show the evolution of the symmetry change at different temperatures. Monoclinic peaks of H1 and H2 within the 2θ range of 24°–30° transform into the tetragonal peak when temperature was within 300–350 °C and 75–150 °C, respectively, which indicates that an apparent M–T phase transition occurred for both H1 and H2. Moreover, this M–T phase transition is fully reversible because the symmetry recovers from tetragonal to monoclinic when the temperature cooled down to RT. For H3 and H4, their tetragonal symmetries remained during the entire heating and cooling steps. The HT-XRD spectra of H1–H4 with full 2θ range are displayed in Figure S1.

HT-Raman spectra of the sample H1 and H2 are displayed in Fig. 3a, b, and frequencies and mode assignments of their main Raman bands are listed in Table S2. For the RT-Raman spectrum of H1 in Fig. 3a, five major bands were observed at ~ 83, ~ 130, ~ 367, ~ 556 and ~ 700 cm−1, while a small shoulder appeared at ~ 600 cm−1. The band at ~ 83 cm−1 is assigned as the vibration mode of tunnel cations (i.e., Ba) [28]. The peak at ~ 130 cm−1 may be attributed to (Fe,Ti)-O symmetric stretching of (Fe,Ti)O6 octahedra, while three peaks at ~ 367, ~ 556 and ~ 700 cm−1 and the shoulder peak ~ 600 cm−1 might arise from the bending mode of (Fe,Ti)O6 octahedra [28,29,30,31,32,33,34]. A number of changes in the Raman spectra across the M–T phase were observed. The intensity of the band ~ 83 cm−1 at RT increased and it shifted to higher wavenumber with increasing temperature, indicating that the interaction between Ba and (Fe,Ti)O6 octahedra framework becomes stronger [28]. Moreover, the bandwidth of the band at ~ 130 cm−1 at RT became slightly broader, implying changes in the symmetric stretching modes due to the (Fe,Ti)O6 octahedra and the M–T phase transition as temperature increased [34]. The bending mode of (Fe,Ti)O6 octahedra was also affected by the M–T phase transition as follows: (1) the band at ~ 367 cm−1 (RT) shifts to lower wavenumber, (2) the intensity of the band ~ 556 cm−1 (RT) gradually decreases, and (iii) the intensity of the shoulder peak ~ 600 cm−1 (RT) gradually increases. In addition, the band appearing at relatively high wavenumber ~ 700 cm−1 becomes less intense as the temperature increases, due to the monoclinic to tetragonal phase transition [34]. Similar changes of Raman bands at different temperatures of H2 are also reflected in Fig. 3b. Consequently, features of the M–T phase transition could be observed both in the long-range ordering as well as the short-range ordering.

Elemental analysis and Cs retention

The elemental concentrations of Ba, Cs, Fe, and Ti of hollandite samples were measured by EDS as shown in Table 1. Some representative sites on the EDS microstructure map of H4 in Figure S2 were selected to serve as an example to illustrate the method. In addition, X-ray elemental maps of H4 in Figure S3 were selected as representatives to evaluate the homogeneity of the elemental distribution. The results generally confirm that nominal stoichiometries were achieved and the elemental distribution in samples was homogeneous. The actual compositions listed in Table 1 were used to calculate enthalpies of formation of H1–H5 in “Calorimetric measurements” section. Figure S4 displays BSE images of H1–H5 revealing no occurrence of distinct phase segregation or secondary phases.

Cs loss is one of the most critical issues when hollandite pellets are sintered at elevated temperatures. Therefore, Cs retention of the post-sintering pellets H2–H5 (H1 did not have Cs content) was determined by EDS measurements and is presented in Fig. 4. It was found that Cs retention was significantly improved in compositions with higher Cs content indicating that Cs could be more favorably incorporated into the hollandite structure rather than through volatilization which agrees with our previous study of Zn-substituted hollandite [5]. Higher Cs retention appears to be linked to enhanced thermodynamic stability of the hollandite phase with higher Cs content, which has been confirmed by calorimetric measurements presented in “Calorimetric measurements” section.

Thermochemistry

Calorimetric measurements

The enthalpies of drop solution (ΔHds) of H1–H5 measured in the molten 3Na2O·4MoO3 solvent at 702 °C were given in Table 3. Using these values and previously reported ΔHds values and the enthalpies of formation at 25 °C from the elements (ΔHf,el) data for BaO, Cs2O, α-Fe2O3 and TiO2 (shown in Table 4), the enthalpies of formation at 25 °C from the constituent oxides (ΔHf,ox) and ΔHf,el values of hollandite were calculated using thermochemical cycles (e.g., those for H4 with actual EDS compositions as shown in Table 5) [35,36,37,38,39]. In Fig. 5a, ΔHf,ox values of H1–H5 are all strongly exothermic, indicating that they are thermodynamically stable relative to the constituent oxides. Moreover, ΔHf,ox values become increasingly exothermic with increasing Cs substitution. It is worth noting that significantly negative enthalpy is the dominating term in the Gibbs free energy in solid-state reaction synthesis, because the overall contribution from changes of the entropic term (including both vibrational and configurational entropic changes) is very small at temperatures below 700 °C [2]. Therefore, it is convincing that the hollandite with higher Cs content is more energetically stable [2, 40].

Calorimetric measurements were also performed for the calcined powder samples H1 (C), H4 (C), and H5 (C) in order to investigate whether the enthalpy of formation of hollandite was affected by different processing conditions (i.e., calcination versus sintering). Actual compositions of the three calcined samples were also measured by EDS and are given in Table S3. ΔHf,ox values of the three calcined samples were calculated by the same approach used for the sintered samples and are displayed in Table S4. Figure 5b clearly shows a consistent trend for both sintered and calcined samples, which is that the hollandite with higher Cs substitution has more negative enthalpy of formation and thereby enhanced thermodynamic stability. It is notable that the ΔHf,ox difference between the calcined and sintered samples is small enough to be neglected compared with experimental errors.

Calculated enthalpies of formation based on sublattice model

ΔHf,el values of H1–H5 calculated using the sublattice model are listed in Table 6. ΔHf,ox values of H1–H5 were derived by subtracting the sum of the oxide formation enthalpies from the elements shown in Table 4 from the ΔHf,el values in Table 6. In a similar manner as the approach illustrated in Table 5, each oxide formation enthalpy was multiplied by a coefficient to obtain the calculated hollandite stoichiometries reported in Table 6 prior to being summed. As indicated by Fig. 5a, ΔHf,ox values derived from this thermodynamic model represent the same fundamental trends observed in the experimental results.

It is notable that reoptimization of the sublattice model did not alter computed compositional results for non-melt processed Fe-substituted hollandite reported by Utlak et al. [22]. Unlike the prior melt-processed hollandite, the Cs-parasitic phase CsAlTiO4 was not observed in this work. Nevertheless, the refined model indeed slightly impacts the computational results for melt-processed Fe-hollandite, so related values were incidentally refined from the data reported by Utlak et al. [22] (Table S5 and 6) and are reported here.

Potential factors impacting thermodynamic stability

- (a)

Symmetry

Compositions of H1 and H2 which exhibited a M–T phase transition with increasing temperature were measured by DSC in order to quantitatively evaluate the effect of symmetry change on thermodynamic stability. As shown in Figure S5(a-b), no thermal peaks were observed for both H1 and H2 during their M–T phase transition, indicating that the enthalpic changes resulting from symmetry changes are small and indistinguishable from baseline heat flow or the quantity of enthalpic changes is below the detection limit of the DSC. This is not unexpected, as minor differences between materials having small symmetry differences are often negligible compared with the enthalpy of formation for many ceramic materials including BaTiO3 perovskite and ZrO2 [41, 42]. Therefore, symmetry in the present case has a minor impact on thermodynamic stability.

- (b)

Relative sizes of cations on A-sites and B-sites

Previous studies have stated that the enthalpic stability increased as RB/RA decreased [2, 23]. As shown in Fig. 6a, this trend is generally applicable for Fe-substituted hollandite in this work, although the enthalpy of formation of the Ba end member H1 is slightly more negative than predicted. Similar behavior was observed in Zn-substituted hollandite, which also exhibited a M–T phase transition with increasing Cs content [5]. The mild enthalpic anomaly might arise from the phase transition and variation of local environments at the atomistic scale, such as different average Fe/Ti–O bond lengths, ordering/discording of A-site cations and vacancies in tunnels and different arrangements of B-site cations [2, 23, 43, 44].

- (c)

Tolerance factor

The thermodynamic stability of hollandite can be related to the tolerance factor [2, 23, 45] which for hollandite (tH) can be calculated by using the following Eq. (2):

where RA and RB are the average ionic radii of A-site and B-site cations, respectively, and RO is the oxygen ion radius [9, 45]. Using the RA and RB given in Table 2, tH values of H1–H5 were calculated and are presented in Table 2. In Fig. 6b, the enthalpy of formation becomes more exothermic as tH increases, indicating that enthalpic stability is improved with higher tH within the tH range of hollandite phase formation (0.93 ≤ tH ≤ 1.16) [45].

- (d)

Optical basicity

According to previous studies, the thermodynamic stability may be affected by the optical basicity (Λ) [2, 46, 47]. The optical basicity of Fe-substituted hollandite (ΛH) was calculated and given in Table 2 by using the expression and related Λ values from previous studies [2, 47]. Figure S6 displays that ΛH values of H1–H5 are mostly unchanged across the compositional range. It is possible that the expected stronger basic character of the hollandite with higher Cs substitution is mitigated by the relatively strong optical basicity of Fe3+ on B-sites, which is slightly higher than that of Ti4+ [47]. Therefore, optical basicity does not affect thermodynamic stability of Fe-substituted hollandite.

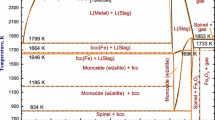

Isothermal pseudo-ternary phase diagram

In Fig. 7, a computed BaO-Cs2O-TiO2 1200 °C isothermal pseudo-ternary phase diagram with 10 mol% Fe2O3 was generated using the developed sublattice model and database (Fig. 7). Such models of the thermodynamic and phase equilibria can allow effective extrapolation to compositional regions that have not been yet experimentally determined [22, 48]. The diagram is computed here for 1200 °C for two reasons: (1) In this work, almost all hollandite samples were sintered at this temperature except the Ba end member H1 and (2) it has been confirmed that this temperature is high enough to synthesize single-phase hollandite phase [4, 23, 24]. The diagram was truncated to display the composition region of interest and limit the extent or required model development which still adequately covering a reliable range over which to project hollandite phase stability.

Computed 1200 °C isothermal phase diagram of pseudo-ternary BaO-Cs2O-TiO2 system with 10 mol% Fe2O3. Numbered phase regions are defined in Table 7

The red composition line in Fig. 7 should share the hollandite formula BaxCsyFe1.6Ti6.4O16 with fixed 10 mol% Fe2O3 content and varying A-site occupancy. The previous study by Utlak et al. [22] concluded that there should be a high fraction of hollandite for the composition located at the boundary of two regions where both contain the hollandite phase, and naturally as well for regions with minimal secondary phases. The hollandite composition Ba0.27Cs1.06Fe1.6Ti6.4O16 (H4|5) is indicated in Fig. 7 with a blue “*” within region No. 6 which also contains cubic BaTiO3 (perovskite) as a secondary phase. Although computed to be stable at 1200 °C, the phase is not present at equilibrium at room temperature with high Cs2O content hollandite, which will be demonstrated in “Implications for immobilization of tunnel cations” section. Therefore, H4|5 likely forms single-phase hollandites on cooling, which agrees well with both experimental and computational results. Furthermore, the optimal single-phase Fe-substituted hollandite-forming composition is predicted as Cs1.42Ba0.09Fe1.6Ti6.4O16, symbolized as green “+”, which has the theoretically highest Cs content and A-site occupancy.

Single-phase hollandite might also form in regions No. 3 and 9 intersected by the red composition line, because both of them only have one type of secondary phases. However, Ba2Ti9O20 in compositions representative of region No. 9 was observed at room temperature in a previous study [9] and the hollandite in this region also has very low Cs loading, so it has limited utility as well. Although Ba4Ti3O13 in the region No. 3 has not been reported in room temperature analyzed samples, it is very difficult to compare the phase stability between hollandite and Ba4Ti3O13 due to the lack of a formation enthalpy from constituent oxides at room temperature for Ba4Ti3O13. The composition in the region No. 3 as well has a much lower Cs content than that of region No. 6, thus not warranting further evaluation.

Implications for immobilization of tunnel cations

Strongly exothermic enthalpies of formation of H1–H5 indicate their excellent thermodynamic stability comparing to their binary constituent oxides, but one must also evaluate their stability with respect to other ternary oxides. Many possible ternary oxides in the hollandite-forming system have been described in Table 7 and Fig. 7. BaTiO3 (perovskite) has to be considered as a potential competing phase as this phase is very likely to form at high temperature (in Fig. 7) and might be maintained along with hollandite upon cooling [2,3,4,5]. Cs–Fe–O, Cs–Ti–O, Ba–Fe–O, and Ba–Ti–O (excluding BaTiO3 perovskite) systems are also possible phases, but they have not been reported at ambient conditions in non-melted processed samples using YSZ attrition balls. In addition, there are some controversies regarding the Fe–Ti–O system. Although some studies claimed that Fe2TiO5 was not stable at ambient conditions [2, 49], a recent study reported its appearance in the hollandite-forming system [9]. Nevertheless, the appearance of Fe2TiO5 does not result in a serious problem for the suitability of Fe-substituted hollandite because tunnel cations (i.e., Cs and Ba) are not incorporated in this phase. Therefore, it will not be considered in the subsequent analysis. Equations (3) and (4) were served as an example to illustrate how to evaluate phase stability and how to calculate the enthalpies of reaction (ΔHrxn) at standard conditions of H1, respectively. This method has been used widely and is also applicable to H2–H4 [2,3,4,5].

where the ΔHf,ox(H1) value was given in Table 3 and ΔHf,ox(BaTiO3) = − 152.3 ± 4.0 kJ/mol [41]. Thus, ΔHrxn values of H1–H4 were calculated and listed in Table 3 as well.

In Fig. 8, it can be concluded that H3 and H4 are energetically stable at room temperature with respect to BaTiO3 (perovskite), Cs2O, α-Fe2O3, and TiO2, because their ΔHrxn values are endothermic. In contrast, H1 is not stable with respect to BaTiO3 (perovskite), α-Fe2O3, and TiO2, since the ΔHrxn value is exothermic. In addition, because the entropy change in a reaction involving solid phases is small, the Gibbs free energy is expected to be positive and hence not favorable [2]. Furthermore, the phase stability of H2 may be comparable to BaTiO3 (perovskite), Cs2O, α-Fe2O3, and TiO2, because its ΔHrxn value is very close to zero within experimental uncertainties [2]. These estimates provide convincing evidence that higher Cs substitution stabilize the hollandite phase.

Chemical durability

Leaching resistance of Cs and Ba in Fe-substituted hollandite was evaluated by leaching tests. Detailed experimental data of sample matrix was summarized in Table S7. Normalized Cs and Ba release values for each composition are given in Table S7. In Fig. 9a, the normalized Cs release (NLCs) values are significantly improved for the high Cs content H4 and Cs end member H5 compared with that of the low Cs content H2. A similar trend is observed in Fig. 9b where results of the normalized Ba release (NLBa) show that almost all Ba cations were retained in H3 and H4 while the H1 resulted in much higher Ba release. Consequently, it is apparent that increasing the Cs content results in improved leaching resistance of tunnel cations (i.e., Cs and Ba) in Fe-substituted hollandite.

NL and average NL of a Cs and b Ba for Fe-substituted hollandite samples with different Cs contents. Error bars of average NL stand for standard deviations (Note NLBa and average NLBa denoted as “*” in (b) roughly showed their order of magnitude because their actual values were even smaller and lower than the detection limit of ICP-AES)

It is noteworthy that the most energetically stable composition H5 does not exhibit the least NLCs. A similar phenomenon has been reported in Ga-substituted hollandite [4]. The nonlinear correlation between thermodynamic stability and chemical durability may be due to a “threshold” effect of Cs substitution. This correlation will be examined in future work by the investigation of additional B-site compositions and the aid of phase diagrams generated from the sublattice computational model.

Conclusion

A series of Fe-substituted hollandite compositions were studied across the A-site solid solution from Ba end member to Cs end member. A phase transition from monoclinic to tetragonal symmetry could be induced by both Cs substitution and heating. Cs volatilization during processing was also reduced in compositions with higher targeted Cs content. Fe-substituted hollandite with higher Cs contents were more thermodynamically stable with respect to their binary constituent oxides as well as to other competing phase assemblages, which agreed well with sublattice model predictions. Moreover, a decreasing RB/RA and increasing tolerance factor with Cs substitution contributed to the enhanced thermodynamic stability. According to a reoptimized sublattice model, a pseudo-ternary diagram was computed extrapolating the phase equilibrium behavior of the hollandite-forming system to regions that had not been experimentally addressed. Results of leaching test confirmed that high Cs content stabilized hollandite phase, although the more explicit correlation between thermodynamic stability and chemical durability is still needed to be addressed in future work.

References

Ringwood AE, Kesson SE, Ware NG, Hibberson W, Major A (1979) Immobilisation of high level nuclear reactor wastes in SYNROC. Nature 278:219–223

Costa GC, Xu H, Navrotsky A (2013) Thermochemistry of barium hollandites. J Am Ceram Soc 96(5):1554–1561

Xu H, Wu L, Zhu J, Navrotsky A (2015) Synthesis, characterization and thermochemistry of Cs-, Rb-and Sr-substituted barium aluminium titanate hollandites. J Nucl Mater 459:70–76

Zhao M, Xu Y, Shuller-Nickles L, Amoroso J, Frenkel AI, Li Y, Gong W, Lilova K, Navrotsky A, Brinkman KS (2019) Compositional control of radionuclide retention in hollandite-based ceramic waste forms for Cs-immobilization. J Am Ceram Soc 102(7):4314–4324

Grote R, Zhao M, Shuller-Nickles L, Amoroso J, Gong W, Lilova K, Navrotsky A, Tang M, Brinkman KS (2019) Compositional control of tunnel features in hollandite-based ceramics: structure and stability of (Ba,Cs)1.33(Zn,Ti)8O16. J Mater Sci 54(2):1112–1125. https://doi.org/10.1007/s10853-018-2904-1

Levins DM, Smart RSC (1984) Effects of acidification and complexation from radiolytic reactions on leach rates of SYNROC C and nuclear waste glass. Nature 309:776–778

Cheary RW (1988) The immobilisation of cesium in synroc. Mater Sci Forum 27(28):397–406

Cheary RW (1986) An analysis of the structural characteristics of hollandite compounds. Acta Crystallogr B 42:229–236

Aubin-Chevaldonnet V, Caurant D, Dannoux A, Gourier D, Charpentier T, Mazerolles L, Advocat T (2007) Preparation and characterization of (Ba, Cs)(M, Ti)8O16 (M = Al3+, Fe3+, Ga3+, Cr3+, Sc3+, Mg2+) hollandite ceramics developed for radioactive cesium immobilization. J Nucl Mater 366(1–2):137–160

Tumurugoti P, Sundaram S, Misture ST (2018) Cesium immobilization in (Ba,Cr)-hollandites: effects on structure. J Solid State Chem 258:72–78

Bailey DJ, Stennett MC, Mason AR, Hyatt NC (2018) Synthesis and characterisation of the hollandite solid solution Ba1.2−xCsxFe2.4−xTi5.6+xO16 for partitioning and conditioning of radiocaesium. J Nucl Mater 503:164–170

Xu H, Costa GC, Stanek CR, Navrotsky A (2015) Structural behavior of Ba1.24Al2.48Ti5.52O16 hollandite at high temperature: an in situ neutron diffraction study. J Am Ceram Soc 98(1):255–262

Tumurugoti P, Sundaram S, Brinkman KS, Amoroso J, Fox K (2014) Melt-processed multiphasic ceramic waste forms. Adv Mater Sci Environ Energy Technol III 250:205–212

Amoroso J, Marra J, Conradson SD, Tang M, Brinkman K (2014) Melt processed single phase hollandite waste forms for nuclear waste immobilization: Ba1.0Cs0.3A2.3Ti5.7O16; A = Cr, Fe, Al. J Alloys Compd 584:590–599

Shannon RD (1976) Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr A 32(5):751–767

Carter M, Vance E, Li H (2003) Hollandite-rich ceramic melts for the immobilisation of Cs. MRS Online Proc Libr Arch 807:249. https://doi.org/10.1557/PROC-807-249

Carter M, Vance E, Mitchell D, Hanna J, Zhang Z, Loi E (2002) Fabrication, characterization, and leach testing of hollandite, (Ba, Cs)(Al, Ti)2Ti6O16. J Mater Res 17(10):2578–2589

Navrotsky A (1997) Progress and new directions in high temperature calorimetry revisited. Phys Chem Miner 24(3):222–241

Navrotsky A (2014) Progress and new directions in calorimetry: a 2014 perspective. J Am Ceram Soc 97(11):3349–3359

ASTM International (2014) C1285-14 standard test methods for determining chemical durability of nuclear, hazardous, and mixed waste glasses and multiphase glass ceramics: the product consistency test (PCT). West Conshohocken, PA

Amoroso J, Marra JC, Tang M, Lin Y, Chen F, Su D, Brinkman KS (2014) Melt processed multiphase ceramic waste forms for nuclear waste immobilization. J Nucl Mater 454(1–3):12–21

Utlak SA, Besmann TM, Brinkman KS, Amoroso JW (2019) Thermodynamic assessment of the hollandite high-level radioactive waste form. J Am Ceram Soc 102(10):6284–6297

Xu Y, Feygenson M, Page K, Nickles LS, Brinkman KS (2016) Structural evolution in hollandite solid solutions across the A-site compositional range from Ba1.33Ga2.66Ti5.34O16 to Cs1.33Ga1.33Ti6.67O16. J Am Ceram Soc 99(12):4100–4106

Xu Y, Wen Y, Grote R, Amoroso J, Nickles LS, Brinkman KS (2016) A-site compositional effects in Ga-doped hollandite materials of the form BaxCsyGa2x+yTi8−2x−yO16: implications for Cs immobilization in crystalline ceramic waste forms. Sci Rep 6:27412. https://doi.org/10.1038/srep27412

Grote R, Hong T, Shuller-Nickles L, Amoroso J, Tang M, Brinkman KS (2019) Radiation tolerant ceramics for nuclear waste immobilization: structure and stability of cesium containing hollandite of the form (Ba,Cs)1.33(Zn,Ti)8O16 and (Ba,Cs)1.33(Ga,Ti)8O16. J Nucl Mater 518:166–176

Post JE, Von Dreele RB, Buseck PR (1982) Symmetry and cation displacements in hollandites: structure refinements of hollandite, cryptomelane and priderite. Acta Crystallogr B 38:1056–1065

Zhang J, Burnham CW (1994) Hollandite-type phases: geometric consideration of unit-cell size and symmetry. Am Miner 79(1–2):168–174

Ishii M, Fujiki Y, Ohsaka T (1985) Raman scattering in one-dimensional ionic conductors Rb-priderites. Solid State Commun 55(12):1123–1126

Ohsaka T, Fujiki Y (1982) Raman spectra in hollandite type compounds K1.6Mg0.8Ti7.2O16 and K1.6Al1.6Ti6.4O16. Solid State Commun 44(8):1325–1327

Roy N, Park Y, Sohn Y, Leung KT, Pradhan D (2014) Green synthesis of anatase TiO2 nanocrystals with diverse shapes and their exposed facets-dependent photoredox activity. ACS Appl Mater Interfaces 6(19):16498–16507

Porto S, Fleury P, Damen T (1967) Raman spectra of TiO2, MgF2, ZnF2, FeF2, and MnF2. Phys Rev 154(2):522–526

Shibata Y, Suemoto T, Ishigame M (1986) Raman scattering studies of mobile ions in superionic conductor hollandites. Phys Status Solidi (B) 134(1):71–79

Poyraz AS, Huang J, Pelliccione CJ, Tong X, Cheng S, Wu L, Zhu Y, Marschilok AC, Takeuchi KJ, Takeuchi ES (2017) Synthesis of cryptomelane type α-MnO2 (KxMn8O16) cathode materials with tunable K+ content: the role of tunnel cation concentration on electrochemistry. J Mater Chem A 5(32):16914–16928

Knyazev AV, Mączka M, Ladenkov IV, Bulanov EN, Ptak M (2012) Crystal structure, spectroscopy, and thermal expansion of compounds in MI2 O–Al2O3–TiO2 system. J Solid State Chem 196:110–118

Ushakov SV, Cheng J, Navrotsky A, Wu JR, Haile SM (2002) Formation enthalpies of tetravalent lanthanide perovskites by high temperature oxide melt solution calorimetry. MRS Online Proc Libr Arch 718(D7):17. https://doi.org/10.1557/PROC-718-D7.17

Ushakov SV, Navrotsky A, Farmer JM, Boatner LA (2004) Thermochemistry of the alkali rare-earth double phosphates, A3RE(PO4)2. J Mater Res 19(7):2165–2175

Majzlan J, Navrotsky A, Neil JM (2002) Energetics of anhydrite, barite, celestine, and anglesite: a high-temperature and differential scanning calorimetry study. Geochim Cosmochim Acta 66(10):1839–1850

Putnam RL, Navrotsky A, Woodfield BF, Boerio-Goates J, Shapiro JL (1999) Thermodynamics of formation for zirconolite (CaZrTi2O7) from T = 298.15 K to T = 1500 K. J Chem Therm 31(2):229–243

Robie RA, Hemingway BS (1995) Thermodynamic properties of minerals and related substances at 298.15 K and 1 Bar (105 Pascals) pressure and at higher temperatures. U.S. Geological Survey Bulletin 2131; U.S. G.P.O., Washington

Wu L, Schliesser J, Woodfield BF, Xu H, Navrotsky A (2016) Heat capacities, standard entropies and Gibbs energies of Sr-, Rb-and Cs-substituted barium aluminotitanate hollandites. J Chem Thermodyn 93:1–7

Takayama-Muromachi E, Navrotsky A (1988) Energetics of compounds (A2+B4+O3) with the perovskite structure. J Solid State Chem 72(2):244–256

Chase MWJ (1998) NIST-JANAF thermochemical tables. American Institute of Physics, University Park, MD. https://janaf.nist.gov/. Accessed 6 Nov 2019

Rane MV, Navrotsky A, Rossetti GA Jr (2001) Enthalpies of formation of lead zirconate titanate (PZT) solid solutions. J Solid State Chem 161(2):402–409

Wen Y, Xu Y, Brinkman KS, Shuller-Nickles L (2018) Atomistic scale investigation of cation ordering and phase stability in Cs-substituted Ba1.33Zn1.33Ti6.67O16, Ba1.33Ga2.66Ti5.67O16 and Ba1.33Al2.66Ti5.33O16 hollandite. Sci Rep 8:5003. https://doi.org/10.1038/s41598-018-22982-7

Kesson S, White T (1986) Radius ratio tolerance factors and the stability of hollandites. J Solid State Chem 63(1):122–125

Duffy JA (2006) Ionic–covalent character of metal and nonmetal oxides. J Phys Chem A 110(49):13245–13248

Lebouteiller A, Courtine P (1998) Improvement of a bulk optical basicity table for oxidic systems. J Solid State Chem 137(1):94–103

Lukas H, Fries SG, Sundman B (2007) Computational thermodynamics: the Calphad method. Cambridge University Press, New York

Navrotsky A (1975) Thermodynamics of formation of some compounds with the pseudobrookite structure and of the FeTi2O5–Ti3O5 solid solution series. Am Miner 60(3–4):249–256

Acknowledgements

All authors acknowledge support of the Center for Hierarchical Waste Form Materials (CHWM), an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences under Award No. DE-SC0016574. Work conducted at the Savannah River National Laboratory was supported by the U.S. Department of Energy under contract DE-AC09-08SR22470. HT-Raman measurements were supported by the National Science Foundation under Grant No. DMR-1626164. Dr. Deepak Patil from Alfred University is acknowledged for HT-XRD and HT-Raman measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhao, M., Russell, P., Amoroso, J. et al. Exploring the links between crystal chemistry, cesium retention, thermochemistry and chemical durability in single-phase (Ba,Cs)1.33(Fe,Ti)8O16 hollandite. J Mater Sci 55, 6401–6416 (2020). https://doi.org/10.1007/s10853-020-04447-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04447-3