Abstract

The synthesis of hybrid oligomers for photopolymer compositions was carried out based on the thiol-ene reaction between the tetraacrylate dihydroxydiphenylsulfide derivative and thiol-siloxane oligomer. Thiol-siloxane oligomer was synthesized by condensation of diphenylsilanediol and 3-(mercaptopropyl)-trimethoxysilane. The thiol-siloxane oligomer structure was identified by 1H, 13C, 29Si NMR spectroscopy including COSY, HSQC, and HMBC methods and by MALDI-TOF mass spectrometry. The hybrid oligomers were obtained at different tetraacrylate:thiol-siloxane oligomer ratios (1:2, 1:1, 2:1). The obtained compositions are resistant to the oxygen inhibition of photopolymerization and give flexible, thermostable, and rigid polymer films under UV light at air atmosphere. The degree of the film photopolymerization was monitored by IR spectroscopy. The thermomechanical properties of photopolymer films were determined using thermogravimetric, differential scanning calorimetric, and dynamic mechanical analyses. The storage modulus (E′) at room temperature (1.16–1.88 GPa) and the glass transition temperatures (78–133 °C) were determined for photopolymer films obtained at different ratios of acrylate and thiol-siloxane units. The photocured hybrid films exhibit high stability to thermal decomposition in the inert (T 10% over 321 °C) and oxidizing (T 10% over 314 °C) atmospheres.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

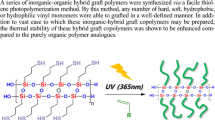

Photopolymer organic–inorganic hybrid materials are being actively developed and studied for the use in integrated optics and other applications [1, 2]. The formation of thin film materials is based on precursors containing active in the sol–gel synthesis siloxane units and silicon-alkoxide groups, providing the flexibility of the resulting polymer, and polymerizable organic groups. For example, the vinyl groups of the organic part of a hybrid material undergo photopolymerization under UV light in the presence of a photoinitiator to form a network of the crosslinked hybrid polymer [3]. This process allows the obtaining of optical elements either directly on the support or by the treatment in a solvent.

Organically modified silane (ORMOSIL) is a popular hybrid material [4, 5]. Monomers in ORMOSIL are presented by acrylate or methacrylate groups which can photopolymerize via the free-radical mechanism. Free-radical polymerization of acrylate groups proceeds efficiently under photoinitiation by UV light in a confined space or in an inert atmosphere. However, thin films are permeable for oxygen, which may inhibit the complete free-radical photopolymerization due to the formation of peroxide radicals in the reactions of primary polymeric carbon-centred radicals with oxygen [6]. Peroxide radicals act as traps for free radicals and block further polymerization. It is known that the presence of thiol groups in the acrylate photopolymer compositions reduces the oxygen-induced inhibition of radical polymerization: the oxidation of thiol groups by peroxide radicals affords the formation of thiyl radicals; that leads to the deceleration of inhibition and the continuation of polymerization [7]. Regarding the photolithographic processes, this type of polymerization for monomers with reactive double bond has the generic name “thiol-ene photocuring”.

The combination of molecules carrying the organosilicate, thiol, and acrylate groups in a photopolymerizing composition (PPC) is very promising for the formation of photopolymer materials with a wide range of physical and chemical characteristics. The variation of the hybrid oligomers gives the diversity of the material properties. For example, thiols can undergo the Michael addition to the acrylate [8]. The thiol-ene approach for producing hybrid materials by the covalent attachment of the acrylate molecules to the silicate core is now developing [9]. In the case of a polyfunctional acrylate monomer, this reaction affords an oligomer with the thiol moiety, which molecular weight and structure can be controlled by the ratio of the initial reactants. That makes possible the synthesis of crosslinked polymers, which properties can vary depending on the ratio of reactants in the Michael addition reaction. In particular, the variations of thermomechanical properties of the photopolymer materials can be expected. That may be very important in practical applications, including the design of diffractive microstructures [10].

The main goals of the present work are the production of the thiol-acrylate PPCs containing siloxane structural blocks, the formation of crosslinked photopolymer films based on these PPCs, and the establishing of their thermomechanical properties depending on the qualitative and quantitative content of the initial PPCs.

Experimental part

Materials

Diphenylsilanediol (“Avocado”, USA, S. Louis, 98 %), 3-(mercaptopropyl)-trimethoxysilane (“Aldrich”, Germany, 95 %), bis-(4-hydroxyphenyl) sulfide (“TCI”, Japan, Tokyo, 98 %), benzyltriethylammonium chloride (“Alfa Aesar”, England, 99 %), epichlorohydrin (“Reachem”, Russia, 99 %), and acryloyl chloride (“Aldrich”, Germany, 96 %) were used as received without further purification. The vacuum distillation of Acrylic acid (“Alfa Aesar”, UK, 99 %) was performed in the presence of hydroquinone. The solvents: benzene, hexane (“Reachem”, Russia, analytical grade), chloroform, and methyl alcohol (“Reachem”, Russia, reagent grade) were used as received. The methylene chloride (“Reachem”, Russia, reagent grade) was dried for 2 days over calcium chloride.

Synthesis of reactants

3-[4-({4-[2,3-bis(prop-2-enoyloxy)propoxy]phenyl}sulfanyl)phenoxy]-3-(prop-2-enoyloxy)propan-2-yl prop-2-enoate (I) synthesis

Tetraacrylate (I) was obtained by acryloylation of 2-hydroxy-3-[4-({4-[2-hydroxy-3-(prop-2-enoyloxy)propoxy]phenyl}sulfanyl)phenoxy]propyl prop-2-enoate (II), synthesized as described in [11] (Scheme 1). 4.5 mL of acryloyl chloride solution (55 mmol, 5.0 g in 10 mL CH2Cl2) was added dropwise to 35 mL of methylene chloride containing 9.4 g (20 mmol) of the compound (II) and 9.45 mL (6.9 g, 68 mmol) of triethylamine under cooling (0–5 °C). Then the cooling was removed, and the mixture was stirred at room temperature for 4 h. After that 100 ml of chloroform was added to the mixture, the organic layer was separated, washed with water, and dried with CaCl2. The solvent was removed under vacuum on the rotary evaporator at room temperature; the residual viscous oil (11.1 g) was dissolved in benzene and purified by column chromatography on SiO2 with benzene as an eluent. The broad light-yellow fraction was collected; the benzene was removed under vacuum on the rotary evaporator at room temperature yielding the viscous oil (65 % yield).

1H NMR (CDCl3, ppm): 4.14 (d, 4H, 2CH2), 4.43 (2H) and 4.51 (2H)—AB-system (2CH2), 5.46 (m, 2H, 2CH), 5.85 (m, 4H), 6.12 (m, 4H), 6.41 (m, 4H)—two acryloyl groups, 6.82 (4Harom), 7.24 (4Harom); calculated m/z 582.15 [M+], measured m/z 582.15 [M+]. Tetraacrylate solution (I, 1 g/mL) was prepared in dry chloroform.

Thiol-siloxane oligomer (III) synthesis

A mixture of 2.16 g (10 mmol) of diphenylsilanediol, 3.8 mL (20 mmol) of 3-(mercaptopropyl)-trimethoxysilane, and 0.2 mL of trimethoxyboroxine in 25 mL of dry chloroform was refluxed for 2 h, cooled, and filtered. The solution was diluted by dry chloroform to a volume of 30 mL. The concentration of compounds (III) in the resulting solution was 0.33 mmol/mL. One mL of the solution was evaporated at 20 °C under reduced pressure. The final viscous substance was analyzed with infrared (IR), 1H, 13C, and 29Si NMR spectroscopy.

IR spectrum of the film (cm−1): 2940 and 2842 (CH2), 2567 (SH), 1429 and 1110 (Si–C6H5), 1085 (Si–O).

1H NMR (CDCl3, ppm): 0.73 (m, 2 Si–CH2), 1.21 (t, SH), 1.22 (t, SH), 1.70 (m, 2 CH2), 2.52 (m, 2 CH2S), 3.53 (m, 4 OCH3), 7.32–7.43 (m, 6H, Harom), 7.64–7.68 (m, 4H, Harom).

Hybrid oligomer synthesis from compounds (I):(III) at a ratio 1:1

2 mL (0.66 mmol) of the compound (III) was mixed with 0.69 mL (0.66 mmol) of tetraacrylate (I) and 0.1 mL of NaOH (3.3 × 10−5 M in methanol). The final volume of the reaction mixture was adjusted to 10 ml with chloroform and kept at 20 °C for 24 h. 1 mL of the solution was evaporated at 20 °C under reduced pressure. The final viscous substance was analyzed with 1H NMR spectroscopy.

1H NMR (CDCl3, ppm): 0.72 (m, 4H, 2CH2), 1.67 (m, 6H, 3CH2), 2.52 (m, 4H, 2CH2), 2.64 (m, 2H, CH2), 2.75 (m, 2H, CH2), 3.53 (br. s, 12H, 4OCH3), 3.81 (m, 4H, 2CH2), 4.16 (m, 4H, 2CH2), 4.45 (m, 2H, CH2), 5.38 (m, 2H, 2CH), 5.90 (m, 2H, 2CH=), 6.15 (m, 2H, 2CH=), 6.44 (m, 2H, 2CH=), 6.83 (d, 4H, Harom), 7.13–7.43 (m, 10H, Harom), 7.65 (m, 4H, Harom).

The synthesis of hybrid oligomers at other ratios of compounds (I) and (III) was conducted under similar conditions. 2,4-Diethyl-9-oxo-10-(4-heptyloxyphenyl)-9H-thioxanthenium hexafluorophosphate, previously synthesized [12], was added to the reaction mixture as the initiator of photopolymerization.

The temperature dependence of the storage modulus (E′), loss modulus (E″), and loss tangent (Tanδ) was determined by dynamic mechanical analysis using a dynamic mechanical analyzer DMA 242C (Netzsch, Germany) in tension mode at 1 Hz frequency and 3 °C/min heating rate. The film thickness was 60–70 μm. The thermal degradation of the films in an inert (helium) and an oxidizing (helium:oxygen at a ratio of 80:20) atmospheres was determined by the thermogravimetric analysis (TGA) using a synchronous TGA/DSC analyzer STA-409 PC (Netzsch, Germany) at 10 °C/min heating rate. The glass transition temperatures (T g) of the films were determined by differential scanning calorimetry (DSC) in an inert atmosphere and 10 °C/min heating rate. The increased heating rate in DSC measurements as compared to DMA measurements was used for more precise determination of the T g values.

1H, 13C, and 29Si NMR spectra were obtained at the Chemical Service Centre of the Siberian Branch of the Russian Academy of Sciences on Bruker AV-300 and AV-600 in CDCl3. For 1H and 13C NMR spectra, the residual proton and carbon signals of the solvent were used as internal references (CHCl3, δ H 7.24 ppm; CDCl3, δ C 76.9 ppm). For 29Si NMR, the external standard tetramethylsilane (δ Si 0 ppm) was used.

The mass spectra were recorded on the Autoflex II (Bruker, Germany) time-of-flight mass spectrometer in the Research Resources Center “Mass spectrometric investigations” of the International Tomography Center of the Siberian Branch of the Russian Academy of Sciences. 0.5 μL of the sample was mixed with 0.5 μL of 2,5-dihydrobenzoic acid (saturated solution in tetrahydrofurane) directly on the standard ground steel target plate (Bruker, Germany) and air-dried at room temperature. The mass spectra were recorded in linear and reflective positive and negative ion modes in the 20–4000 m/z range. High resolution mass spectra for compound (I) were recorded on the DFS mass spectrometer (Thermo Scientific, Germany) at direct injection. The source temperature was kept 180 °C and 70 eV electron energy.

The degree of double bonds conversion was determined in real time under UV irradiation on the Tensor 27 IR spectrometer (Bruker, Germany). UV-curing of the samples was performed using CS-410 irradiator (ThorLabs, USA) with the 90 mW/cm2 output intensity of the UV lamp. The distance from the radiation source to the sample was 2 cm. The samples for IR analysis were prepared on the KBr tablet with 10 μm layer thickness.

Results and discussion

The production of the hybrid organic–inorganic compositions included the synthesis of the tetrafunctional acrylate monomer polymerizing under UV irradiation and the synthesis of the thiol-siloxane oligomer retarding the oxygen inhibition during the photopolymerization. The acrylate monomer 3-[4-({4-[2,3-bis(prop-2-enoyloxy)propoxy]phenyl}sulfanyl)phenoxy]-3-(prop-2-enoyloxy)propan-2-yl prop-2-enoate—tetraacrylate (I)—was synthesized by the reaction of 2-hydroxy-3-[4-({4-[2-hydroxy-3-(prop-2-enoyloxy)propoxy]phenyl}sulfanyl)phenoxy]propyl prop-2-enoate (II) with acryloyl chloride (Scheme 1) [11]. Tetraacrylate (I) was mentioned in the patent [13], but without description of its synthesis and structure verification. The 1H NMR and high resolution mass spectrometric data for tetraacrylate (I) are given in the “Experimental part” section.

Thiol-siloxane oligomer (III) was synthesized by non-hydrolytic condensation of diphenylsilanediol (IV) and 3-(mercaptopropyl)-trimethoxysilane (V) in a molar ratio of 1:2. The reaction was conducted under reflux in dry chloroform in the presence of catalytic amounts of trimethoxyboroxine to avoid strong siloxane condensation and the formation of polymer occurring in the solvent-free reaction [3]. The resulting reaction mixture is a viscous liquid, soluble in anhydrous organic solvents.

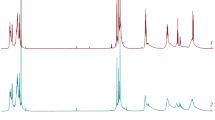

1H, 13C and 29Si NMR spectra of the product show the combination of overlapping narrow and broadened signals. This suggests that the condensation product is a mixture of oligomers (III) and, possibly, their associates, the complete structure elucidation being impossible. However, the assignment of NMR signals to different functional groups annotated in Fig. 1 can be performed using the 2D correlations 1H–1H, 1H–13C, and 1H–29Si (COSY, HSQC, HMBC).

1H NMR, ppm, δ (CHCl3) = 7.24: 7.72–7.50 (Ho), 7.50–7.37 (Hp), 7.37–7.09 (Hm), 3.67–3.18 (OCH3), 2.74–2.12 (H3), 1.86–1.47 (H2), 1.39–1.28 (SH), 0.90–0.44 (H1). All spectral regions contain the superposition of narrow and broadened multiplets, which cannot be analyzed in more details. The relative integral intensities of signal regions Ho + Hm + Hp:OCH3:H1:H2:H3 ≈ 10:12:4:4:4 correspond to the hypothetic compound (IIIa), a condensation product of one diphenylsilanediol molecule and two molecules of 3-(mercaptopropyl)-trimethoxysilane (Scheme 2). The integral intensity of the SH signal region is approximately one half from the theoretical one. Probably, the protons of SH-groups may undergo exchange with the protons of residual water from the solvent causing signal attenuation, or be eliminated in the intramolecular crosslinks involving the sulfur atom. It is important to note that the well-identified signal of hydroxyl groups from diphenylsilanediol (IV) (the singlet at 6.00 ppm) is absent in the 1H NMR spectrum of the final product, which confirms the complete consumption of diphenylsilanediol.

13C NMR, ppm, δ (CDCl3) = 76.9: 134.7–133.2 (Co, Ci), 130.4–129.5 (Cp), 127.9–127.0 (Cm), 50.5–49.6 (OCH3), 27.8–26.6 (C2, C3), 10.0–7.5 (C1).

29Si NMR (1H–29Si HMBC projection on the F 1 axis, Fig. 1), ppm, external standard: −29 to −31 (SiAr), −36 to −38 (SiAr), −41 to −45 (SiAlk), −49 to −52 (SiAlk), −58 to −60 (SiAlk).

The 29Si NMR signal δ −29 ppm, SiAr, should be assigned to the D0 atom of diphenyldimetoxysilane (Scheme 2, Fig. 1). Other 29Si NMR signal regions correspond to silicon-containing terminal aryl groups D1 (−36 to −38 ppm, SiAr), terminal alkyl groups T1 (−41 to −45 ppm, SiAlk), groups within the chain T2 (−49 to −52 ppm, SiAlk), and T3 (−58 to −60 ppm, SiAlk) [3, 14, 15].

On the basis of the spectral data, it can be assumed that the reaction of condensation proceeds via the methoxylation of diphenylsilanediol hydroxy group followed by the mercapto-siloxane monomers addition, and affords a set of asymmetric siloxane molecules containing two or more mercapto-siloxane units (Scheme 2).

The product of condensation—3-[3-(3-mercaptopropyl)-1,1,3,5-tetramethoxy-5,5-diphenyltrisiloxanyl]propane-1-thiol (IIIa)—predominates in the mixture of oligomers. We will designate it as thiol-siloxane dimer due to the condensation of two 3-(mercaptopropyl)-trimetoxysilane molecules and diphenylsilanediol.

MALDI-TOF mass spectrum for the thiol-siloxane oligomers shows three groups of signals at m/z 480, 642, and 804 (Fig. 2). The ions with these m/z values may be formed via the addition of two, three, or four molecules of 3-(mercaptopropyl)-trimetoxysilane to diphenylsilanediol. Mercaptans can lose the hydrogen atom and form cyclic sulfide derivatives under laser irradiation in MALDI-TOF measurements. It is also known that mercaptans may also lose H, SH, H2S, C2H2, C2H4, CH2SH, and CS groups during the mass spectrum acquisition [16]. Scheme 3 shows the possible transformations of mercaptosilane oligomers in MALDI-TOF experiments.

Based on the MALDI-TOF data, it may be assumed that a set of thiol-siloxane oligomers from dimers to tetramers is formed in the reaction of condensation (Scheme 2). It should be noted that the intensity of the signal corresponding to the thiol-siloxane dimer is an order of magnitude higher than the signal of thiol-siloxane tetramer.

The resulting thiol-siloxane oligomers can undergo an addition reaction to tetraacrylate (I) via either the radical mechanism under UV irradiation or the ion mechanism under the alkaline conditions. It is known that both ionic and radical mechanisms of the addition of mercaptans to the derivatives of acrylic acid afford the same product, which has a S–C bond at the carbon atom in β-position in respect to the carbonyl group [17] (Scheme 4).

The synthesis of the hybrid oligomers was performed in anhydrous chloroform with the addition of a catalytic amount of NaOH in methanol at a predetermined molar ratio of acrylate and thiol groups via the procedure similar to that described for the reaction of 2-mercaptoethanol with acrylonitrile [18]. The hybrid oligomer formation progress was controlled using the 1H NMR data. The 1H NMR spectrum of the starting tetraacrylate (I) contains proton signals from three acryloyl groups CH2=C=CH–O at 5.85, 6.12 and 6.41 ppm, and the signal from the proton at methine carbon atom at 5.46 ppm whose intensity does not change during the addition reaction. The chemical shift of protons on the carbon atom of –CH2–SH group of the starting thiol-siloxane oligomer (III) in the 1H NMR spectrum is 2.52 ppm. The intensity of proton signals of acryloyl groups in the product formed at the 1:1 molar ratio of tetraacrylate (I) and thiol-siloxane oligomer (III) decreases by a factor of 2, and new signals from two CH2 groups at 2.64 and 2.75 ppm appear in the spectrum. Thus, two out of four acryloyl groups in the product remain unreacted and capable to the further photopolymerization.

The similar changes were observed in 1H NMR spectra of hybrid oligomers formed with other ratios of reactants. Table 1 shows the data on the relative changes in the intensity of the proton signals in 1H NMR spectra observed during the synthesis and the number of remaining acryloyl groups in the resulting hybrid oligomer.

MALDI-TOF mass spectra for the thiol-siloxane-acrylate oligomer synthesized with the 4:2 ratio of acryl and mercapto groups shows groups of signals with the averaged m/z values 697, 1034, 1372, 1708, 2046, and 2383 (Fig. 3). These signals in the mass spectra correspond to the fragments of the products of two molecules of tetraacrylate (I) and one or two molecules of thiol-siloxane dimer (IIIa). The fragmentation may occur via the cleavage of the terminal acrylate groups of the hybrid oligomer and substituted diphenylsulfide blocks during the laser desorption and ionization (Scheme 5).

The signals which can be attributed to the siloxane-acrylate oligomers, formed from trimers or tetramers of thiol-siloxane oligomers, were not detected in the mass spectrum. It can be assumed that the hybrid oligomers formed in the Michael reaction (Scheme 4) with thiol-siloxane dimer are predominantly linear. We may conclude that hybrid tetraacrylate (VI) is predominant hybrimer formed from predominant thiol-siloxane dimer 3-[3-(3-mercaptopropyl)-1,1,3,5-tetramethoxy-5,5-diphenyltrisiloxanyl]propane-1-thiol (IIIa) in the reaction of condensation with tetraacrylate (I) (Scheme 6).

Photopolymer compositions and their thermomechanical properties

Based on the synthesized hybrid oligomers (Hol), six photopolymer compositions have been obtained. Three compositions Hol 2:1, Hol 1:1 and Hol 1:2 were the chloroform solutions of the photoinitiator and hybrid oligomers. The hybrid oligomers were prepared by Michael reaction in the presence of NaOH (Scheme 4) with different ratios of tetraacrylate (I): thiol-siloxane oligomer (III) (2:1, 1:1, 1:2). Three other compositions, Hmix 2:1, Hmix 1:1, and Hmix 1:2, were the mixtures of tetraacrylate (I): thiol-siloxane oligomer (III) in the same proportions. Each composition was coated on a glass plate, dried till the complete solvent evaporation, and then exposed to the UV irradiation in the ELC-500 UV irradiator (Electro-light Corporation) for 10 min to obtain a solid polymer film. Then the film was peeled off from the plate for the measurements of its thermomechanical properties by the dynamic mechanical analysis.

To control the effect of thiol groups on the inhibition of the polymeric grid formation, the photopolymer sample was prepared with the use of tetraacrylate monomer (I) only, Ol–1. The degree of the double bond conversion during the photopolymerization measured by IR spectroscopy is presented in Table 2. The degree of conversion for the film was calculated from the changes in the absorption of acrylate double bonds –C=C– before and after UV irradiation, using the Eq. 1 [19]:

where (A C=C)after UV and (A C=C)resin are the integrals of peaks of acrylate –C=C– bond vibrations at 1410 cm−1 before and after UV exposure, respectively. During the calculation of the degree of oligomer conversion, the conversion of –C=C– groups prior the photopolymerization was taken into account.

Due to the oxygen inhibition of the solidification process, the tetraacrylate (I) films (Ol–1) are characterized by the lowest degree (20 %) of the double bonds conversion (Table 2) and the lowest coefficient of elasticity at room temperature. Actually, the solidification was not completed, and the film remained sticky after the exposure. The degree of photopolymerization for hybrid oligomers was approximately 80 %. Thus, the presence of thiol groups significantly augments the degree of polymerization of hybrid oligomers, which leads to the formation of the rigid networks.

The temperature dependences for the loss tangent (Fig. 4a, b) and for the storage modulus E′ for the films prepared on the basis of the Hmix and Hol complexes have been obtained. The results are shown in Table 2 and in supplementary material.

Photopolymerization of the hybrid thiol-siloxane-acrylate compositions leads to the formation of crosslinked material. The properties of hybrid polymer networks differ depending on the ratio of the reacting components and on the topology of networks determined by different methods of the composition preparation (Hol or Hmix). The formation of the hybrid network structures in such systems occurs via two different mechanisms initiated by UV irradiation—the radical chain mechanism due to the opening of double bonds of tetraacrylic monomer (I), and the process of chain growth due to the thiol-ene addition. The photochemical process initiates the formation of thiol-ene blocks in Hmix complexes, while for Hol complexes this process occurs in the preliminary dark reaction, which was confirmed by 1H NMR measurements. Therefore, the degree of double bonds conversion in the starting oligomeric Hol compositions increases comparing to the Hmix compositions. That, in turn, leads to the enhanced values of storage modulus E′ at room temperature for Hol photopolymers. The heating of Hmix polymers may result in the thermal formation of additional crosslinks due to the thiol-ene polymerization and the polymerization of acrylate groups. Therefore, the storage modulus E′ and the T g values for Hmix photopolymer films in rubbery state increase in comparison with Hol films. It should also be noted that the formation of the branched polymer network occurs due to the attachment of tettraacrylate monomers. The structures of the polymer network junctions are shown in Fig. 5. The attachment of the thiol-siloxane blocks does not result in the formation of new junctions.

The method of the introducing the thiol-siloxane unit during the synthesis affects the topology of the crosslinked polymer chains. When the photoinitiation of the growth of acrylate polymer chain proceeds via the thiyl radicals of thiol-siloxane unit, the thiol-siloxane oligomer (III) connects two tetraakrylic units by preferential incorporation into the growing polymer chain. When the thiol-siloxane unit is introduced through the Michael reaction, the thiol-siloxane oligomer (III) connects two tetraakrylic units without the incorporation into the growing acrylate chain. Figure 6 shows two hypothetical topological forms of the crosslinked hybrid polymer networks, where thiol-siloxane unit as a more flexible part is schematically marked as a spring, acrylate chain—as a zigzag, and tetraacrylate unit—as a rectangle.

The increase of the quantity of organosilicon monomer with thiol functional groups leads to two opposite trends in photopolymerization: the degree of double bonds conversion for tetraacrylate monomer increases, while the density of the polymer grid decreases due to the dilution of tetraacrylate component in the PPC.

The storage modulus E′ for rubber-like polymers depends not only on the monomer composition, but also on the density of the grid. The network structure of the obtained films ensures high storage modulus E′ at temperatures above the glass transition temperature. The increase in the proportion of the organosilicon monomer in PPCs reduces the storage modulus E′ of the films due to the decrease in the density of the acrylate network. The highest value of the storage modulus E′ is observed when the ratio of tetraacrylate (I): thiol-siloxane oligomer (III) is equal 2:1 in the Hmix 2:1 composition; in that case, the acrylate monomer has the maximal functionality of 4.

The hybrid films containing silicon in the structure exhibit only a single glass transition temperature, which indicates a homogeneous single-phased morphology of the obtained films. Only one peak associated with the glass transition can be observed in the Tanδ temperature dependence. The T g value decreases with the increase of the organosilicon monomer quantity in the composition. The reduction of T g can be explained by the following factors: the decrease in the density of the acrylate grid; the greater flexibility of the thiol-siloxane moiety comparing to the acrylate unit; the enhanced quantity in the film of bulky phenyl groups playing the role of an internal plasticizer. The same features can also be observed for the commercially available thiol and acrylate monomer pairs [20]. On should note that the enhanced segmental mobility due to the increased proportion of organosilicon monomer in the hybrid grids results in the increase of the Tanδ maximum.

The resulting photopolymer hybrid films exhibit high thermal stability to decomposition in both inert and oxidizing atmospheres. The T 10% temperatures are above 321 °C in the inert atmosphere and 314 °C on air, respectively (Table 3, supplementary material). The films are generally more resistant to the heat degradation in the inert atmosphere than in the oxidizing one. A number of factors can influence the thermal stability of the films including the nature of the monomer in the film structure, the degree of solidification, the presence of functional groups, the presence of UV-curing residues, and others. The hybrid films based on the oligomeric compositions demonstrate the same trend in the thermal stability: the increase in the quantity of thiol-siloxane units and the decrease of acrylate units initially leads to the decrease of the decomposition temperature followed by its increase.

During the decomposition in the inert atmosphere polymer films show more than 35 % of carbon residue (R 700°C); the coke increases proportionally to the quantity of the siloxane unit in the hybrid grid in an oxidizing atmosphere. Nevertheless, the polymerized film remains stable, does not decompose and retains its state after coking.

Conclusion

The synthesis of the initial building blocks for further photopolymer compositions was performed in this work, and the hybrid thiol-siloxane-acrylate photopolymer compositions were obtained as solid hybrid polymer films. It was shown that the introduction of the thiol-siloxane oligomer to the photopolymer composition in combination with the dihydroxydiphenylsulfide tetraacrylate derivative leads to the effective reduction of the oxygen-induced inhibition of radical polymerization and increases the polymerization degree up to 80–90 % comparing to the 20 % for tetraacrylate only.

Thiol-siloxane oligomer was synthesized by the nonhydrolytic condensation of diphenylsilanediol and 3-(mercaptopropyl)-trimethoxysilane in the ratio 1:2. The thiol-siloxane oligomer structure was identified by 1H, 13C, 29Si NMR spectroscopy method including COSY, HSQC, HMBC techniques, and MALDI-TOF mass spectrometry method. It was shown that the nonhydrolytic condensation leads to the formation of the set of asymmetric oligomers, with the thiol-siloxane dimer predominating in the mixture.

The photopolymer compositions have a variable content, retain high photochemical activity, and provide an opportunity to obtain solid crosslinked films with flexible variations of their thermomechanical properties, which is very important for optical and adhesive technologies. The storage modulus E′ of films and the glass transition temperature for polymer films can be regulated by the changing the ratio of thiol-siloxane and acrylate units in the oligomer compositions, as well as by the methods used for the incorporating of thio-siloxane units: by preliminary dark thiol-ene reaction or by photopolymerization of the mixture of the tetraacrylate and thiol-siloxane oligomer.

In this work, we obtained the transparent and thermally stable (T 10% over 314 °C) cured hybrid polymer films, with variation of the storage modulus E′ in the glassy state in the range from 1.16 to 1.88 GPa, and the glass transition temperature from 78 to 133 °C. The thermomechanical properties of the photopolymer films were studied for the limited number of ratios for the tetraacrylate and thiol-siloxane oligomer (2:1, 1:1. 1:2). However, there is no doubt that the thermomechanical properties of the crosslinked polymers can be adjusted using the wider range of the ratios for the tetraacrylate and thiol-siloxane oligomer.

References

Sanchez C, Rozes L, Ribot F, Laberty-Robert C, Grosso D, Sassoye C, Boissiere C, Nicole L (2010) “Chimie douce”: a land of opportunities for the designed construction of functional inorganic and hybrid organic-inorganic nanomaterials. C R Chim 13:3–39

Malashkevich GE, Poddeneznyi EN, Mel’nichenko IM, Prokopenko VB, Dem’yanenko DV (1998) Luminescence-spectrum and strength properties of rhodamine 6G-doped silica gel films. Phys Solid State 40:427–431

Kim JS, Yang SCh, Park HJ, Bae BS (2011) Photo-curable siloxane hybrid material fabricated by a thiol–ene reaction of sol–gel synthesized oligosiloxanes. Chem Commun 47:6051–6053. doi:10.1039/c1cc11297j

Wheeler PA, Brungs M, Atkins GR (2003) Reduction of entrained hydroxy species in ormosil films for integrated optics. J Sol Gel Sci Technol 27:321–326

Trejo-Valdez M, Jenouvrier P, Fick J, Langlet M (2004) Characterization of optically active and photocurable ORMOSIL thin films deposited using the Aerosol process. J Mater Sci 39:2801–2810. doi:10.1023/B:JMSC.0000021457.85382.1c

Decker C, Zahouily K, Keller L, Benfarhi S, Bendaikha T, Baron J (2002) Ultrafast synthesis of bentonite-acrylate nanocomposite materials by UV-radiation curing. J Mater Sci 37:4831–4838. doi:10.1023/A:1020818414927

Hoyle CE, Lee TY, Roper T (2004) Thiol-enes: chemistry of the past with promise for the future. J Polym Sci Part A 42:5301–5338

Rydholm AE, Held NL, Benoit DS, Bowman CN, Anseth KS (2008) Modifying network chemistry in thiol-acrylate photopolymers through postpolymerization functionalization to control cell-material interactions. J Biomed Mater Res A 86:23–30

Mai TB, Tran TN, Rafiqul Islam Md, Park JM, Lim KT (2014) Covalent functionalization of silica nanoparticles with poly(N-isopropylacrylamide) employing thiol-ene chemistry and activator regenerated by electron transfer ATRP protocol. J Mater Sci 49:1519–1526. doi:10.1007/s10853-013-7833-4

Lenkova GA, Korolkov VP, Koronkevich VP, Nasyrov RK, Gutman AS, Iskakov IA, Treushnikov VM (2008) Diffractive-refractive intraocular lenses. Avtometry 44:75–88 [article in Russian]

Podkoscielna B, Worzakowska M (2010) Synthesis, characterization, and thermal properties of diacrylic/divinylbenzene copolymers. J Therm Anal Calorim 101:235–241

Loskutov VA, Shelkovnikov VV (2006) Synthesis of 2-ammonio(phosphonio)methyl-9-oxo-10-(4-heptyl-oxyphenyl)thioxanthenium bis[hexafluorophosphates(V)]. Russ J Org Chem 42:1097–1100

Fujiwara Y, Suzuki T, Nagai K, Tamura H, Ikuno H, Kami H (2008) Electrophotographic photoreceptor, and image forming method and apparatus using the same. Patent 0138725 USA, A1

Buestrich R, Kahlenberg F, Popall M, Dannberg P, Muller-Fiedler R, Rosch O (2001) ORMOCER(R)s for optical interconnection technology. J Sol Gel Sci Technol 20:181–186

Eo YJ, Lee TH, Kim SY, Kang JK, Han YS, Bae BS (2005) Synthesis and molecular structure analysis of nano-sized methacryl-grafted polysiloxane resin for fabrication of nano hybrid materials. J Polym Sci Part B 43:827–836

Silverstein RM, Webster FX, Kiemle D (2005) Spectrometric identification of organic compounds, 7th edn. Wiley, Mew York

Knunyants IL, Fokin AV (1950) Addition reaction to the acetylenic and diene hydrocarbons. Usp Khim 19:545

Hurd CD, Gershbein LL (1947) Reactions of mercaptans with acrylic and methacrylic derivatives. J Am Chem Soc 69:2328–2335

Studer K, Decker C, Beck E, Schwalm R (2003) Overcoming oxygen inhibition in UV-curing of acrylate coatings by carbon dioxide inerting, Part I. Prog Org Coat 48:92–100

Schreck KM, Leung D, Bowman CN (2011) Hybrid organic/inorganic thiol-ene-based photopolymerized networks. Macromolecules 44:7520–7529

Acknowledgements

The research was partly performed with the financial support from the RFBR (Project No 14-29-08134). Mass spectrometric works were performed with the financial support from the Russian Scientific Foundation (Grant No 14-14-00056).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shelkovnikov, V.V., Ektova, L.V., Orlova, N.A. et al. Synthesis and thermomechanical properties of hybrid photopolymer films based on the thiol-siloxane and acrylate oligomers. J Mater Sci 50, 7544–7556 (2015). https://doi.org/10.1007/s10853-015-9265-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9265-9