Abstract

We report a facile approach to synthesize superhydrophobic and superoleophilic “sponge-like” aerogels through sol–gel reaction followed by supercritical drying, in which MTES and DMDES are used as co-precursors, EtOH as a solvent, CTAB as a surfactant, and HCl and NH3·H2O as catalysts. The MTES–DMDES-based aerogels formed at the optimal molar ratio of MTES: DMDES: EtOH: H2O: HCl: NH3·H2O: CTAB at 1.1: 0.9: 6: 12: 2 × 10−3: 2 × 10−3: 0.14 with a low density of 0.0897 g/cm3 show a compression ratio of 80 % under 36.85 kPa stress. They are superhydrophobic and superoleophilic with a water contact angle of 153.6° and an oil contact angle of 0°. We find that the MTES–DMDES-based aerogels show the high adsorption capacity for various kinds of organic liquids and the excellent recyclability in removing oil from water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Oil spillage occurs frequently in the production, storage, and transportation of oils and their related products, which causes not only serious environmental pollution but also the significant loss of valuable resources [1, 2]. The removal or collection of oil pollutants from water has attracted worldwide concerns [3]. The conventional strategies including combustion, dispersion, coagulation, bioremediation, gravity separation, ultrasonic separation, containment booms, and absorbent materials are widely used for solving this problem [4]. Owing to their capability of removing and collecting oil from oil spill sites, absorbent materials including inorganic mineral products (such as zeolites, activated carbon, expanded perlite) [5, 6], natural materials (such as straw, wool fibers) [7, 8], and synthetic polymers (such as polyester, polyurethane) [9, 10] are considered as the most desirable choice for the cleanup of oil spillage. However, there are still some limitations in using them for practical applications, such as mineral reserves, inconvenience of recycling, low absorption capacity, low stability, poor recyclability, environmental unfriendly, and so on [11]. In particular, some of these materials absorb both oils and water, which reduces their separation efficiencies. Therefore, there is an urgent need in designing and synthesizing hydrophobic and oleophilic materials to overcome this aforementioned limitation in the development of oil–water separation technology.

Aerogels are highly porous materials derived from hydrogels, in which the liquid phase confined in the networks of the hydrogels is replaced with a gas phase [12]. Due to the unique properties such as low density, high porosity, and large surface area, aerogels have exhibited excellent performances as catalyst supports, electrochemical energy storages, drug delivery systems, and super adsorbents [13, 14]. However, the aerogels from tetraethoxysilane (TEOS) are fragile and moisture sensitive, which limit their potential applications in the oil–water separation technology [15, 16]. One of the promising ways for overcoming these issues is to make aerogels hydrophobic and flexible using organoalkoxysilanes as precursors. Rao and coworkers [17, 18] have reported that the aerogels synthesized from methyltrimethoxysilane (MTMS) and methyltriethoxysilane (MTES) precursors are superhydrophobic and elastic with the high uptake capacity of organic liquids. However, the formation of the aerogels from these trifunctional alkoxysilane precursors is still limited because we need stronger toughness structure in potential applications [19]. Hayase et al. [20] have synthesized aerogels from methyltrimethoxysilane (MTMS)/dimethyldimethoxysilane (DMDMS) co-precursors which keep at 80 °C for gelation and be soaked in solvent several times before drying. The method is effective in improving the flexibility of aerogels, while they require complicate processes and are time-consuming.

Here, we present a simple route to synthesize the superhydrophobic “sponge-like” aerogels through sol–gel process using MTES and DMDES as co-precursors, EtOH as solvents, CTAB as surfactant, and HCl and NH3·H2O as catalysts at room temperature. The resulting MTES–DMDES-based aerogels at the MTES: DMDES: EtOH: H2O: HCl: NH3·H2O: CTAB molar ratio of 1.1: 0.9: 6: 12: 2 × 10−3: 2 × 10−3: 0.14 have an interconnected 3D network structure with a very low density of 0.0897 g/cm3. They are elastic with the compression ratio of 83.33 % as well as superhydrophobic and superoleophilic with a water contact angle of 153.6° and an oil contact angle of 0°, respectively. We demonstrate that the MTES–DMDES-based aerogels are highly efficient in removing oil from water with an excellent recyclability.

Experimental

Materials

Methyltriethoxysilane (MTES, 99 % purity), dimethyldiethoxylsilane (DMDES, 98.5 % purity), ethanol (99.5 % purity), hexadecyltrimethylammonium bromide (CTAB 99 % purity), concentrated hydrochloric acid (HCl, 37 %), and concentrated ammonia (NH3·H2O, 25 %) were obtained from Sinopharm Chemical Reagent (Shanghai, China). All chemicals were used without further purification.

Synthesis of MTES–DMDES-based aerogels

The aerogels were synthesized through sol–gel process using MTES and DMDES as co-precursors, EtOH as solvents, CTAB as surfactant, and HCl and NH3·H2O as catalysts. The starting composition ratios for the synthesis of gels are listed in Table 1. The synthesis process includes three simple routine steps. Firstly, CTAB was dissolved with EtOH and H2O for forming homogeneous solution, followed by addition of MTES and DMDES co-precursors and 0.1 mol/L HCl alcohol solution (acidic catalyst). The mixed solution was stirred for 2 h for the complete hydrolysis. Secondly, 5 mol/L NH3·H2O alcohol solution (basic catalyst) was added to the mixed solution to accelerate condensation reactions. The resultant sol was stirred for 10 min and then transferred to airtight glass tubes. The gelation took place after 20–80 min at room temperature, and the sol–gel process was finished within 4 h. In order to remove the surfactant confined in gel networks and enhance the skeleton strength, the gels were aged in an EtOH bath (fresh EtOH was replaced twice each at 24 h) for 3 days. Finally, the MTES–DMDES-based aerogels were obtained by the supercritical drying at 260 °C and 10 MPa.

Characterizations

The bulk density (ρ = m/V) of MTES–DMDES-based aerogels was calculated from mass (m) to volume ratio (V). The flexibility of cylindrical aerogels (12 × 12 × 20 mm3) was defined by the compression ratio (S = ΔL/L), where ΔL is the largest length change of the aerogels under stress and L is the original length of the aerogels. The mechanical tests were performed using KDII-0.01 testing machine (Shenzhen Kaiqiangli Testing Instruments, Shenzhen, China) and equipped with two flat-surface compression stages and 100 N load cells. A JC2000A contact angle analyzer (Shanghai Advanced Photoelectric Technology, Shanghai, China) was employed to measure the contact angle of water or ethanol droplets on MTES–DMDES-based aerogels. To characterize the chemical composition of MTES–DMDES-based aerogels, Fourier transform-infrared spectroscopy (FT-IR, Avatar 360, Thermo Nicolet, Madison, USA) and power X-ray diffraction (XRD, X’pert PRO.) were used. Thermo gravimetric and differential thermal analysis (TGA/DTA, STA 409 EP/DIL 404, Netzsch, Selb, Germany) was performed at a rate of 10 °C/min from room temperature to 800 °C under air flow. The microstructure of MTES–DMDES-based aerogels was characterized using scanning electron microscopy (SEM, SU70, Hitachi, Tokyo, Japan) and energy dispersive X-ray spectroscopy (EDS). All samples were coated with gold before SEM measurements.

The absorption capacity (q %) of MTES–DMDES-based aerogels for various solvents and oils at the room temperature, including n-hexane, ethanol, methanol, coal oil, dimethylbenzene, soybean oil, N, N dimethylformamid, dichloromethane, and chloroform, was measured, in which the aerogels with a known weight (m 0) were put into organic liquids for approximately 5 min, and then picked out and weighed (m s) after removing liquids from their surface with a filter paper. The percentage absorption capacity was calculated via the following formula: q % = {(m s − m 0)/m 0} × 100. Weight measurements were done in 1 min to avoid the evaporation of adsorbed liquids. Other absorption materials such as paper towel, oil absorbent sheet and oil absorbent pad (obtained from Shanghai Xinluo Filter Material Co., Ltd), polyurethane sponge, and activated carbon (obtained from Shanghai Xinhui Activated Carbon Co., Ltd.) were also tested with the same method for the comparison.

Results and discussion

Effect of starting compositions

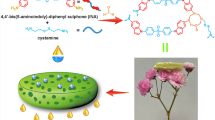

We succeeded in the preparation of sponge-like aerogels derived from MTES and DMDES co-precursors, in which MTES and DMDES were partially hydrolyzed. The presence of the non-polar methyl groups in their backbones leads to the formation of network structures with large pore sizes and minimizes the interchain cohesion [21], which makes the aerogels easily deformable. The hydrolysis and condensation reaction of the co-precursors are shown in Fig. 1. The porous structure and flexibility of this material can be achieved by changing the starting composition, such as precursor ratios and solvent contents.

In this reactant system, ethanol acts as a diluting solvent. The effect of ethanol concentrations on the properties of MTES–DMDES-based aerogels was studied by varying the ethanol molar ratio from 2 to 10, while the molar ratio of MTES: DMDES: H2O: HCl: NH3·H2O: CTAB is remained the same (Sample E1, E2, E3, E4, E5). In Fig. 2a, we find that the gelation time increases with the increase of ethanol molar ratios. This is due to the fact that the high dispersion of MTES/DMDES molecules in ethanol solvent would slow down the hydrolysis and condensation reaction rate [18]. Simultaneously, the change of the ethanol molar ratio also leads to the change of the aerogels density and flexibility. As can be seen in Fig. 2b, the density of MTES–DMDES-based aerogels decreases from 0.1292 to 0.0944 g/cm3 with the increase of the ethanol molar ratio from 2 to 6. However, a slight density increase from 0.944 to 0.1017 g/cm3 is observed when the ethanol molar ratio increases from 6 to 10. The compression ratio of MTES–DMDES-based aerogels increases from 48.82 to 80.98 % as the increase of the ethanol molar ratio from 2 to 6 (Fig. 2c). When the ethanol molar ratio increases to 10, we notice a slight decrease in the compression ratio (79.21 %).

The diversification of flexibilities for the MTES–DMDES-based aerogels formed at different molar ratios is attributed to the various microstructures of the aerogel samples. From the SEM images shown in Fig. 3, we observe that these samples all have branched microstructures, in which silica aggregates interconnect to form a porous network. The increase of ethanol molar ratios leads larger pores in the network. At the same time, the resultant network skeleton becomes weaker, resulting in the increase of volume shrinkages or even collapse during drying. The network with large pore sizes and strong skeletons could avoid the damage under stress and hence is more flexible.

By keeping the molar ratio of EtOH: H2O: HCl: NH3·H2O: CTAB and varying the molar ratio of MTES/DMDES (MD1, MD2, MD3, MD4, MD5), we study the effect of co-precursors molar ratios on the properties of MTES–DMDES-based aerogels. It is observed that the gel time increases from 18 to 54 min with the increase of DMDES precursor concentrations (Fig. 4a). Compared to MTES precursor, DMDES precursor only has two hydrolysable ethoxy groups (Si–OC2H5) to be hydrolysized to the Si–OH, which is then condensed into silica networks. Thus, we can expect the increase of gel time as the increase of DMDES precursor molar ratios. In addition, the increase of DMDES molar ratio from 0.6 to 1.0 also leads to the decrease in the gel density from 0.1284 to 0.07808 g/cm3 (Fig. 4b). But a further increase leads no monolithic gel formation due to the high hydrophobicity of MTES/DMDES oligomers. Figure 4c shows that the compression ratio of MTES–DMDES-based aerogels increases from 45.43 to 81.74 % as the increase of the DMDES molar ratio from 0.6 to 0.9 and decreases a little when the DMDES molar ratio reaches to 1.0. At the MTES/DMDES molar ratio of 1:1 (MD5), the sample cannot recover to its original length immediately. SEM images show the different microstructures of the MTES–DMDES-based aerogels formed at different MTES/DMDES molar ratios (Fig. 5). We observe that the increase in the amount of DMDES leads to larger pores in the network. However, the excess amount of DMDES makes the poor connection of the network, leading to the decrease of the compression ratio. From the above results, we conclude that the MTES–DMDES-based aerogels (MD4) with the maximum elasticity of 83.33 % and the minimum density of 0.0897 g/cm3 can be obtained at the MTES: DMDES: EtOH: H2O: HCl: NH3·H2O: CTAB molar ratio of 1.1:0.9:6:12: 2 × 10−3: 2 × 10−3: 0.14.

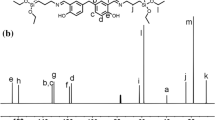

Structure and composition

A piece of the MTES–DMDES-based aerogel (MD4) with the density of 0.0897 g/cm3 can stand on the top of a dandelion (Fig. 6a). The high-resolution SEM images clearly show that the network of the MTES–DMDES-based aerogel contains large porous structures, and the skeletons consist of particles (Fig. 6b), which provide a rough microscopic surface with the superhydrophobicity. Figure 6c shows the XRD pattern of the MTES–DMDES-based aerogel. A broad diffraction peak at approximately 22° is associated with the spacing of Si atoms and angle of the group Si–O–Si [22]. The diffuse peak suggests that the MTES–DMDES-based aerogel has low crystallinity, a typical amorphous silica material. The FT-IR spectrum of MTES–DMDES-based aerogel is shown in Fig. 6d. The band at 1112 and 778 cm−1 presents the stretching of Si–O bonds. The C–H bonds at 2965, 2909, and 2839 cm−1 and the Si–CH3 bonds at 1266 and 852 cm−1 are also visible. These results confirm the inorganic skeleton structure having the Si–O–Si network with non-polar methyl groups. Furthermore, the composition concentration of the MTES–DMDES-based aerogel is confirmed by the energy dispersive X-ray spectroscopy (EDS) as shown in Fig. 6e. The spectrum shows peaks for carbon (7.46 %), oxygen (58.89 %), and silicon (33.65 %).

Flexibility and superhydrophobicity

Due to its low density and high porosity, the MTES–DMDES-based aerogel exhibits excellent mechanical behaviors during compression and recovery experiments. As can be seen from Fig. 7a, the cylindrical aerogel can be compressed to 83.33 % of its original length and recovers completely after releasing the stress. The compression and recovery process can be repeated many times without fractures. The mechanical properties of the aerogel are further studied by a universal testing machine. Figure 7b displays the stress–strain (ε–σ) curves of the aerogel at the set strain maxima of 40, 60, and 80 %. It is interesting that the unloading curves show that the strain σ returns to zero at ε = 0 for all tests, which suggests that the aerogel can rapidly and completely recover their original size. In addition, the curves of the loading process show two distinct stages: an initial linear elastic region at ε < 60 %, followed by a final densification region at ε > 60 %. In the initial deformation region, the compressive stress gradually increases with the strain, owing to the elastic bending of the skeleton structure. The rapidly increasing stress in the densification region can be attributed to the skeleton impinge upon each other. Most impressively, at ε = 80 %, the maximal stress is measured to be 36.85 kPa, suggesting that the aerogel is a quite soft material. We further conduct consecutive compression cycles at 60 % strain to characterize the stability of the cyclic resilient property of the aerogel. There is no plastic deformation observed after six cycles (Fig. 7c), suggesting that the aerogel is mechanical robustness. The structural integrity under large deformations may be a result of the interconnected robust 3D branched porous microstructure of the aerogel (Fig. 6b). The aerogels can be easily cut into different shapes with a sharp scissor, which is critical for the development of their practical applications.

As can be seen from Fig. 8a, MTES–DMDES-based aerogels can float on the surface of water, and an external force is needed to push it into water. The aerogel sample immersed in water exhibits the Cassie–Baxter non-wetting behavior and appears as a silver mirror-like surface due to the formation of a continuous air layer on the hydrophobic surface of the immersed aerogel. After being washed with running tap water for several minutes, the cylindrical aerogel remains its hydrophobic nature. We observe that water rolls off the surface of the aerogels immediately (Fig. 8b), just like lotus leaves. The contact angle of water droplets (3 μL) on the aerogel is ~153.6° (Fig. 8c). However, the aerogel is able to absorb the ethanol droplets ejected from a syringe onto its surface. The contact angle of ethanol droplets on the aerogel is ~0° (Fig. 8d). These experiments of water repellency and ethanol absorption confirm the hydrophobicity and oleophilicity of MTES–DMDES-based aerogels. The hydrophobicity of the aerogels is a result of the geometrical rough surface derived from the 3D network structures with methyl rich groups, which is evident from the FT-IR spectrum as shown in Fig. 6d, in which the peaks of 1274 and 856 cm−1 are associated with the stretching of the Si-CH3 bond at the surface of the networks.

Organic liquids/water separation

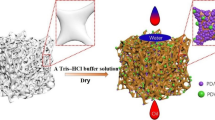

Since the oil spill accidents cause serious environmental pollution and energy waste, the removal of oils from water has attracted academic and commercial interest [23]. The low density, sponge-like aerogels with superhydrophobic and superoleophilic properties are an ideal candidate for the adsorption of organic pollutants from water (Fig. 9). A series of experiments were carried out to prove the capability of the aerogels in removing oil from the surface of water.

The MTES–DMDES-based aerogels can absorb various kind organic solvents. The absorption capacity (q %) for n-hexane, ethanol, methanol, coal oil, dimethylbenzene, soybean oil, N–N dimethylformamid, dichloromethane, and chloroform is in the range from 683.33 to 1693.10 % (Fig. 10a). Due to the nature of physical absorptions, the absorbed solvent is stored in the pores of the aerogels. The differences of the absorbed solvent/aerogel weight ratios are mainly attributed to the organic liquid densities [24]. We further tested the absorption capacity of common absorption materials to soybean oil (Fig. 10b). The absorption capacity is 596.43 % for paper towels, 693.33 % for oil absorbent sheets, 658.06 % for oil absorbent pads, 840 % for polyurethane sponges, and 130.61 % activated carbons. The absorption capacity of the porous MTES–DMDES-based aerogels with high hydrophobic surfaces for soybean oil area can reach to 1214.29 %, which is higher than these commercial absorbents [25]. Compared to the conventional cleaning polyurethane sponges which sink in water, MTES–DMDES-based aerogels float on the surface of water. There is no water droplet observed in the collected oil by the aerogels, while water droplets were clearly visible in the oil collected from the polyurethane sponges (Fig. 10c). These results indicate that MTES–DMDES-based aerogels have a more efficient for water/oils separations.

a Maximum absorption capacities of MTES–DMDES-based aerogels (MD4) for nine different organic solvents, b maximum absorption capacities for six different absorption materials, c the difference of oil collection from the MTES–DMDES-based aerogels (MD4) and polyurethane sponges, d the photographs of the absorption of n-hexane from the surface of water by MTES–DMDES-based aerogels (MD4), e the ethanol adsorption–desorption process cycles, f SEM images of the MTES–DMDES-based aerogels (MD4) before the adsorption and after the desorption of ethanol

By dipping a small piece of MTES–DMDES-based aerogels into n-hexane/water mixtures, we observe the contraction of the n-hexane film (dyed with Oil Red O), resulting in a transparent water region around the aerogel. The n-hexane film removed completely from water within a few seconds (Fig. 10d). This is because the strong van der Waals force and capillary action which pull the organic liquid into the pores of the hydrophobic network of the aerogel [26]. Due to the low density and hydrophobic nature, the aerogels suspend on the water surface after uptaking the entire oil, even after 100 days, illustrating their excellent hydrophobic stability. This high buoyancy characteristic of the aerogels is very useful for subsequently recover oil from spill areas, reducing the cost of recycling the absorbent and avoiding the secondary environment pollution.

The recyclability of the absorbed oil is a key requirement in oil cleanup applications [27]. We test the recycling ability of MTES–DMDES-based aerogels using ethanol as a model organic compound. Figure 10e shows that the aerogel samples remain their original shape and stable absorption performance after 10 adsorption–desorption process cycles. In our experiments, the samples were dried in an oven at 60 °C for 2 h to evaporate the ethanol, which avoids the residual ethanol influence of the absorption capacity of the samples during every cycle. There is no change in the 3D network structure after absorption and desorption cycles (Fig. 10f).

Conclusion

The highly flexible, superhydrophobic, and superoleophilic MTES–DMDES aerogels have been prepared from two-step acid–base sol–gel reaction from the co-precursors of MTES and DMDES. Under the optimal MTES: DMDES: EtOH: H2O: HCl: NH3·H2O: CTAB molar ratio of 1.1: 0.9: 6: 12: 2 × 10−3: 2 × 10−3: 0.14, the aerogels show a sponge-like behavior with a low density of 0.0897 g/cm3. The water/oil contact angle on the aerogels is 153.6° and 0°, respectively. Owing to the elastic 3-D network structure, the superhydrophobic and superoleophilic aerogels show an excellent recyclability in the removal of oil from water.

References

Shannon MA, Bohn PW, Elimelech M, Georgiadis JG, Marinas BJ, Mayes AM (2008) Science and technology for water purification in the coming decades. Nature 452(7185):301–310

Zhang Z, Sèbe G, Rentsch D, Zimmermann T, Tingaut P (2014) Ultralightweight and flexible silylated nanocellulose sponges for the selective removal of oil from water. Chem Mater 6(8):5924–5929

Bi H, Huang X, Wu X, Cao X, Tan C, Yin Z, Lu X, Sun L, Zhang H (2014) Carbon microbelt aerogel prepared by waste paper: an efficient and recyclable sorbent for oils and organic solvents. Small 38(2):199–210

Gupta VK, Carrott PJM, Carrott M, Suhas (2009) Low-cost adsorbents: growing approach to wastewater treatment: a review. Crit Rev Environ Sci Technol 39(10):783–842

Rajakovic-Ognjanovic V, Aleksic G, Rajakovic L (2008) Governing factors for motor oil removal from water with different sorption materials. J Hazard Mater 154(1–3):558–563

Liu L, Ma W, Zhang Z (2011) Macroscopic carbon nanotube assemblies: preparation, properties, and potential applications. Small 7(11):1504–1520

Radetic M, Ilic V, Radojevic D, Miladinovic R, Jocic D, Jovancic P (2008) Efficiency of recycled wool-based nonwoven material for the removal of oils from water. Chemosphere 70(3):525–530

Annunciado TR, Sydenstricker THD, Amico SC (2005) Experimental investigation of various vegetable fibers as sorbent materials for oil spills. Mar Pollut Bull 50(11):1340–1346

Zhu Q, Chu Y, Wang ZK, Chen N, Lin L, Liu FT, Pan QM (2013) Robust superhydrophobic polyurethane sponge as a highly reusable oil-absorption material. J Mater Chem A 1(17):5386–5393

Yin S, Niu Z, Chen X (2012) Assembly of graphene sheets into 3D macroscopic structures. Small 8(16):2458–2463

Rajakovic V, Aleksic G, Radetic M, Rajakovic L (2007) Efficiency of oil removal from real wastewater with different sorbent materials. J Hazard Mater 143(1–2):494–499

Rao AV, Kalesh RR, Pajonk G (2003) Hydrophobicity and physical properties of TEOS based silica aerogels using phenyltriethoxysilane as a synthesis component. J Mater Sci 38(21):4407–4413. doi:10.1023/A:1026311905523

Soleimani Dorcheh A, Abbasi M (2008) Silica aerogel; synthesis, properties and characterization. J Mater Process Tech 199(1):10–26

Wang D, Xu Z, Chen Z, Liu X, Hou C, Zhang X, Zhang H (2014) Fabrication of single-hole glutathione-responsive degradable hollow silica nanoparticles for drug delivery. ACS Appl Mater Inter 6(15):12600–12608

Gurav JL, Rao AV, Nadargi D, Park H-H (2010) Ambient pressure dried TEOS-based silica aerogels: good absorbents of organic liquids. J Mater Sci 45(2):503–510. doi:10.1007/s10853-009-3968-8

Wang D, McLaughlin E, Pfeffer R, Lin YS (2012) Adsorption of oils from pure liquid and oil-water emulsion on hydrophobic silica aerogels. Sep Purif Technol 99:28–35

Nadargi DY, Rao AV (2009) Methyltriethoxysilane: new precursor for synthesizing silica aerogels. J Alloy Compd 467(1):397–404

Hegde ND, Venkateswara Rao A (2007) Physical properties of methyltrimethoxysilane based elastic silica aerogels prepared by the two-stage sol–gel process. J Mater Sci 42(16):6965–6971. doi:10.1007/s10853-006-1409-5

Dong H, Brook MA, Brennan JD (2005) A new route to monolithic methylsilsesquioxanes: gelation behavior of methyltrimethoxysilane and morphology of resulting methylsilsesquioxanes under one-step and two-step processing. ChemMater 17(11):2807–2816

Hayase G, Kanamori K, Nakanishi K (2011) New flexible aerogels and xerogels derived from methyltrimethoxysilane/dimethyldimethoxysilane co-precursors. J Mater Chem 21(43):17077–17079

Bhagat SD, Oh CS, Kim YH, Ahn YS, Yeo JG (2007) Methyltrimethoxysilane based monolithic silica aerogels via ambient pressure drying. Microporous Mesoporous Mater 100(1–3):350–355

Cui S, Liu Y, Fan MH, Cooper AT, Lin BL, Liu XY, Han GF, Shen XD (2011) Temperature dependent microstructure of MTES modified hydrophobic silica aerogels. Mater Lett 65(4):606–609

Xue ZX, Cao YZ, Liu N, Feng L, Jiang L (2014) Special wettable materials for oil/water separation. J Mater Chem A 2(8):2445–2460

Jiang F, Hsieh Y-L (2014) Amphiphilic superabsorbent cellulose nanofibril aerogels. J Mater Chem A 2:6337–6342

Gui X, Wei J, Wang K, Cao A, Zhu H, Jia Y, Shu Q, Wu D (2009) Carbon nanotube sponges. Adv Mater 22(5):617–621

Nguyen ST, Feng J, Le NT, Le TAT, Hoang N, Tan VB, Duong HM (2013) Cellulose aerogel from paper waste for crude oil spill cleaning. Ind Eng Chem Res 52(51):18386–18391

Yang Y, Tong Z, Ngai T, Wang C (2014) Nitrogen-rich and fire-resistant carbon aerogels for the removal of oil contaminants from water. ACS Appl Mater Inter 6(9):6351–6360

Acknowledgements

Financial support from the Natural Science Foundation of China (51175444), the Aviation Science Foundation of China (2013ZD68009), New Century Excellent Talents in Fujian Province University (2013), the Natural Science Foundation of Fujian Province of China (2014J01206), and Xiamen Municipal Bureau of Science and Technology (3502Z20143009) is acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yu, Y., Wu, X. & Fang, J. Superhydrophobic and superoleophilic “sponge-like” aerogels for oil/water separation. J Mater Sci 50, 5115–5124 (2015). https://doi.org/10.1007/s10853-015-9034-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9034-9